Culture sewage processing system based on EGSB anaerobic reactor

An anaerobic reactor and aquaculture sewage technology, which is applied in the field of aquaculture sewage treatment system, can solve the problems of endangering ecological health and safety, increasing organic pollution and ammonia nitrogen load, and many solid impurities, so as to reduce impact and facilitate stable operation , Improve the effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The present embodiment is based on the aquaculture sewage treatment system of EGSB anaerobic reactor, comprising: grid tank, fine particle screening device, pH adjustment tank, oil separation adjustment tank, water volume adjustment tank, EGSB anaerobic reactor and tower connected in series type biological filter, oxidation pond, subsurface constructed wetland;

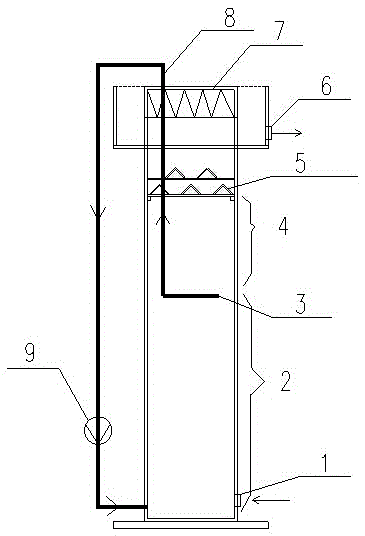

[0044]The EGSB anaerobic reactor includes a water distribution device, a reaction area, a three-phase separator, and a water collection area arranged sequentially from bottom to top, and also includes a reaction area division device, which includes an adjustable riser, and the The perforated pipe vertically connected with the lifting pipe, the reaction zone is divided into the first sludge zone and the second sludge zone above the perforated pipe with the position of the perforated tube as the boundary, and the lifting tube is driven to lift in the reaction zone. , lowering lifting drive device, the lifting pip...

Embodiment 2

[0051] This embodiment is based on the aquaculture sewage treatment system of the EGSB anaerobic reactor. On the basis of Example 1, a rotating return water pipe device is also provided in the reaction zone, and the rotating return water pipe device includes a central water inlet pipe, which is in line with the described For several branch pipes connected by the central water pipe, the mud inlet end of each main pipe is connected to the central mud inlet pipe, and the mud outlet end is connected to an arc pipe. The angle formed by the intersection of each adjacent two main pipes is equal. Each arc The two mud outlet ends of the shaped pipe are respectively connected to a pipe, and a reinforcement pipe is connected between the branch pipe and the main pipe;

[0052] Wherein, the branch pipes, main pipes, and reinforcement pipes are all perforated pipes, and the central water inlet pipe is connected to the circulation pump.

[0053] Further, the rotary return pipe device is comp...

Embodiment 3

[0056] This embodiment is based on the aquaculture sewage treatment system of the EGSB anaerobic reactor. On the basis of Example 1, the water distribution device includes a number of straight water pipes evenly distributed at the bottom of the EGSB anaerobic reactor. There are valves at both ends, and the sewage to be treated enters the reactor through one end of the water distributor.

[0057] The water distributor is composed of several independent perforated water distribution pipes, which are evenly distributed in the EGS reactor, and each end is controlled by two valves outside the reactor, one end controls water intake, and the other end can be vented. When one of the perforated pipes is blocked and the other valves are closed, the perforated pipe can be opened by pressure. If the blockage is serious, the water inlet control valve can be closed and the vent valve can be opened to unclog it. This will not affect the normal operation of the entire EGSB system, because in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com