Slurry reactor methanol synthesis process

A methanol synthesis and slurry bed technology, which is applied in the preparation of hydroxyl compounds, the preparation of organic compounds, the separation/purification of hydroxyl compounds, etc., can solve the problems that the catalyst cannot be replaced online, the economic benefits of the device are affected, and the inert solvent is easily entrained. Achieve the effects of avoiding economic losses, reducing engineering investment and device energy consumption, and reducing bed temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

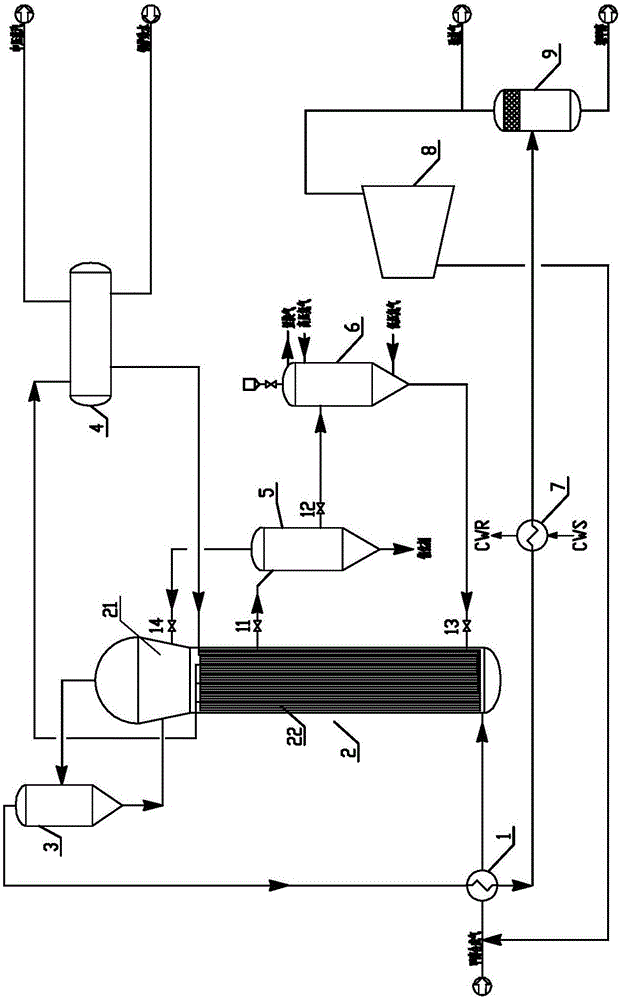

Method used

Image

Examples

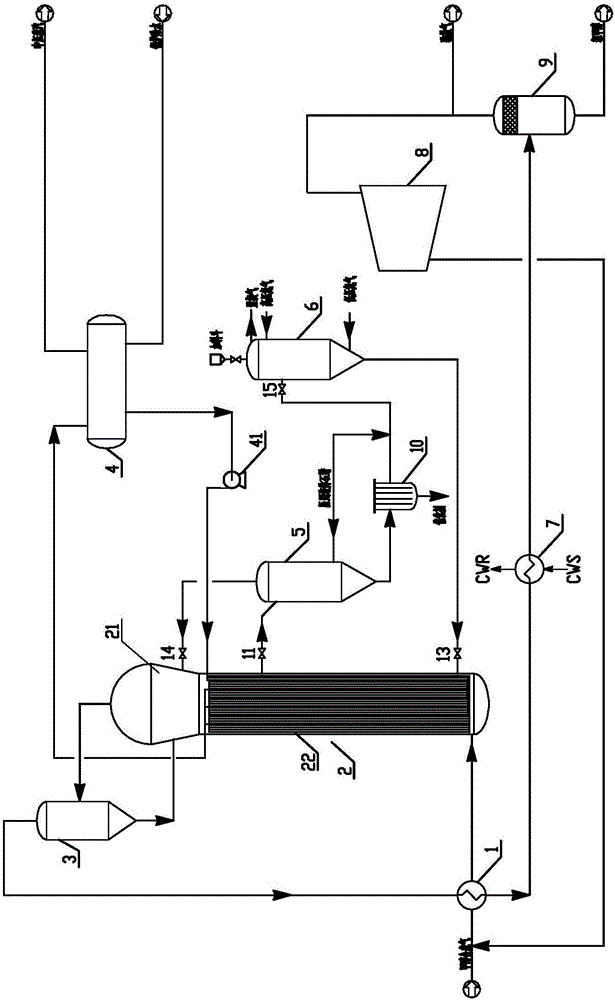

Embodiment 2

[0047] Such as figure 2 As shown, in the present embodiment, when the catalyst needs to be replaced, the slurry extraction pipeline root valve 11 on the upper part of the slurry bed reactor reaction zone 22, the gas phase return pipeline cut-off valve 14 of the cross-flow filter 5, and the catalyst filter 10 and the catalyst filter 10 are opened. The cut-off valve 15 of the inert solvent connection pipeline between the preparation tanks 6.

[0048] The slurry in the upper part of the reaction zone 22 is introduced into the cross-flow filter 5, and the slurry is initially filtered and concentrated; the gas contained in the slurry and the synthesis gas produced by the new reaction are returned to the slurry bed reactor from the top of the cross-flow filter 5 In the gas phase space 21 of 2, the inert solvent filtered out enters the catalyst preparation tank 6 relying on the pressure difference; the catalyst slurry concentrated by the cross-flow filter 6 enters the filter 10 for ...

Embodiment 1

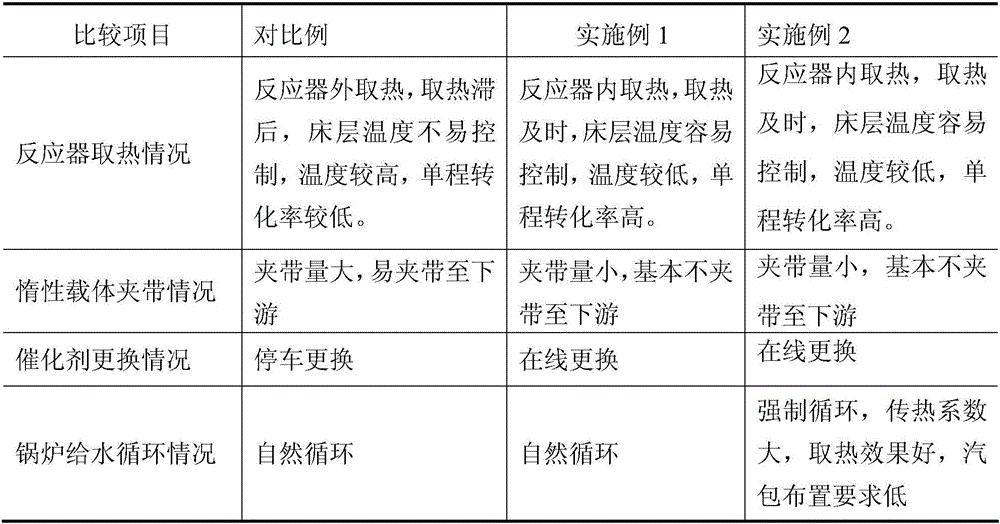

[0054] The comparison of embodiment 1 and embodiment 2 and comparative example is shown in table 1.

[0055] Table 1

[0056]

[0057] As can be seen from Table 1, in the slurry bed methanol synthesis process provided by the present invention, the reactor takes heat in a timely manner, the bed temperature is stable and easy to control, the single-pass conversion rate is high, and the circulating gas volume is small, which greatly reduces engineering investment and equipment. Energy consumption; the amount of inert carrier entrainment is small, basically no entrainment to the downstream; the catalyst is replaced online, which avoids the economic loss of parking due to catalyst replacement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com