Leak-proof device capable of quickly replacing liquid temperature measuring sensor, and mounting structure and use method thereof

A technology for temperature measurement sensors and anti-leakage, which is applied in the direction of measuring devices, parts of thermometers, instruments, etc., can solve the problems of preventing leakage that do not involve the replacement of liquid temperature measurement devices, and achieve the effect of simple structure and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

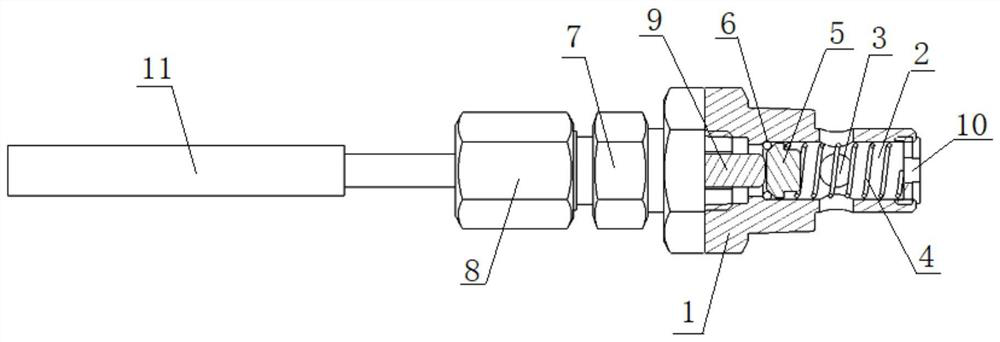

[0026] Such as figure 1 As shown, a leak-proof device for quickly replacing a liquid temperature measuring sensor includes a self-sealing joint 1, a housing chamber 2 is provided in the self-sealing joint 1, and one end of the self-sealing joint 1 is an opening communicating with the housing chamber 2, The other end of the self-sealing joint 1 is closed, and the surface of the self-sealing joint 1 is provided with a liquid flow hole 3, the liquid flow hole 3 communicates with the accommodating cavity 2, and the accommodating cavity 2 is provided with a spring 4, and one end of the spring 4 is against the self-sealing cavity. One end of the sealing joint 1 is closed, the other end of the spring 4 is connected with a sealing cap 5, and an O-ring 6 is fixed in the accommodating cavity 2, and the outer edge of the O-ring 6 is in sealing connection with the inner wall of the accommodating cavity 2, O The inner diameter of the type ring 6 is smaller than the outer diameter of the ou...

Embodiment 2

[0030] Such as figure 1 As shown, a leak-proof device for quickly replacing a liquid temperature measuring sensor includes a self-sealing joint 1, a housing chamber 2 is provided in the self-sealing joint 1, and one end of the self-sealing joint 1 is an opening communicating with the housing chamber 2, The other end of the self-sealing joint 1 is closed, and the surface of the self-sealing joint 1 is provided with a liquid flow hole 3, the liquid flow hole 3 communicates with the accommodating cavity 2, and the accommodating cavity 2 is provided with a spring 4, and one end of the spring 4 is against the self-sealing cavity. One end of the sealing joint 1 is closed, the other end of the spring 4 is connected with a sealing cap 5, and an O-ring 6 is fixed in the accommodating cavity 2, and the outer edge of the O-ring 6 is in sealing connection with the inner wall of the accommodating cavity 2, O The inner diameter of the type ring 6 is smaller than the outer diameter of the ou...

Embodiment 3

[0035] Such as figure 1 As shown, a leak-proof device for quickly replacing a liquid temperature measuring sensor includes a self-sealing joint 1, a housing chamber 2 is provided in the self-sealing joint 1, and one end of the self-sealing joint 1 is an opening communicating with the housing chamber 2, The other end of the self-sealing joint 1 is closed, and the surface of the self-sealing joint 1 is provided with a liquid flow hole 3, the liquid flow hole 3 communicates with the accommodating cavity 2, and the accommodating cavity 2 is provided with a spring 4, and one end of the spring 4 is against the self-sealing cavity. One end of the sealing joint 1 is closed, and the other end of the spring 4 is connected with a sealing cap 5, and the edge of the sealing cap 5 is matched with the inner wall of the accommodating cavity 2, and an O-ring 6 is fixed in the accommodating cavity 2, and the O-ring The outer edge of 6 is sealingly connected with the inner wall of the accommodat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com