Self-propelled positioning and level measuring device on basis of complicated mineral separation environments

A technology of material level measurement and automatic walking, which is applied in the direction of measuring device, lubrication indicator device, liquid/fluid solid measurement, etc. It can solve the problems of low safety, high labor intensity, emptying of silo or crushing ore, etc., and achieve improvement Effects of operating environment, reducing operators, and reducing operating intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

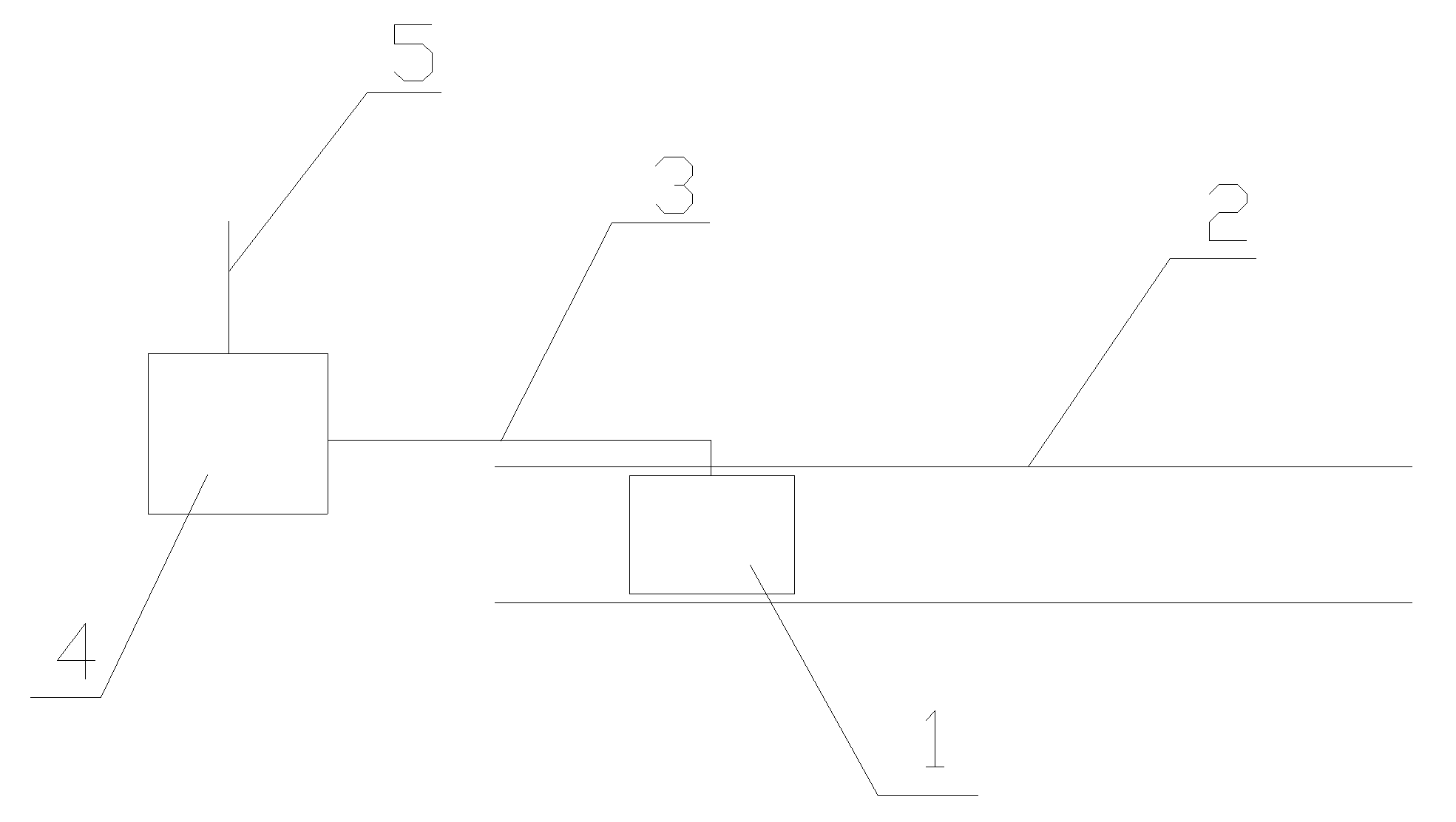

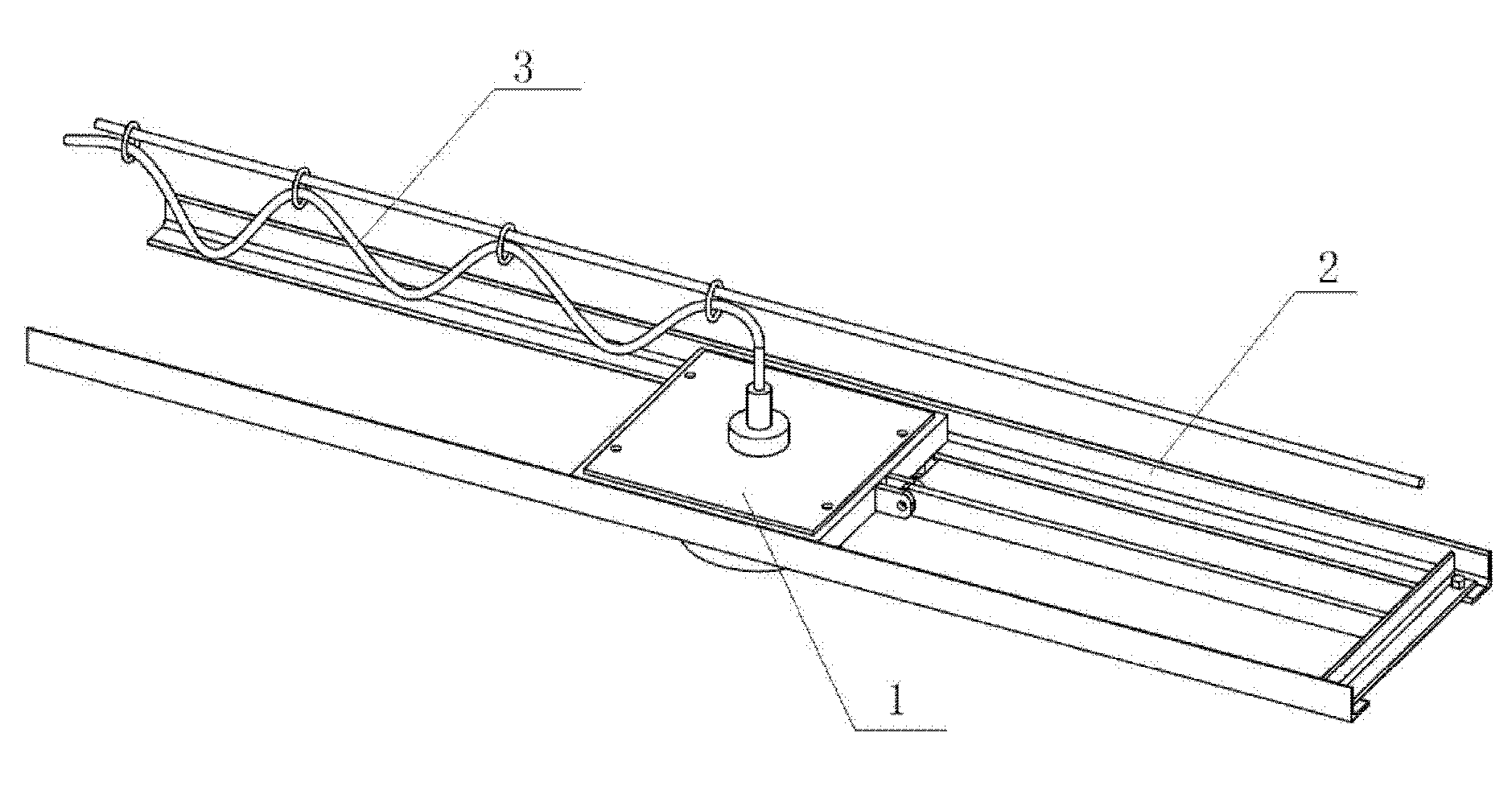

Method used

Image

Examples

Embodiment 1

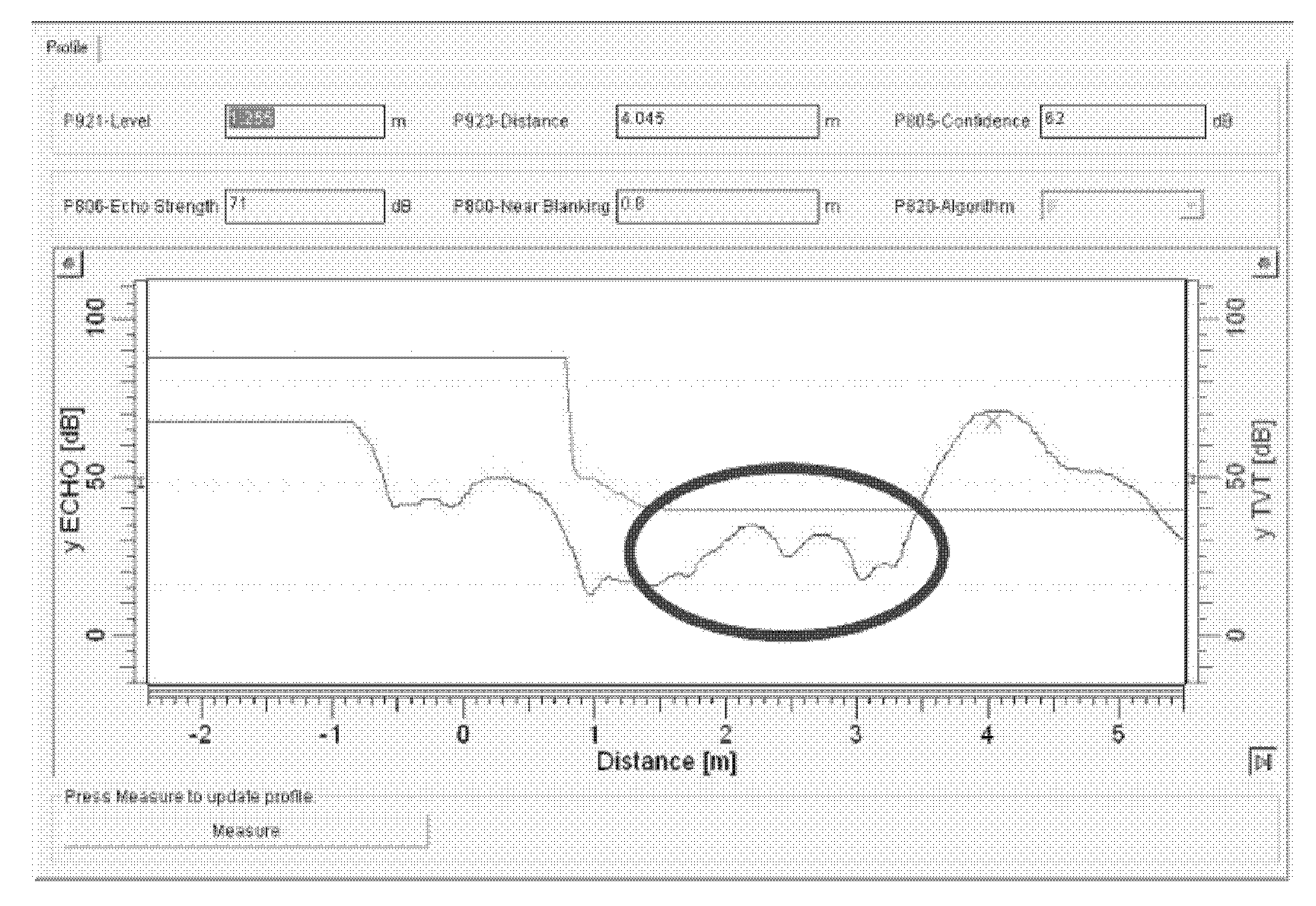

[0045] Such as image 3 As shown, the echo interference at 0.5 meters is shielded, but it is found that there are still echoes at 2-3 meters.

[0046] After adopting the present invention as Figure 4 As shown, the echo interference is basically removed, and the actual measured material level is consistent with the manually measured material level.

[0047] After adopting the present invention, the accurate positioning of the ore leakage vehicle and automatic material distribution are realized, and the operator can remotely control the ore leakage vehicle on the upper computer of the centralized control room according to the material level of the ore leakage vehicle, and change the ore discharge position of the ore leakage vehicle at any time to achieve Reduce the number of operators and operating intensity, and improve the working environment.

[0048] After the failure of the material level sensor, the computer will prompt the failure, and rely on the automatic walking dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com