High-concentration fluorine chemical wastewater treatment technology

A technology of chemical wastewater and treatment process, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve the problem of high investment in chemical wastewater treatment, high toxicity of fluorine chemical wastewater, and difficult biodegradation Dealing with and other issues to achieve the effect of reducing processing costs, reducing expenses, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

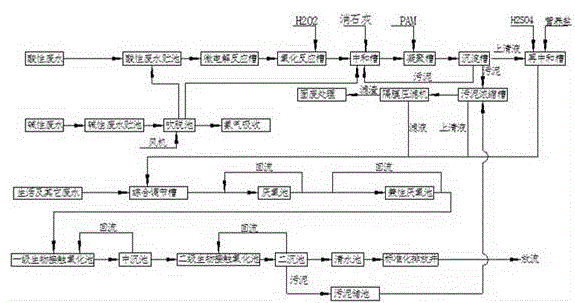

Image

Examples

Embodiment 1

[0027] Example 1: A factory in Fuxin Fluorine Chemical Industrial Park produced 300 tons of waste water, and the influent water quality indicators are shown in Table 1:

[0028] Table 1 Water quality of two kinds of wastewater

[0029] pH F - NH 4 + COD Cr acid wastewater 2 50mg / L 18000mg / L alkaline wastewater 12 10mg / L 2000mg / L 5000mg / L

[0030] The treatment process is as follows:

[0031] Chemical wastewater classification collection, oil separation, settling unit

[0032] The chemical wastewater is divided into two categories, namely ①acidic wastewater and ②alkaline wastewater. The chemical wastewater produced by the chemical production line is classified and discharged into the corresponding wastewater oil separation sedimentation tank through pipelines for oil separation treatment and sedimentation treatment. The treated wastewater is sent to the acid storage tank and alkaline storage tank respectively. The wastewat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com