Efficient anaerobic bioreactor for treating leachate of waste incineration plant

A technology of waste incineration and anaerobic biology, applied in anaerobic digestion treatment, waste fuel, etc., can solve the problems of easy blockage of reactors and related equipment, easy loss of granular sludge, and inability to withstand impact loads, etc., to achieve automatic control , short construction period, and the effect of reducing load impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

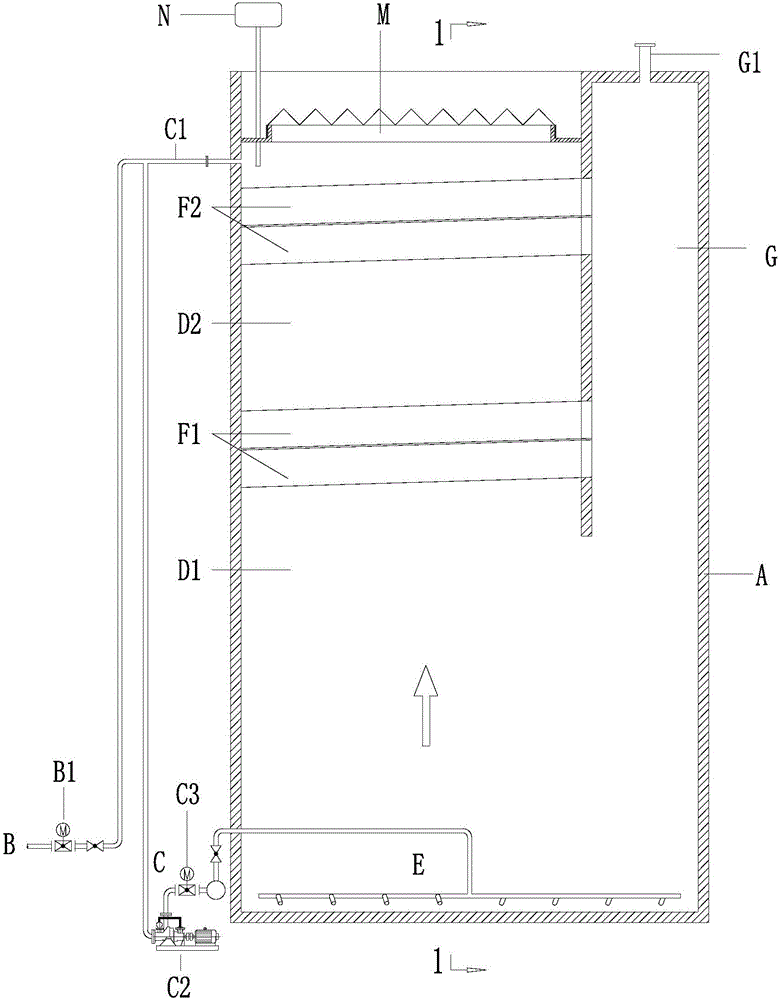

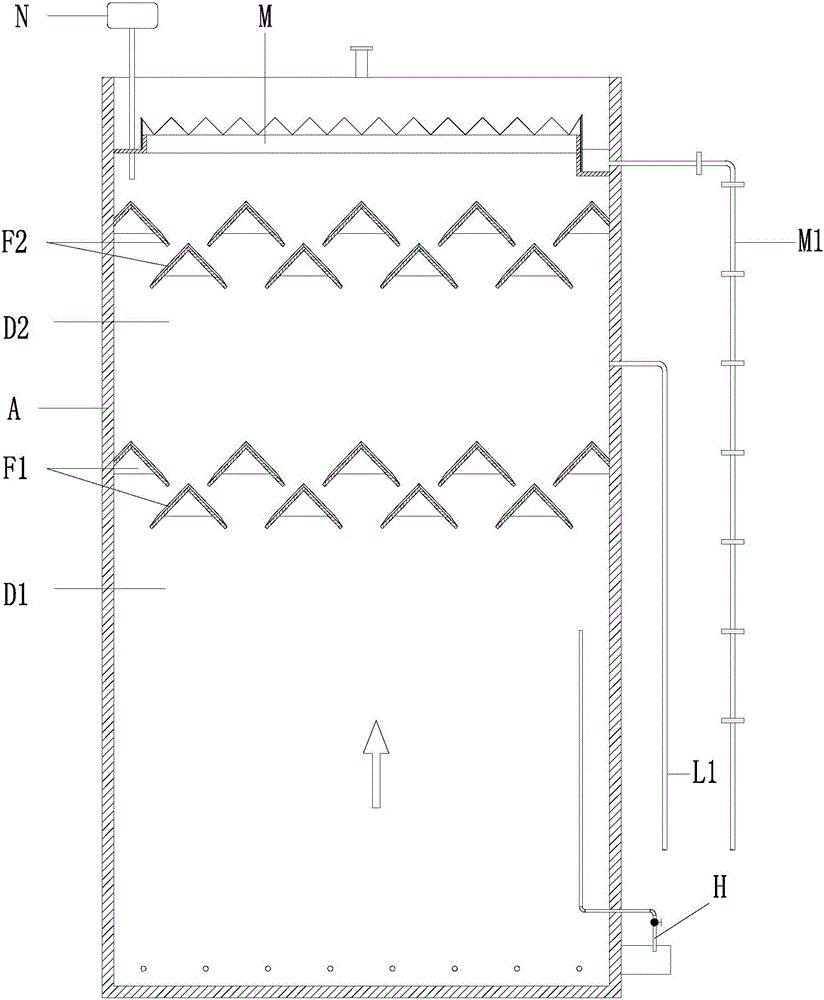

[0026] Structure of the present invention sees figure 1 , 2 shown. A high-efficiency anaerobic bioreactor for treating leachate in waste incineration plants, mainly including anaerobic tank (A), water inlet system (B), return system (C), reaction system (D), water distribution system (E ), three-phase separator (F), biogas collection chamber (G), sampling system (H), water outlet system (M), on-line monitoring (N) and sludge discharge system (L).

[0027] The reaction system (D) includes a first reaction zone (D1) and a second reaction zone (D2), and the part below the lower three-phase separator (F1) to the bottom of the tank (A) is the first reaction zone (D1 ), the part between the lower three-phase separator (F1) and the upper double-layer three-phase separator (F2) is the second reaction zone (D2).

[0028] The water inlet system (B) is directly connected to the return pipe (C1). After the landfill leachate is mixed with the return effluent, it flows into the water dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com