Anti-clogging spray gun for injection desulfurization of molten iron

A technology for desulfurization of molten iron and nozzles, applied in the field of molten iron pretreatment, can solve the problems of difficulty in cleaning the sticky slag of reactants and dredging of nozzles, difficulty in achieving the effect of stream splitting, limited improvement of dynamic conditions, etc., so as to ensure the ability to resist damage. , easy to replace, reduce the effect of spray flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

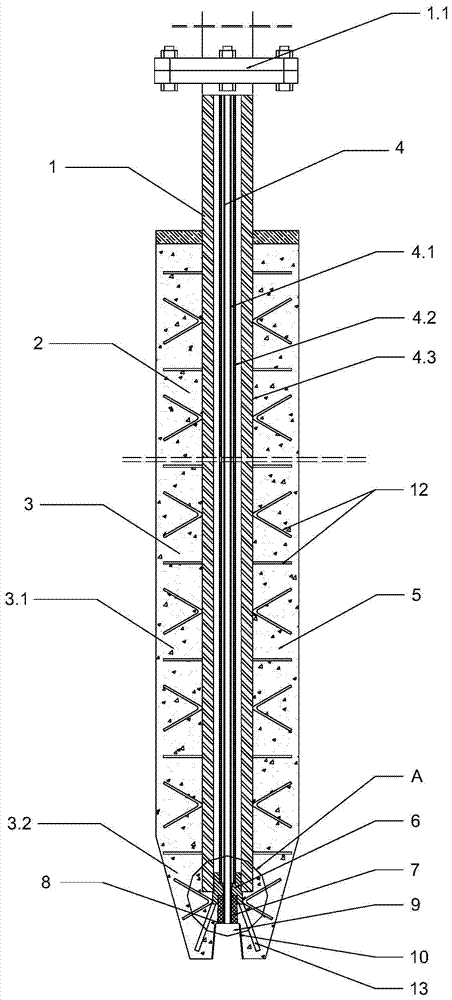

[0036] Such as figure 1 , 5 , 9, a nozzle anti-blocking spray gun for hot metal desulfurization injection, it is made up of connecting section 1, gun body section 2 and injection section 3, connecting section 1 is made up of connecting flange 1.1 and composite gun core 4 successively, the gun The body 2 and the outer wall of the injection section 3 are casted by refractory materials and form the refractory gun lining 5; the injection section 3 includes the injection section gun body 3.1 and the gun head 3.2 arranged on the top of the injection section gun body 3.1, and the gun head 3.2 The shape is round and round.

[0037] The composite gun core 4 runs through the entire gun body section 2 and the injection section gun body 3.1 and extends into the middle of the gun head 3.2; the composite gun core 4 is composed of an inner insertion tube 4.1, a main tube 4.2 and a reinforced tube 4.3 from the inside to the outside, and the bottom of the reinforced tube 4.3 An inner tube gu...

Embodiment 2

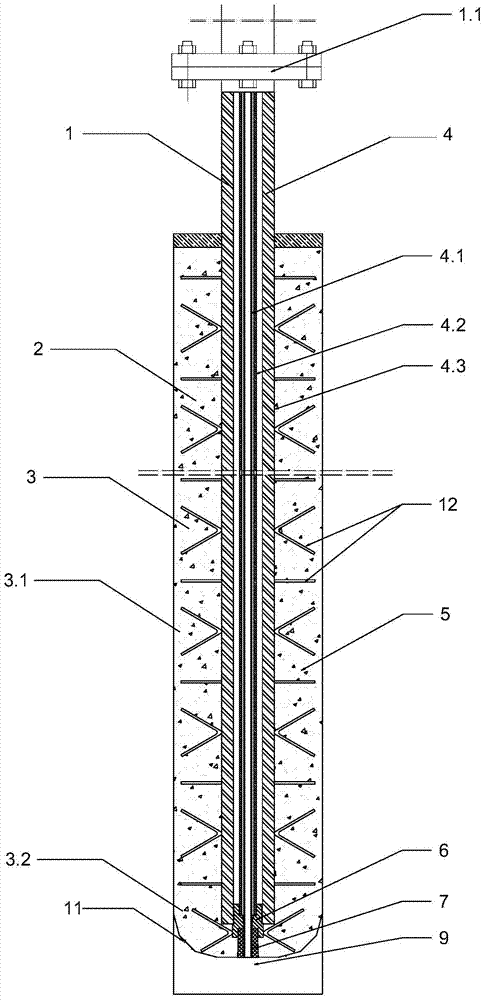

[0046] Such as figure 2 and 6 As shown, a nozzle anti-blocking spray gun for hot metal desulfurization injection, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is:

[0047] The side wall of the gun head 3.2 is provided with a diversion groove 13, which communicates with the groove 9; the shape of the gun head 3.2 is a cylindrical structure.

Embodiment 3

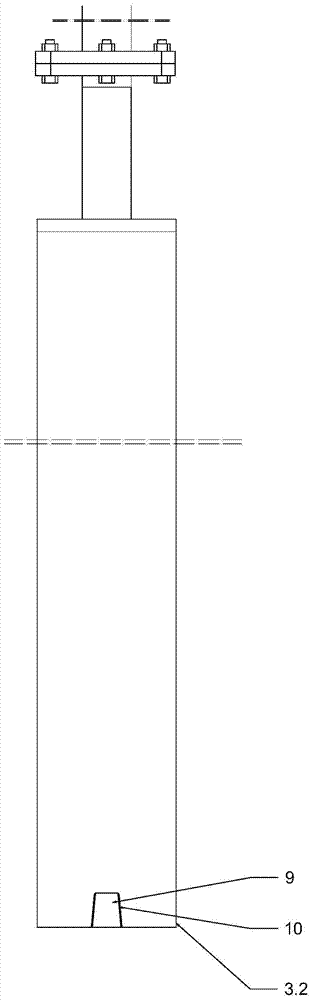

[0049] Such as image 3 and 7 As shown, a nozzle anti-blocking spray gun for hot metal desulfurization injection, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is:

[0050] The groove 9 is a star-shaped triple groove; the shape of the gun head 3.2 is a cylindrical structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com