Patents

Literature

32results about How to "Easy online replacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System for deep treatment of coking wastewater by means of catalytic ozonation-ceramic membrane filtration

InactiveCN102849875AStrong upward impactInhibition falls intoMultistage water/sewage treatmentParticulatesChemical oxygen demand

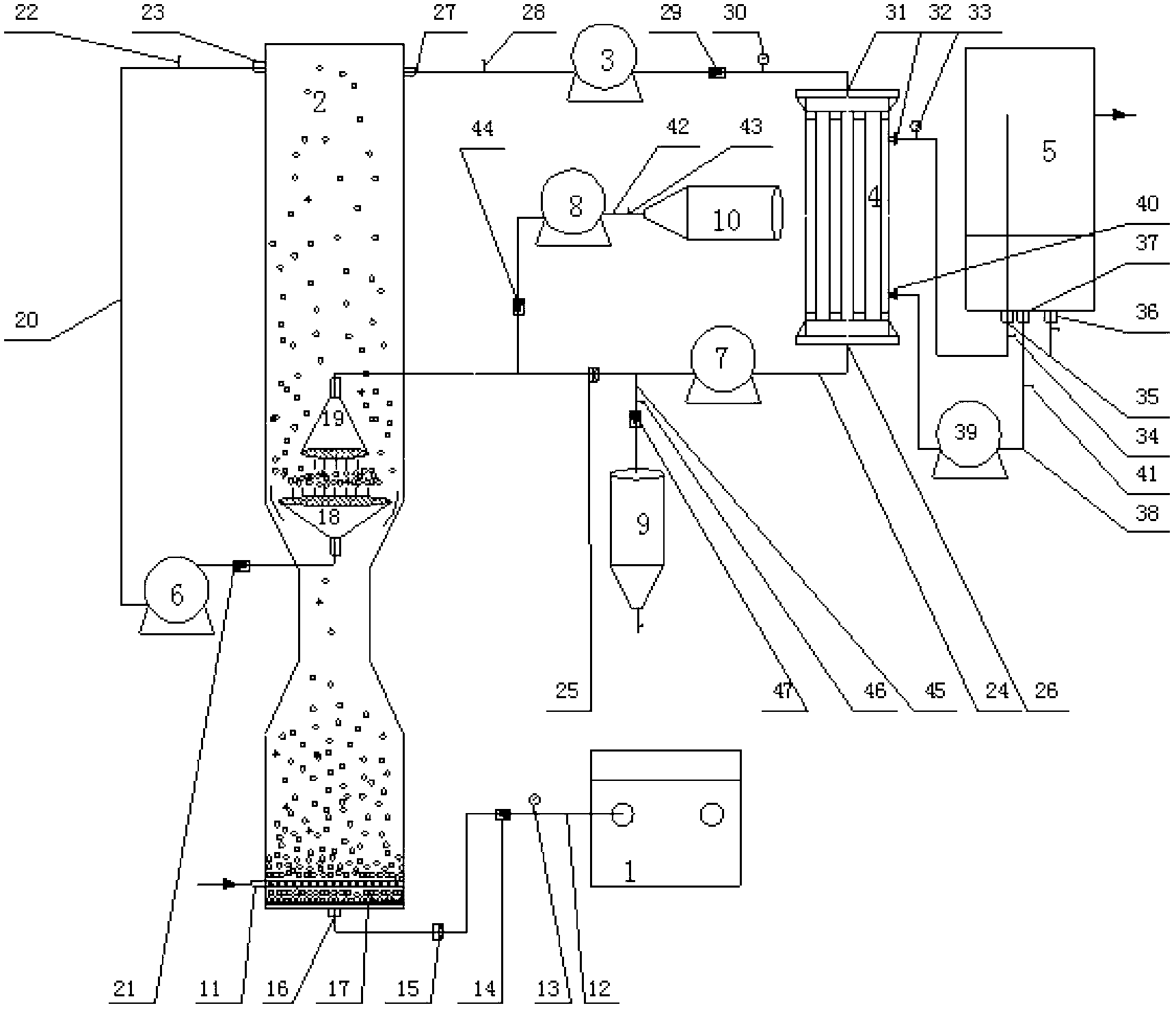

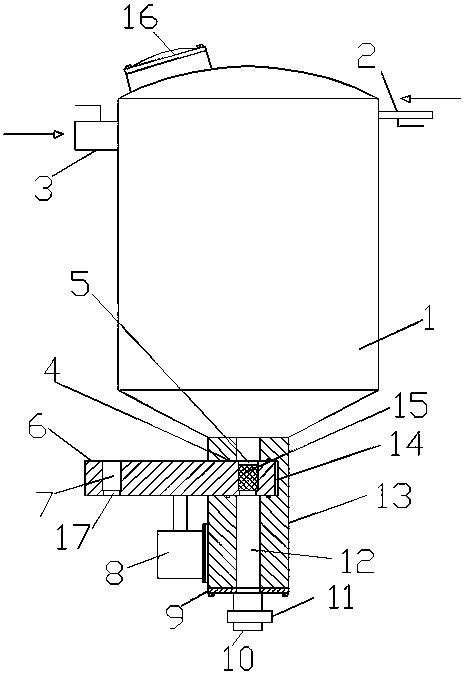

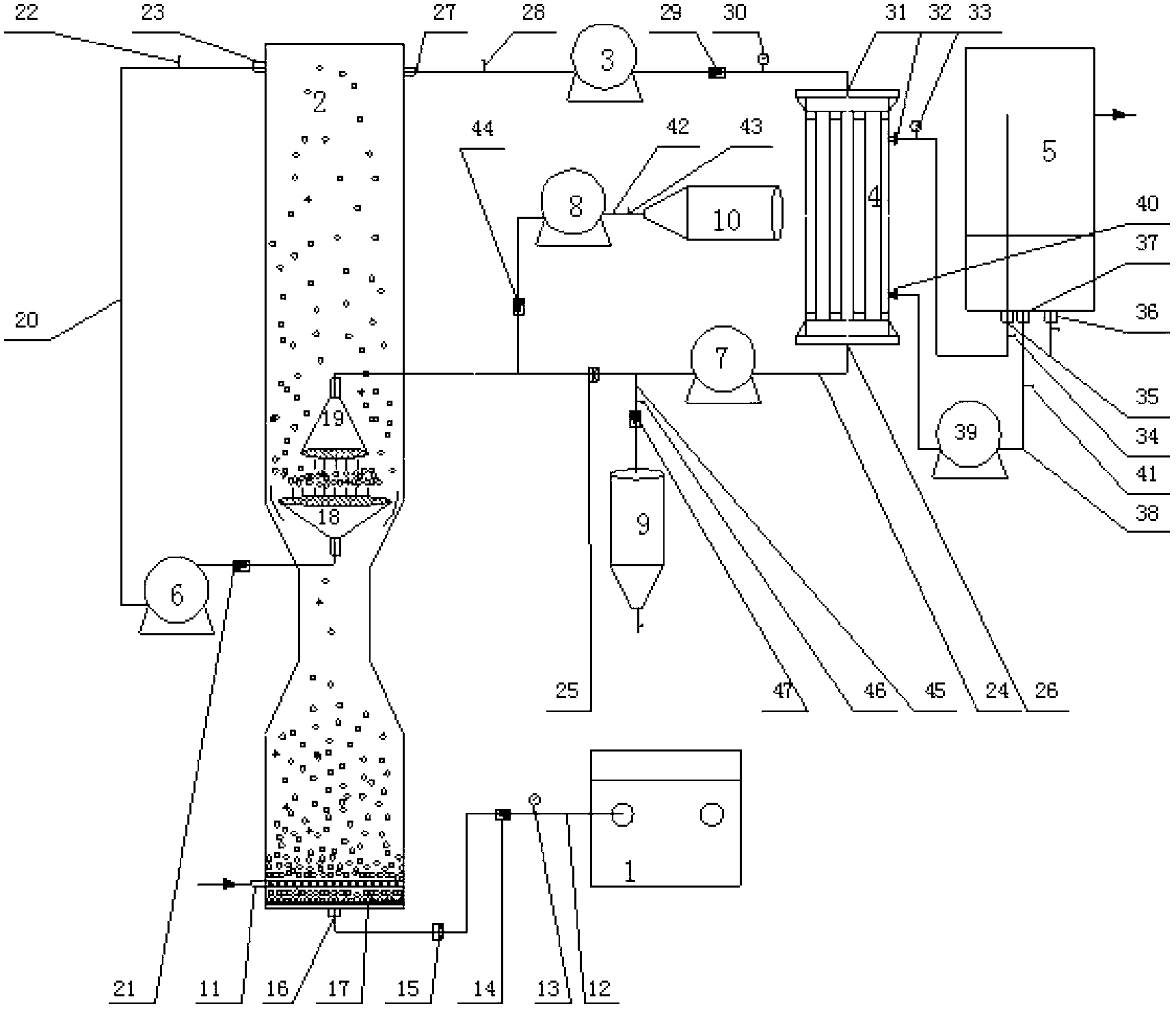

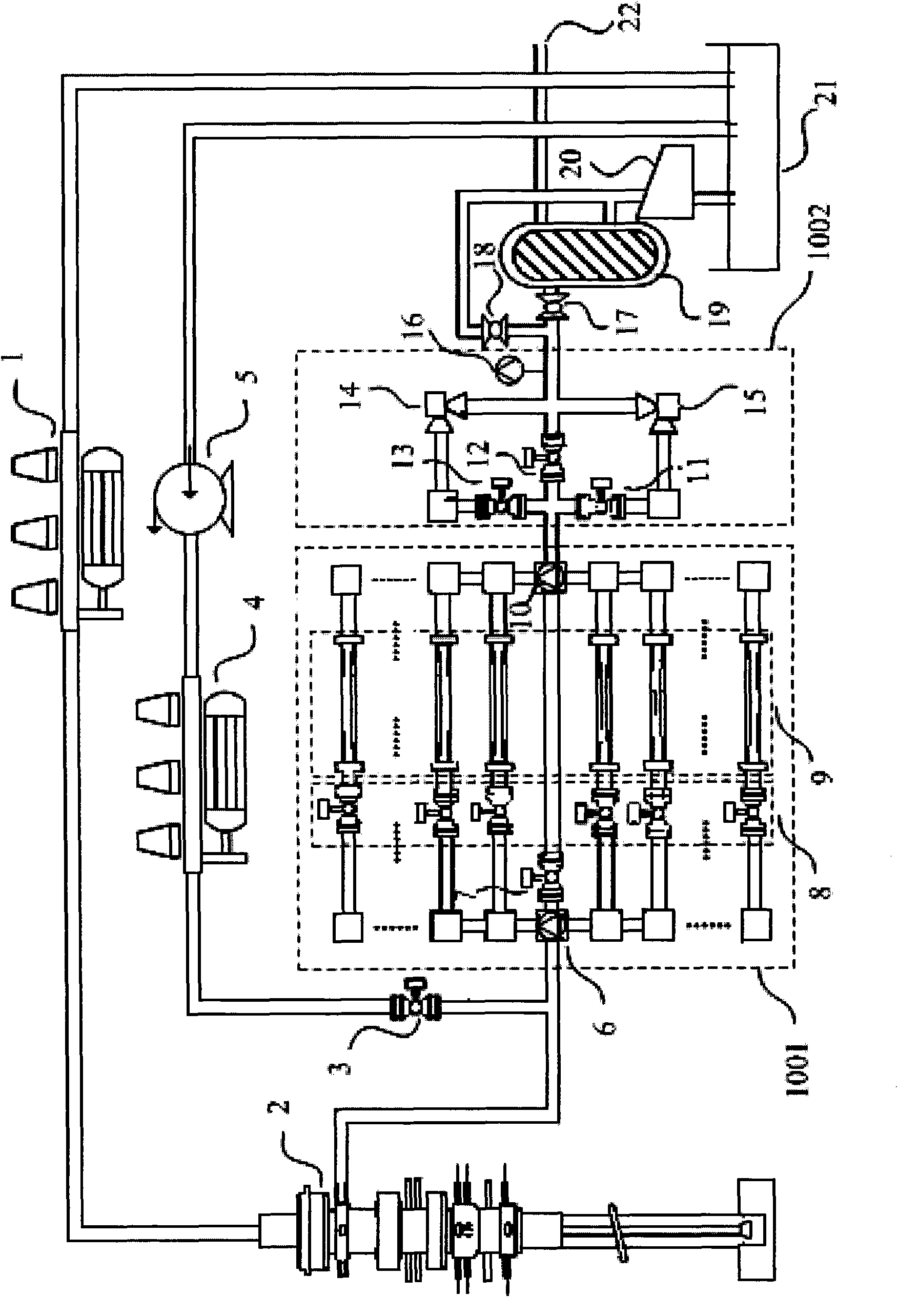

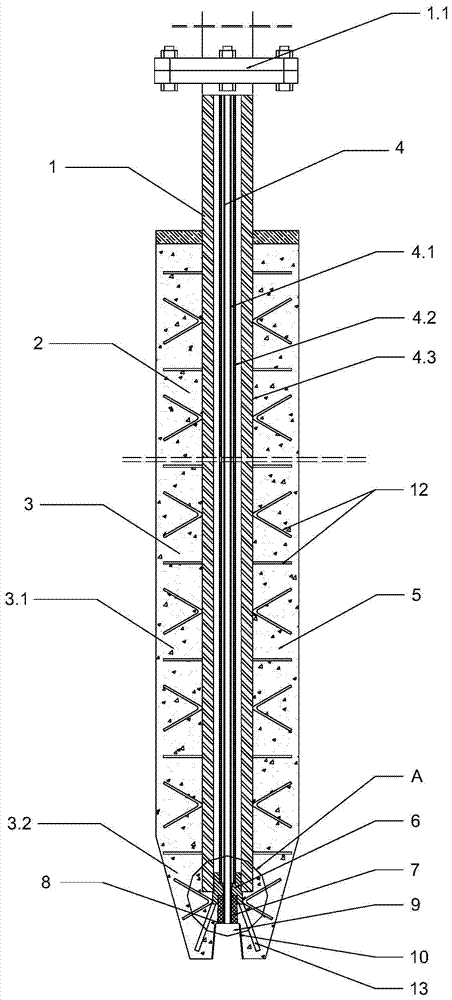

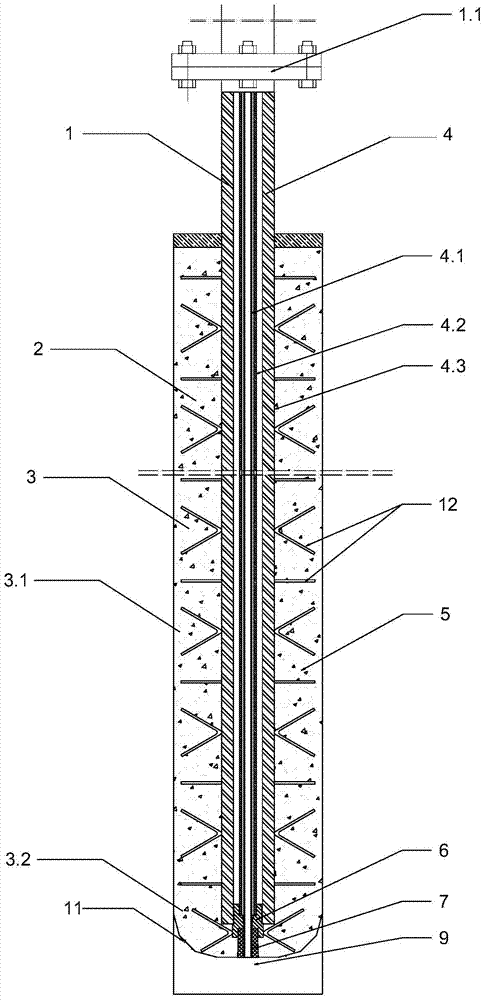

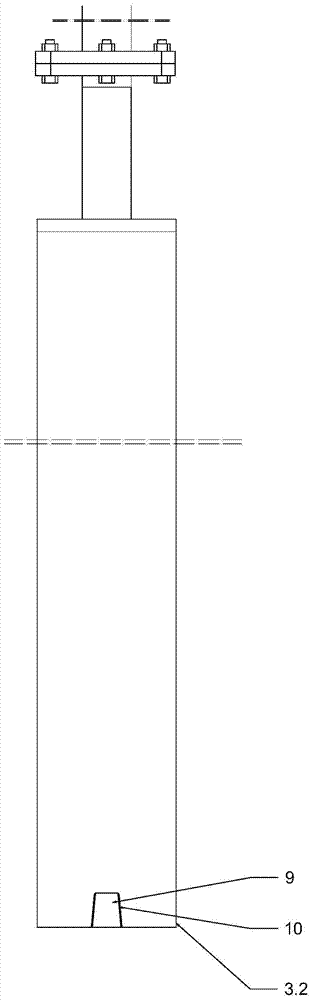

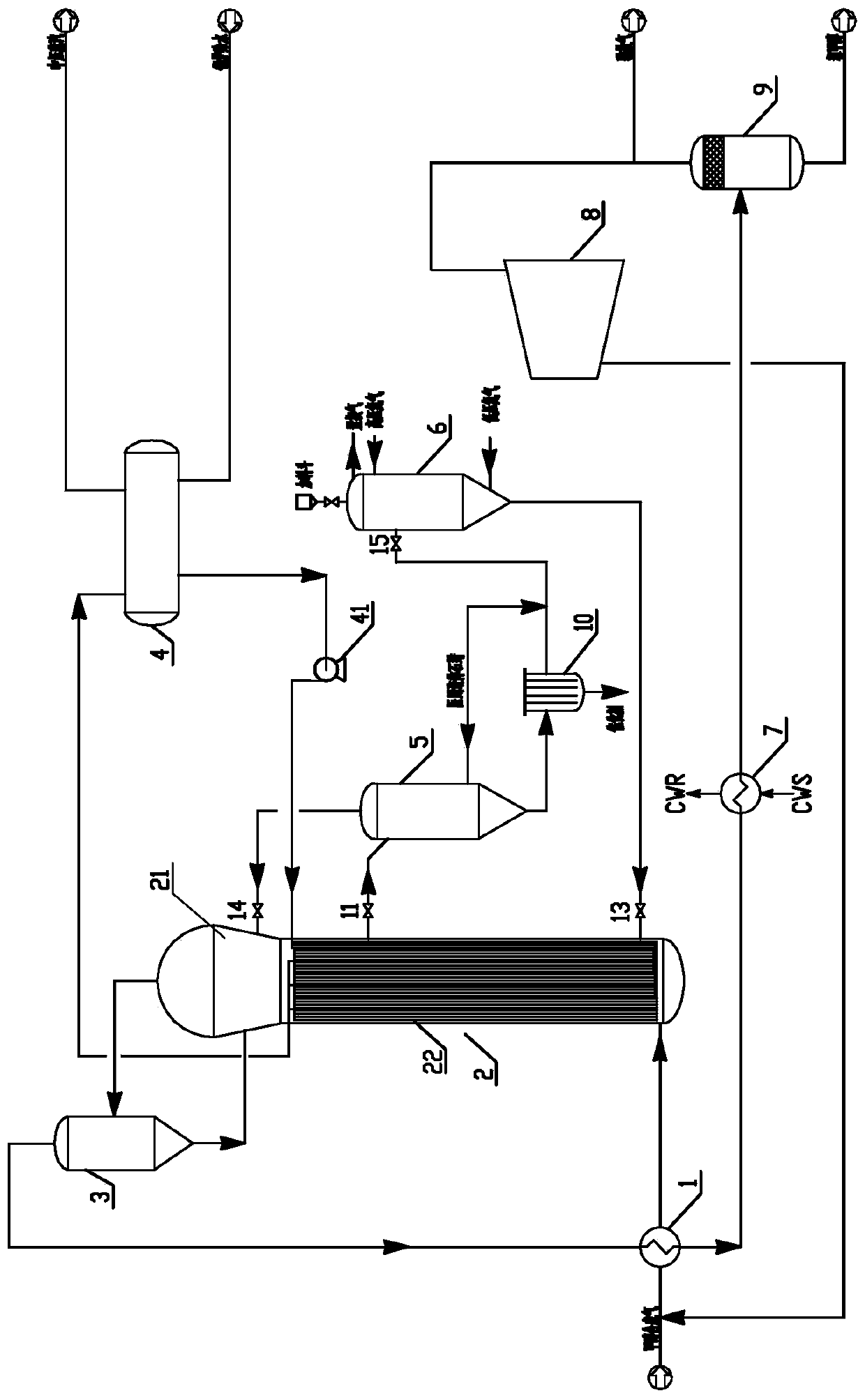

The invention discloses a system for deep treatment of coking wastewater by means of catalytic ozonation-ceramic membrane filtration, mainly consisting of an ozone generator, an ozone oxidation reactor, a booster pump, a ceramic membrane component, a gas-liquid separator, a tail gas absorbing device, a wastewater reflowing pump, a catalyst reflowing pump, a catalyst adding pump, a catalyst outflowing groove, a catalyst adding groove and corresponding pipe fittings, valves and instruments. According to the system, the application of a powder catalyst in a dynamic reactor can be realized due tothe combination of the catalytic ozonation and the ceramic membrane separation; the ozonation and the catalytic ozonation can be guaranteed to be carried out in a single reactor in a segmental way due to the convection current of the reflowing wastewater and the catalyst slurry and the impact of upcurrent; the mass transfer resistance when the ozonation and the catalytic ozonation are independently used can be reduced; the use ratio of hydroxyl free radical and the removal rate of organic matters can be improved; the aims, such as the COD (chemical oxygen demand), the chroma and the turbidityof the deeply-treated coking wastewater, can be achieved; and the problems that the activity is suddenly reduced when the powder catalyst is formed into particulates, the running needs to be suspended when the mass transfer resistance is increased due to the use of the particulate catalyst and the particulate catalyst is changed and the like can be solved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

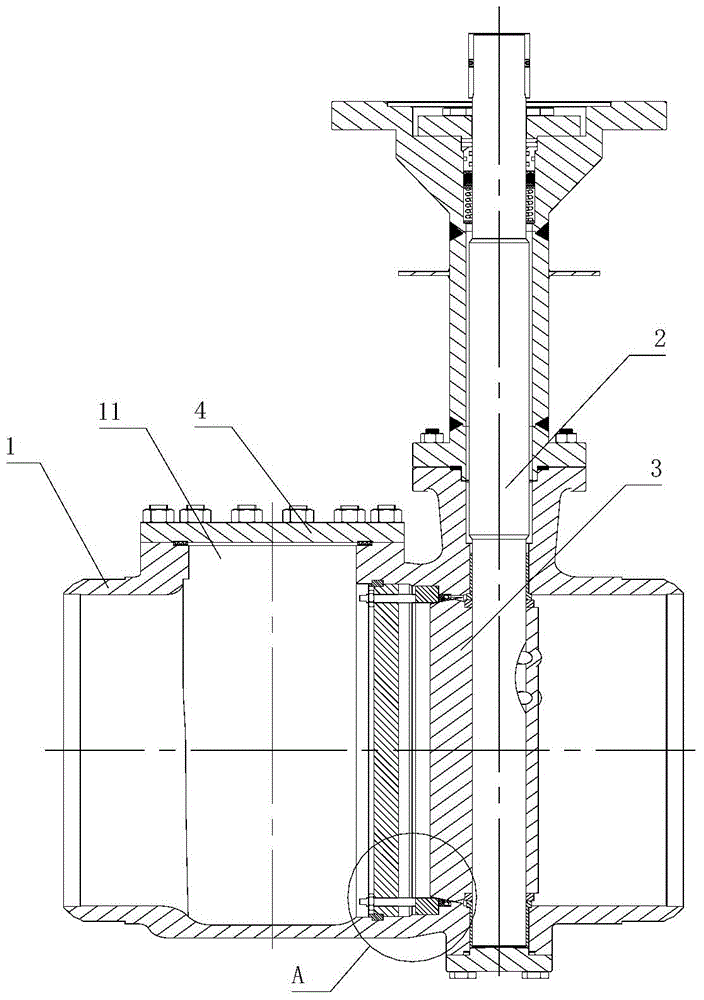

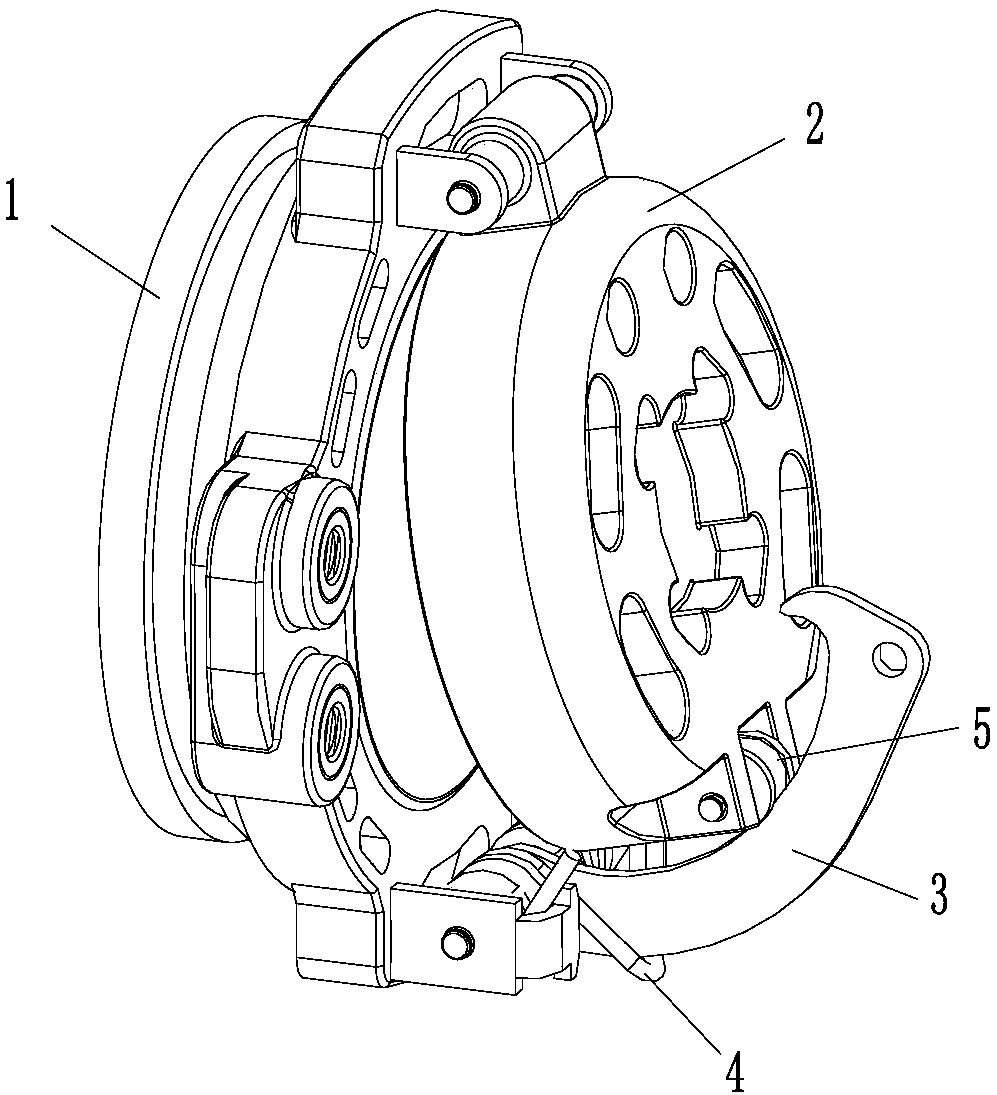

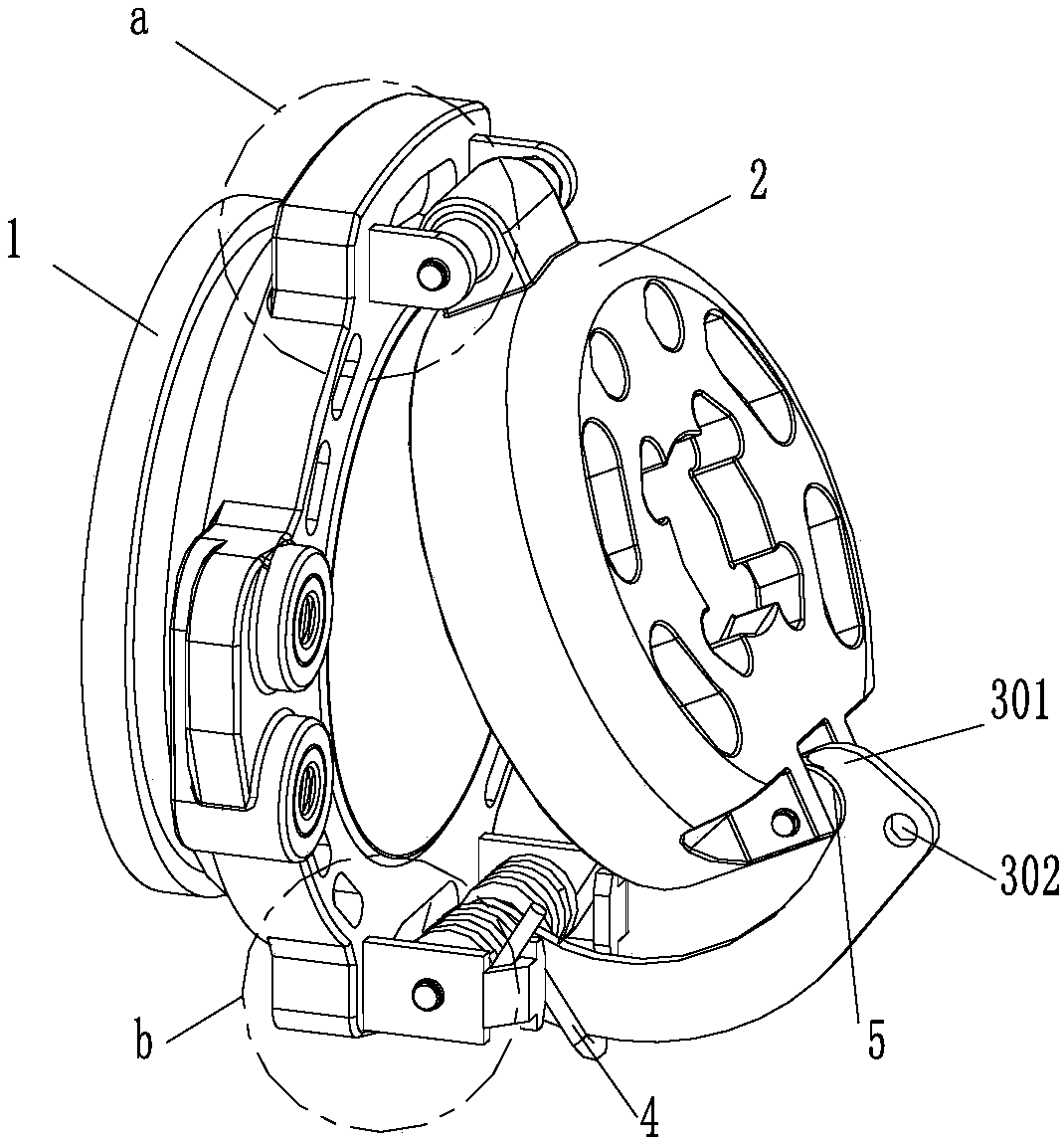

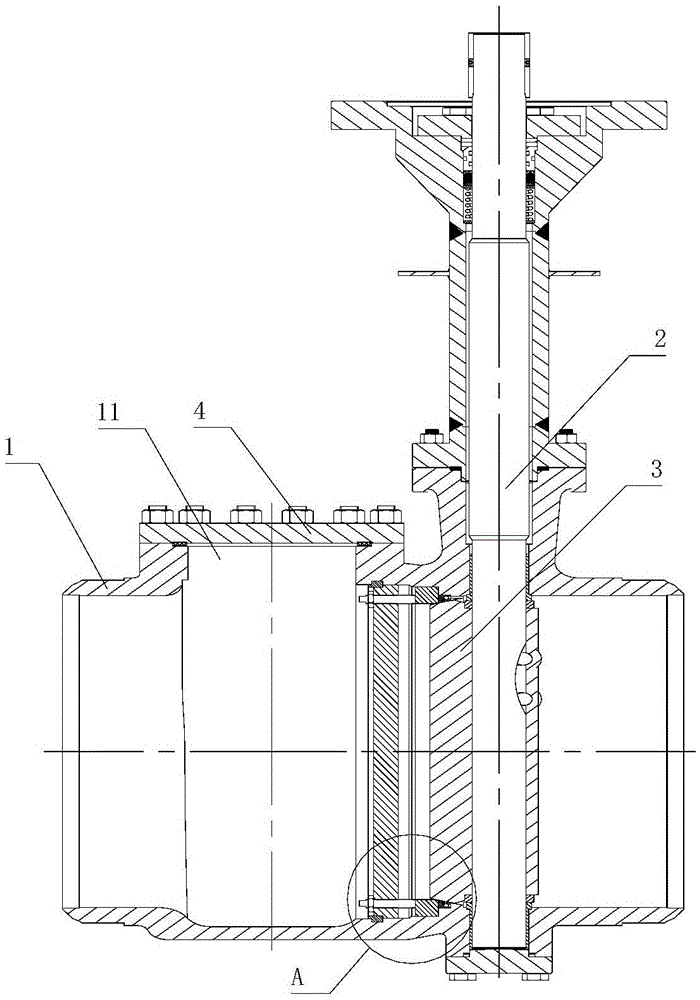

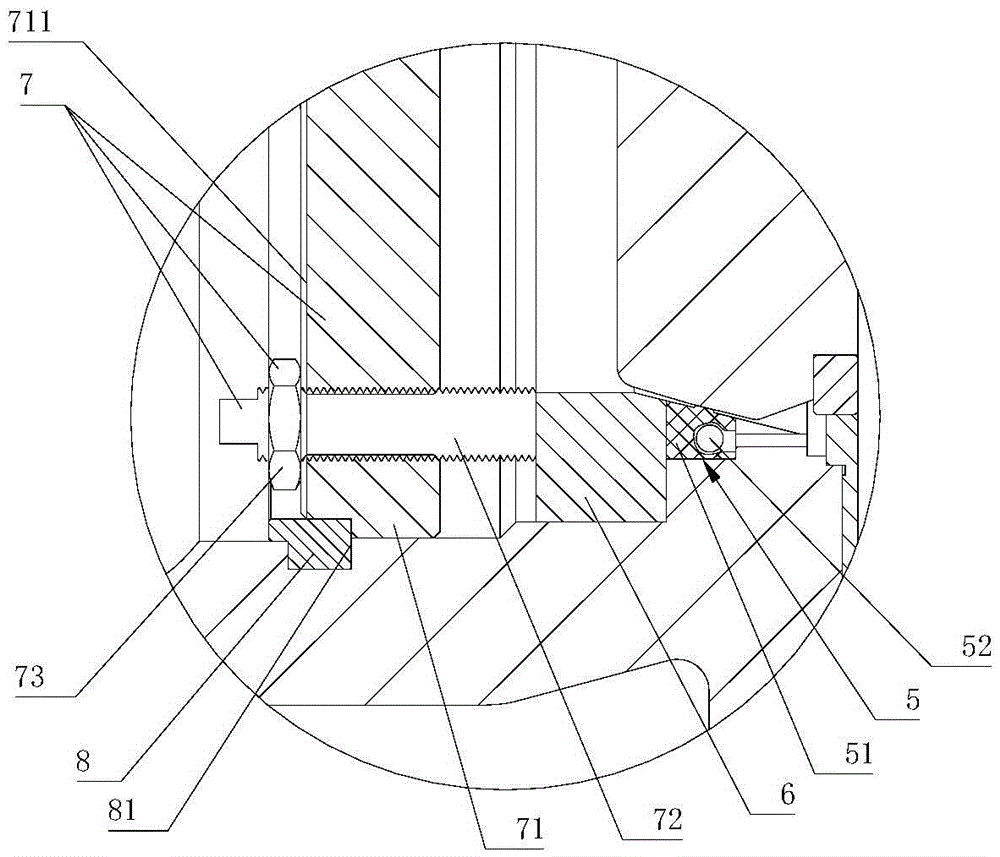

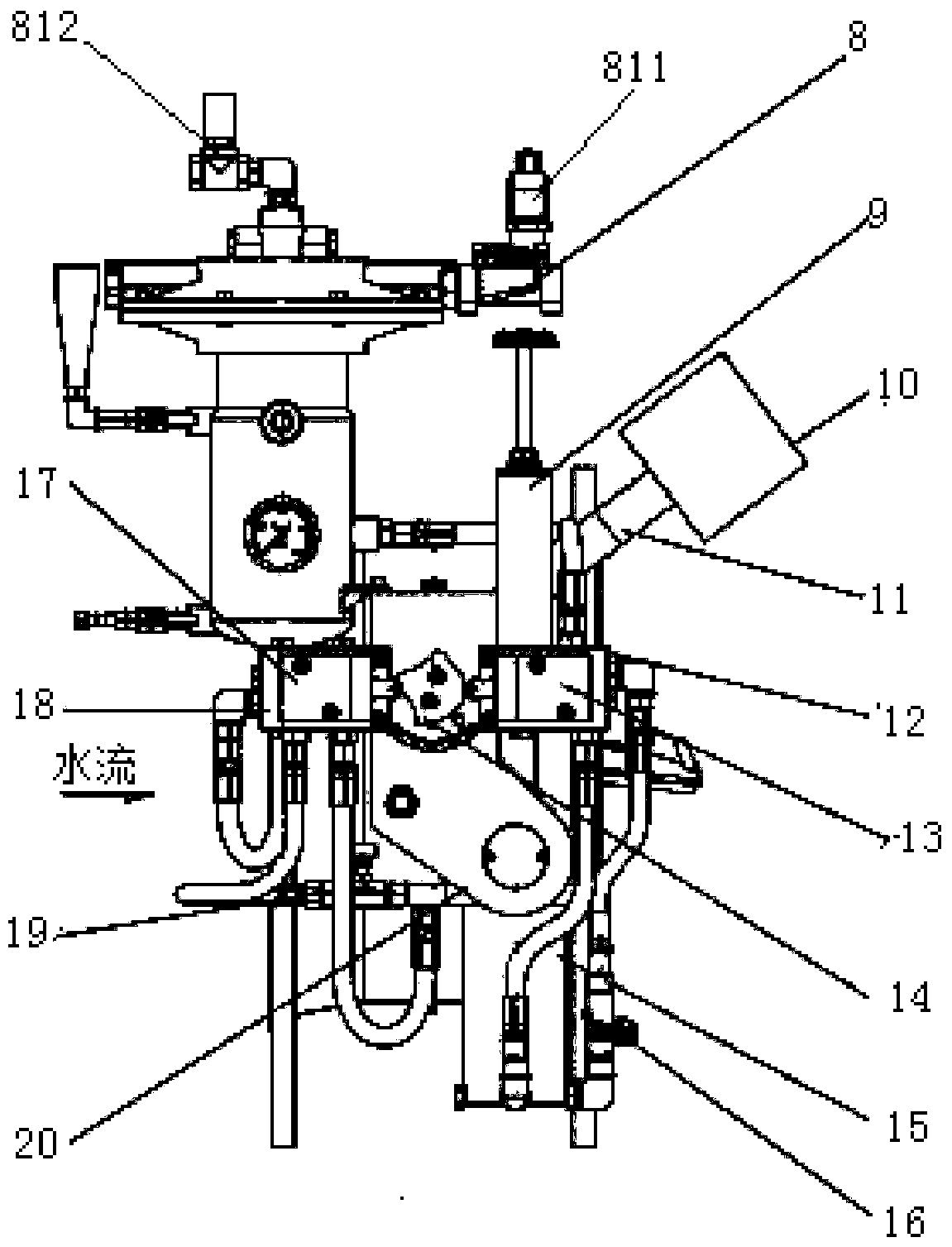

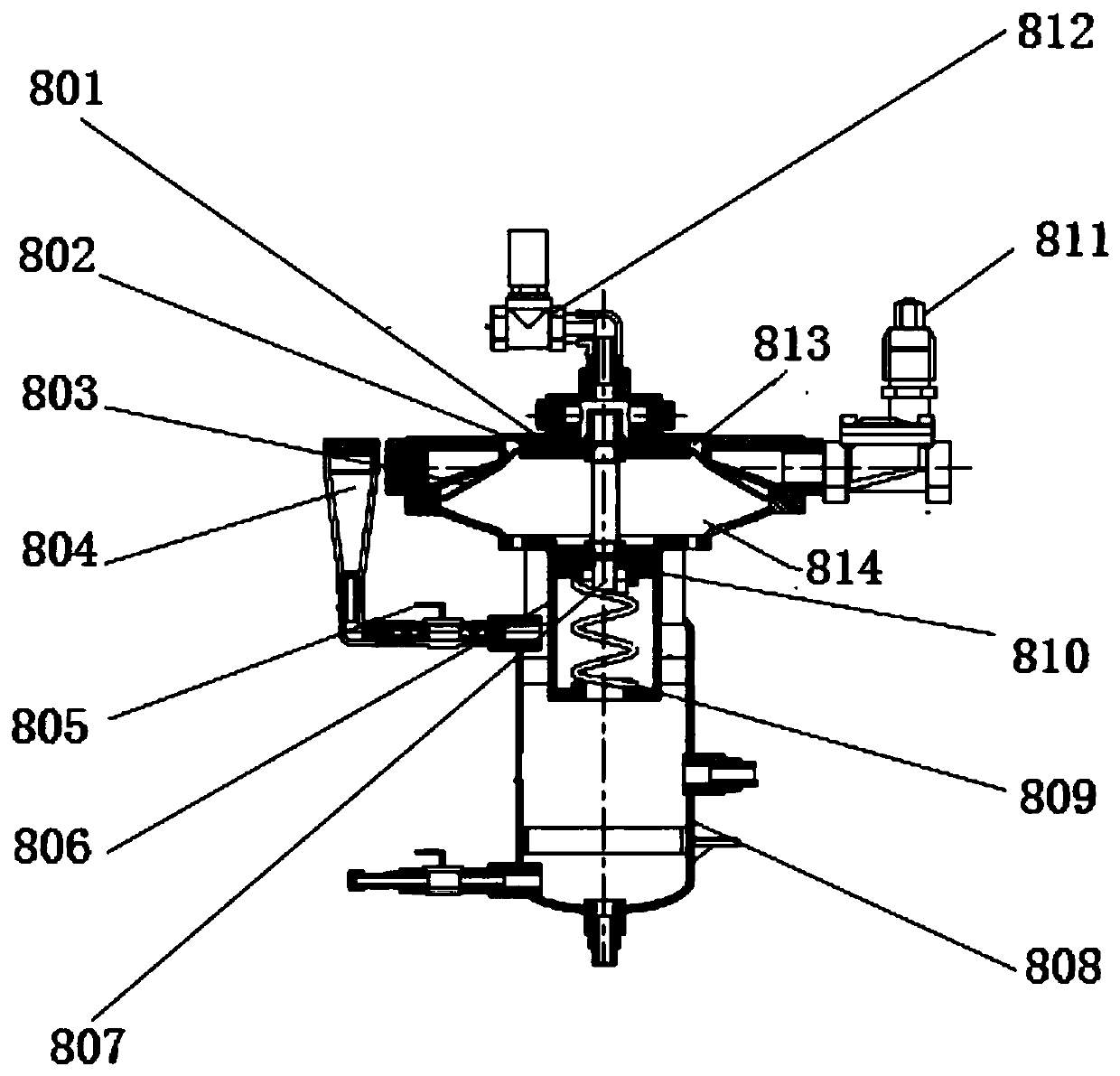

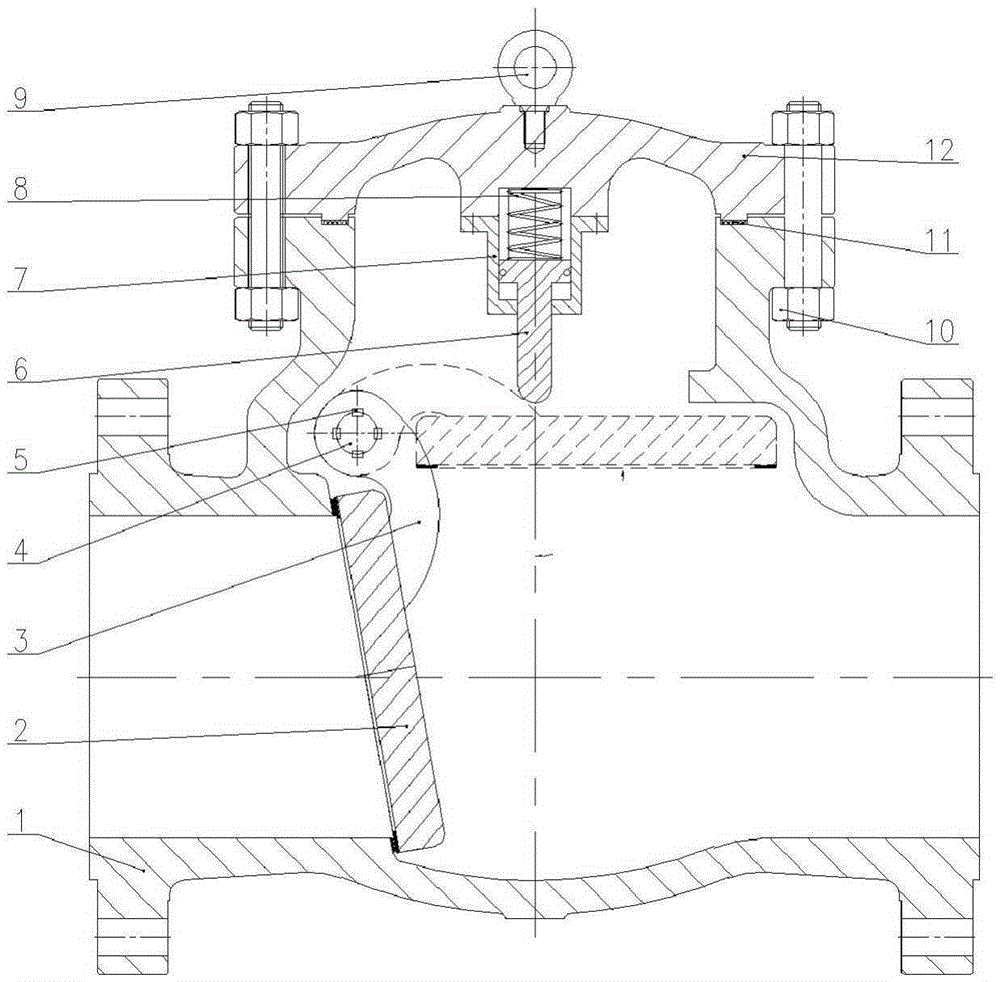

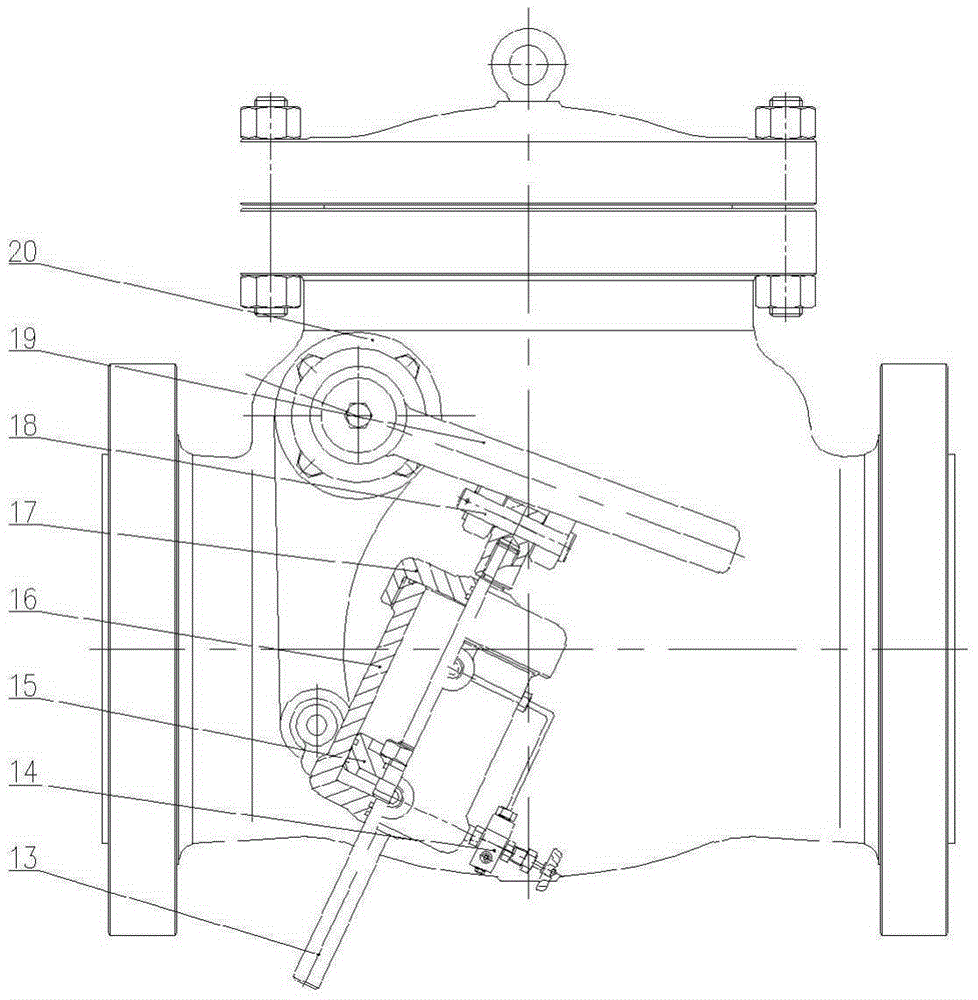

Reduced-pressure type backflow preventer

ActiveCN106594325ABackflow effect is goodOff stableCheck valvesMultiple way valvesSpring forceEngineering

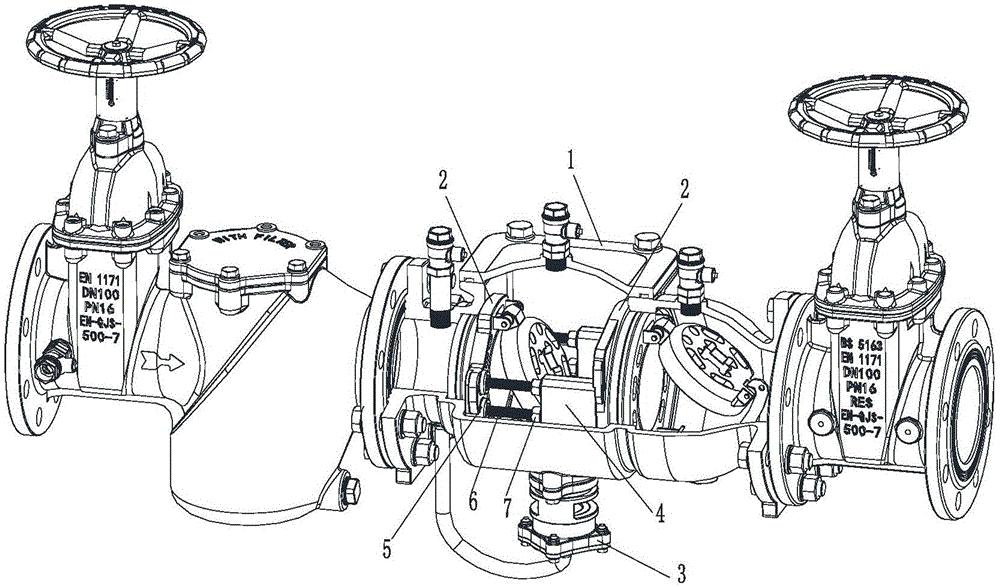

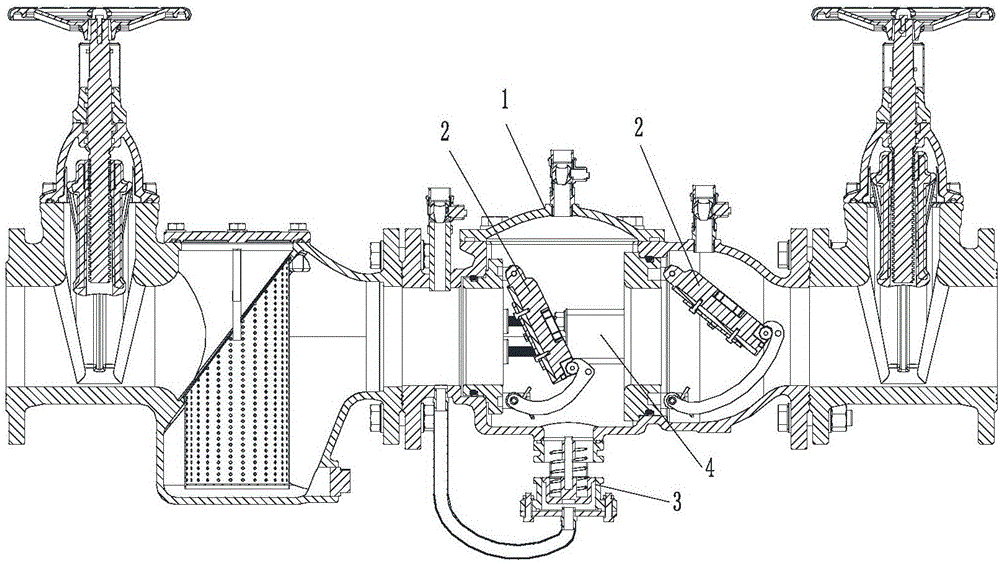

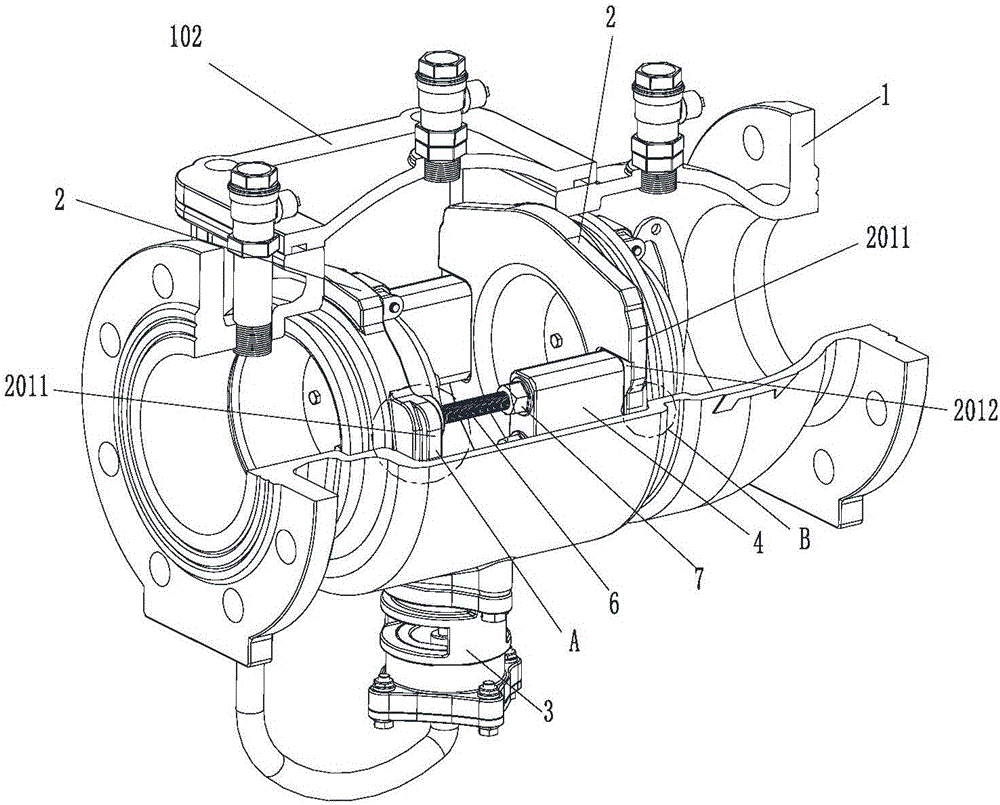

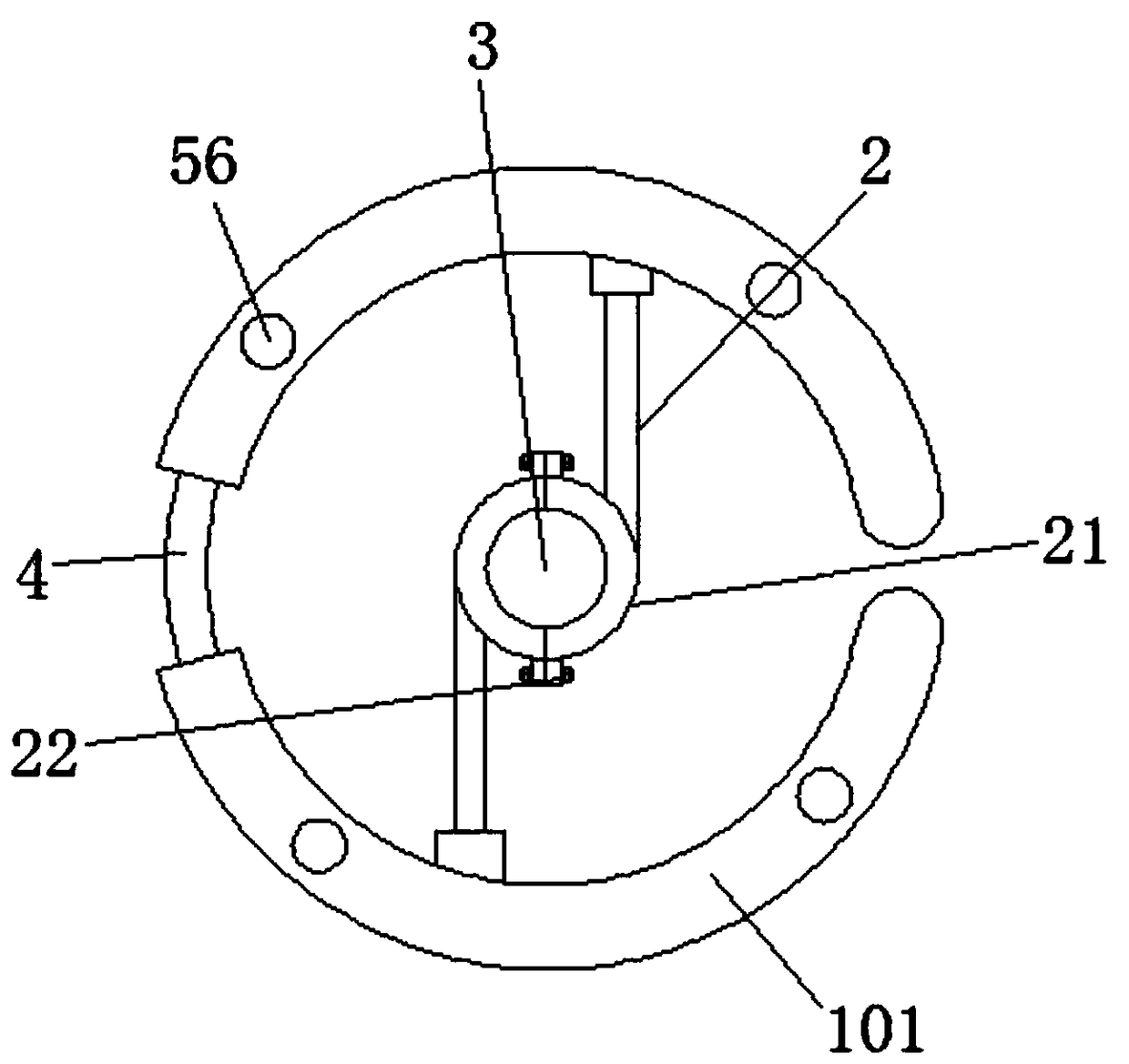

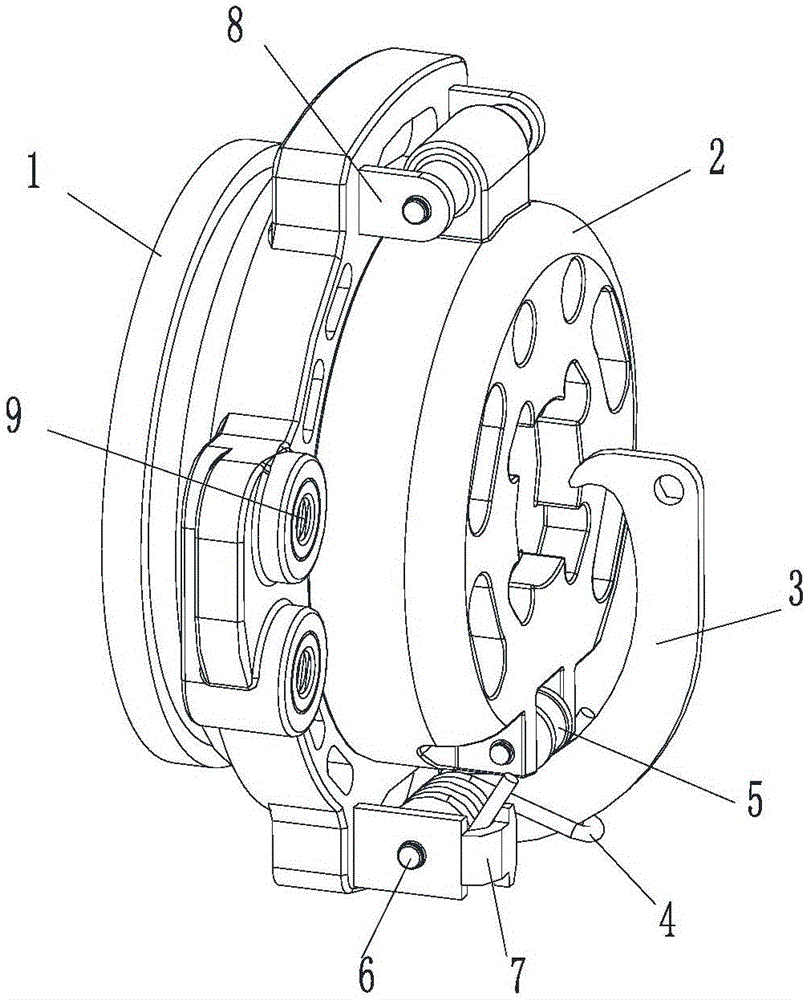

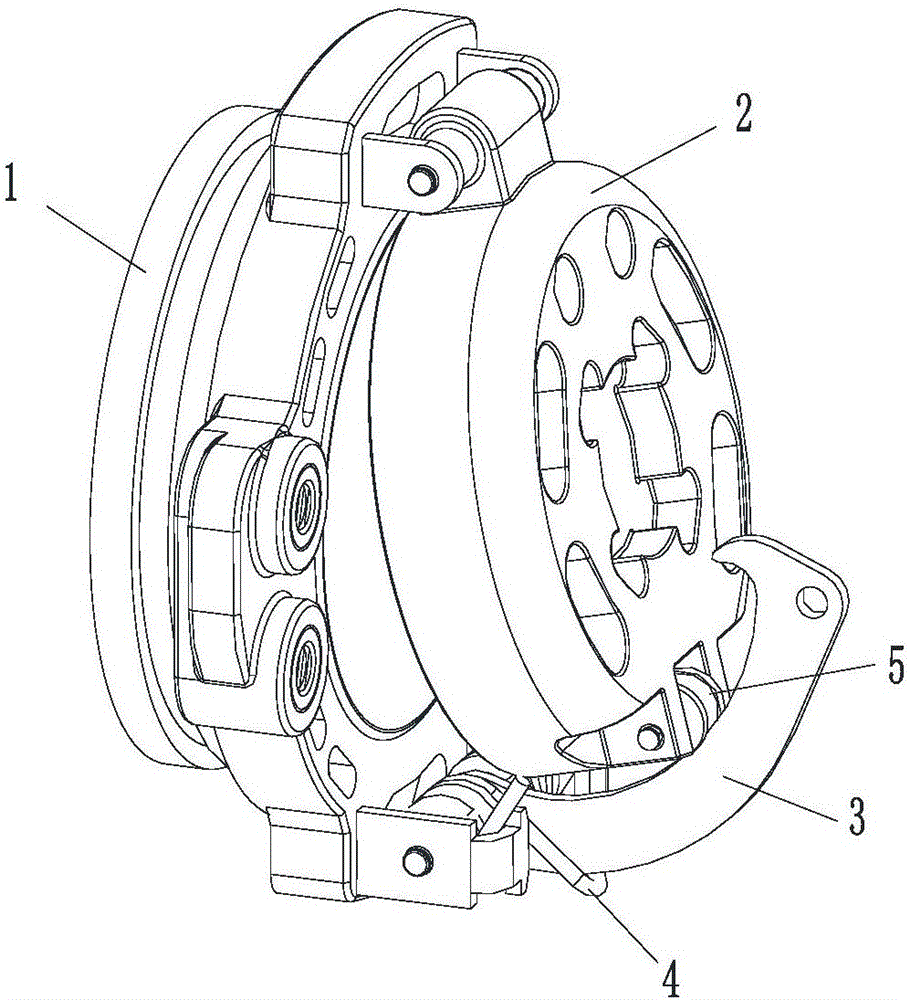

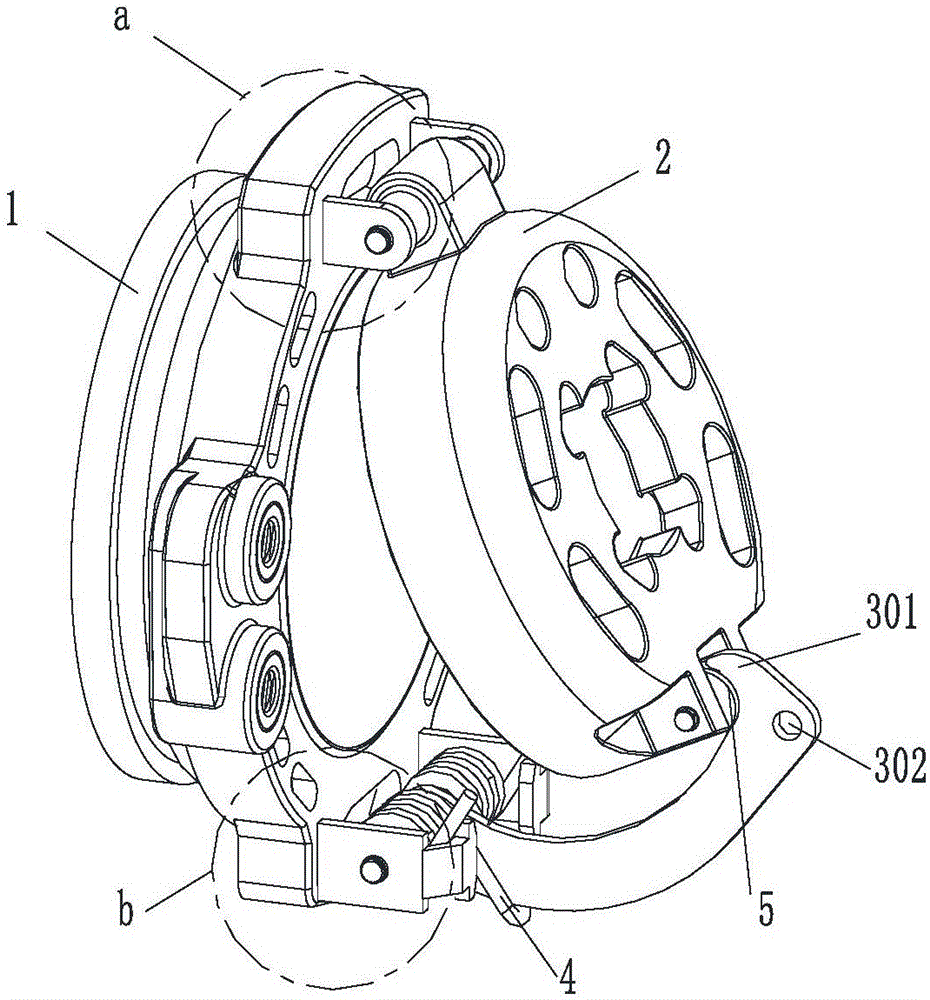

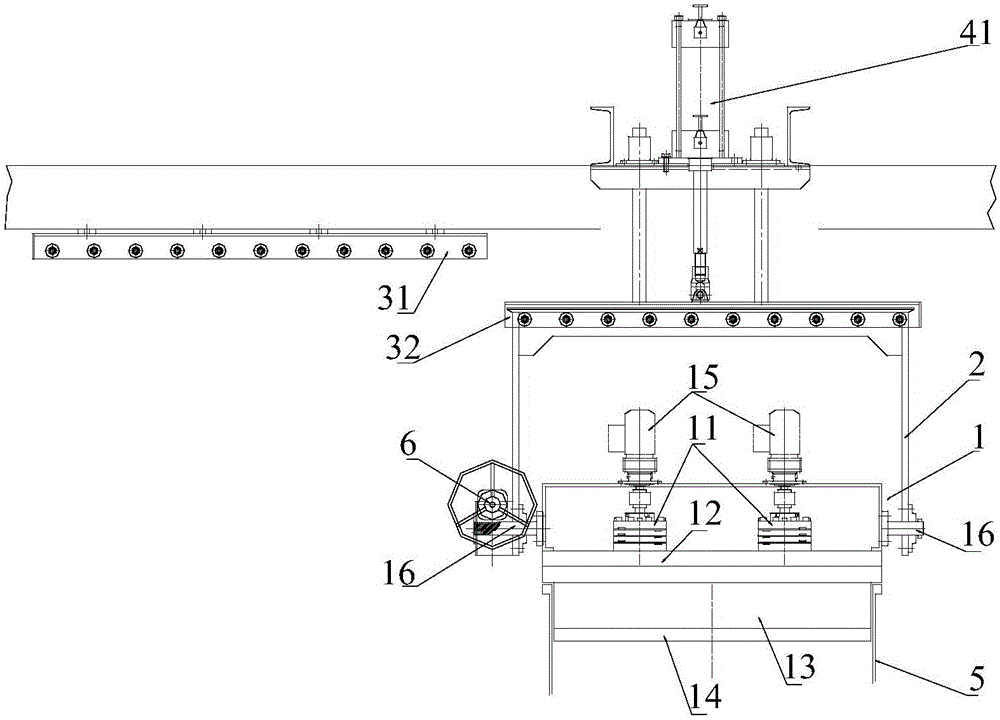

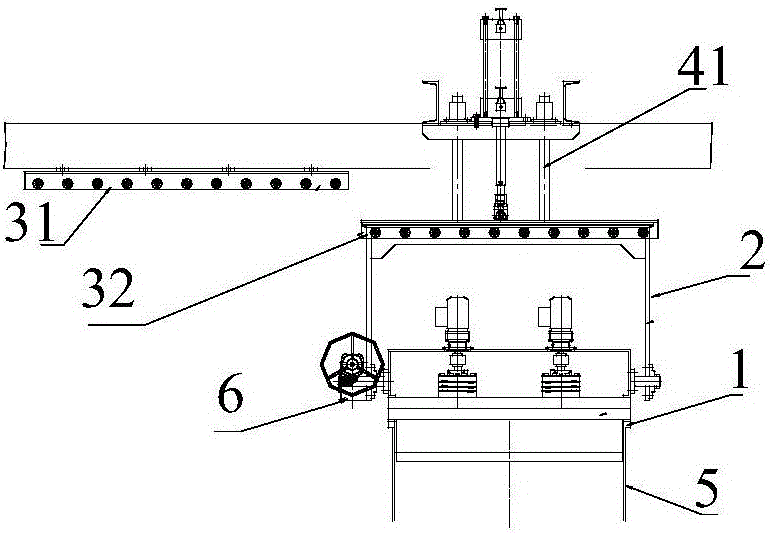

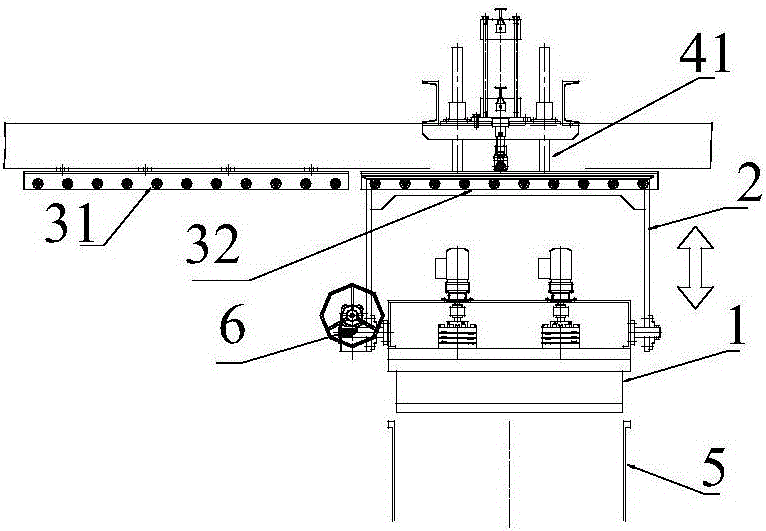

The invention discloses a reduced-pressure type backflow preventer which comprises a valve body, two check valves with the same structure and a drain valve, wherein a cavity is formed in the valve body, and a water inlet, a water outlet and a drain opening are formed in the valve wall of the valve body; the two check valves are fixedly mounted in the valve body through support pieces and are located at the water inlet and the water outlet respectively; the drain valve is mounted outside the valve body and located at the drain opening; each check valve comprises a valve seat, a valve clack, a rocker and a twins torsional spring; one side of each valve clack is hinged to the upper end of the corresponding valve seat, and rollers are mounted on the other sides of the valve clacks; the rockers are connected with the lower ends of the valve seats through pin shafts; the rollers are propped against the rockers and slide on the rockers; the pin shafts are sleeved with the twins torsional springs; and the spring forces of the twins torsional springs act on the rockers to keep the valve clacks in a normally-closed state, and the rollers on the valve clacks are enabled to roll on the rockers by external forces to realize the opening of the valve clacks. Owing to the twins torsional spring-rocker structures of the check valves, the reduced-pressure type backflow preventer achieves a better flow prevention effect.

Owner:GUANGDONG YONGQUAN VALVE TECH

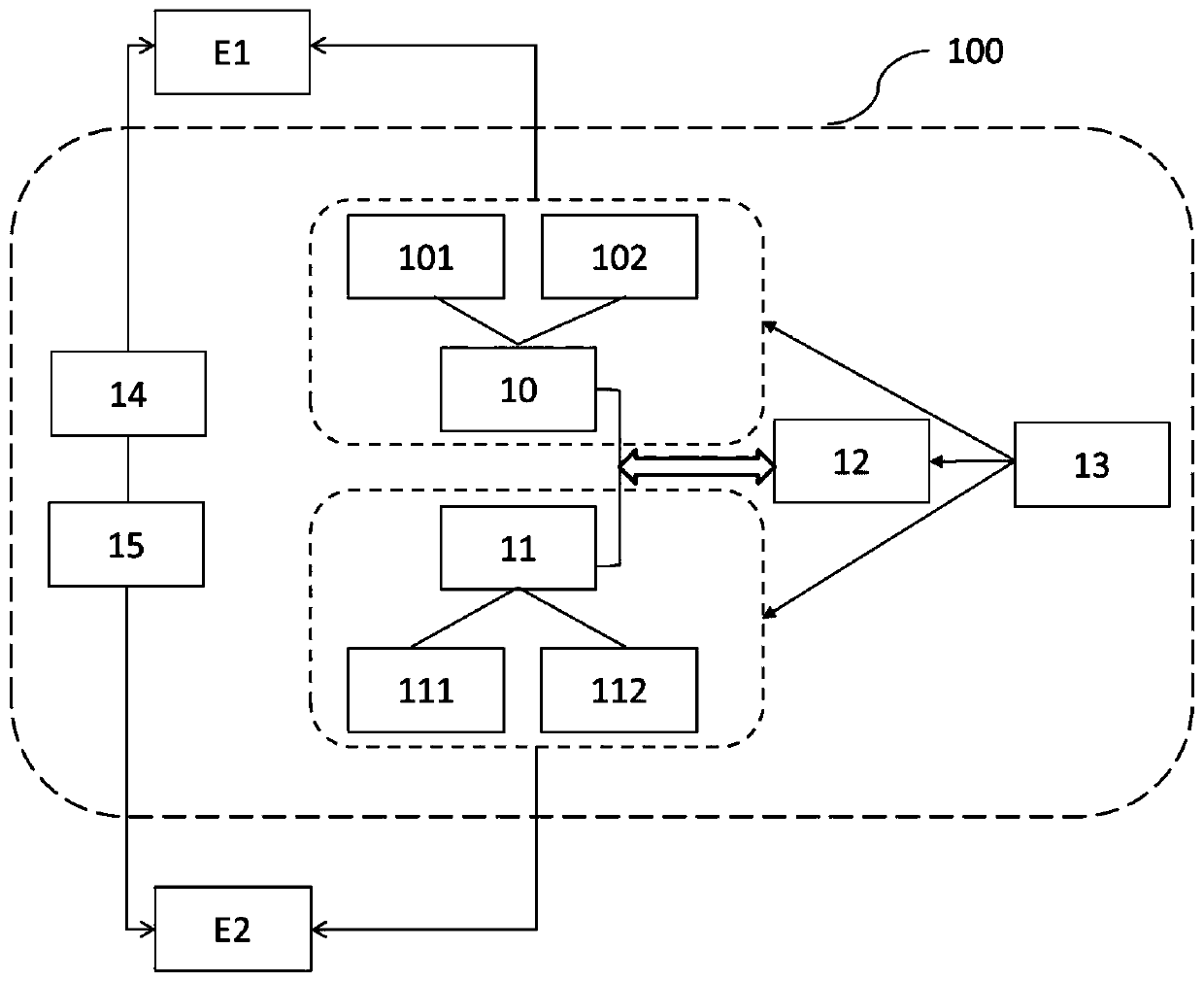

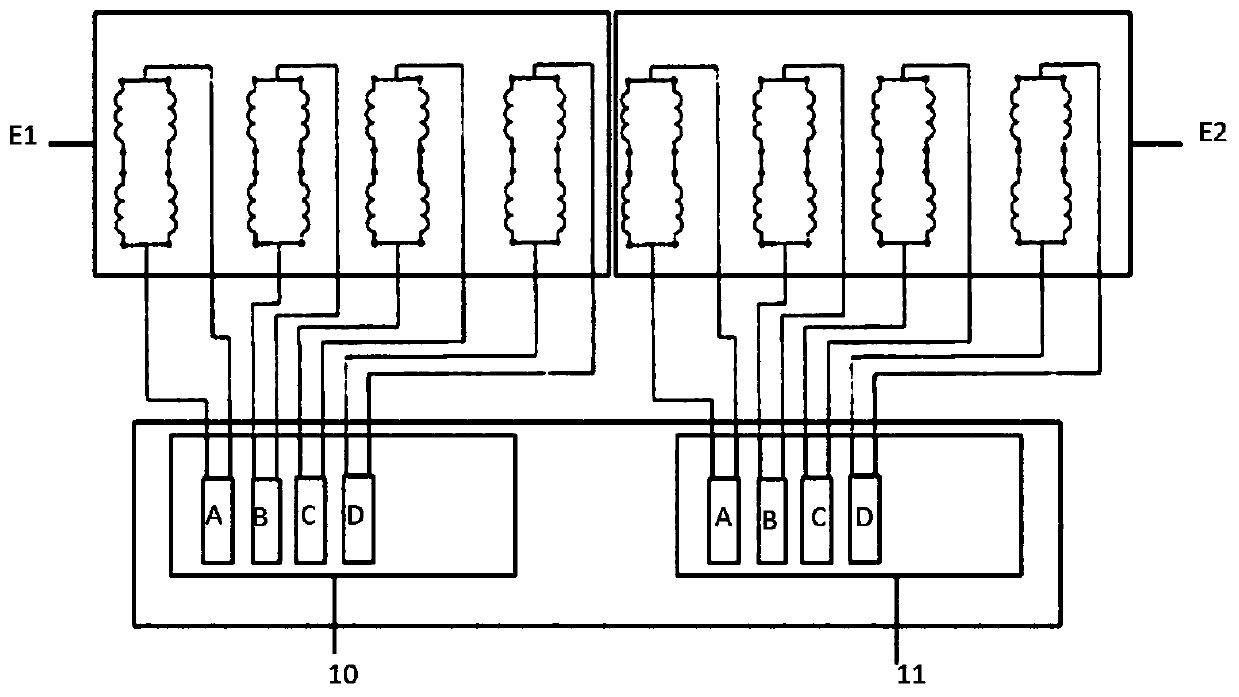

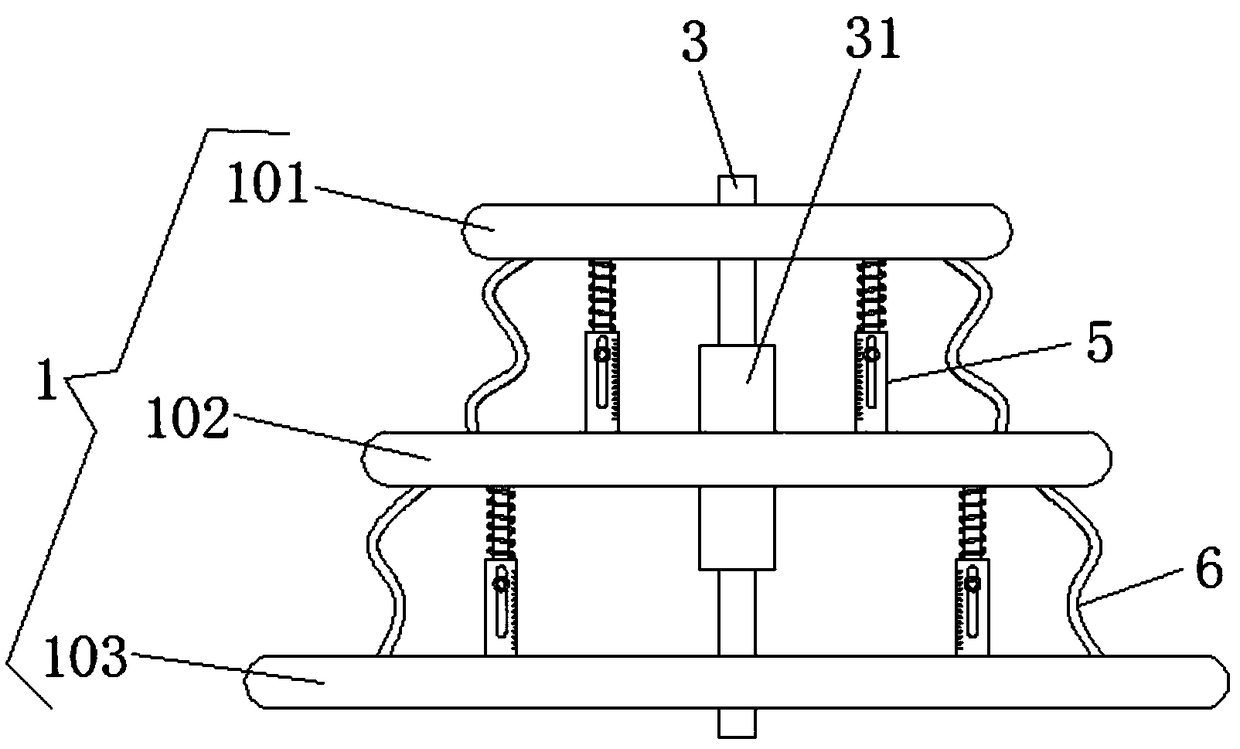

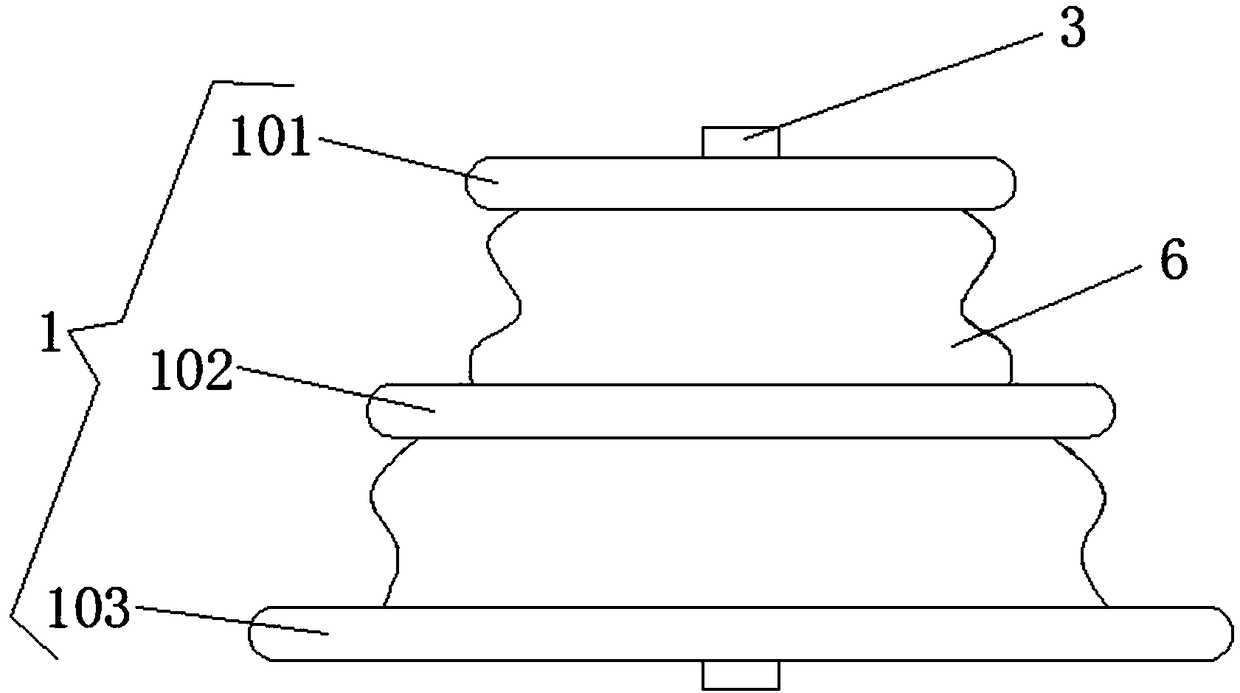

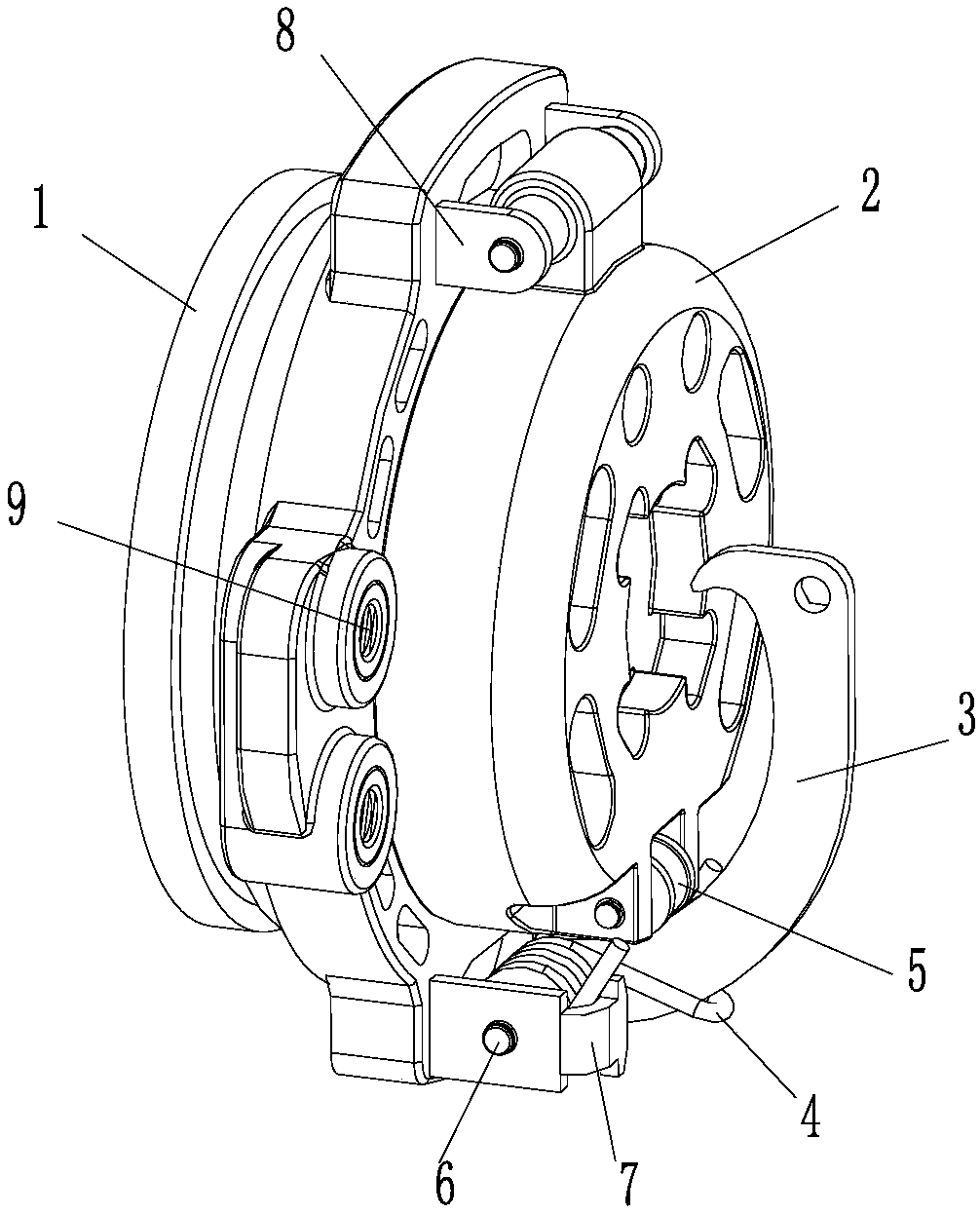

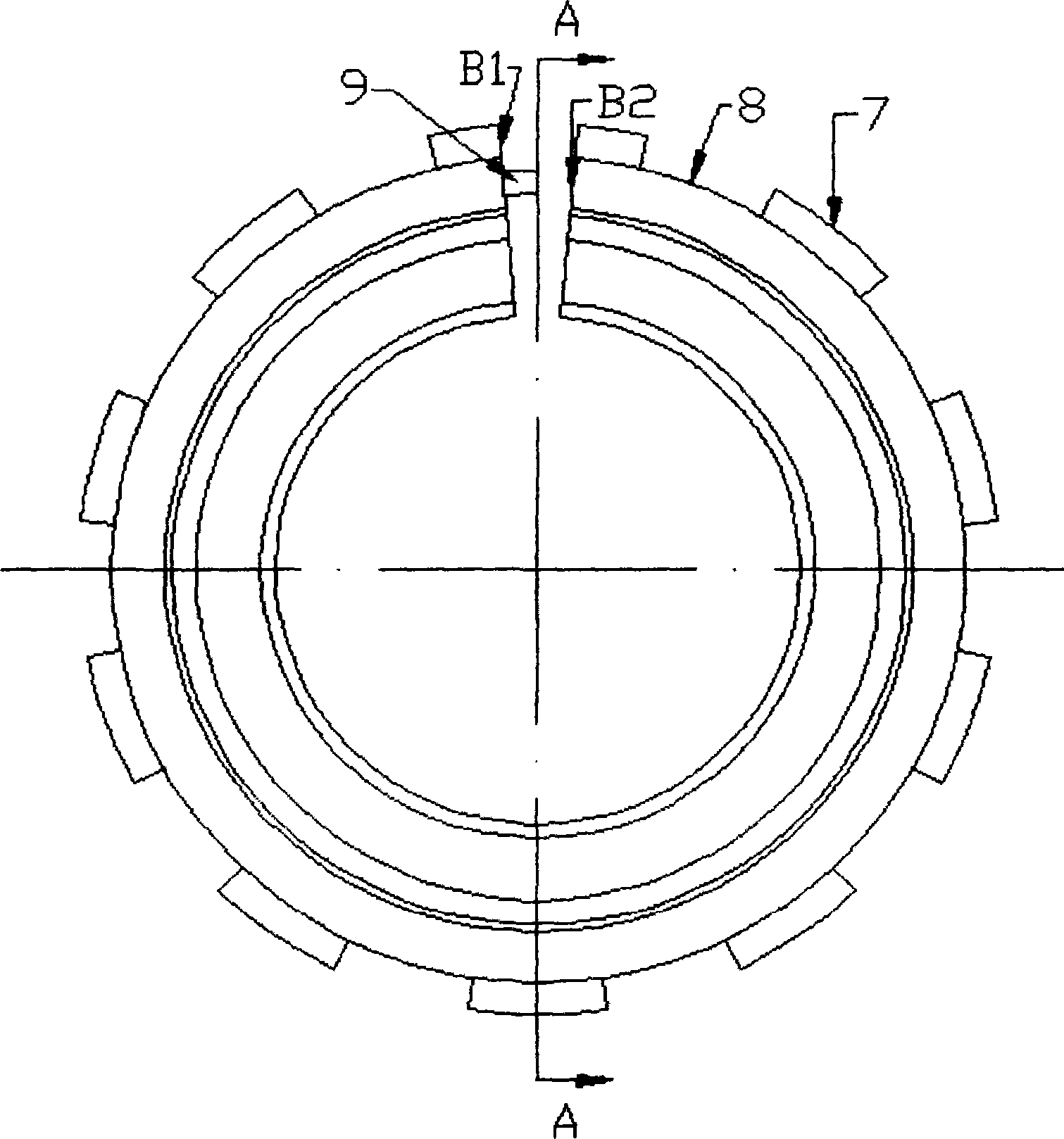

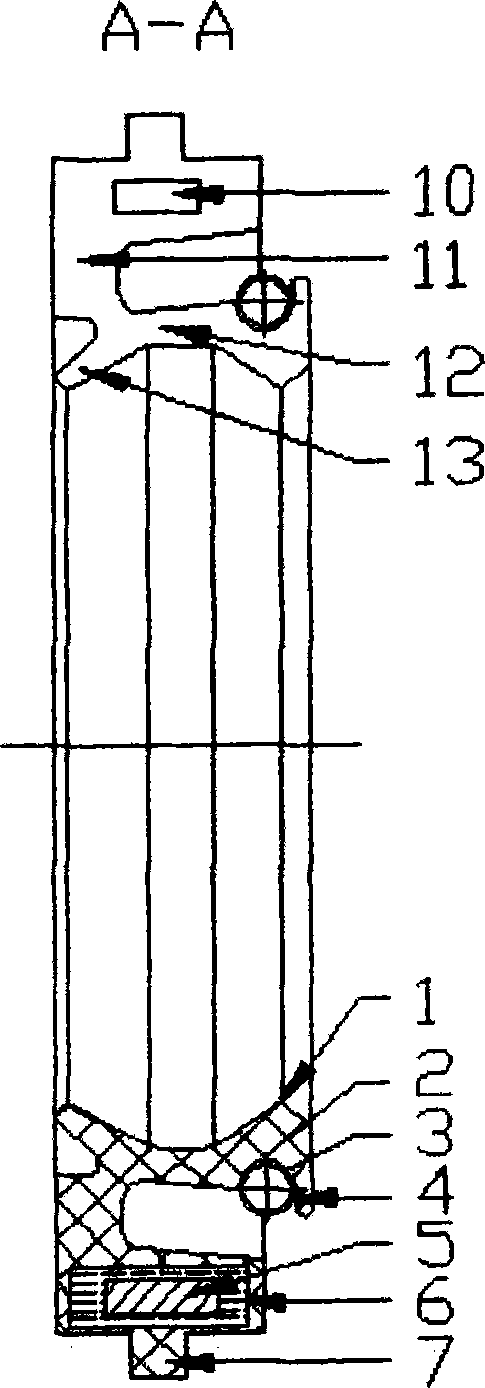

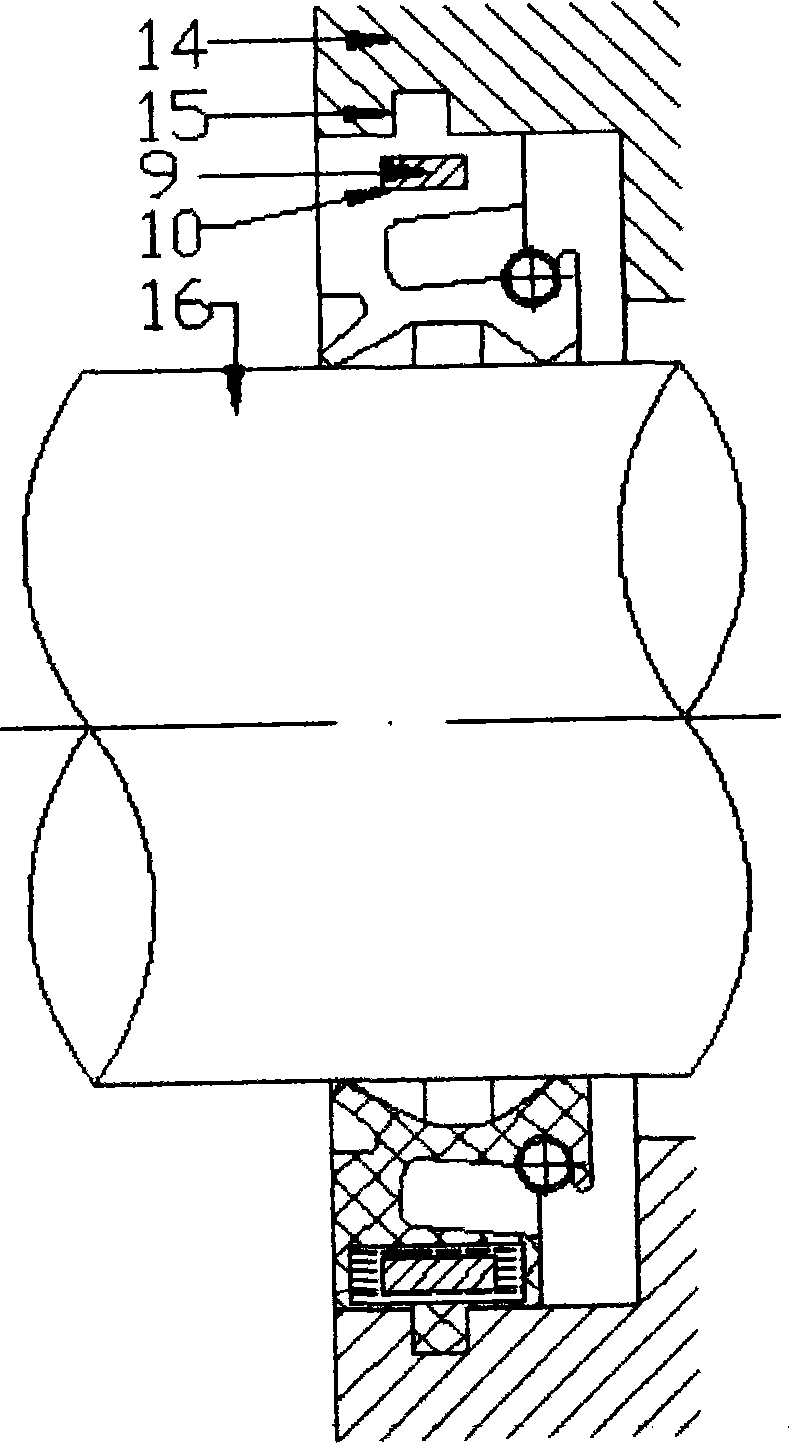

Driving system and operation method for driving device of fast reactor control rod driving mechanism

ActiveCN111355439AEasy to control independentlyEasy online replacementElectric motor controlNuclear energy generationElectric machineryNuclear power plant

The invention discloses a driving system and an operation method for a driving device of a fast reactor control rod driving mechanism. The embodiment of the invention provides the driving system whichcomprises a first driving device, a second driving device, a control module and a power supply module. The first driving device is arranged to control the first motor to drive a main shaft of a control rod driving mechanism to drive a control rod to move or suspend the control rod at a target position, the second driving device is arranged to control a second motor such that the second motor drives a gripper of the control rod driving mechanism to be connected with or separated from the control rod; only one of the first motor and the second motor is allowed to work at one time; the first driving device is used for independently controlling each phase of the first motor; and the second driving device independently controls each phase of the second motor. According to the driving system, the improvement of the operation reliability of a nuclear power plant is facilitated. The embodiment of the invention also provides the operation method of the driving device for the fast reactor control rod driving mechanism, the online maintenance of the driving device can be realized, the operation is simple, and the maintenance difficulty is low.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Aluminum equalizing ring for insulators

ActiveCN109360695AIncrease diversityReduced insulation performanceInsulatorsArchitectural engineeringEconomic benefits

The invention relates to the technical field of power transmission protection equipment and discloses an aluminum equalizing ring for insulators, which comprises an equalizing ring body. The equalizing ring body includes a small equalizing ring, a medium equalizing ring and a large equalizing ring; adjusting bars are threadedly mounted at the bottom of the small equalizing ring in nested manner; afixing socket bar is movably mounted at the bottom of each adjusting bar in sleeving manner; the bottoms of the fixing socket bars are fixedly connected to the top of the medium equalizing ring. Thealuminum equalizing ring for insulators is provided with openings which may act as discharge gaps; when too much electric charges are accumulated, self-discharging can occur to allow relief; the operation demand of a + / -8000 kV DC line can be well met; the ends of insulators can be well protected from being eroded by an electric field; online replacement and installation are also facilitated; linemaintenance cost is greatly reduced; the good material also helps effectively avoid rusting and ensure long-term reliable operation; the aluminum equalizing ring for insulators has good market application prospect and social and economic benefits.

Owner:扬州旺源电气有限公司

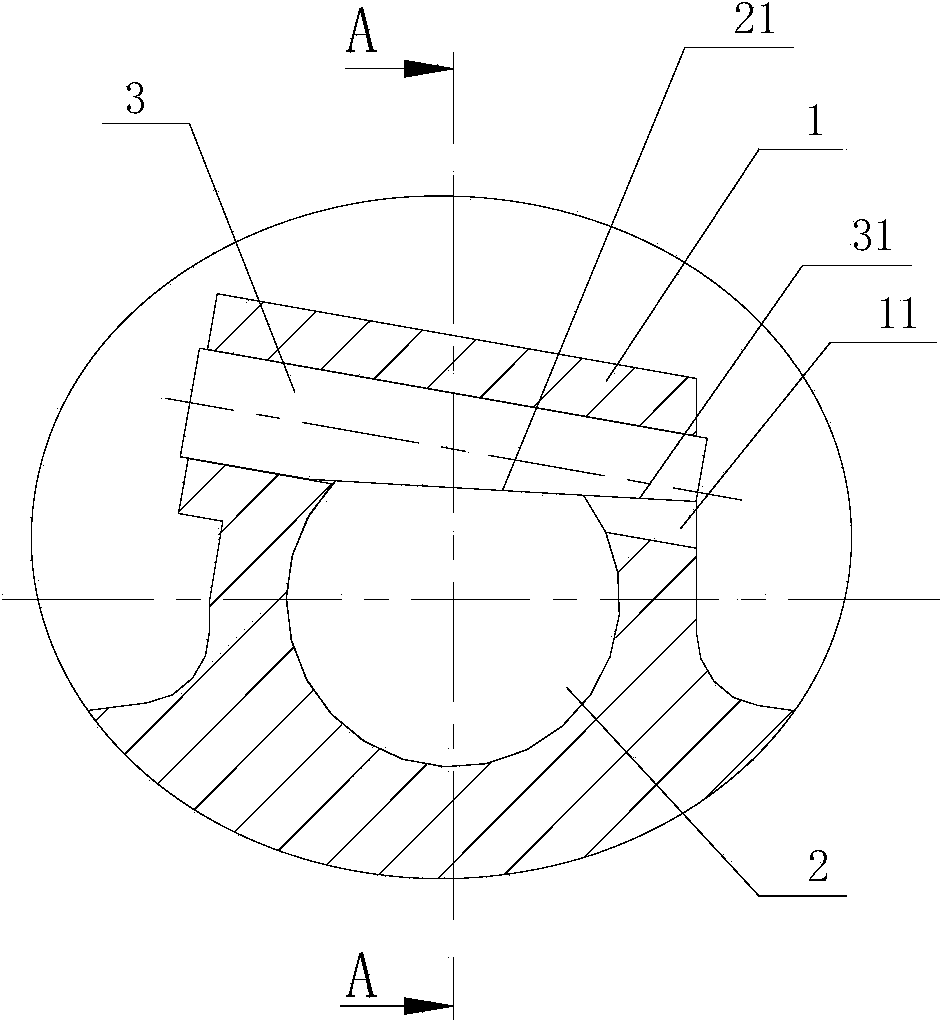

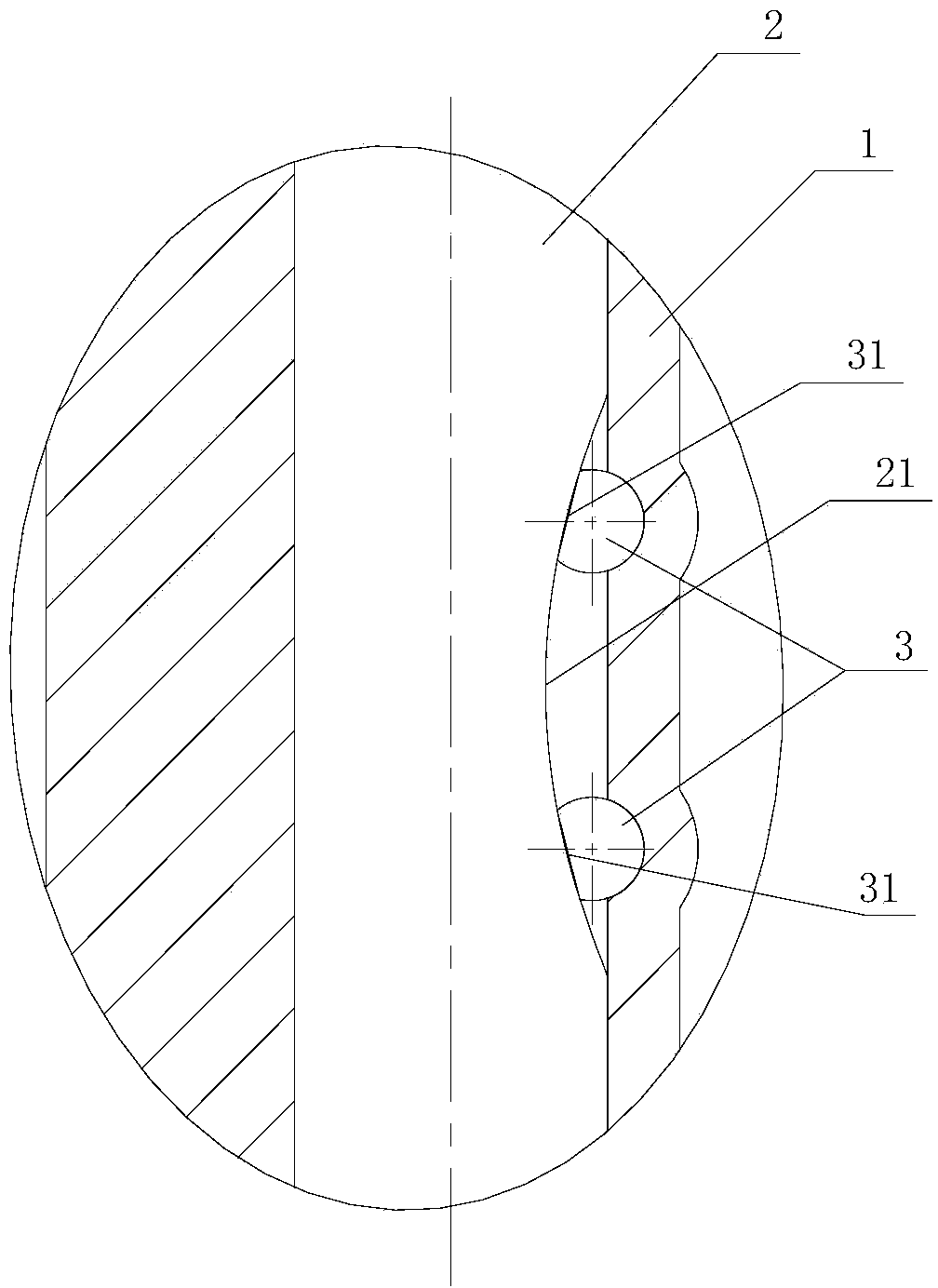

Pressure reducing backflow-preventing check valve

ActiveCN106594332AReduce resistanceReduce reaction forceCheck valvesLift valveSpring forceEngineering

The invention discloses a pressure reducing backflow-preventing check valve. The pressure reducing backflow-preventing check valve comprises a valve seat, a valve clack, a rocker and double torsional springs. One side of the valve clack is hinged to the upper end of the valve seat while a roller is mounted at the other side; one end of the rocker is a fixed end while the other end is a free end, and the fixed end of the rocker is connected to the lower end of the valve seat through a pin roll; the roller leans against the rocker and slides between the fixed end of the rocker and the free end of the rocker; two limiting hanging hooks are arranged at the lower end of the valve seat; the double torsional springs are arranged on the pin roll in a sleeving manner and are symmetrically arranged on two sides of the rocker left and right, middle torsion beams of the double torsional springs are limited by the rocker, and the two torsion beams which extend left and right of the two torsional springs are limited by the limiting hanging hooks at the lower end of the valve seat; and the spring forces of the double torsional springs act on the rocker, so that the valve clack is in a normally closed state, and the roller on the valve clack rolls on the rocker by virtue of an external force to open the valve clack. As a result of a structure of the double torsional springs and the rocker, the check valve achieves a better backflow-preventing effect.

Owner:GUANGDONG YONGQUAN VALVE TECH

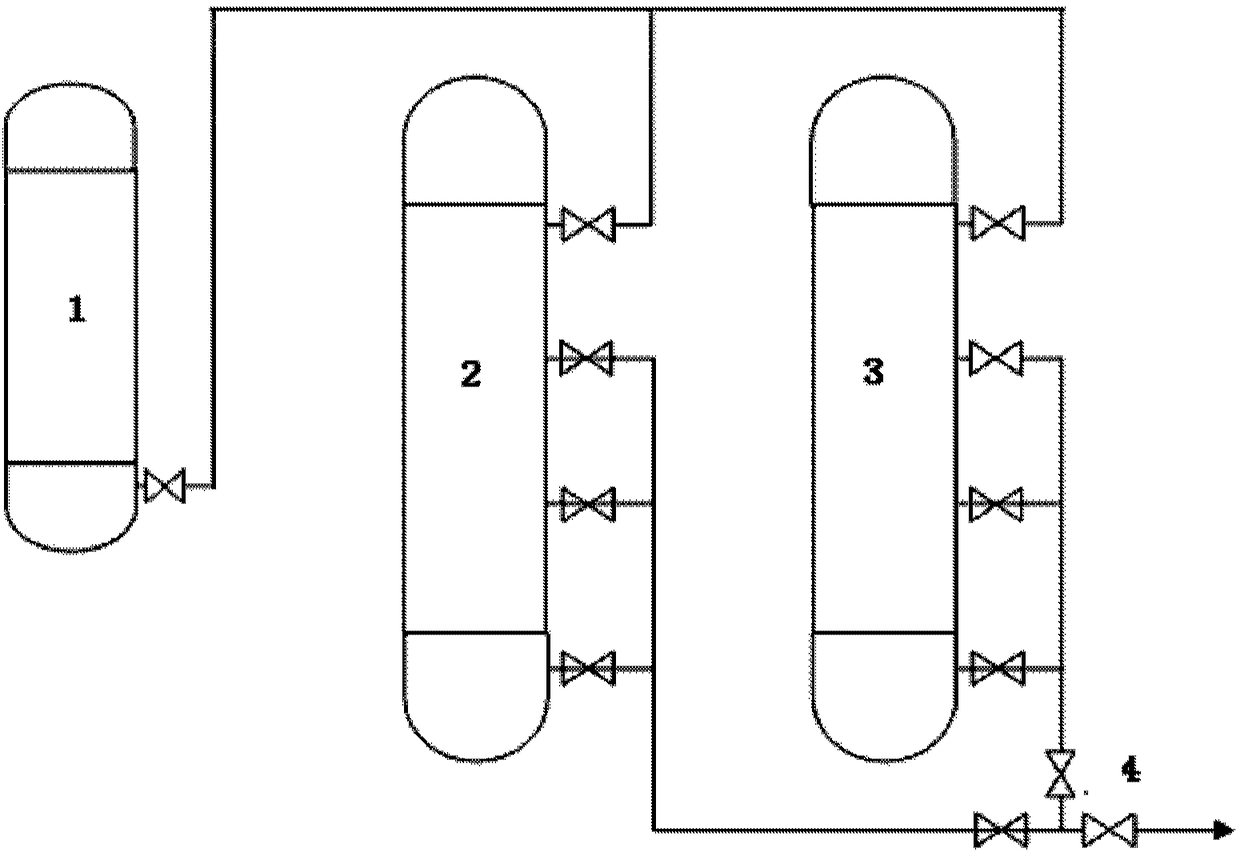

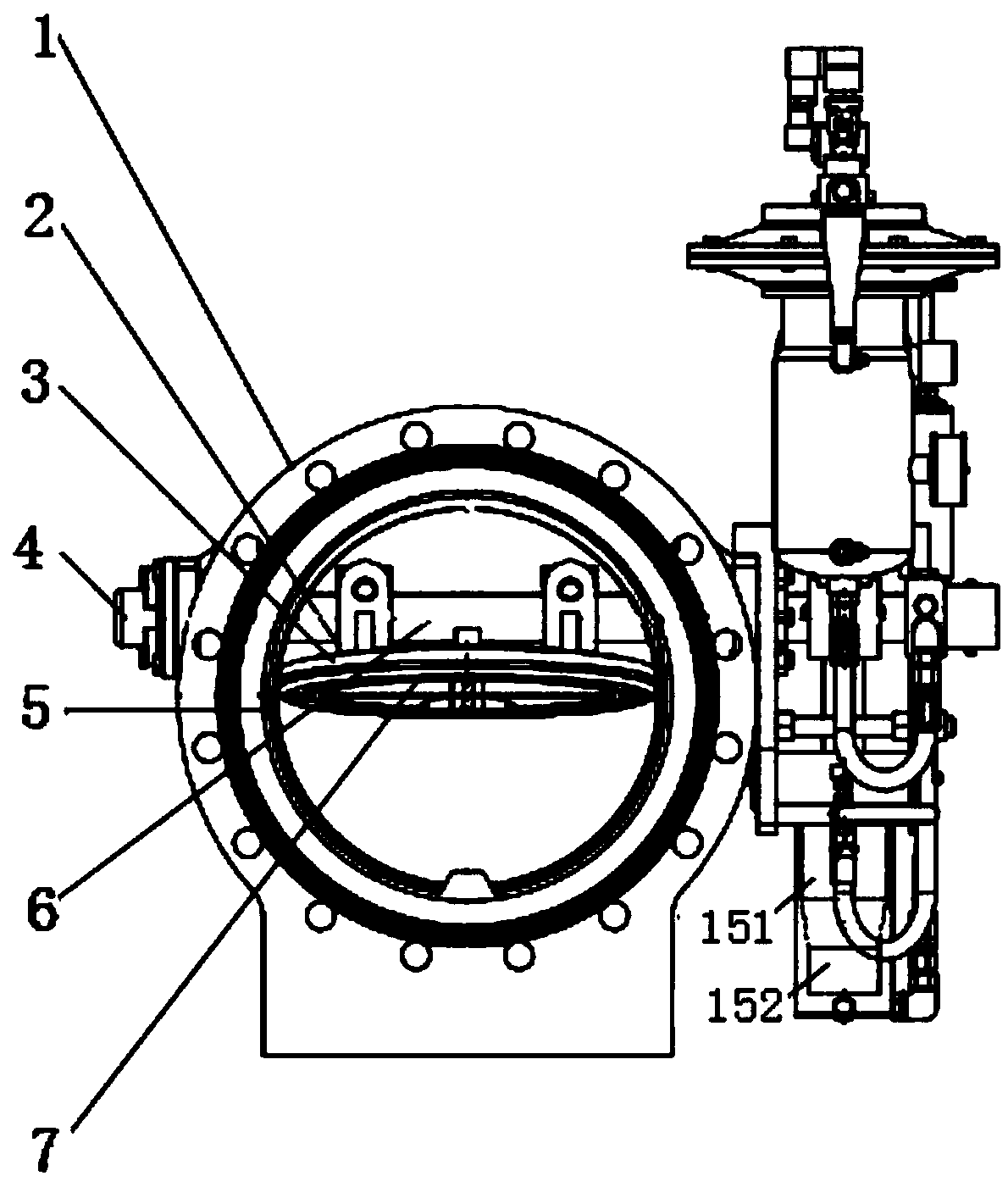

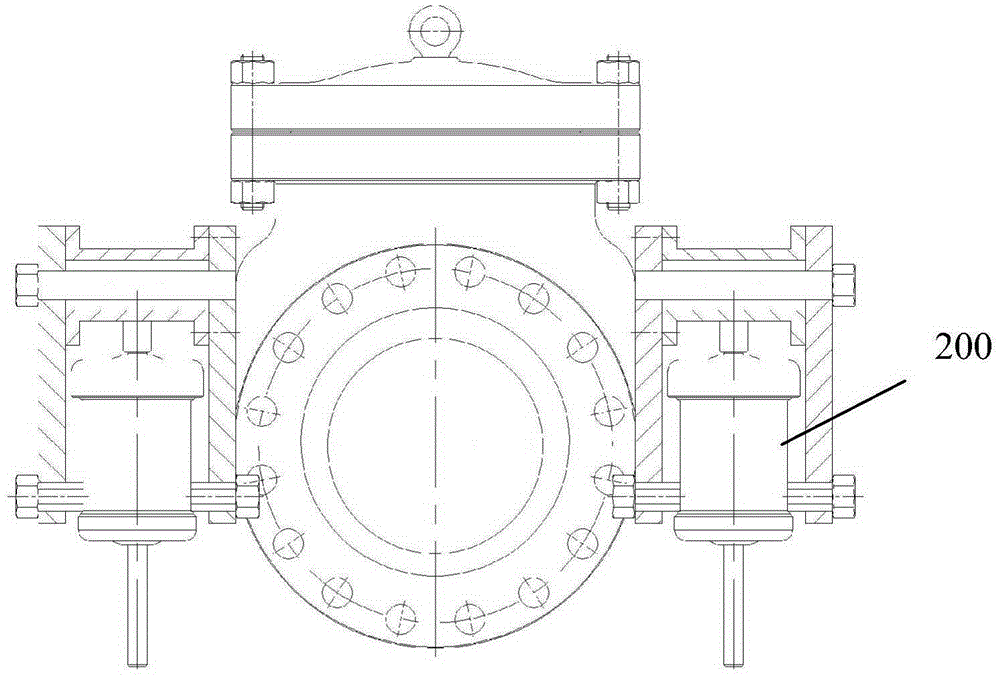

Double-eccentric ultralow temperature butterfly valve

ActiveCN103603994ARealize online maintenanceEasy online maintenanceValve arrangementsEngineeringButterfly valve

A double-eccentric ultralow temperature butterfly valve comprises a valve body, a valve rod and a butterfly plate. The double-eccentric ultralow temperature butterfly valve is characterized in that a manhole is formed in the valve body, and an upper maintenance cover is arranged at the position of the manhole; a sealing component composed of a sealing ring, a pressing ring and a jacking and pressing component is included; the inner side face of the sealing ring is sealed with the butterfly plate, the jacking and pressing component comprises a locking ring, a plurality of jacking and pressing screws arranged on the locking ring and locking nuts connected with the jacking and pressing screws, the end portions of the jacking and pressing screws are pressed on the outer end face of the pressing ring, a circular bead face is arranged at the end, away from the pressing ring, of the locking ring, and a compression ring compressed on the circular bead face is inserted in the inner cavity wall of the valve body. Through the structure, the sealing ring is convenient to replace online, and the online maintenance of the valve body is more convenient and faster. In the maintenance process, only the upper maintenance cover needs to be opened, and the sealing component is dismounted one by one. In addition, the position of the pressing ring is controlled by adjusting the jacking and pressing screws, the compression amount of the sealing ring can be adjusted, and therefore the sealing performance of the valve is guaranteed, and the safe reliability of the valve is improved.

Owner:TIANJIN XIANGJIA FLUID CONTROL SYST CO LTD

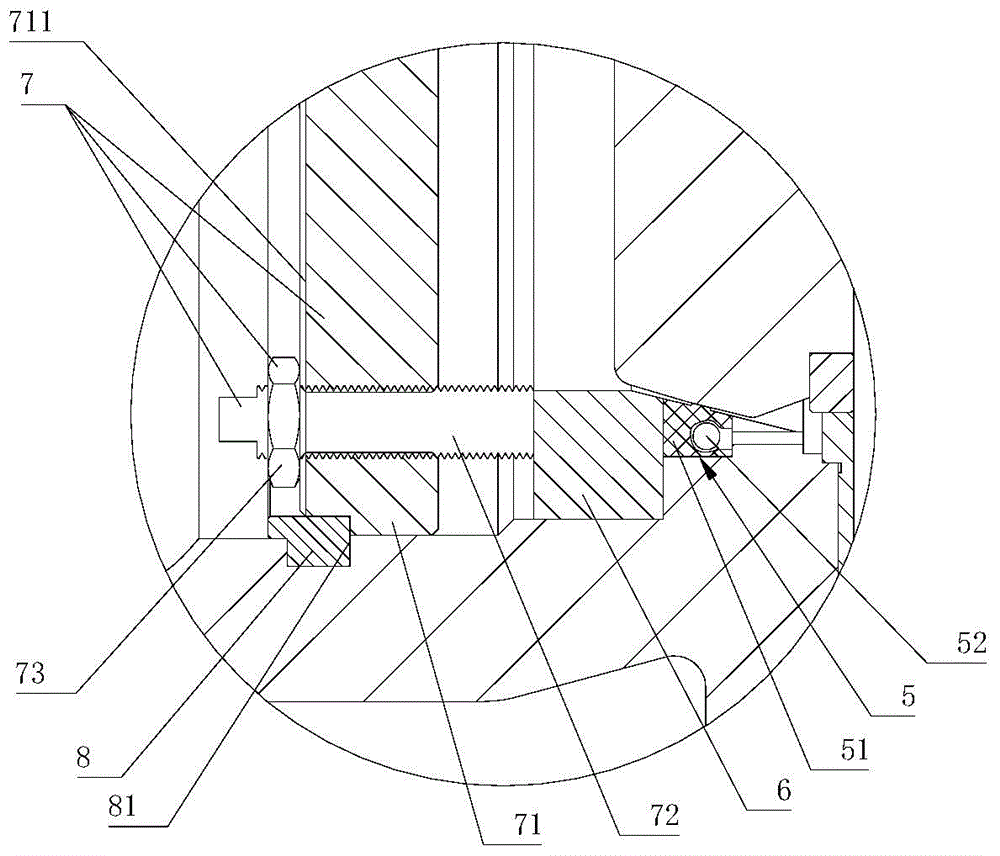

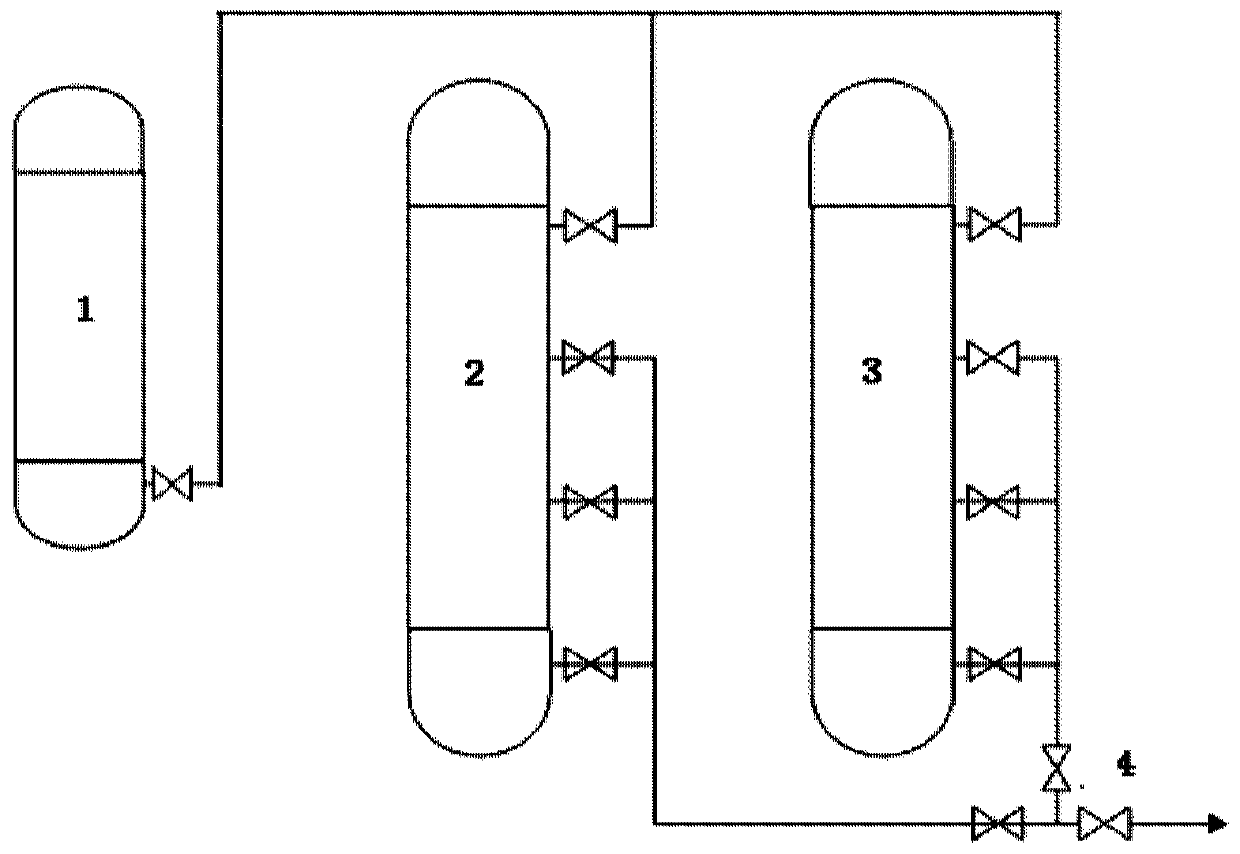

Starting method for double-series Fischer-Tropsch reaction device

ActiveCN108285809AReduce dosageReduce drive costsLiquid hydrocarbon mixture productionLow loadEconomic benefits

The invention discloses a starting method for a double-series Fischer-Tropsch reaction device. The starting method includes the following steps that heavy diesel is added into a single synthesis reactor, a certain quantity of iron-based catalyst is prepared through a reduction system to be added into the synthesis reactor, and the double-series Fischer-Tropsch reaction device is started step by step; when the reactor operates at full load, a half of mixed materials in the synthesis reactor is pressed into another synthesis reactor, and the loads of the two synthesis reactors reach 50% or above; the catalyst is supplemented to the two synthesis reactors through a reduction reactor respectively till the two synthesis reactors operate at full load. According to the starting method for the double-series Fischer-Tropsch reaction device, by changing an original starting scheme of the double-series Fischer-Tropsch synthesis device, original starting raw materials are saved, low-load running time of a Fischer-Tropsch reactor is shortened, the whole starting time is shortened, the loads of the two Fischer-Tropsch reaction systems reach 50% or above in a short time, the two Fischer-Tropsch reaction systems stably run, the starting cost is saved, and economic benefits are rapidly created.

Owner:INNER MONGOLIA YITAI COAL BASED NEW MATERIALS RES INST CO LTD +1

Pressure reducing type anti-backflow check valve

ActiveCN106594332BReduce resistanceReduce reaction forceCheck valvesLift valveSpring forceCheck valve

The invention discloses a pressure reducing backflow-preventing check valve. The pressure reducing backflow-preventing check valve comprises a valve seat, a valve clack, a rocker and double torsional springs. One side of the valve clack is hinged to the upper end of the valve seat while a roller is mounted at the other side; one end of the rocker is a fixed end while the other end is a free end, and the fixed end of the rocker is connected to the lower end of the valve seat through a pin roll; the roller leans against the rocker and slides between the fixed end of the rocker and the free end of the rocker; two limiting hanging hooks are arranged at the lower end of the valve seat; the double torsional springs are arranged on the pin roll in a sleeving manner and are symmetrically arranged on two sides of the rocker left and right, middle torsion beams of the double torsional springs are limited by the rocker, and the two torsion beams which extend left and right of the two torsional springs are limited by the limiting hanging hooks at the lower end of the valve seat; and the spring forces of the double torsional springs act on the rocker, so that the valve clack is in a normally closed state, and the roller on the valve clack rolls on the rocker by virtue of an external force to open the valve clack. As a result of a structure of the double torsional springs and the rocker, the check valve achieves a better backflow-preventing effect.

Owner:GUANGDONG YONGQUAN VALVE TECH

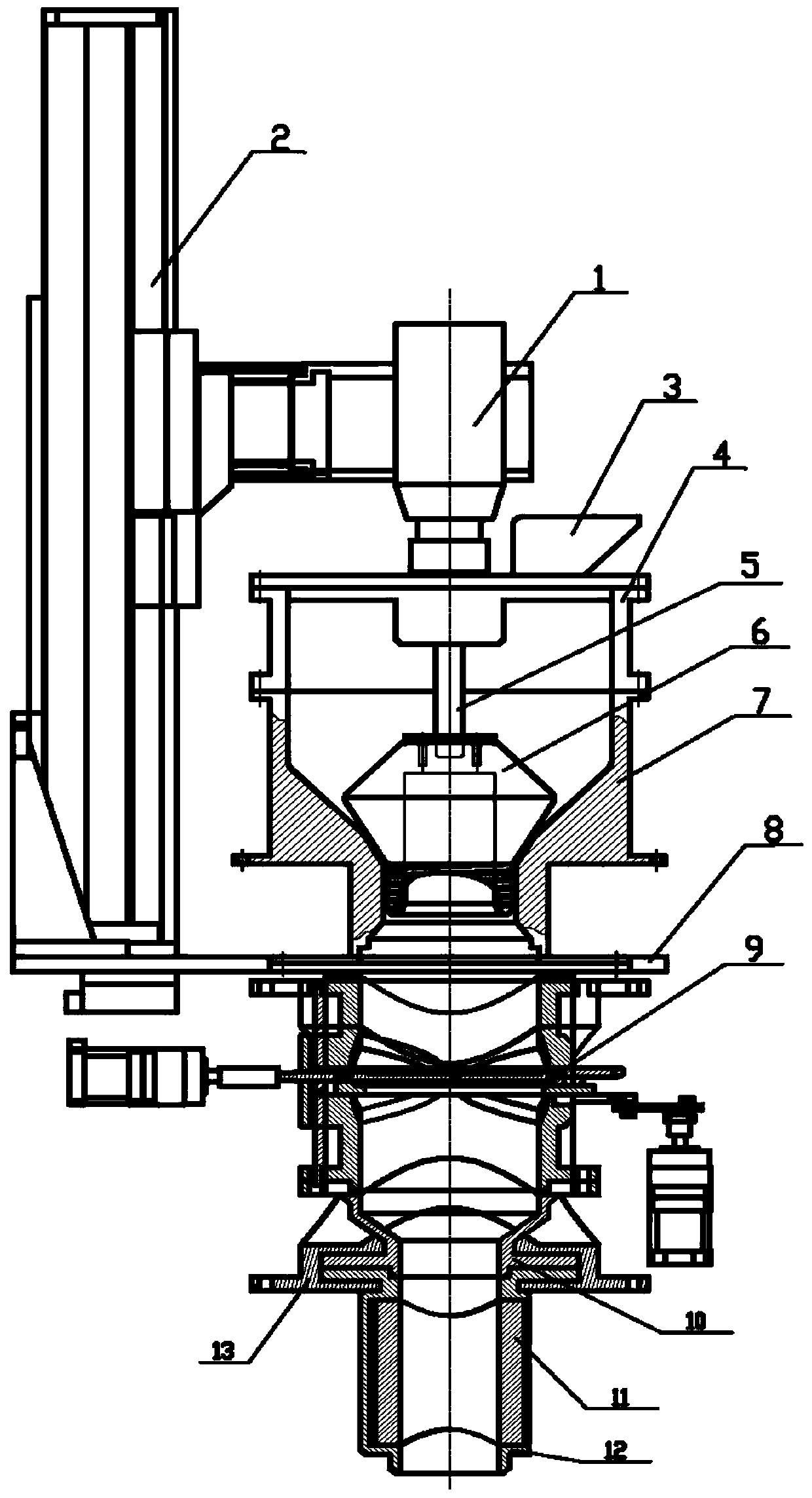

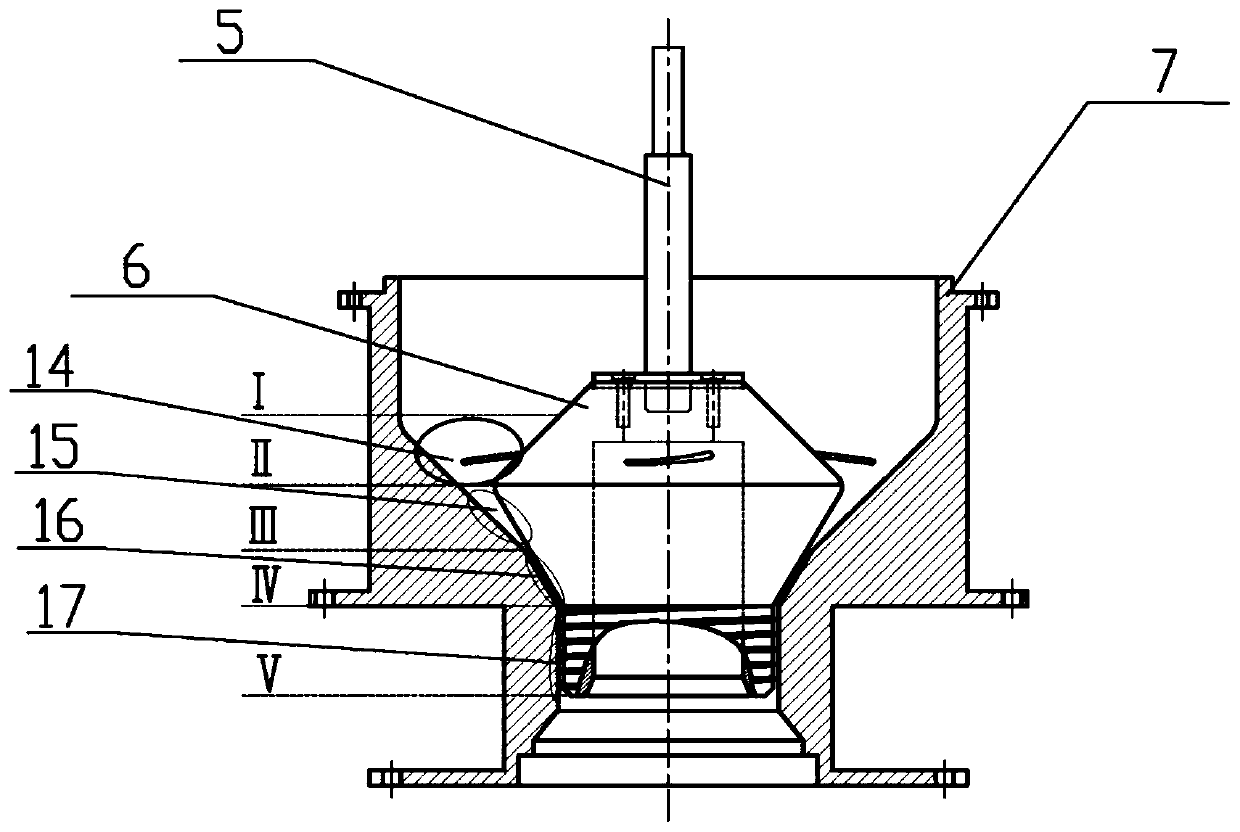

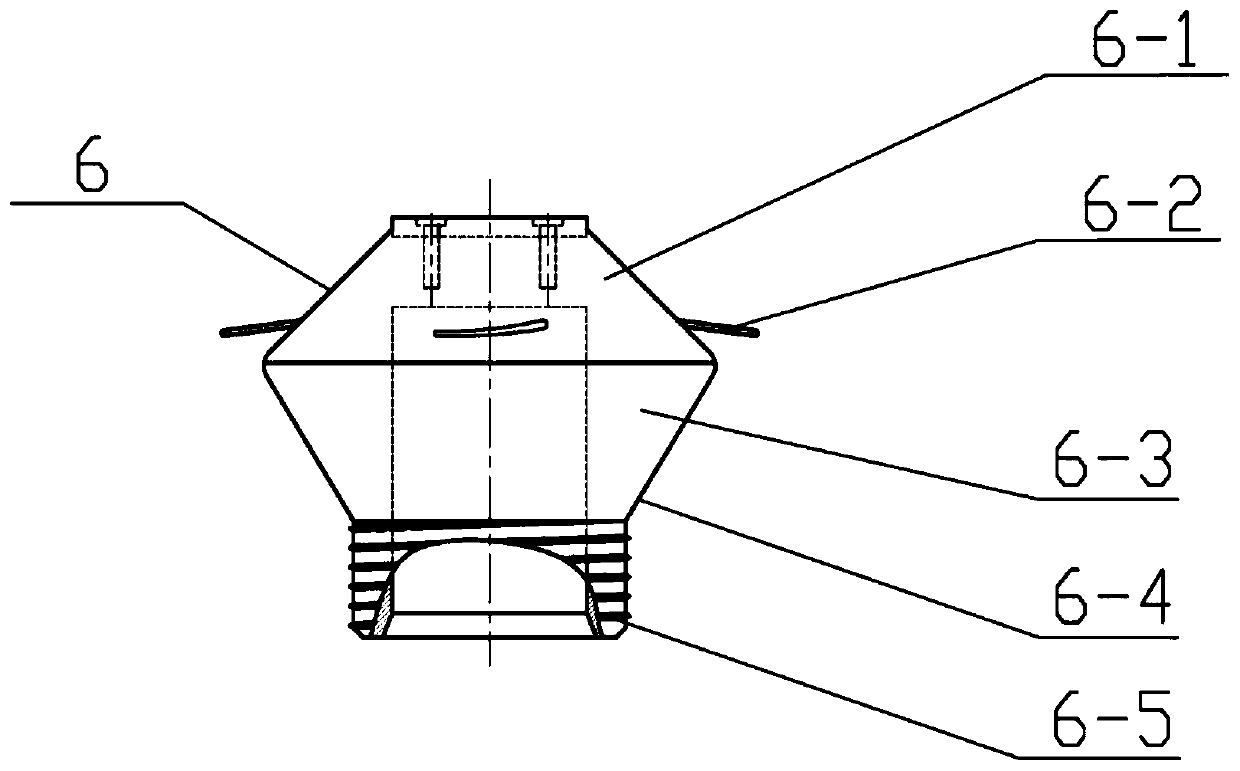

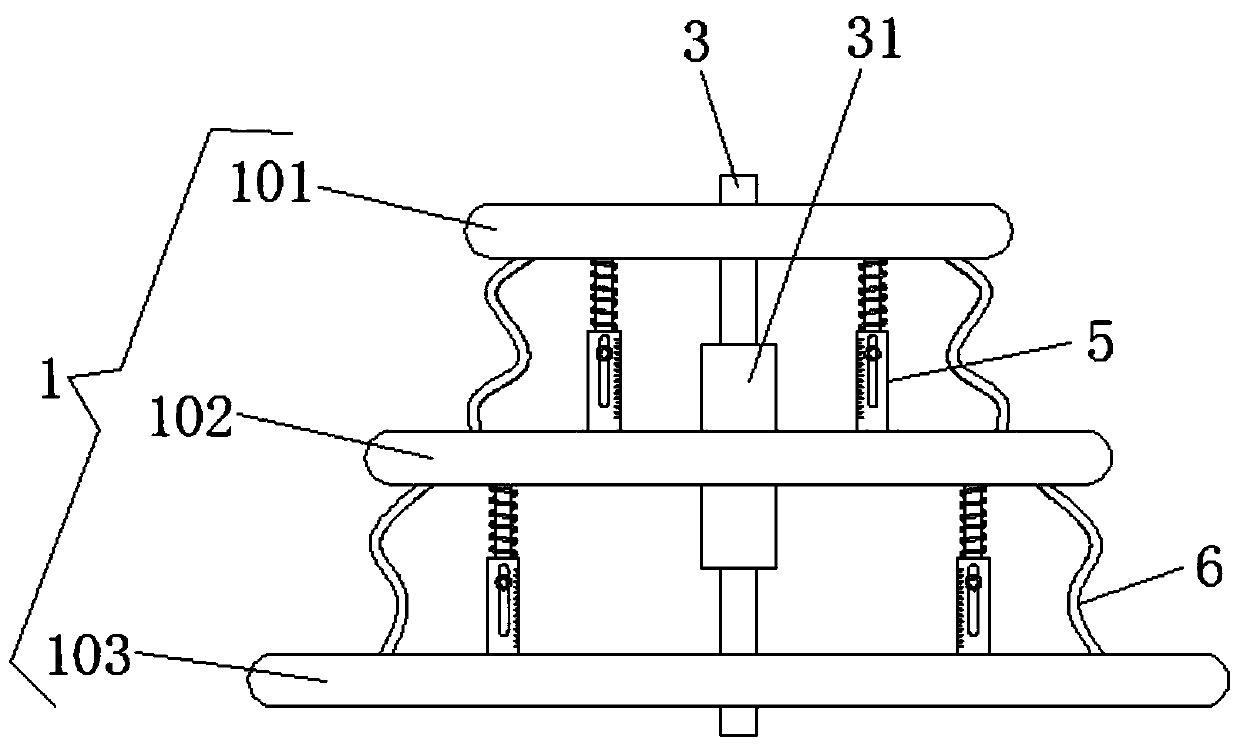

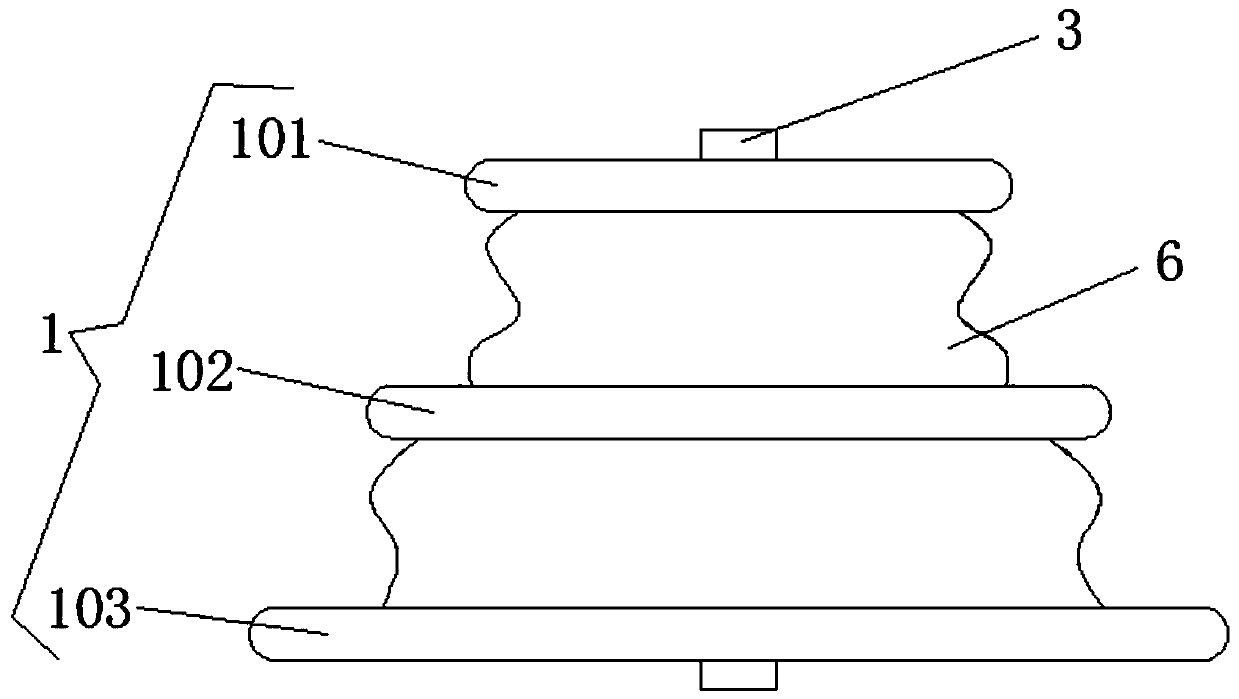

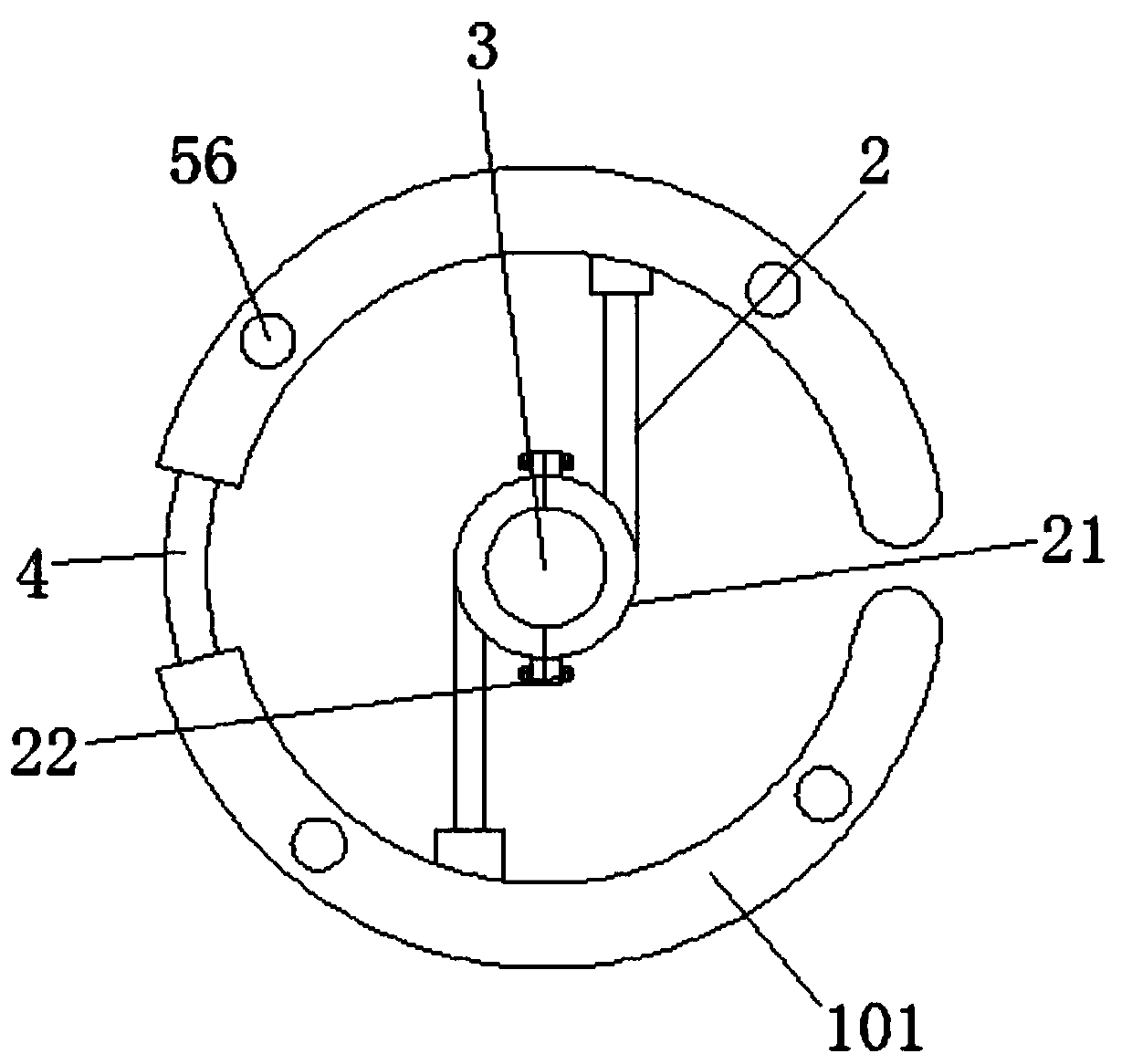

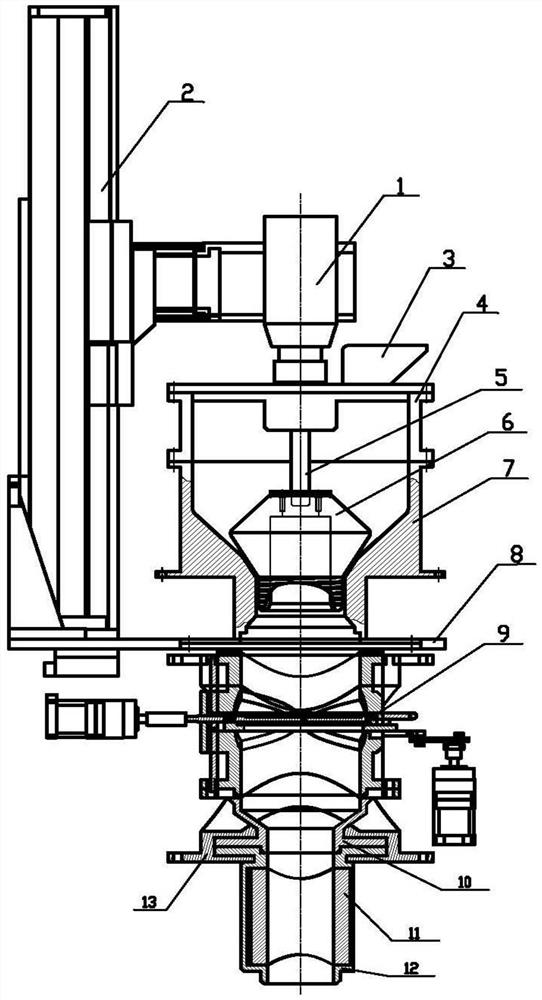

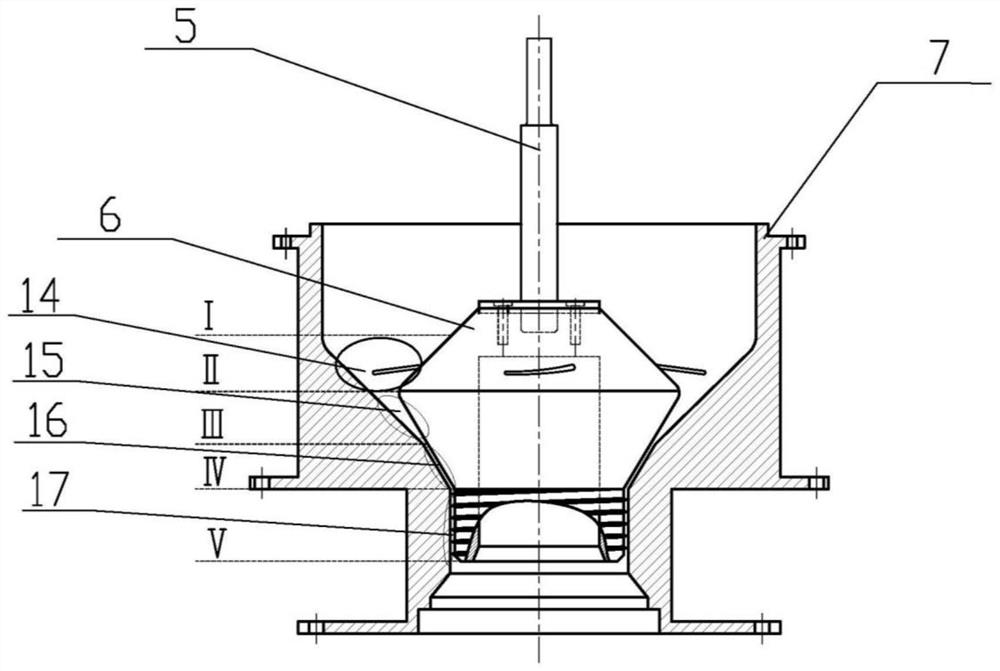

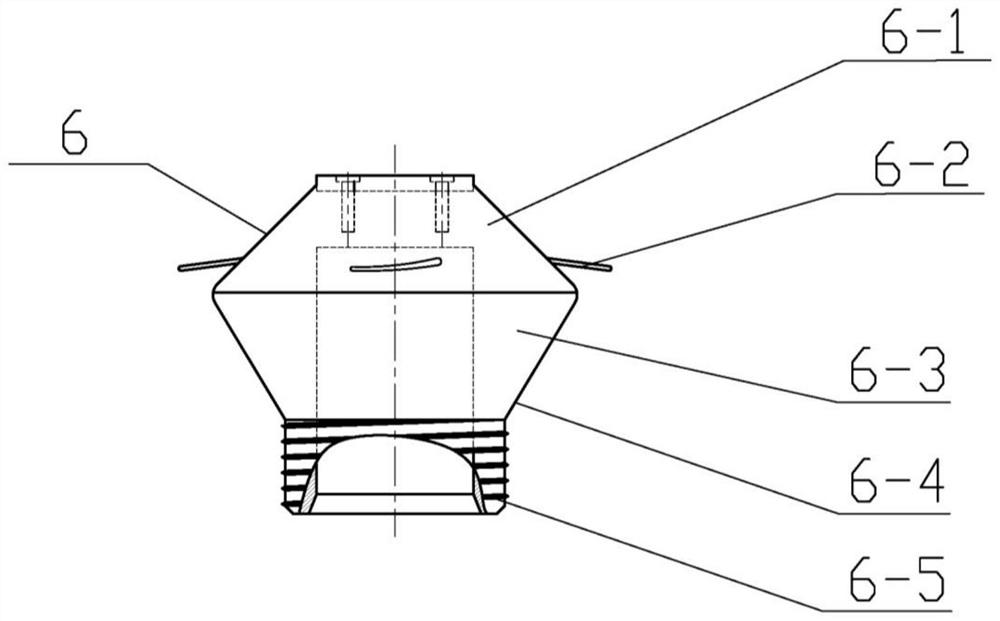

Adjustable modular crushing and grinding device

The invention provides an adjustable modular crushing and grinding device. The adjustable modular crushing and grinding device comprises a grinding assembly and a filtering assembly. The grinding assembly comprises a driving source, a lifting mechanism, a crushing and grinding hammer, a plurality of cutting blades and a crushing and grinding cylinder. The crushing and grinding hammer comprises anupper end body, a lower end body, a material-pushing body and the cutting blades, a first round circular truncated cone chamber, a second circular truncated cone chamber and a second cylindrical chamber are arranged in the crushing and grinding cylinder, and the first round circular truncated cone chamber, the second circular truncated cone chamber and the second cylindrical chamber are arranged coaxially from top to bottom in sequence; the inner diameter of the first round circular truncated cone chamber and the inner diameter of the second round circular truncated cone chamber decreases in sequence from top to bottom. The filtering assembly comprises a cylinder, a vibrating body, a first power source, an overturning rod, a screen fixing sleeve, a screen and a second power source. Coarsegrinding and fine grinding are achieved, and the fine grinding particle size of a material is adjusted without changing the grinding hammer; and meanwhile, the screen can be automatically overturned to automatically pour out the material which remains on the screen after screening.

Owner:JIANGSU UNIV +1

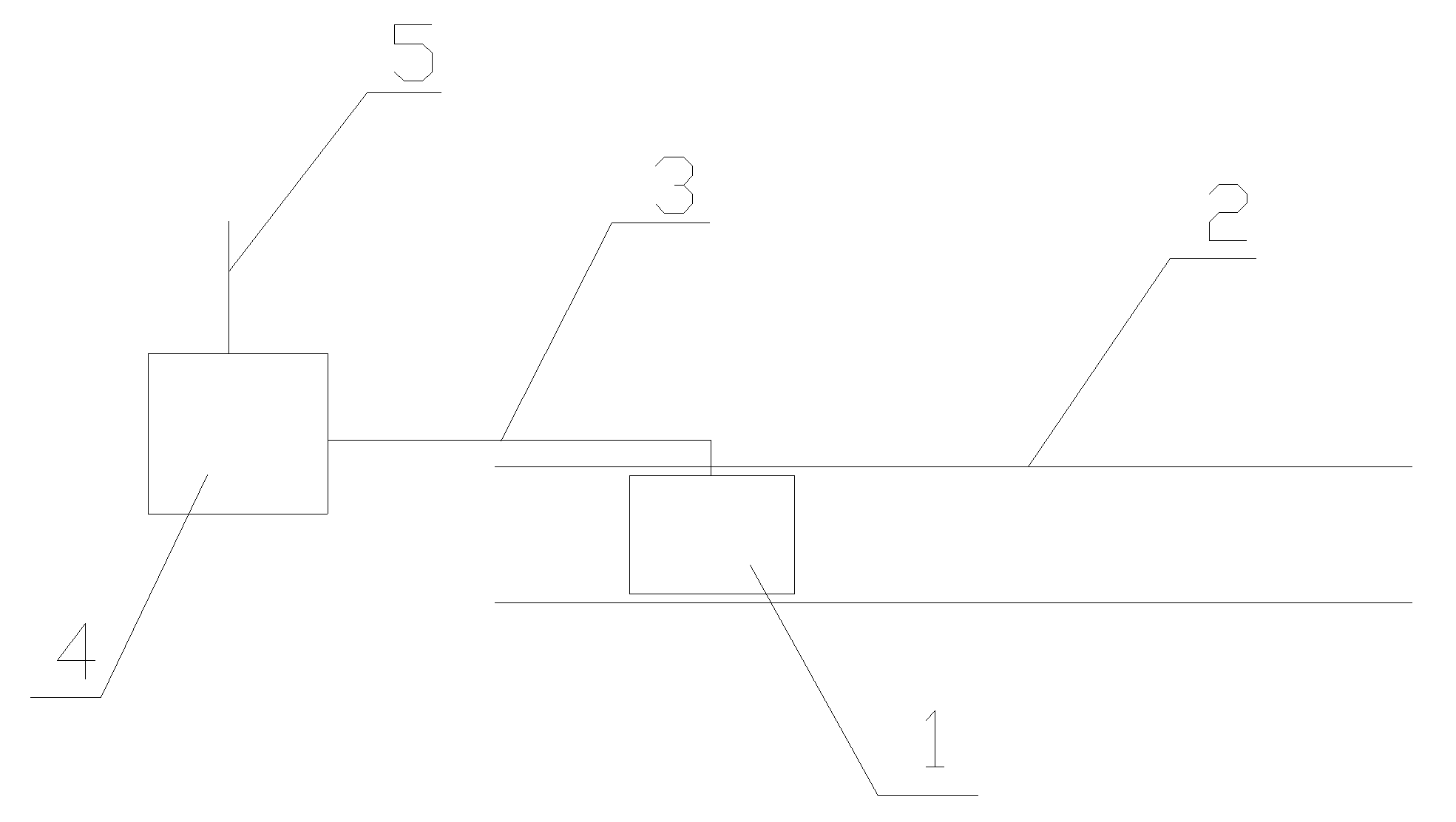

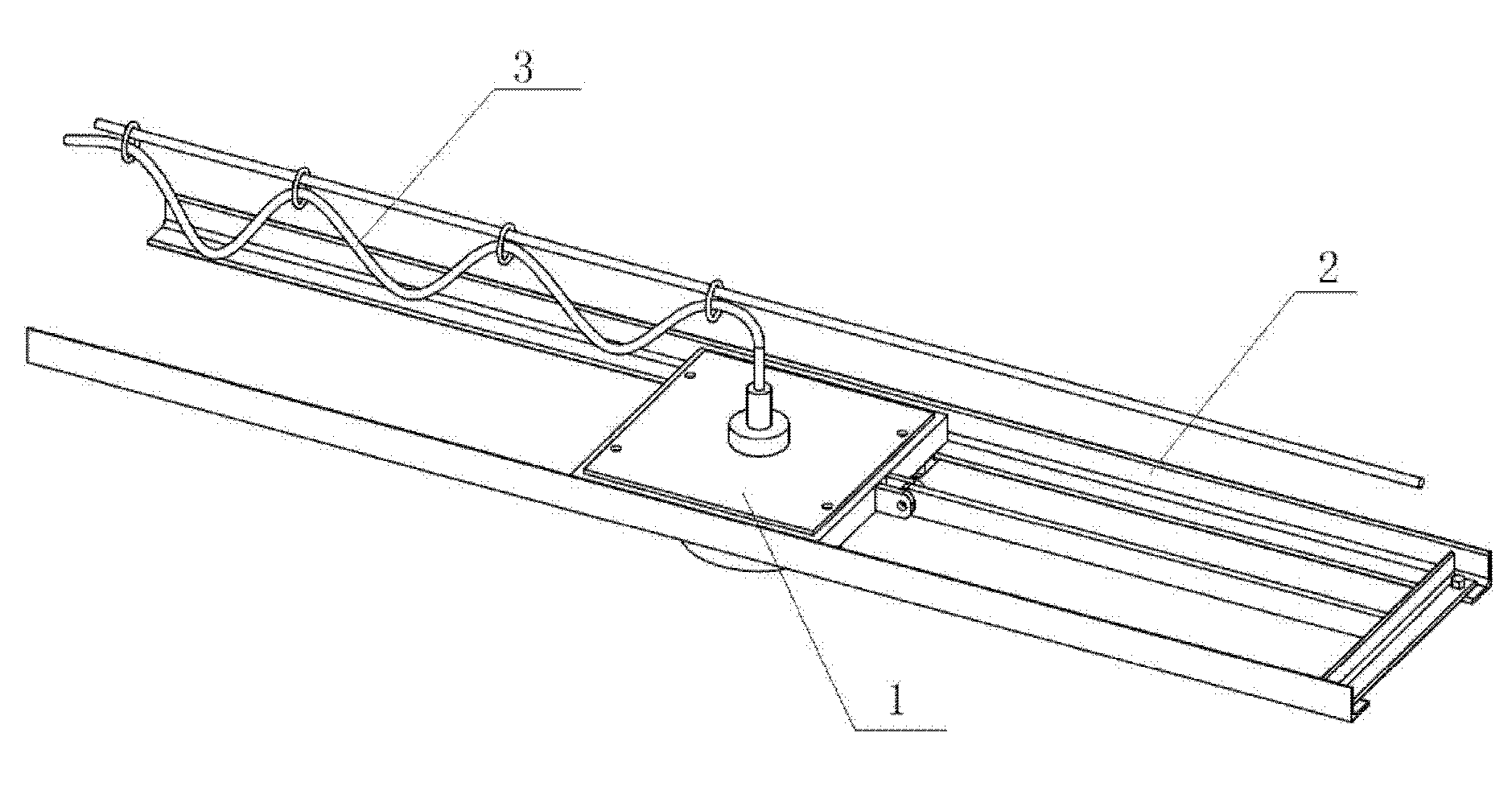

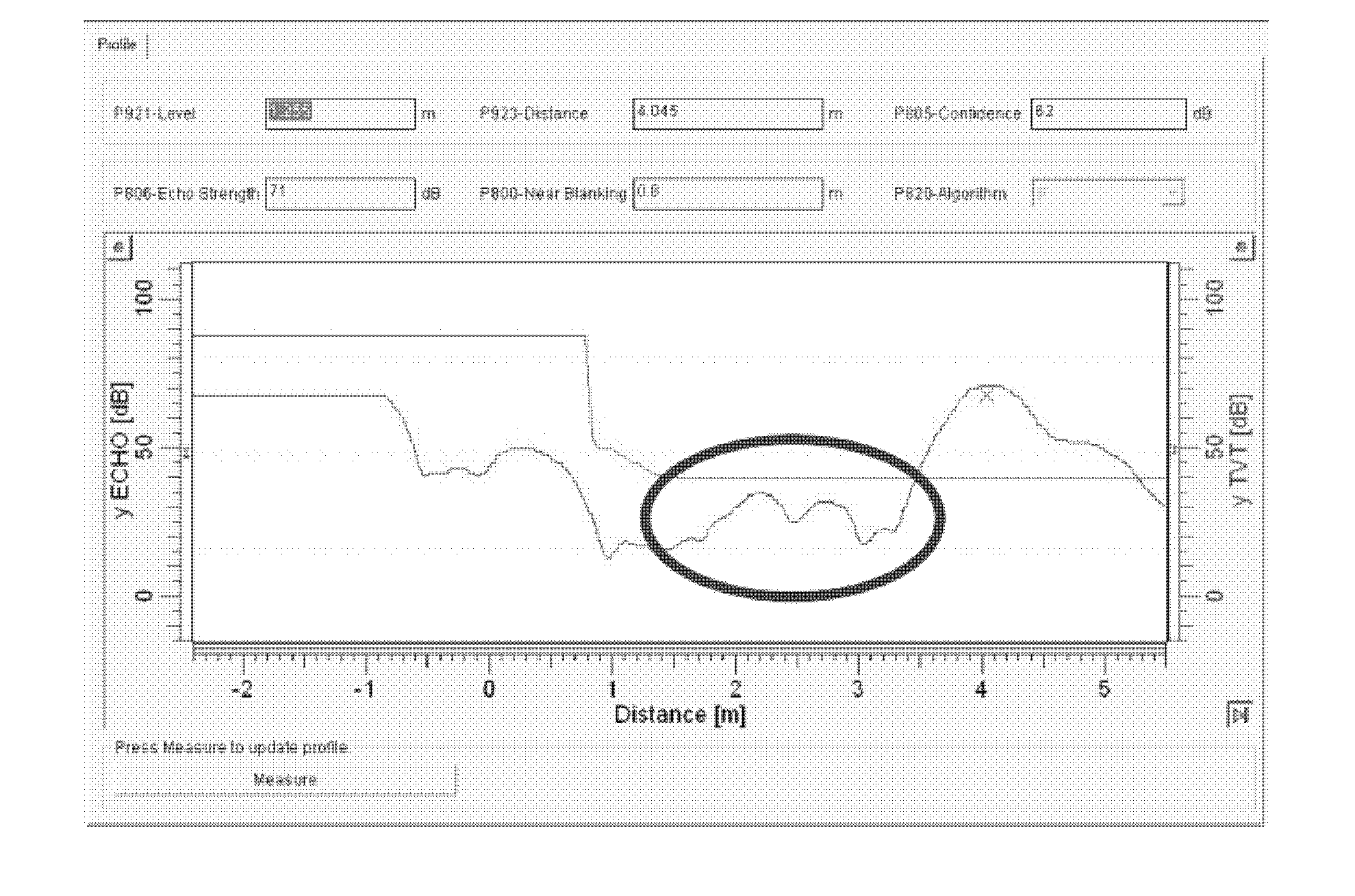

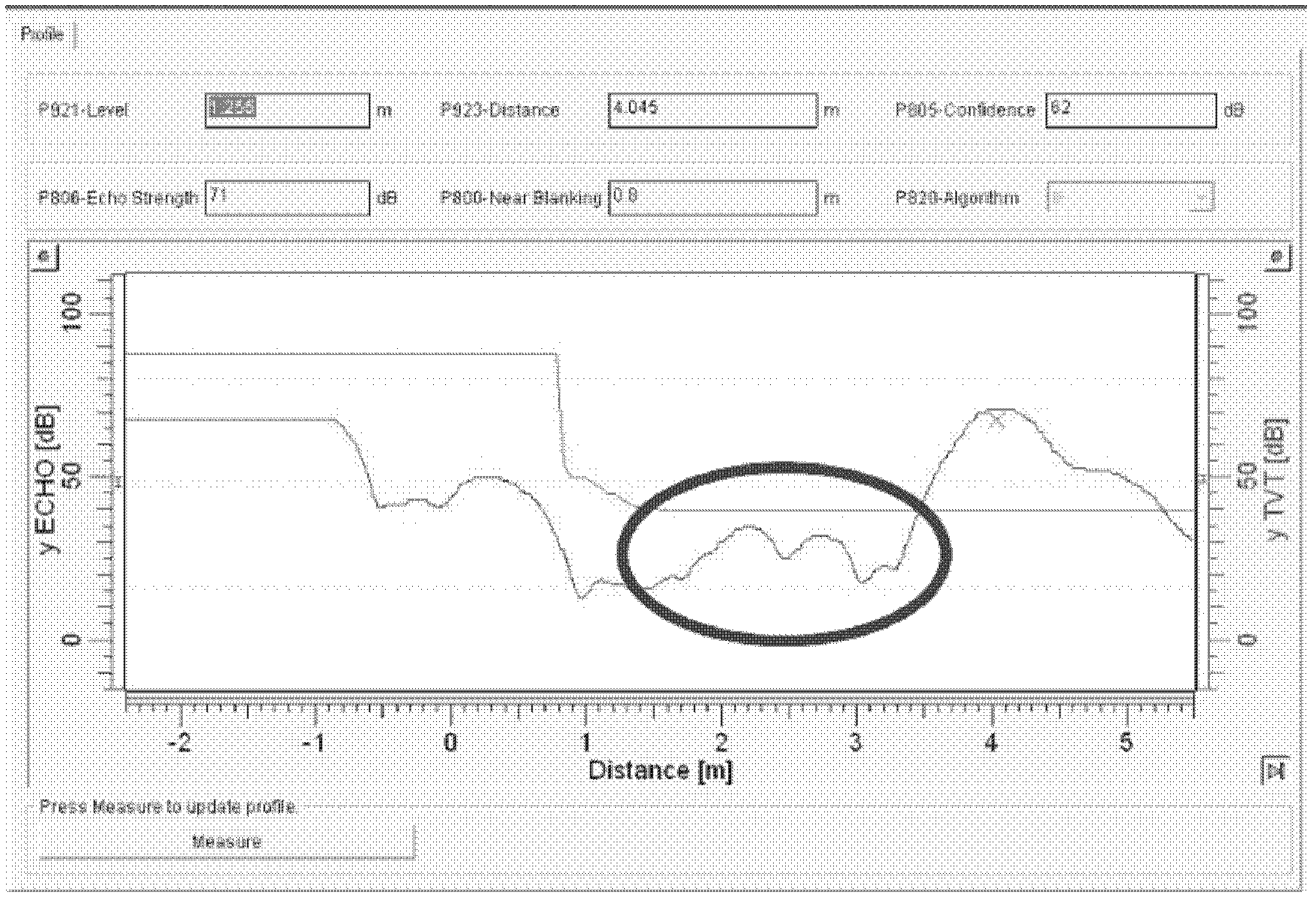

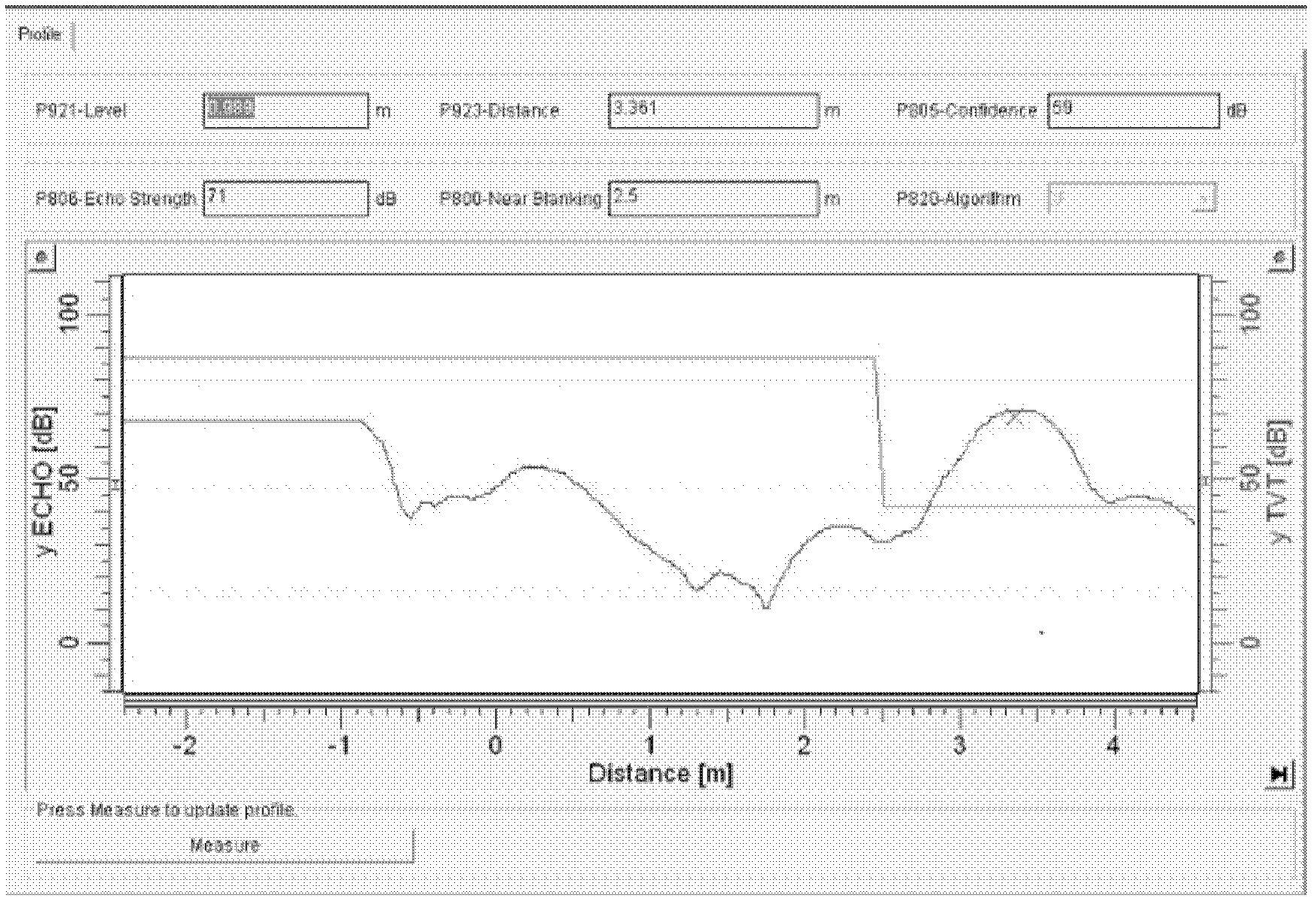

Self-propelled positioning and level measuring device on basis of complicated mineral separation environments

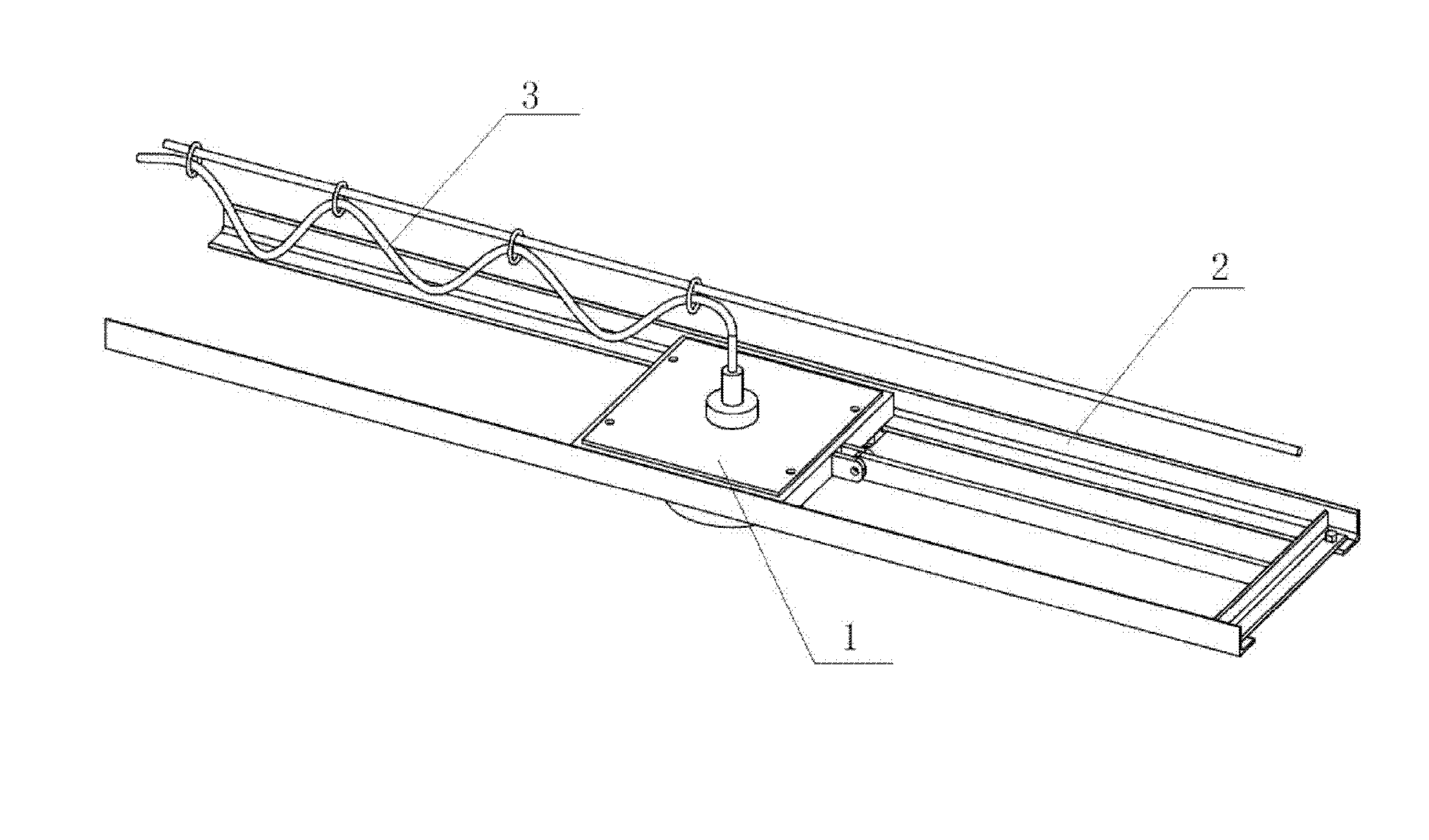

ActiveCN102506958BPrecise positioningReduce operating intensityMachines/enginesLevel indicatorsControl signalLevel sensor

The invention relates to a self-propelled positioning and level measuring device on the basis of complicated mineral separation environments, which comprises a level sensor, a signal wire, a guide rail, a computer system and a control signal wire. The level sensor is arranged below a mine draining car, is used for monitoring level conditions of the mine draining car, runs on the guide rail, and is connected with the computer system through the signal wire, and the control signal wire is connected with the computer system to handle actual situations selectively. By the aid of the self-propelled positioning and level measuring device on the basis of complicated mineral separation environments, the mine draining car can be positioned accurately and realizes automatic mineral distribution, operators can remotely control the mine draining car according to the level conditions of the mine draining car so as to change mineral unloading position of the mine draining car at any time, and accordingly the number of the operators and operation intensity thereof are reduced while operating environments are improved.

Owner:NANJING DELTO TECH

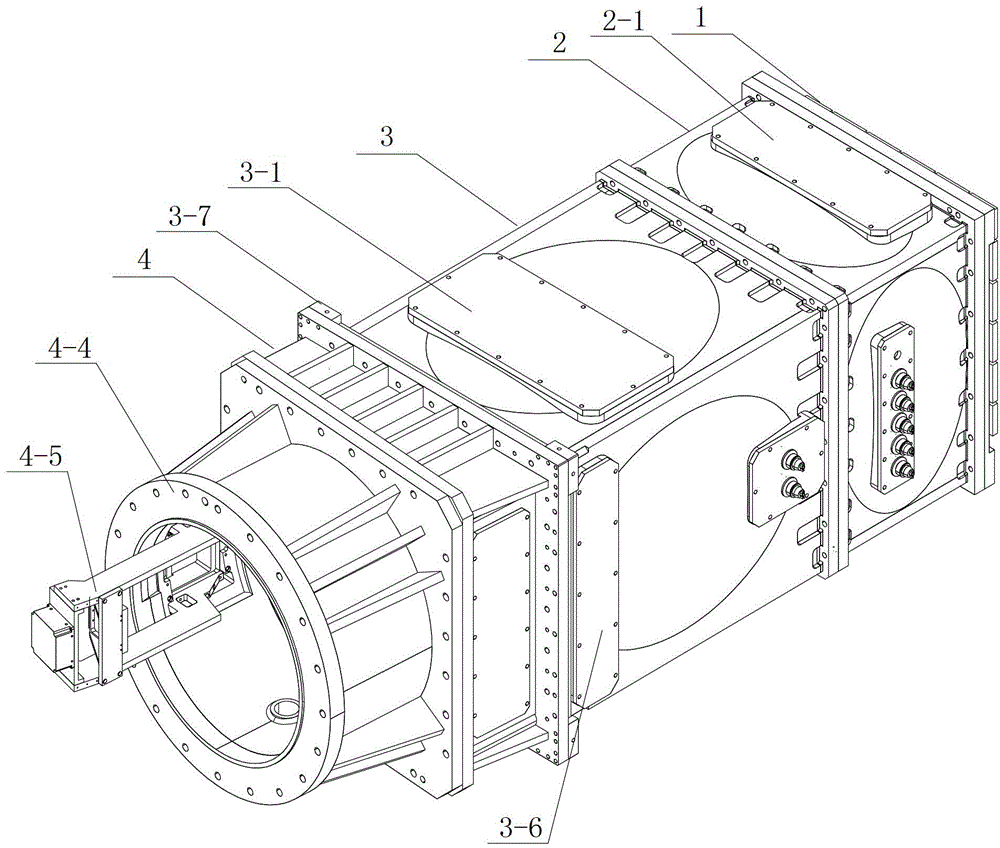

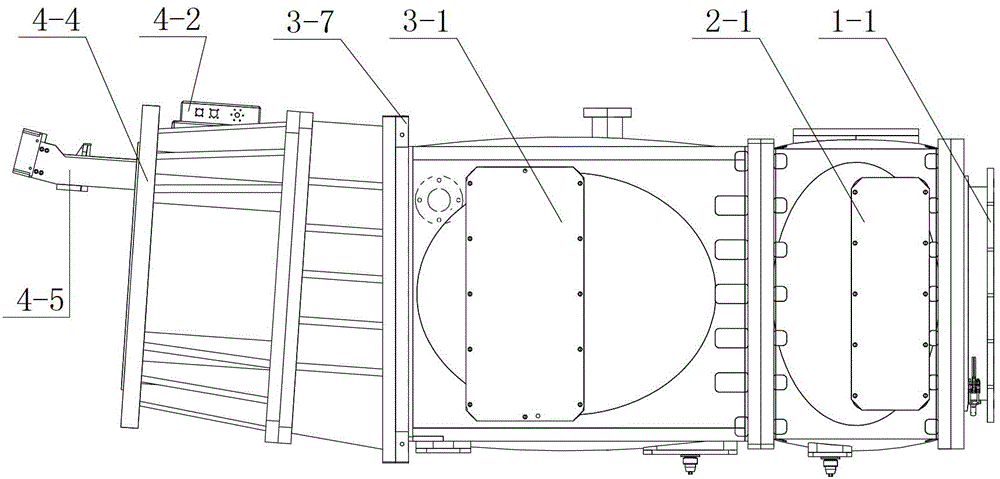

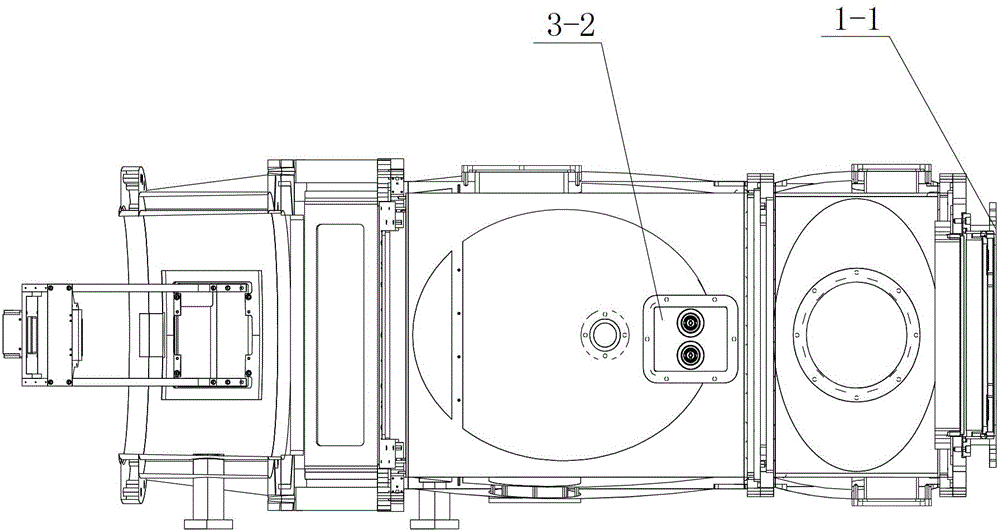

Vacuum controllable high-flux heavy-caliber optical focusing and frequency conversion system

ActiveCN103258575BMeet the functional requirements of frequent replacementFree from sputter contaminationNuclear energy generationThermonuclear fusion reactorFrequency conversionHigh flux

The invention relates to a vacuum controllable high-flux heavy-caliber optical focusing and frequency conversion system and belongs to the technical field of optical focusing and frequency conversion. The vacuum controllable high-flux heavy-caliber optical focusing and frequency conversion system solves the problem that an integral structure of an existing optical focusing and frequency conversion system is not beneficial to on-line replacement. The vacuum controllable high-flux heavy-caliber optical focusing and frequency conversion system comprises a target window unit part, a frequency conversion unit part, a focusing lens unit part and a light beam measuring sampling part, wherein the tail end of the target window unit part is in sealing connection with a shell body at the head end of the frequency conversion unit part through a flange, the tail end of the frequency conversion unit part is in sealing connection with a shell body at the head end of the focusing lens unit part through a flange, the tail end of the focusing lens unit part is in sealing connection with a shell body at the head end of the light beam measuring sampling part through a flange, and an atmosphere chamber is formed by the target window unit part, the frequency conversion unit part and the focusing lens unit part. The mechanical structure is designed into a detachable assembly, and rapid replacement of each composition part and each internal assembly can be achieved by a rapid disassembly mechanism through corresponding hatches formed in the shell bodies. The vacuum controllable high-flux heavy-caliber optical focusing and frequency conversion system is applicable to the heavy-caliber optical focusing and frequency conversion.

Owner:HARBIN INST OF TECH

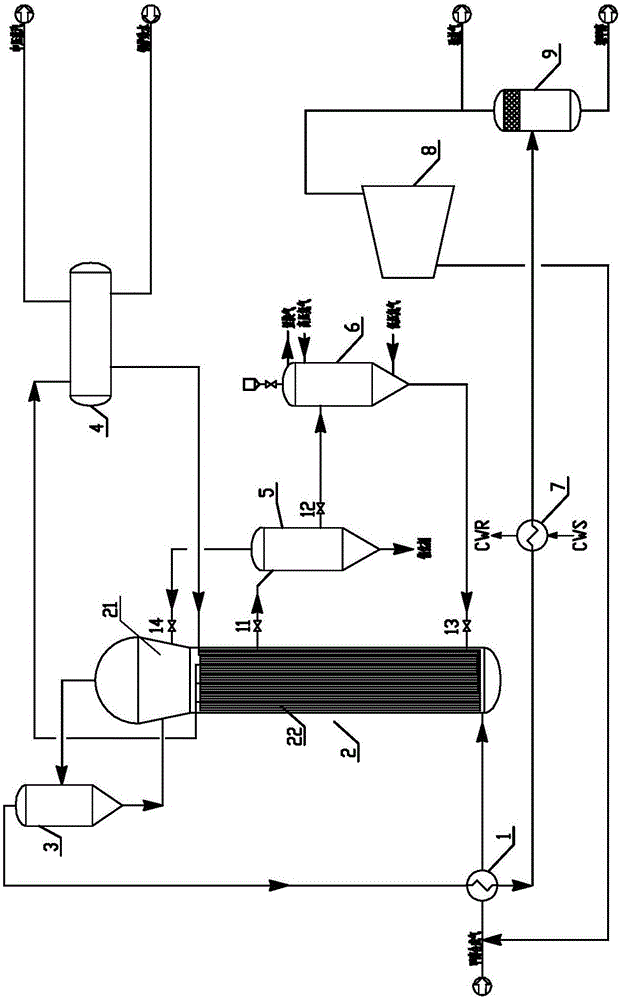

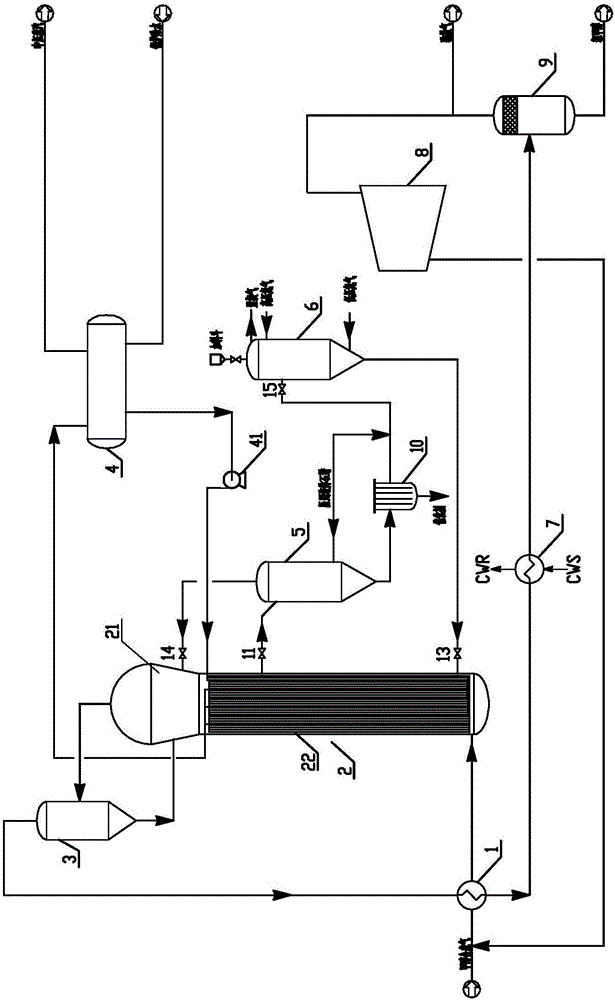

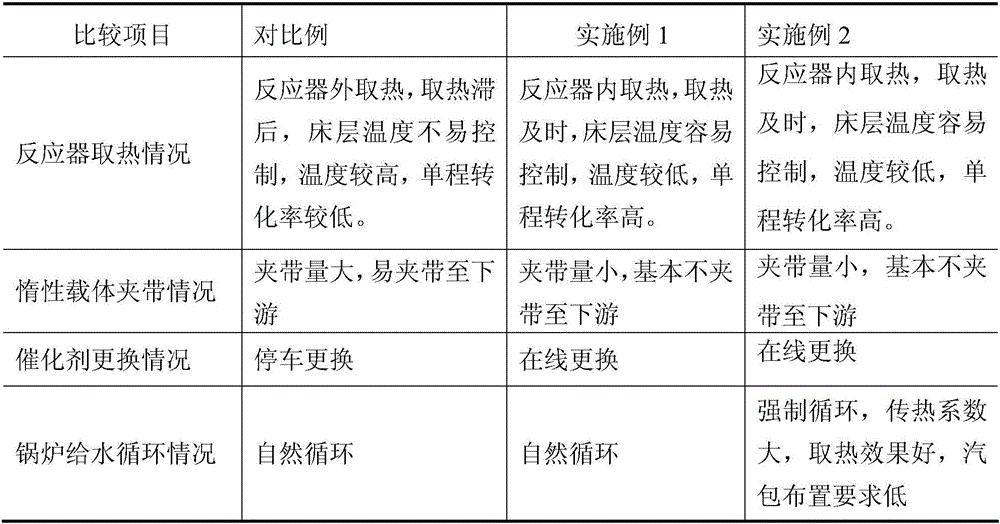

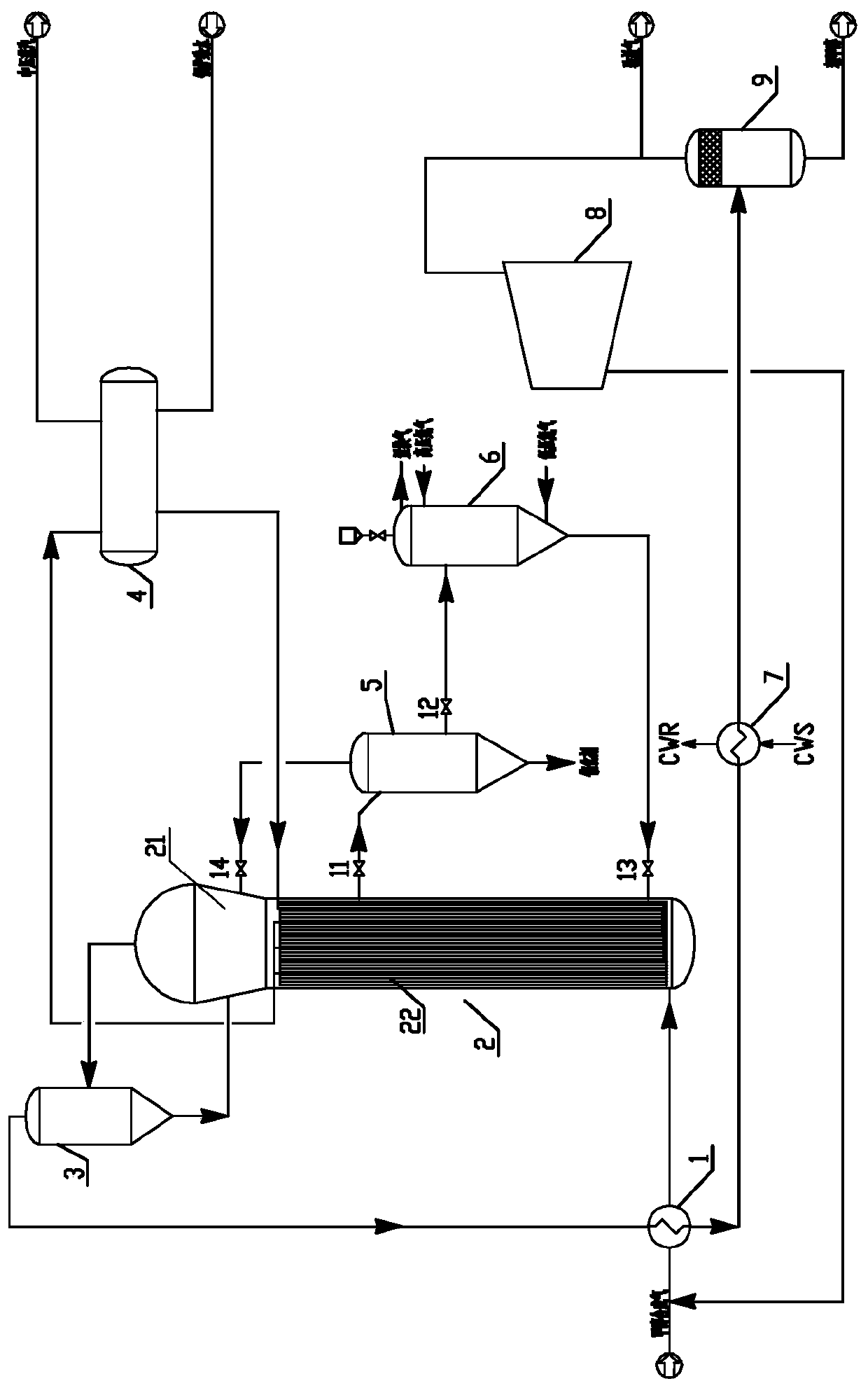

Slurry reactor methanol synthesis process

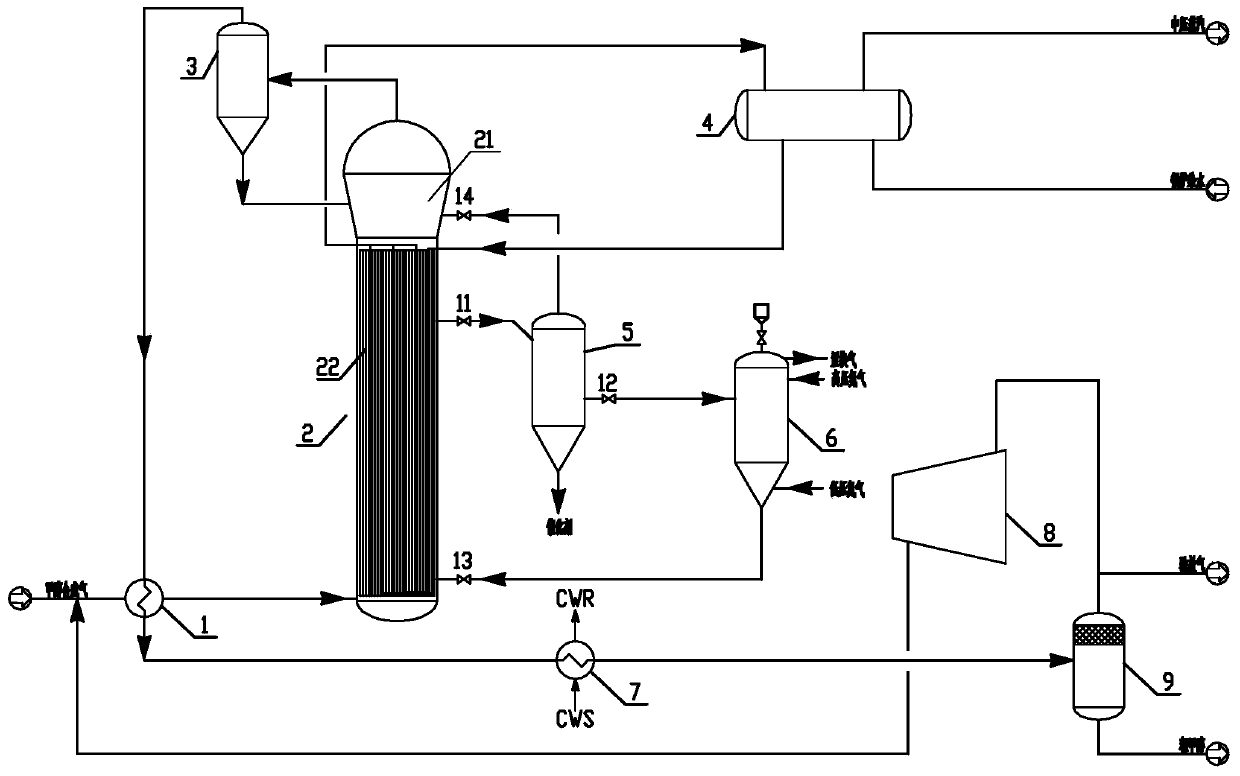

ActiveCN106588574AImprove heat transfer performanceEasy temperature controlOrganic compound preparationHydroxy compound separation/purificationSyngasVapor–liquid separator

The invention relates to a slurry reactor methanol synthesis process. The slurry reactor methanol synthesis process is characterized by comprising the following steps: mixing raw material gas from upstream with circulating gas to form mixed gas, enabling the mixed gas to enter a shell side of the reactor from the bottom after heat exchange to be in contact with a catalyst in the shell side to perform reaction; enabling bubble point boiler water to enter a tube side of the reactor; discharging the reaction gas generated by the reaction out of the top of the reactor and enabling the reaction gas to enter a separator to perform separation; enabling the separated non-gas phase to return to the reactor from the gas phase space at the upper part of the reactor, enabling the separated gas phase, namely crude methanol synthesis gas, to enter a gas liquid separator after heat exchange, pressurizing the separated gas phase to serve as circulating gas, wherein the separated liquid phase is crude methanol; when catalyst abrasion reaches to a set value, extracting catalyst slurry from the reactor; supplementing fresh catalyst slurry into the shell side of the reactor. According to the slurry reactor methanol synthesis process, the catalyst can be changed timely without shutdown.

Owner:SINOPEC NINGBO ENG +2

A double eccentric ultra-low temperature butterfly valve

ActiveCN103603994BRealize online maintenanceEasy online maintenanceValve arrangementsButterfly valveCavity wall

A double-eccentric ultralow temperature butterfly valve comprises a valve body, a valve rod and a butterfly plate. The double-eccentric ultralow temperature butterfly valve is characterized in that a manhole is formed in the valve body, and an upper maintenance cover is arranged at the position of the manhole; a sealing component composed of a sealing ring, a pressing ring and a jacking and pressing component is included; the inner side face of the sealing ring is sealed with the butterfly plate, the jacking and pressing component comprises a locking ring, a plurality of jacking and pressing screws arranged on the locking ring and locking nuts connected with the jacking and pressing screws, the end portions of the jacking and pressing screws are pressed on the outer end face of the pressing ring, a circular bead face is arranged at the end, away from the pressing ring, of the locking ring, and a compression ring compressed on the circular bead face is inserted in the inner cavity wall of the valve body. Through the structure, the sealing ring is convenient to replace online, and the online maintenance of the valve body is more convenient and faster. In the maintenance process, only the upper maintenance cover needs to be opened, and the sealing component is dismounted one by one. In addition, the position of the pressing ring is controlled by adjusting the jacking and pressing screws, the compression amount of the sealing ring can be adjusted, and therefore the sealing performance of the valve is guaranteed, and the safe reliability of the valve is improved.

Owner:TIANJIN XIANGJIA FLUID CONTROL SYST CO LTD

Online bioengineering solution filtering device

InactiveCN109432868AEasy online replacementAvoid downtimeFiltration separationEngineeringFilter element

The invention discloses an online bioengineering solution filtering device which comprises a reaction tank, an export cylinder, filtering elements, a rotating disk and a rotating driving device, wherein the export cylinder is vertically arranged at the bottom of the reaction tank, a circular arc groove is formed in one side of the outer circle of the export cylinder in an internally concave manner, a through hole, downwards penetrating through the circular arc groove in an inserting manner, is formed in the export cylinder; the rotating disk is concentrically arranged on a rotating shaft of the rotating driving device and the edge of the rotating disk extends into the circular arc groove; a plurality of filtering element mounting holes are formed in the rotating disk in a ring-shaped arraymanner; the filtering elements are respectively arranged in the filtering element mounting holes; and sealing rings in contact with the top surface and the bottom surface of the rotating disk are arranged at the top surface and the bottom surface of the circular arc groove. According to the online biological engineering solution filtering device, the rotating driving device drives the rotating disk to intermittently rotate, so that the different filtering element mounting holes can be concentric with the through hole in sequence, the online manual replacement of old filtering elements is facilitated, the downtime problem is avoided, and the production efficiency is greatly improved.

Owner:CHANGSHU RES INST OF DALIAN UNIV OF TECH CO LTD

Player progress bar dynamic display method and device and storage medium

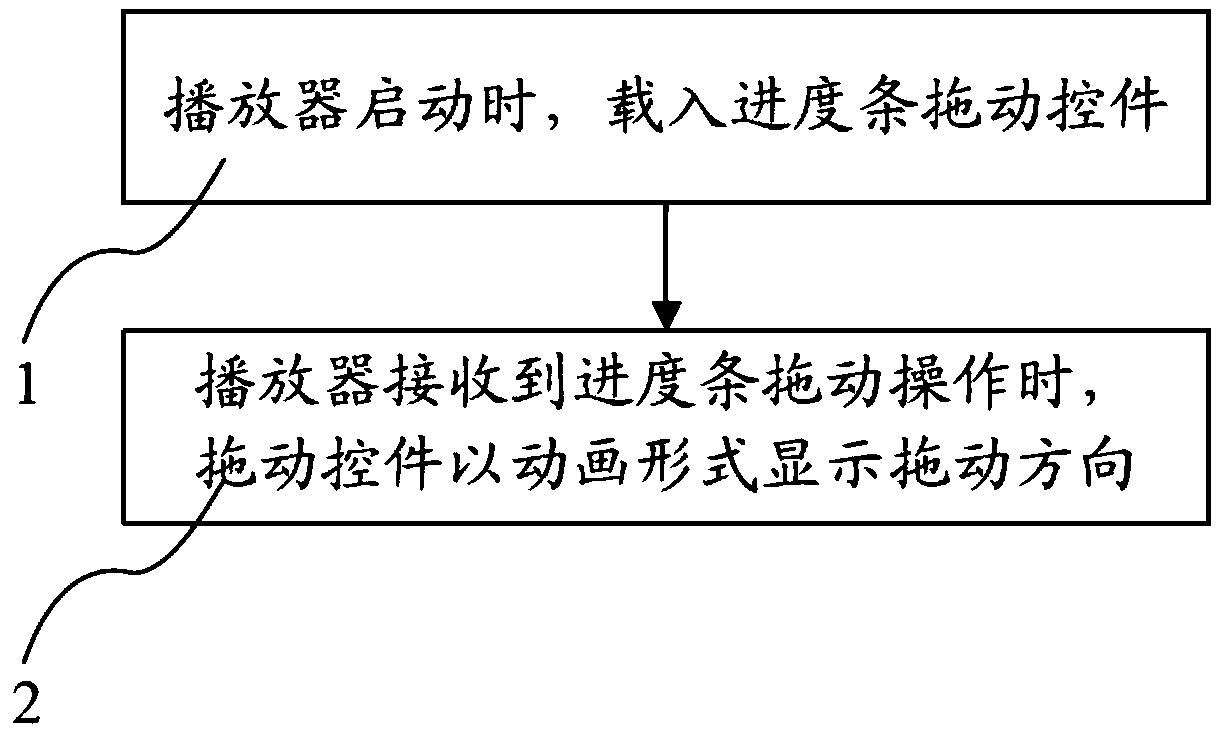

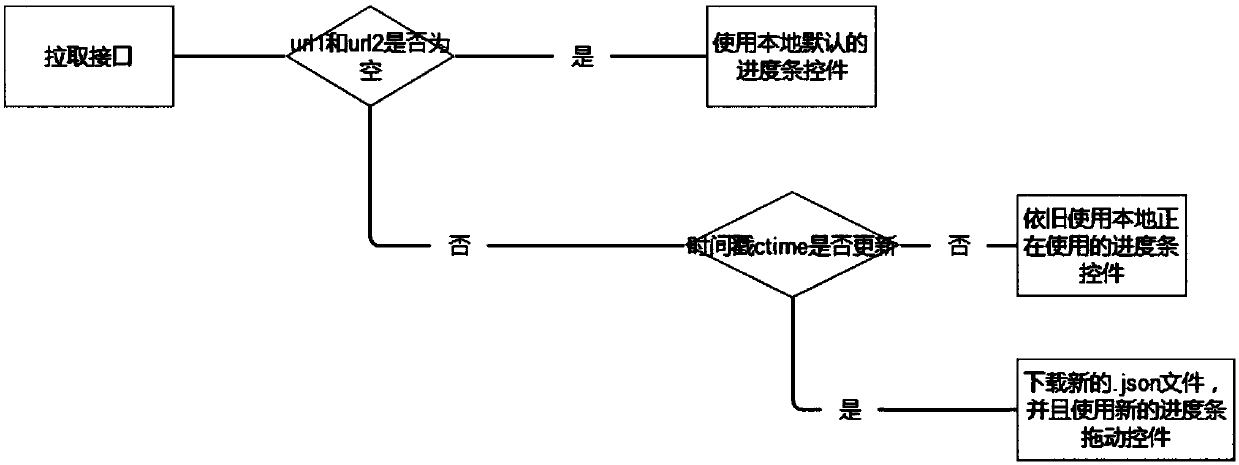

PendingCN110839179AImprove experienceEasy online replacementSelective content distributionComputer hardwareProgress bar

The invention relates to a player progress bar dynamic display method and device and a storage medium, and belongs to the technical field of the Internet. By adopting the player progress bar dynamic display method and device and the storage medium, when a player is started, progress bar dragging control is loaded; and when the player receives a progress bar dragging operation, dragging control displays a dragging direction in an animation form. Therefore, the dragging operation of a user can be dynamically fed back, the user experience is improved, meanwhile, the progress bar dragging controlcan be conveniently replaced online through the dynamic dragging control, and operation is convenient. The player progress bar dynamic display method and device and the storage medium are easy and convenient to implement, low in implementation cost and quite wide in application range.

Owner:SHANGHAI BILIBILI TECH CO LTD

System for deep treatment of coking wastewater by means of catalytic ozonation-ceramic membrane filtration

InactiveCN102849875BStrong upward impactInhibition falls intoMultistage water/sewage treatmentParticulatesChemical oxygen demand

The invention discloses a system for deep treatment of coking wastewater by means of catalytic ozonation-ceramic membrane filtration, mainly consisting of an ozone generator, an ozone oxidation reactor, a booster pump, a ceramic membrane component, a gas-liquid separator, a tail gas absorbing device, a wastewater reflowing pump, a catalyst reflowing pump, a catalyst adding pump, a catalyst outflowing groove, a catalyst adding groove and corresponding pipe fittings, valves and instruments. According to the system, the application of a powder catalyst in a dynamic reactor can be realized due tothe combination of the catalytic ozonation and the ceramic membrane separation; the ozonation and the catalytic ozonation can be guaranteed to be carried out in a single reactor in a segmental way due to the convection current of the reflowing wastewater and the catalyst slurry and the impact of upcurrent; the mass transfer resistance when the ozonation and the catalytic ozonation are independently used can be reduced; the use ratio of hydroxyl free radical and the removal rate of organic matters can be improved; the aims, such as the COD (chemical oxygen demand), the chroma and the turbidityof the deeply-treated coking wastewater, can be achieved; and the problems that the activity is suddenly reduced when the powder catalyst is formed into particulates, the running needs to be suspended when the mass transfer resistance is increased due to the use of the particulate catalyst and the particulate catalyst is changed and the like can be solved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Elastic Fiber Dry Spinning Mechanism and Spinning Parts Maintenance Control Method

ActiveCN104831366BReduce maintenance workloadEasy online replacementSpinnerette packsDry spinning methodsFiberTemperature control

Owner:ZHENGZHOU ZHONGYUAN SPANDEX ENG TECH

An aluminum equalizing ring for an insulator

ActiveCN109360695BReduce maintenance costsNot subject to electric field erosionInsulatorsElectricity deliveryEngineering physics

The invention relates to the technical field of power transmission protection equipment and discloses an aluminum equalizing ring for insulators, which comprises an equalizing ring body. The equalizing ring body includes a small equalizing ring, a medium equalizing ring and a large equalizing ring; adjusting bars are threadedly mounted at the bottom of the small equalizing ring in nested manner; afixing socket bar is movably mounted at the bottom of each adjusting bar in sleeving manner; the bottoms of the fixing socket bars are fixedly connected to the top of the medium equalizing ring. Thealuminum equalizing ring for insulators is provided with openings which may act as discharge gaps; when too much electric charges are accumulated, self-discharging can occur to allow relief; the operation demand of a + / -8000 kV DC line can be well met; the ends of insulators can be well protected from being eroded by an electric field; online replacement and installation are also facilitated; linemaintenance cost is greatly reduced; the good material also helps effectively avoid rusting and ensure long-term reliable operation; the aluminum equalizing ring for insulators has good market application prospect and social and economic benefits.

Owner:扬州旺源电气有限公司

Start-up method of dual-series Fischer-Tropsch reactor

ActiveCN108285809BReduce dosageReduce drive costsLiquid hydrocarbon mixture productionPtru catalystEconomic benefits

The invention discloses a starting method for a double-series Fischer-Tropsch reaction device. The starting method includes the following steps that heavy diesel is added into a single synthesis reactor, a certain quantity of iron-based catalyst is prepared through a reduction system to be added into the synthesis reactor, and the double-series Fischer-Tropsch reaction device is started step by step; when the reactor operates at full load, a half of mixed materials in the synthesis reactor is pressed into another synthesis reactor, and the loads of the two synthesis reactors reach 50% or above; the catalyst is supplemented to the two synthesis reactors through a reduction reactor respectively till the two synthesis reactors operate at full load. According to the starting method for the double-series Fischer-Tropsch reaction device, by changing an original starting scheme of the double-series Fischer-Tropsch synthesis device, original starting raw materials are saved, low-load running time of a Fischer-Tropsch reactor is shortened, the whole starting time is shortened, the loads of the two Fischer-Tropsch reaction systems reach 50% or above in a short time, the two Fischer-Tropsch reaction systems stably run, the starting cost is saved, and economic benefits are rapidly created.

Owner:INNER MONGOLIA YITAI COAL BASED NEW MATERIALS RES INST CO LTD +1

Disc and valve stem positioning structure

InactiveCN103697178AHigh positioning accuracyGuaranteed positioning accuracyLift valveMetal working apparatusEngineeringValve stem

A disc and valve stem positioning structure comprises a disc, a valve stem, and positioning pins, wherein the valve stem is in inserted connection with the disc and the disc and the valve stem are axially positioned through the positioning pins. The disc is provided with pinholes. The disc and valve stem positioning structure is characterized in that the pinholes are arranged at one edge of a disc mounting hole, the outside of each positioning pin is provided with a wedge surface A which is a flat wedge surface, the corresponding part of the outside of the valve stem is provided with a wedge surface B, and the wedge surface B is an arc wedge surface axially arranged along the valve stem. The positioning structure is available for wedge positioning; through the application of the positioning structure, fitting faces of parts are machined in advance, so that drilling the pinholes during assembly is not required; the positioning structure is especially applicable to conditions with complex structures and difficulty in drilling and even failure of drilling; the radial size of the positioning pins is adjustable, so that positioning is accurate and highly precise; through wedge positioning, the positioning precision can be guaranteed even after multiple mounting and demounting; in addition, the positioning structure has the advantages that mounting and demounting are convenient, a valve connector is easy to replace after being damaged and maintenance cost is low.

Owner:TIANJIN XIANGJIA FLUID CONTROL SYST CO LTD

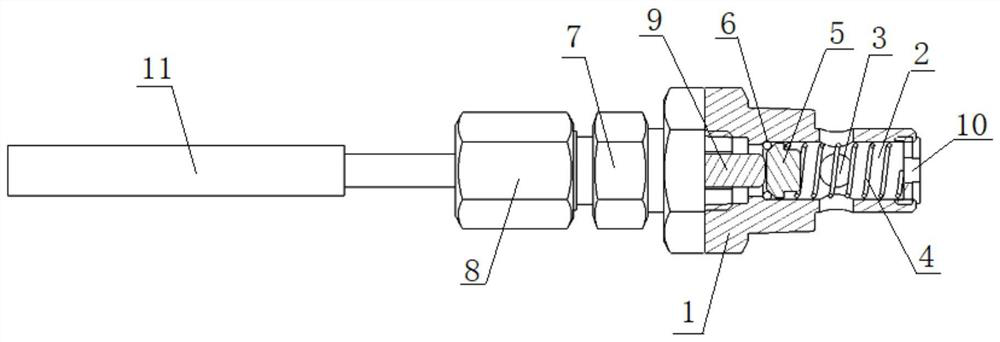

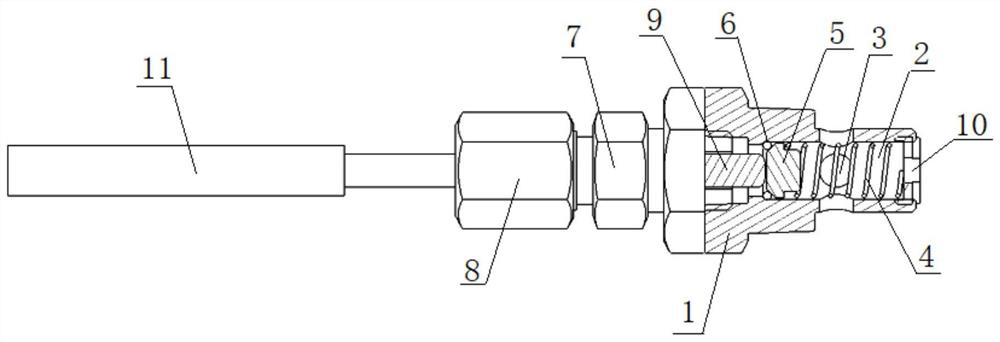

Leak-proof device capable of quickly replacing liquid temperature measuring sensor, and mounting structure and use method thereof

PendingCN113959570ASimple structureEasy maintenanceThermometer detailsEngineeringElectrical and Electronics engineering

The invention relates to the technical field of power assembly test, and discloses a leak-proof device capable of rapidly replacing a liquid temperature measurement sensor. The device comprises a self-sealing joint; a containing cavity is formed in the self-sealing connector, one end of the self-sealing connector is an opening communicated with the containing cavity, and a liquid circulation hole is formed in the surface of the self-sealing connector. The liquid circulation hole is communicated with the accommodating cavity; a spring is arranged in the containing cavity, one end of the spring abuts against the closed end of the self-sealing connector, and the other end of the spring is connected with a sealing cap. An O-shaped ring is further fixedly arranged in the containing cavity, wherein the inner diameter of the O-shaped ring is smaller than the outer diameter of the outer end of the sealing cap, and the outer end of the sealing cap abuts against the O-shaped ring under the action of the spring. The invention further discloses a mounting structure and a using method of the leakage-proof device for quickly replacing the liquid temperature measurement sensor. According to the leak-proof device for quickly replacing the liquid temperature measurement sensor and the mounting structure and the use method thereof, operation and maintenance personnel can conveniently replace the sensor for measuring high-temperature liquid on line, and the risk of liquid leakage is avoided.

Owner:DONGFENG COMML VEHICLE CO LTD

A hydraulic differential butterfly pump control valve

ActiveCN105889608BEssentially simple and practicalAvoid tripping and other bad phenomenaOperating means/releasing devices for valvesPositive displacement pump componentsInlet valveEngineering

Owner:SHANGHAI KARON VALVES MACHINERY +1

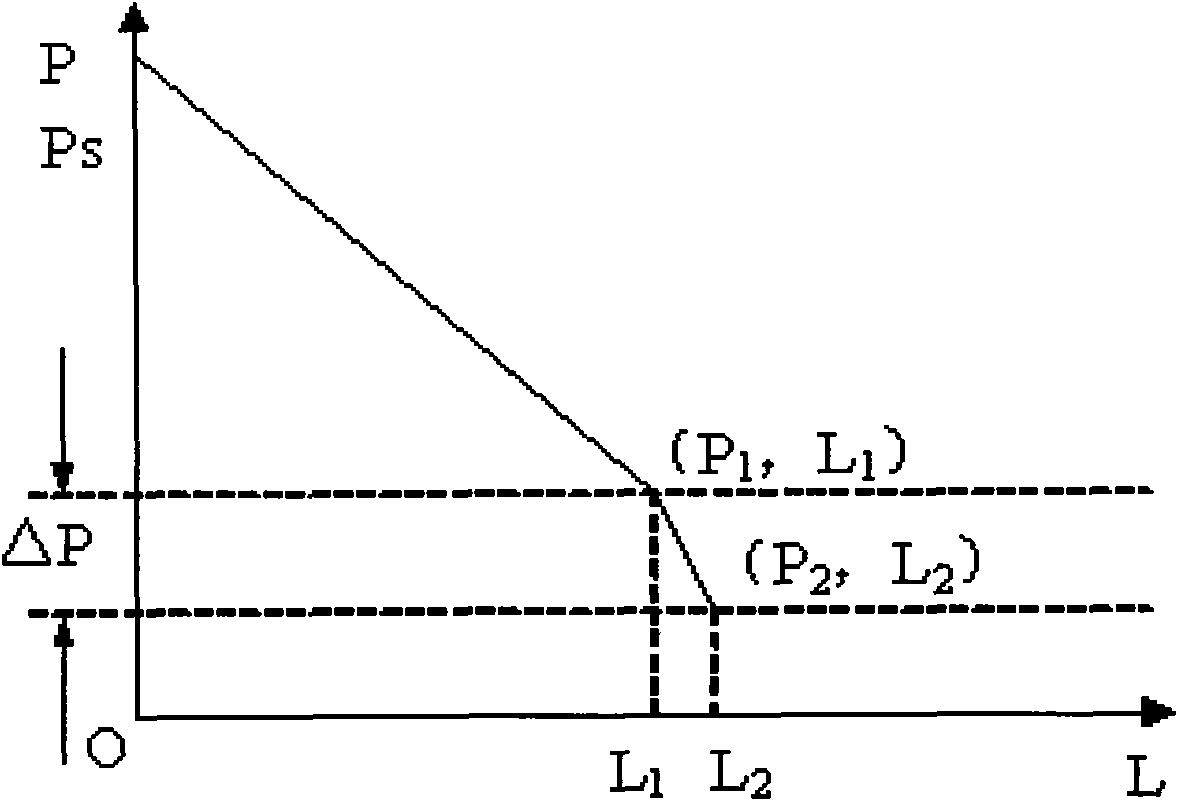

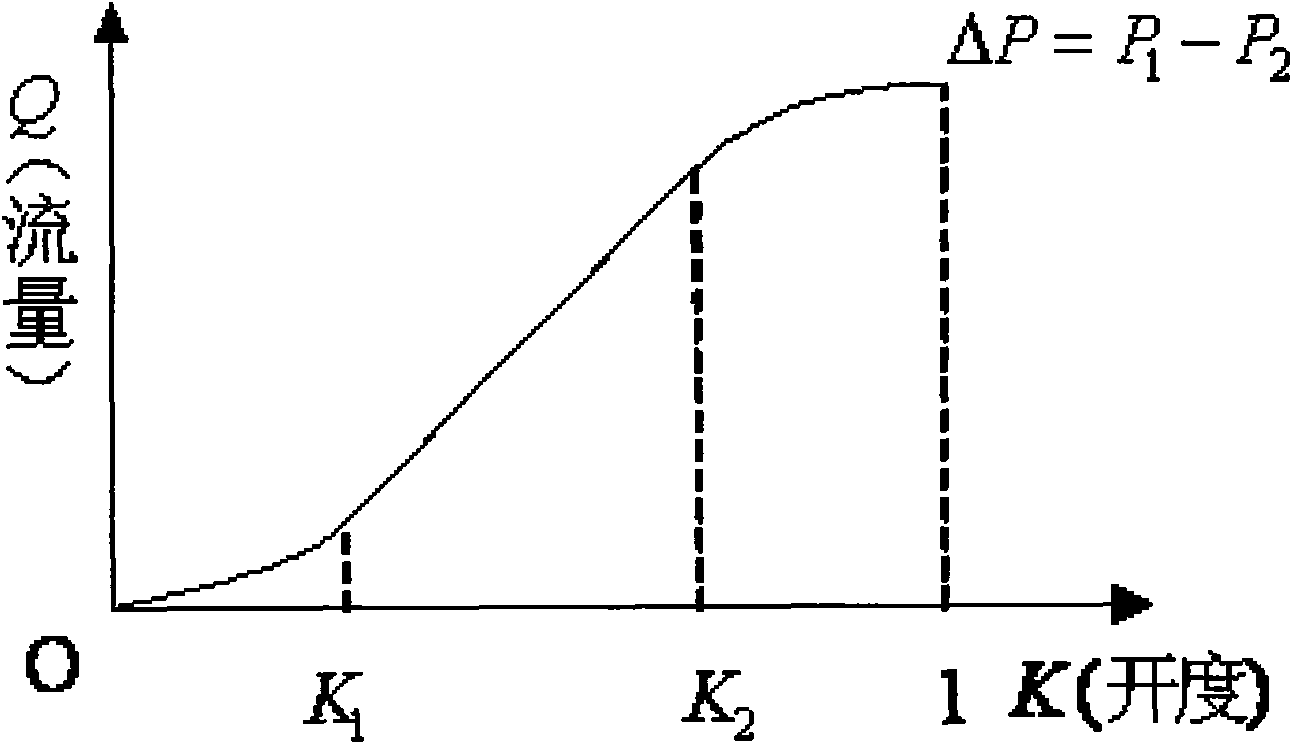

Combined multi-stage pressure control method and device

The invention discloses a combined multi-stage pressure control method, which is applied in petroleum and natural gas drilling pressure control. In the invention, a rough adjustment throttling control system and a fine adjustment throttling control system are connected in series to control the circulating pressure loss of drilling fluid and adjust a bottom-hole pressure. The rough adjustment throttling control system consists of a plurality of rough adjustment throttling channels and a straight flow channel, which are connected in parallel; and each rough adjustment throttling channel is formed by connecting a self-control flat valve and a throttling short connector in series, and the self-control flat valves as well as the throttling short connectors of all rough adjustment throttling channels are the same. The method has the advantages that: the mode of connecting various throttling channels in parallel or series is adopted, so the control range of the throttling pressure differenceof a throttling short connector is kept in a certain range; the circulating pressure of the drilling fluid is adjusted roughly to approach or reach a bottom-hole pressure control range; and the fine adjustment throttling control system finely adjust the circulating pressure of the drilling fluid to meet the requirements for high-precision bottom-hole pressure control.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

An adjustable modular crushing and grinding equipment

The invention provides an adjustable modular crushing and grinding equipment, which includes a grinding assembly and a filter assembly. The grinding assembly includes a driving source, a lifting mechanism, a crushing and grinding hammer, several cutting knife bodies and a crushing and grinding cylinder. The crushing and grinding hammer includes an upper end body, The lower end body, the pusher body and a number of cutting knife bodies, the crushing and grinding cylinder includes the first conical chamber, the second conical chamber and the second cylindrical chamber coaxially arranged in sequence from top to bottom, the first conical chamber and the The inner diameter of the second round platform chamber decreases sequentially from top to bottom, and the filter assembly includes a cylinder body, a vibrating body, a first power source, a turning bar, a screen fixing sleeve, a screen and a second power source. The present invention can realize Coarse grinding and fine grinding, and can adjust the fine grinding particle size of the material without changing the grinding hammer. At the same time, the screen can be automatically turned over to automatically dump out the materials remaining on the screen after screening.

Owner:JIANGSU UNIV +1

Energy-saving non-resistance check valve

ActiveCN103925395BPrevent backflowImprove work efficiencyPositive displacement pump componentsCheck valvesCheck valveWater hammer

An energy-saving resistance-free check valve comprises a valve body, a valve clack and a valve deck. A valve rod is arranged in the valve body. The axial direction of the valve rod is perpendicular to the axial direction of a medium inlet. The valve rod penetrates through the upper portion of a valve cavity. The two ends of the valve rod extend out of the front side and the rear side of the valve body respectively. A rotating pair is arranged between the valve rod and the valve body. A rocker is connected to one side of the valve clack. The upper end of the rocker is connected with the valve rod. A limiting device is connected to the bottom side of the valve deck. The front side and the rear side of the valve body are respectively provided with a hydraulic slow-closing device. According to the energy-saving resistance-free check valve, gravity and buoyancy enable a medium to pass through the valve body fully without resistance when the valve clack is fully opened, so that the work efficiency of a water pump is improved, power consumption is lowered, and the energy-saving effect is achieved; since the valve body is in a streamline form, the medium cannot deposit in the valve cavity, and the energy-saving resistance-free check valve is suitable for conveying media with particles prone to deposition; in the closing process, water hammer can be effectively reduced, and damage of the water hammer to a pipeline and valve equipment is lowered; under the condition that the pressure of return water is very low, sealing can be guaranteed, and therefore the conveying medium can be effectively prevented from flowing back in the quick-closing process.

Owner:SHANGHAI DONGFANGWEI VALVE CO LTD

Anti-clogging spray gun for injection desulfurization of molten iron

The invention discloses a nozzle anti-blocking spray gun for molten iron desulfurization injection, which is composed of a connecting section, a gun body section and an injection section, the connecting section is sequentially composed of a connecting flange and a composite gun core, and the composite gun core is from the inside to the The outside includes an inner intubation tube, a main pipe and a strengthening tube in turn, an inner intubation tube connector is installed on the inner wall of the bottom end of the strengthening tube, and a hollow fixing groove is opened at the lower end of the inner intubation tube guide, and a fixed groove is installed in the fixing groove The graphite blowing tube, the main pipe is fixed on the inner wall of the upper end of the inner insertion tube guide, and the inner insertion tube is inserted into the graphite injection tube through the inner insertion tube guide. The invention realizes the comprehensive purposes of preventing the spray gun from clogging, facilitating maintenance and replacement of clogged parts, prolonging the service life of the spray gun, reducing the maintenance cost of the spray gun and the consumption of desulfurizing agent, and improving the operation rate of desulfurization production.

Owner:武汉钢铁有限公司

A slurry bed methanol synthesis process

ActiveCN106588574BImprove heat transfer performanceEasy temperature controlOrganic compound preparationHydroxy compound separation/purificationSyngasVapor–liquid separator

The invention relates to a slurry reactor methanol synthesis process. The slurry reactor methanol synthesis process is characterized by comprising the following steps: mixing raw material gas from upstream with circulating gas to form mixed gas, enabling the mixed gas to enter a shell side of the reactor from the bottom after heat exchange to be in contact with a catalyst in the shell side to perform reaction; enabling bubble point boiler water to enter a tube side of the reactor; discharging the reaction gas generated by the reaction out of the top of the reactor and enabling the reaction gas to enter a separator to perform separation; enabling the separated non-gas phase to return to the reactor from the gas phase space at the upper part of the reactor, enabling the separated gas phase, namely crude methanol synthesis gas, to enter a gas liquid separator after heat exchange, pressurizing the separated gas phase to serve as circulating gas, wherein the separated liquid phase is crude methanol; when catalyst abrasion reaches to a set value, extracting catalyst slurry from the reactor; supplementing fresh catalyst slurry into the shell side of the reactor. According to the slurry reactor methanol synthesis process, the catalyst can be changed timely without shutdown.

Owner:SINOPEC NINGBO ENG +2

Self-propelled positioning and level measuring device on basis of complicated mineral separation environments

ActiveCN102506958APrecise positioningReduce operating intensityMachines/enginesLevel indicatorsControl signalLevel sensor

The invention relates to a self-propelled positioning and level measuring device on the basis of complicated mineral separation environments, which comprises a level sensor, a signal wire, a guide rail, a computer system and a control signal wire. The level sensor is arranged below a mine draining car, is used for monitoring level conditions of the mine draining car, runs on the guide rail, and is connected with the computer system through the signal wire, and the control signal wire is connected with the computer system to handle actual situations selectively. By the aid of the self-propelled positioning and level measuring device on the basis of complicated mineral separation environments, the mine draining car can be positioned accurately and realizes automatic mineral distribution, operators can remotely control the mine draining car according to the level conditions of the mine draining car so as to change mineral unloading position of the mine draining car at any time, and accordingly the number of the operators and operation intensity thereof are reduced while operating environments are improved.

Owner:NANJING DELTO TECH

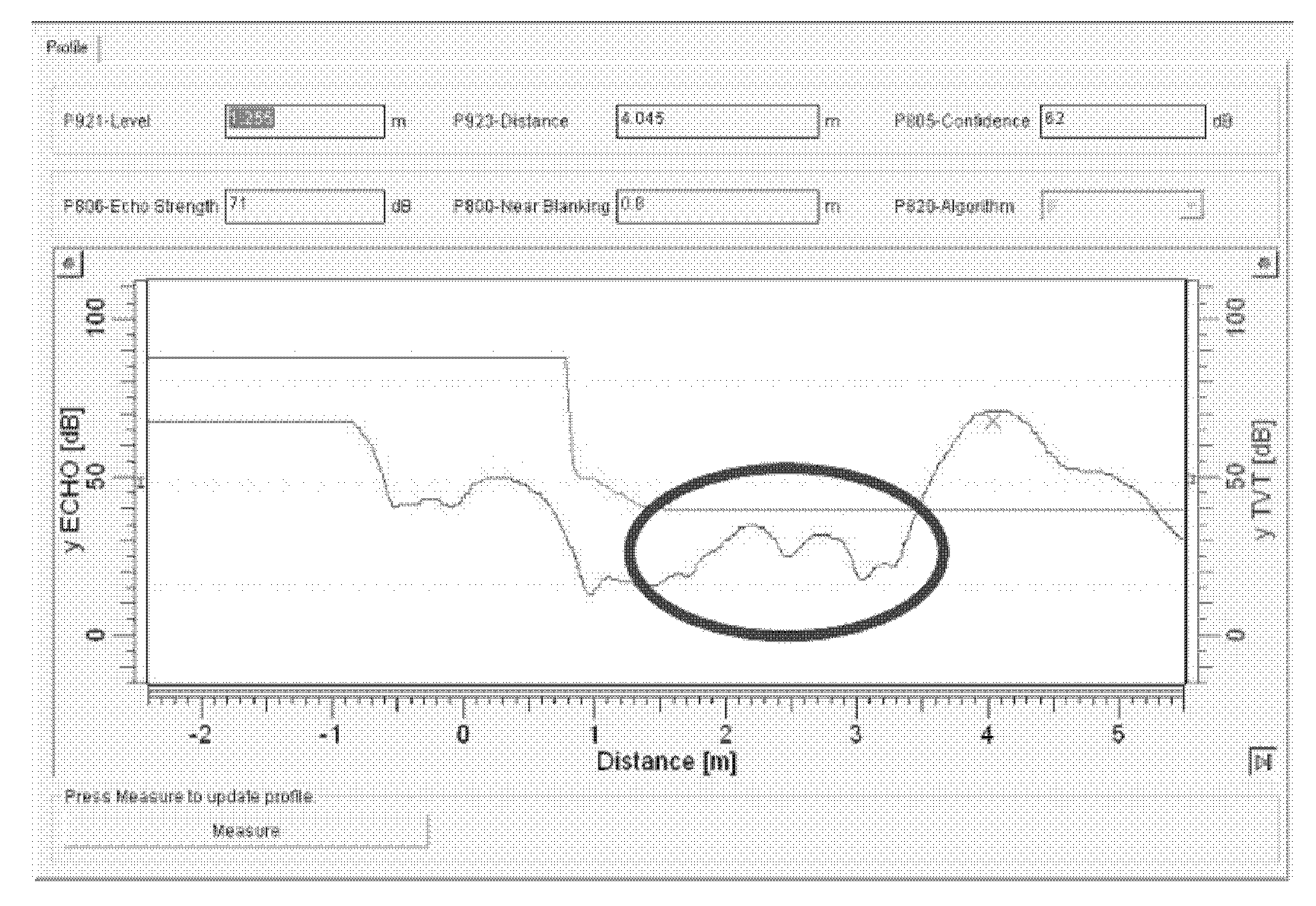

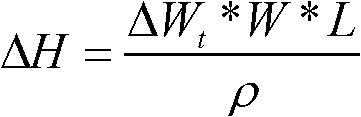

Measurement method capable of realizing automatic traveling to position material level based on complex beneficiation environment

InactiveCN102519539APrecise positioningReduce operating intensityMachines/enginesLubrication indication devicesMathematical modelLevel measurement

The invention relates to a measurement method capable of realizing automatic traveling to position a material level based on a complex beneficiation environment. The method is characterized in that the weight of ores is measured by a technological front-end belt scale, an increased height mathematical model of a material bin within a certain period of time is provided according to capacity of the bin after multiple acquisition by the aid of a computer, and transmitted to an ore material level measuring system in an actual automatic distributing process, and the material level measuring system computes the actual optimal measuring position according to the increased height mathematical model, and guides a mine car of the material level measuring system to travel to realize positioning. Accordingly, the material level is accurately measured, and accurate material level measurement is provided for a follow-up full-automatic mine car distributing system.

Owner:NANJING DELTO TECH

Assembly type split framework oil seal

The invention discloses an assembly type split framework oil seal. The assembly type split framework oil seal comprises a sealing lip, a cap portion, a spring groove, a framework, a shoulder portion, bosses, grooves, a plug pin, a plug hole, a back portion, a waist portion and a dustproof lip which form a splitting integrative structure. The sealing lip is arranged outside the cap portion, the spring groove is arranged inside the cap portion, the dustproof lip is arranged outside the waist portion, bosses are arranged in the middle of the external periphery of the shoulder portion, each groove is arranged between two neighboring bosses, the back portion is connected in one with the shoulder portion, the bosses, the grooves, the waist portion, the dustproof lip, the cap portion, the sealing lip and the spring groove, the spring is independently arranged inside the spring groove, the shoulder portion is provided with the framework, the two ends of the split part of the shoulder portion are provided with the plug pin and the plug hole respectively. The assembly type split framework oil seal is convenient and rapid to install, the framework designed inside the shoulder portion greatly enhances the strength of the shoulder portion to guarantee the radial tight cooperation between the shoulder portion and the end cover of a splitting type device; the framework inside the shoulder portion is made of spring steel and accordingly guarantees no deformation during installation; the assembly type split framework oil seal is simple in structure, low in cost and good in adaptability, facilitates online replacement, effectively improves the working efficiency and saves time and the equipment maintenance cost.

Owner:湖北新置密封件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com