Patents

Literature

48results about How to "Speed up the response" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acid-base bifunctional metal organic skeletal catalyst and preparation method and application thereof

InactiveCN107213915AShorten the timeFast preparationOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsWater bathsFiltration

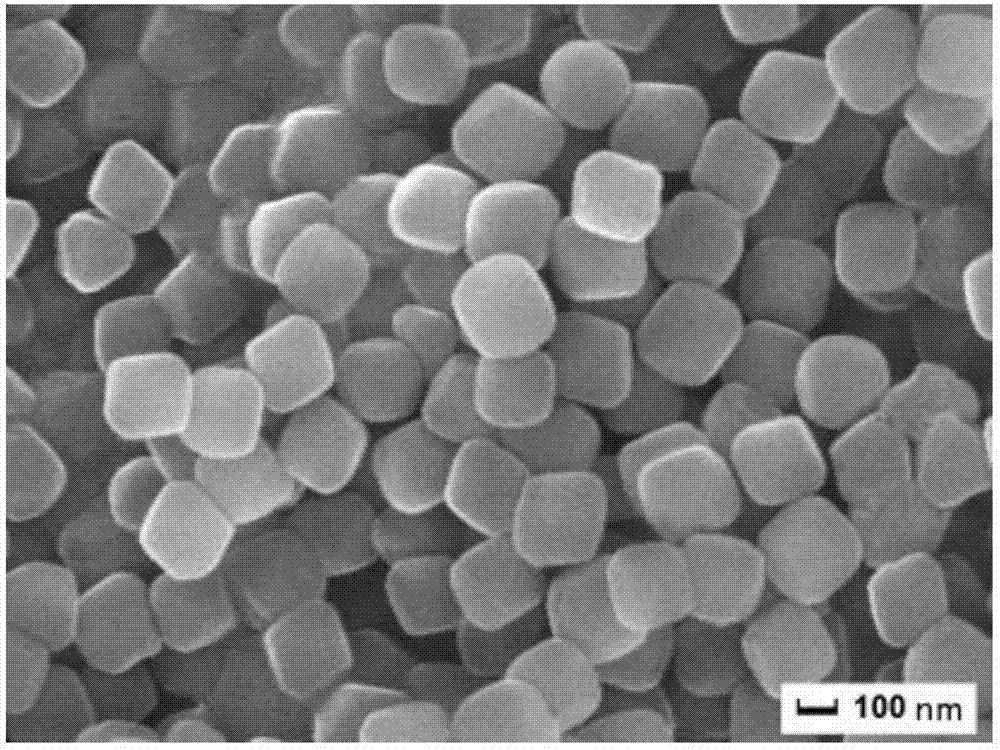

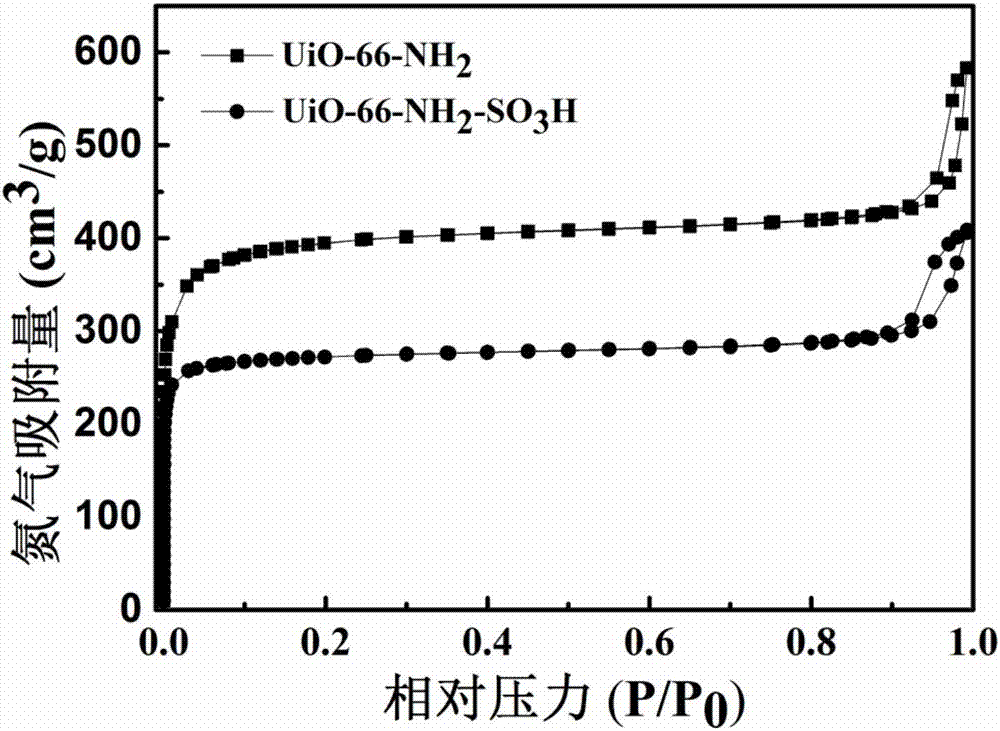

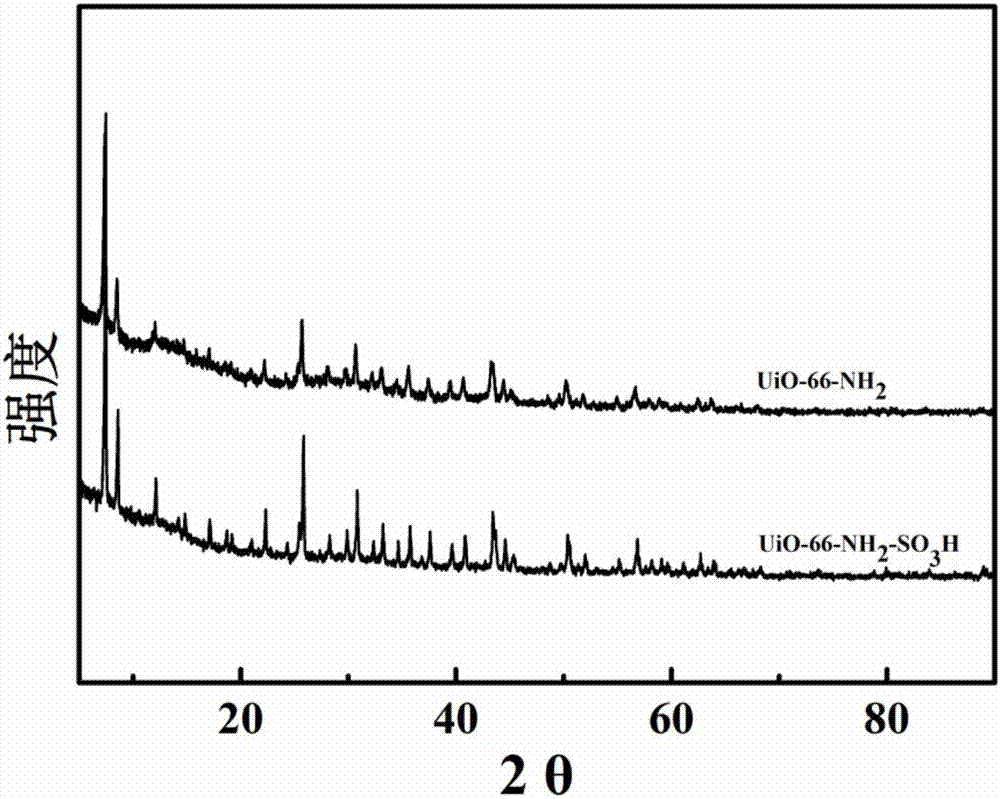

The invention provides an acid-base bifunctional metal organic skeletal catalyst and a preparation method and an application thereof. The preparation steps are as follows: zirconium salt and 2-aminaterephthalic acid are dissolved in weakly acidic solution, and the obtained mixed solution is uniformly dispersed under an ultrasonic condition, and reacts in water bath; after reaction, the product is filtered, collected and washed; after the washed product is immersed in low-boiling point solvent, filtration is carried out, vacuum drying is then carried out, and thereby a UiO-66-NH2 material is obtained; trichloromethane solution which contains 1,3-propane sultone is prepared, added with the prepared UiO-66-NH2 material and heated in water bath to react, and the prepared solid product is then centrifugally separated and washed by using Soxhlet extraction; the obtained solid material is put into a vacuum drying oven, and thereby the acid-base bifunctional metal organic skeletal catalyst is obtained. The process of preparing the product is simple, the preparation cost is low, the acid-base bifunctional metal organic skeletal catalyst is used in the preparation of 5-hydroxymethylfurfural by one-step catalysis of dextrose, the reaction progress is accelerated, and the reaction process is simplified.

Owner:JIANGSU UNIV

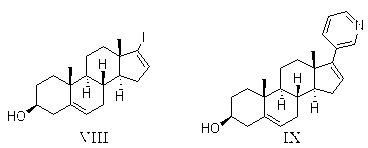

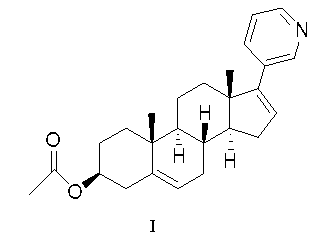

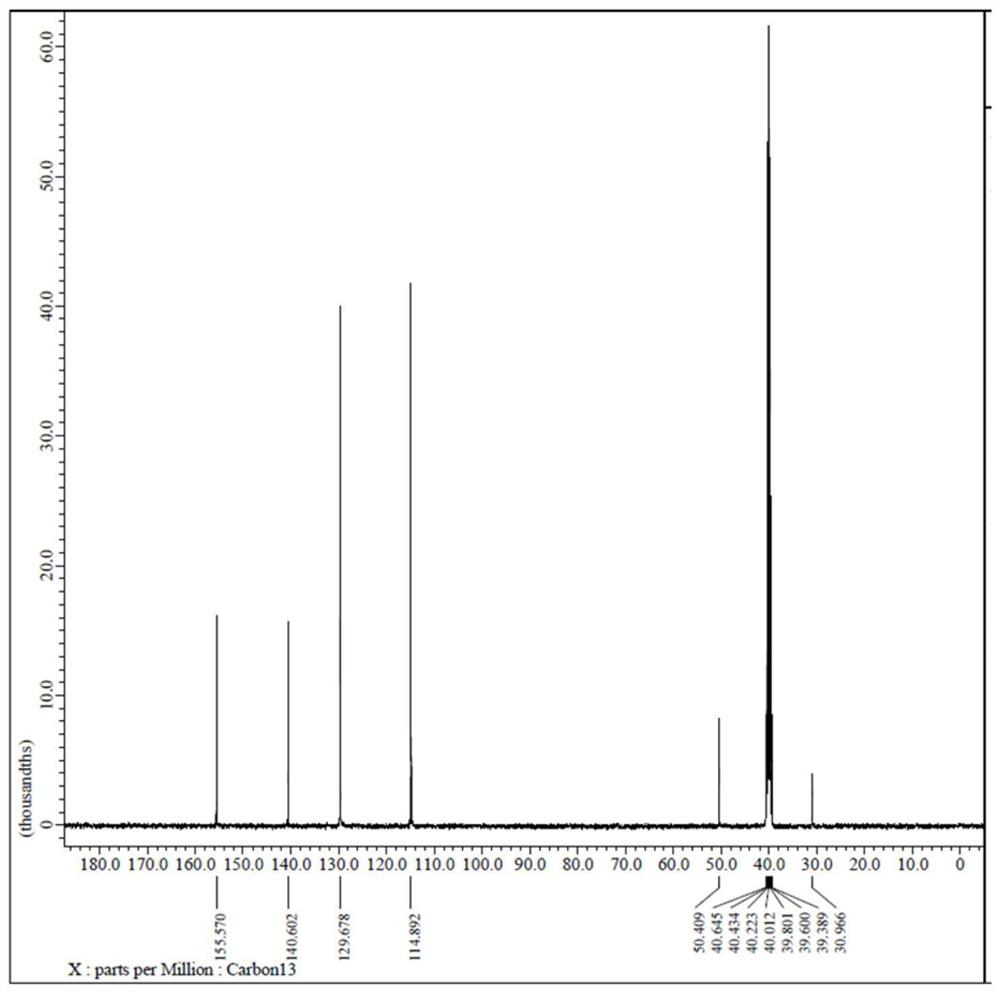

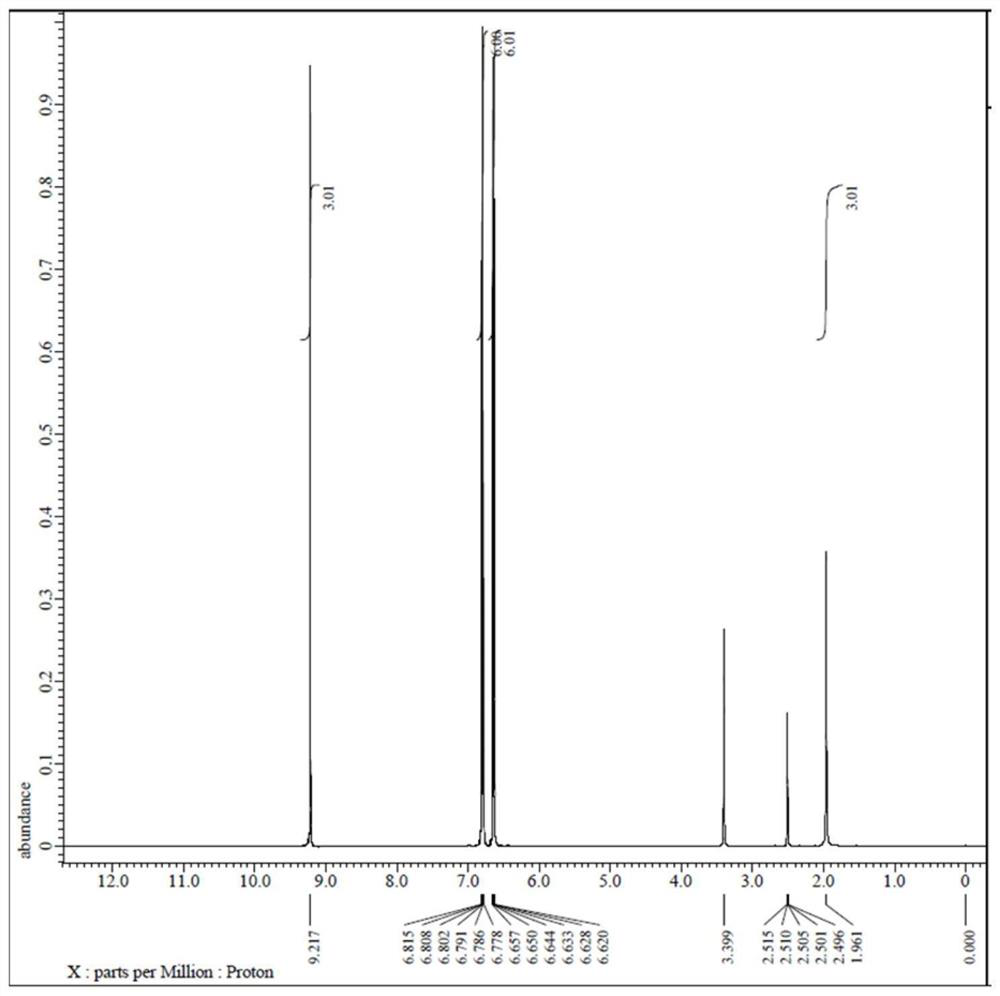

Methods for preparing abiraterone acetate and intermediate thereof

The invention relates to a method for preparing abiraterone which is a key intermediate of abiraterone acetate serving as a medicament for treating prostatic cancer and a method for preparing the abiraterone acetate by using the intermediate thereof. The methods are simple in processes, and the products have high purity and low content of impurities.

Owner:CHONGQING PHARMA RES INST

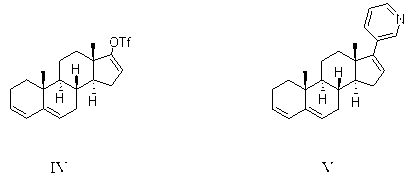

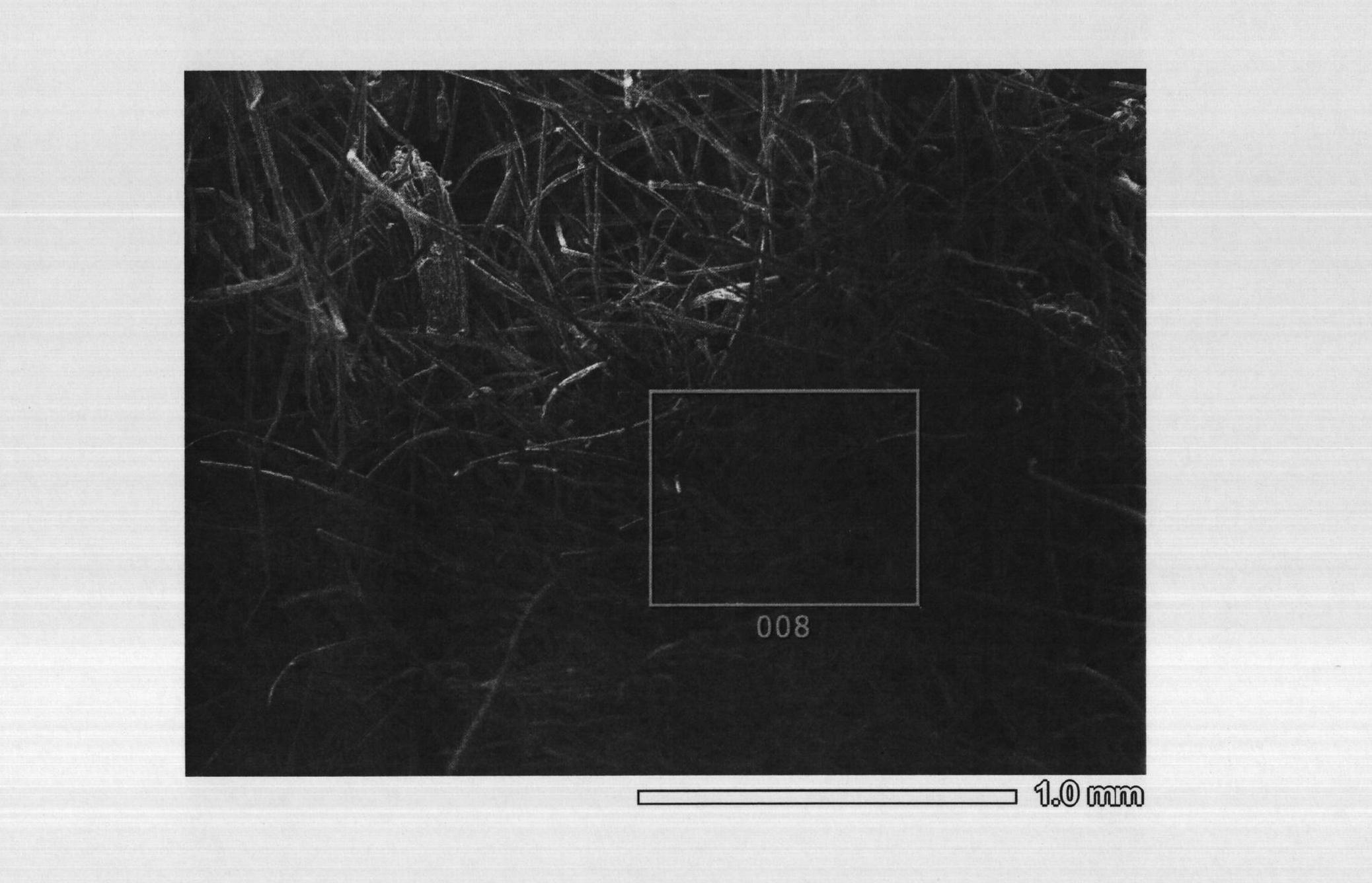

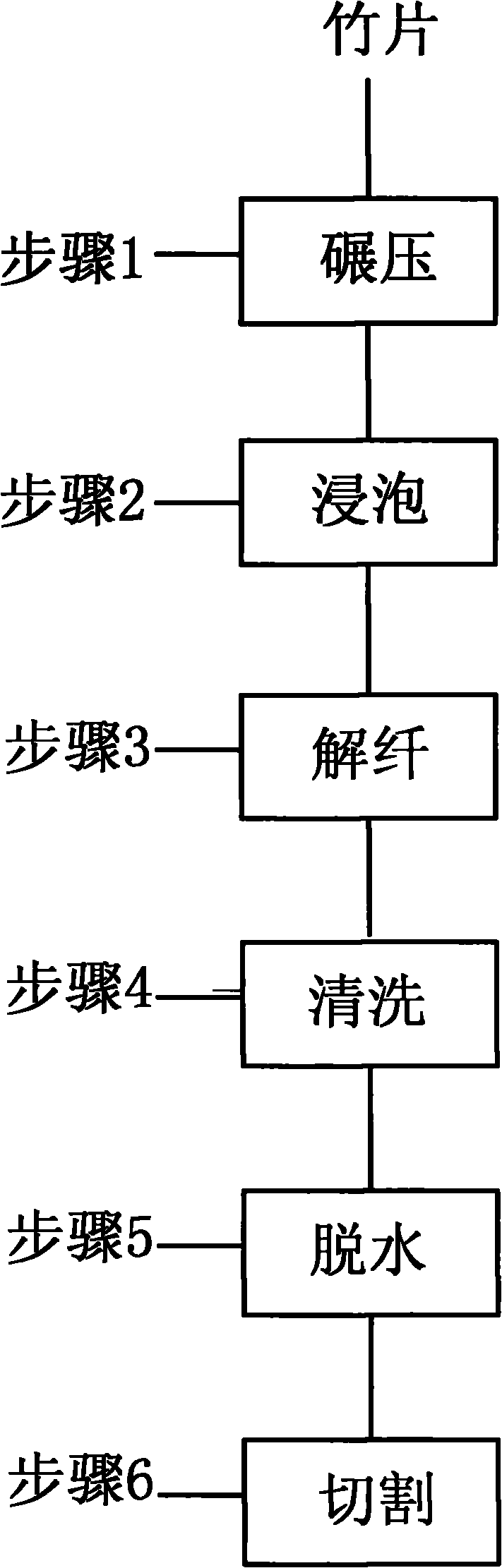

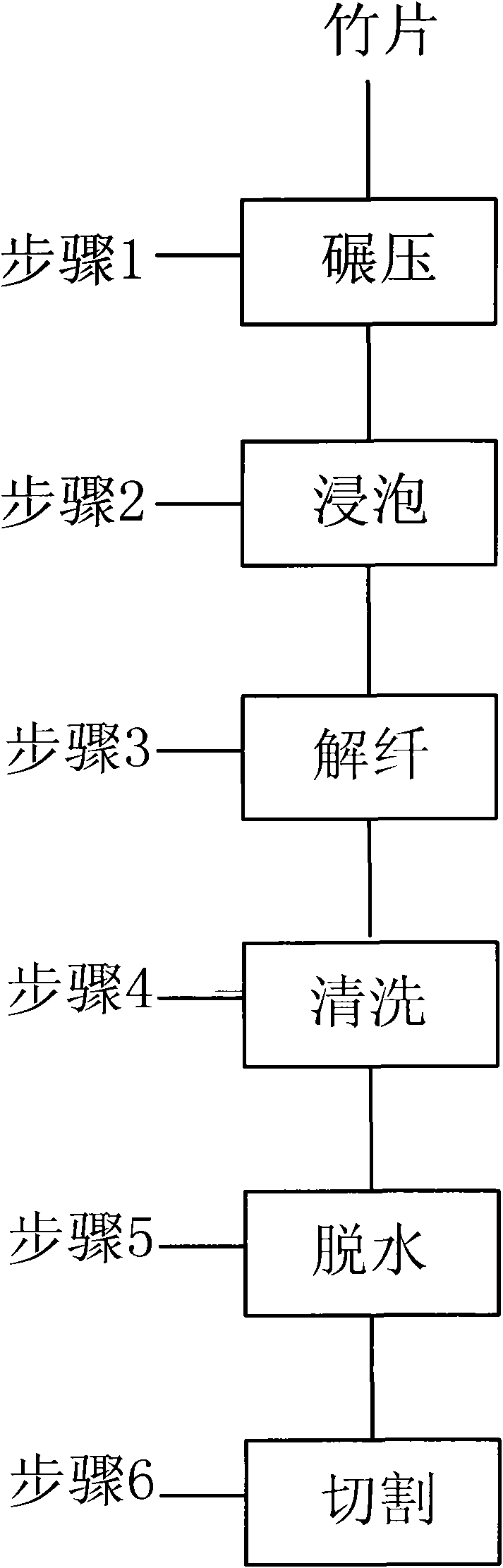

Method for manufacturing bamboo fibers

ActiveCN101934545AQuick removalReduce chemical pollutionWood working apparatusChemical reactionSingle fiber

The invention provides a method for manufacturing bamboo fibers. The method comprises the following steps of: 1) rolling: rolling to crack a bamboo chip to ensure that the bamboo fibers are possibly dispersed; 2) dipping: putting the bamboo chip into a reaction kettle, and mixing with a proper amount of reactant for 10 to 90 minutes to remove lignin, polysaccharide, colloid and protein on the surface of the bamboo fiber; 3) defibering: reducing the pressure instantaneously to standard atmospheric pressure to ensure that the bamboo chip is exploded in the reaction kettle and defibered to form a single-fiber bamboo chip; 4) cleaning: washing the bamboo fibers with hot water with the temperature of between 50 and 100 DEG C at least twice to remove byproducts from the surfaces of the bamboo fibers; 5) dewatering: drying the cleaned bamboo fibers to obtain a dry bamboo fiber finished product; and 6) cutting: cutting the bamboo fibers into bamboo fibers with a proper length. By adopting a physical instantaneous depressurized explosion mode and a chemical reaction reagent dipping mode, the bamboo chip is treated by steps, and the instantaneous depressurized explosion also accelerates thereacting speed of the chemical reagent and the bamboo chip to achieve the effect of quickly removing the lignin, the polysaccharide, the colloid and other substances from the surface of the bamboo chip.

Owner:宁波竹源新材料科技有限公司

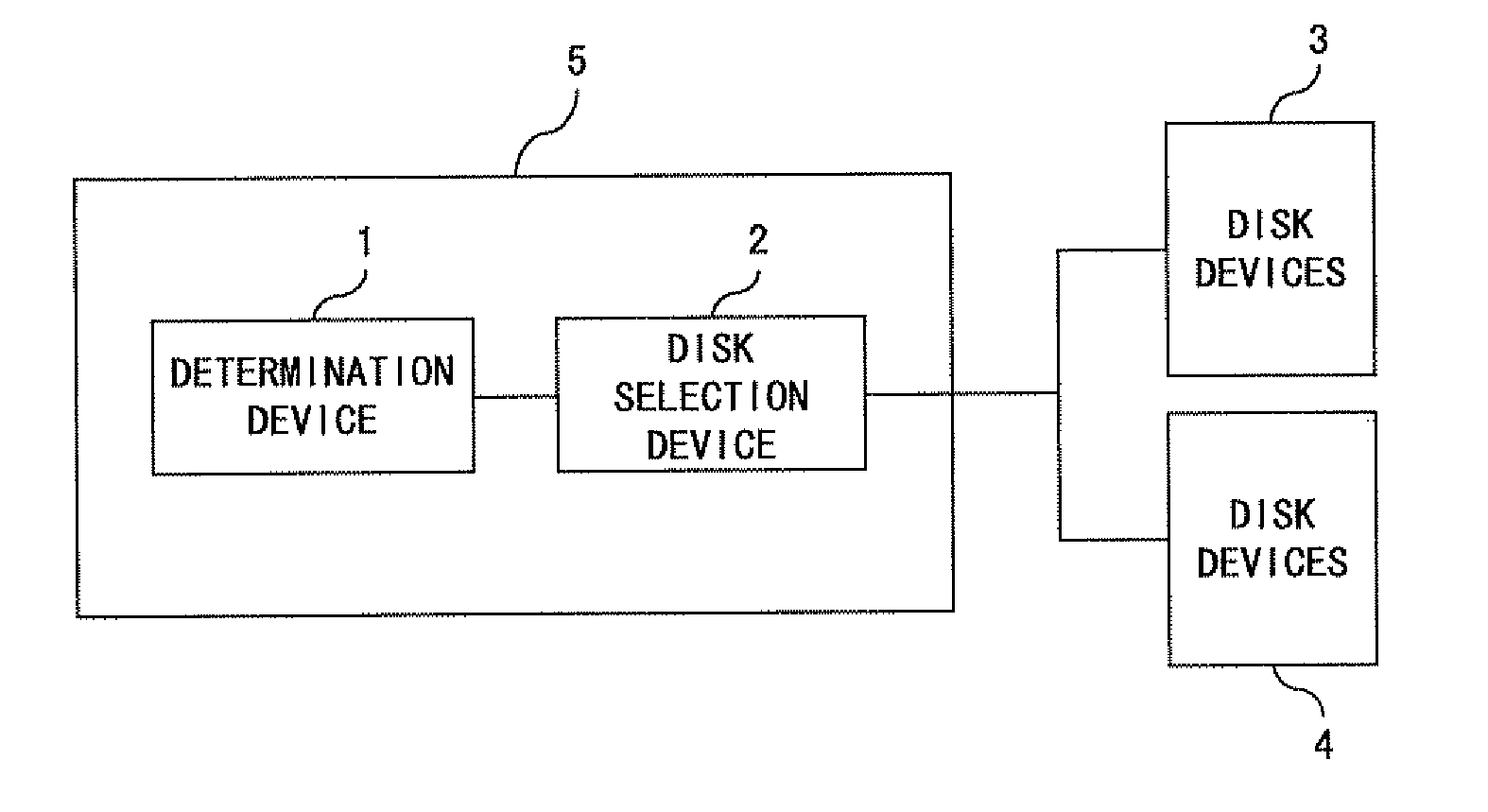

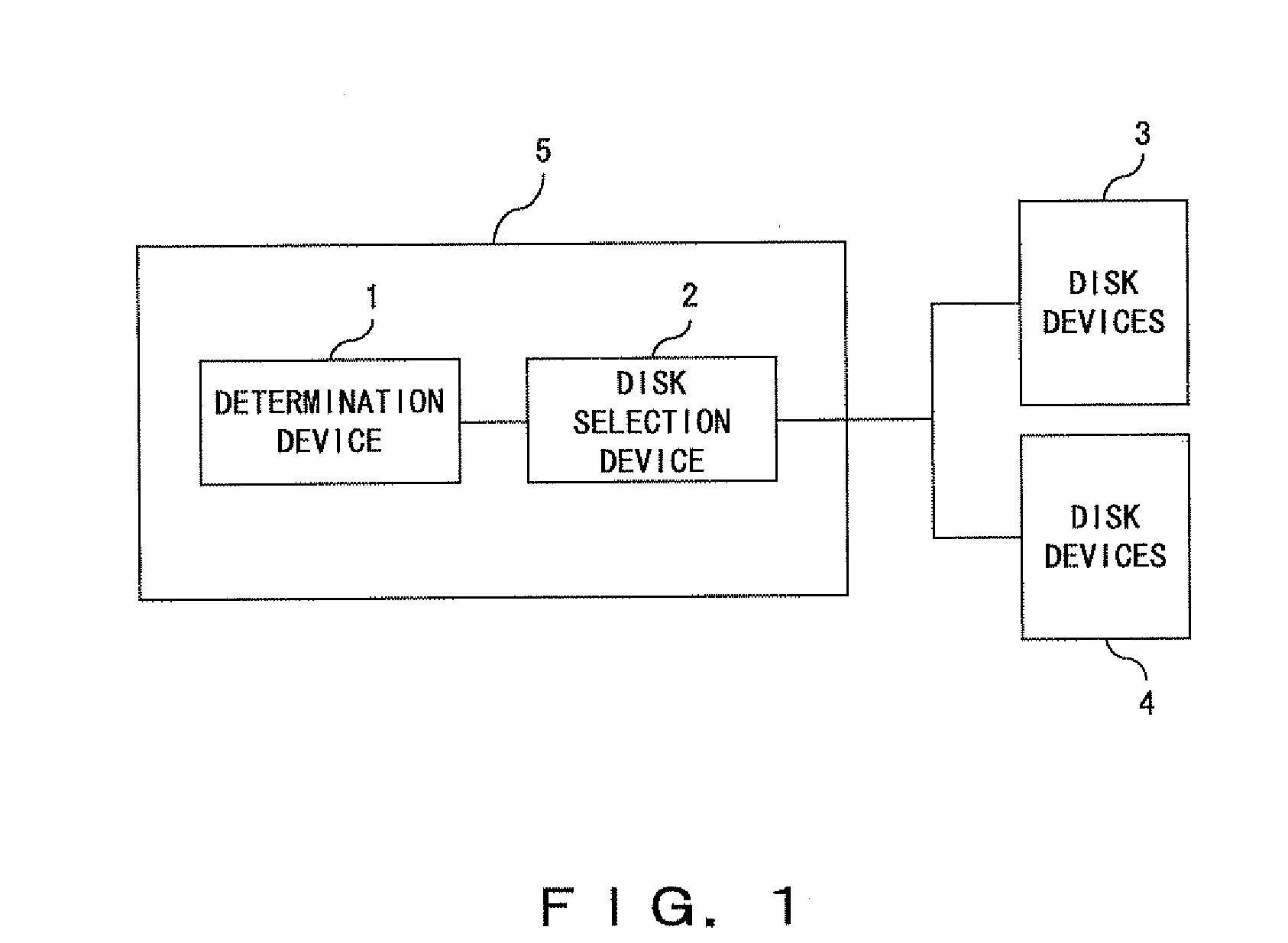

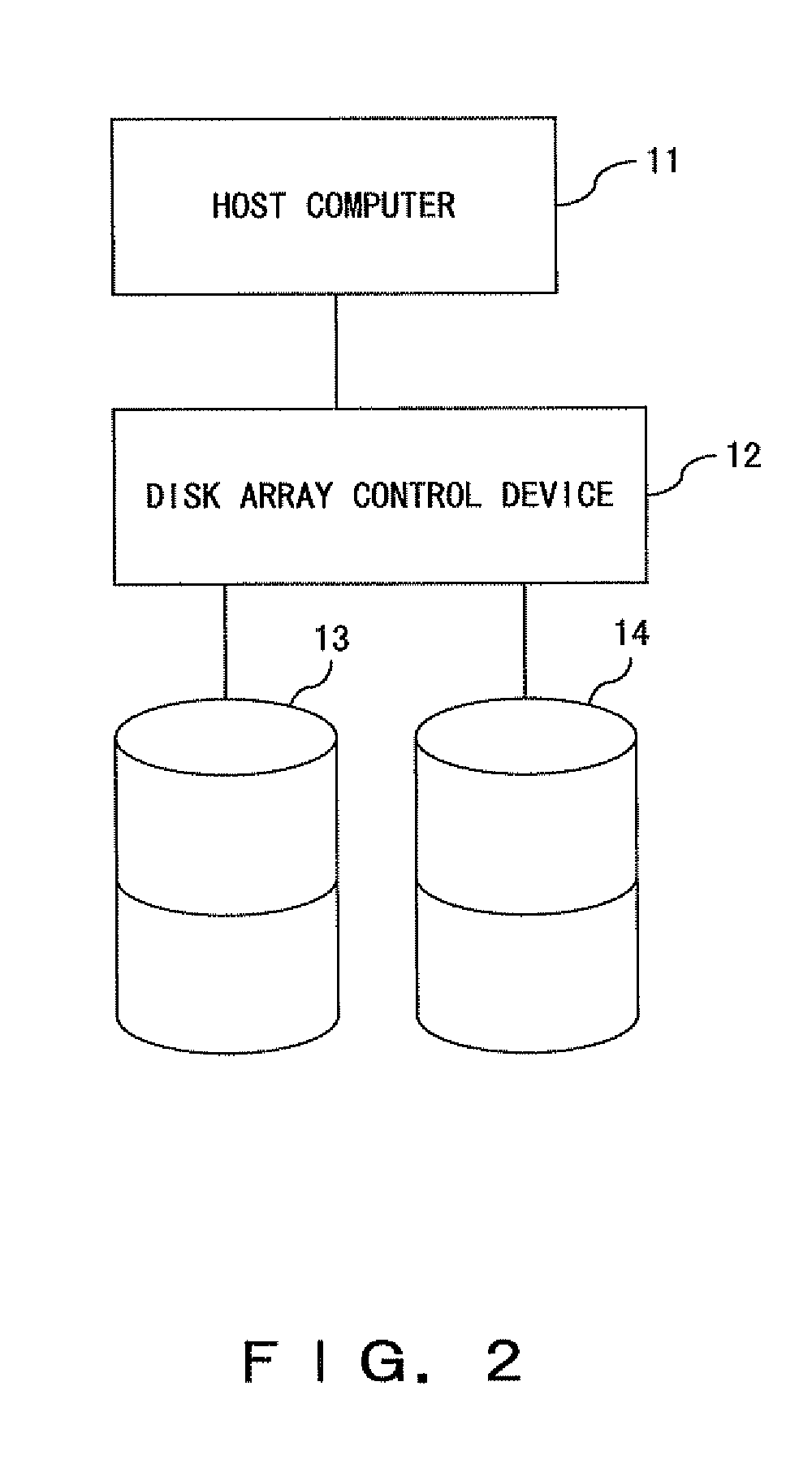

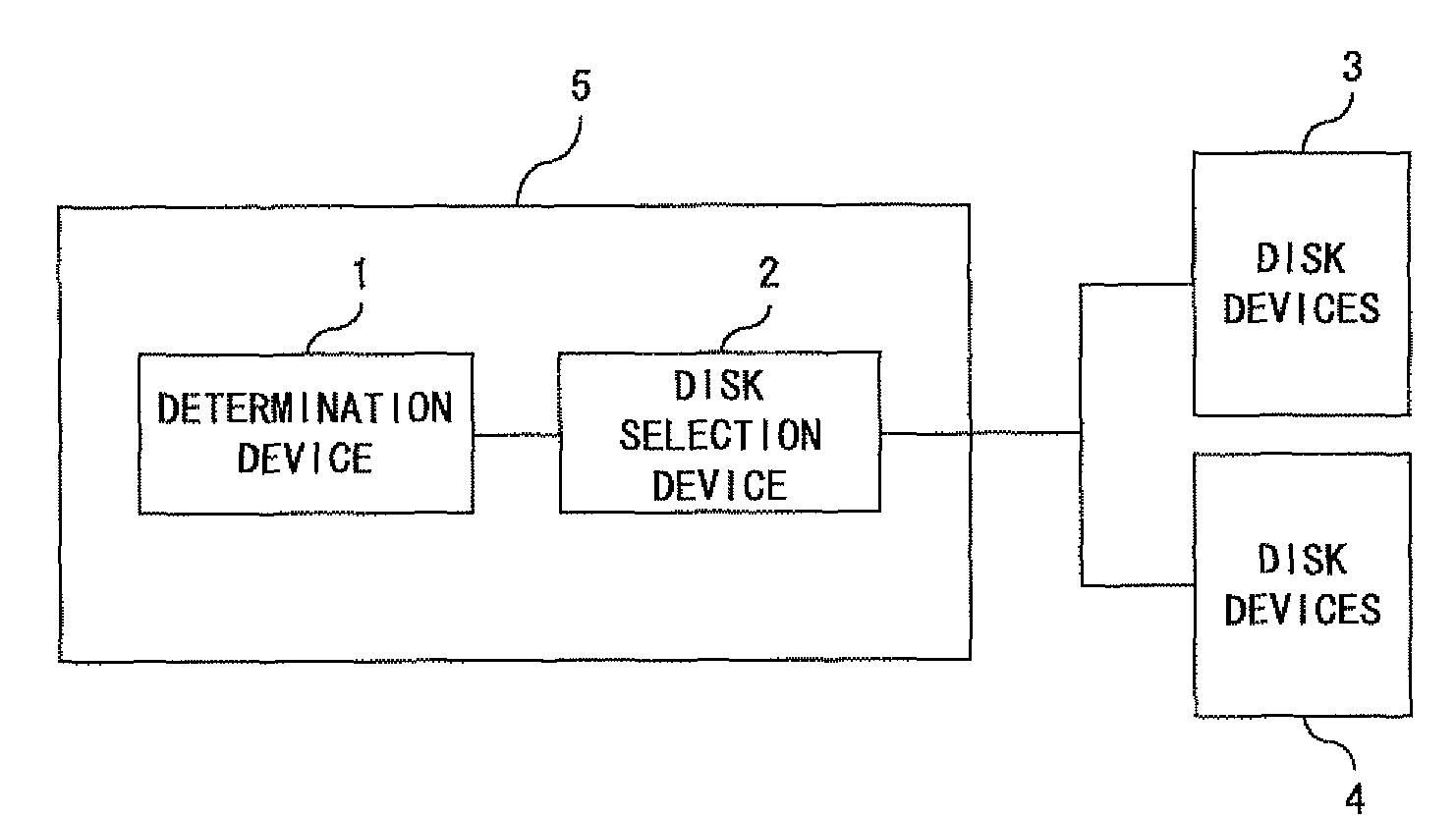

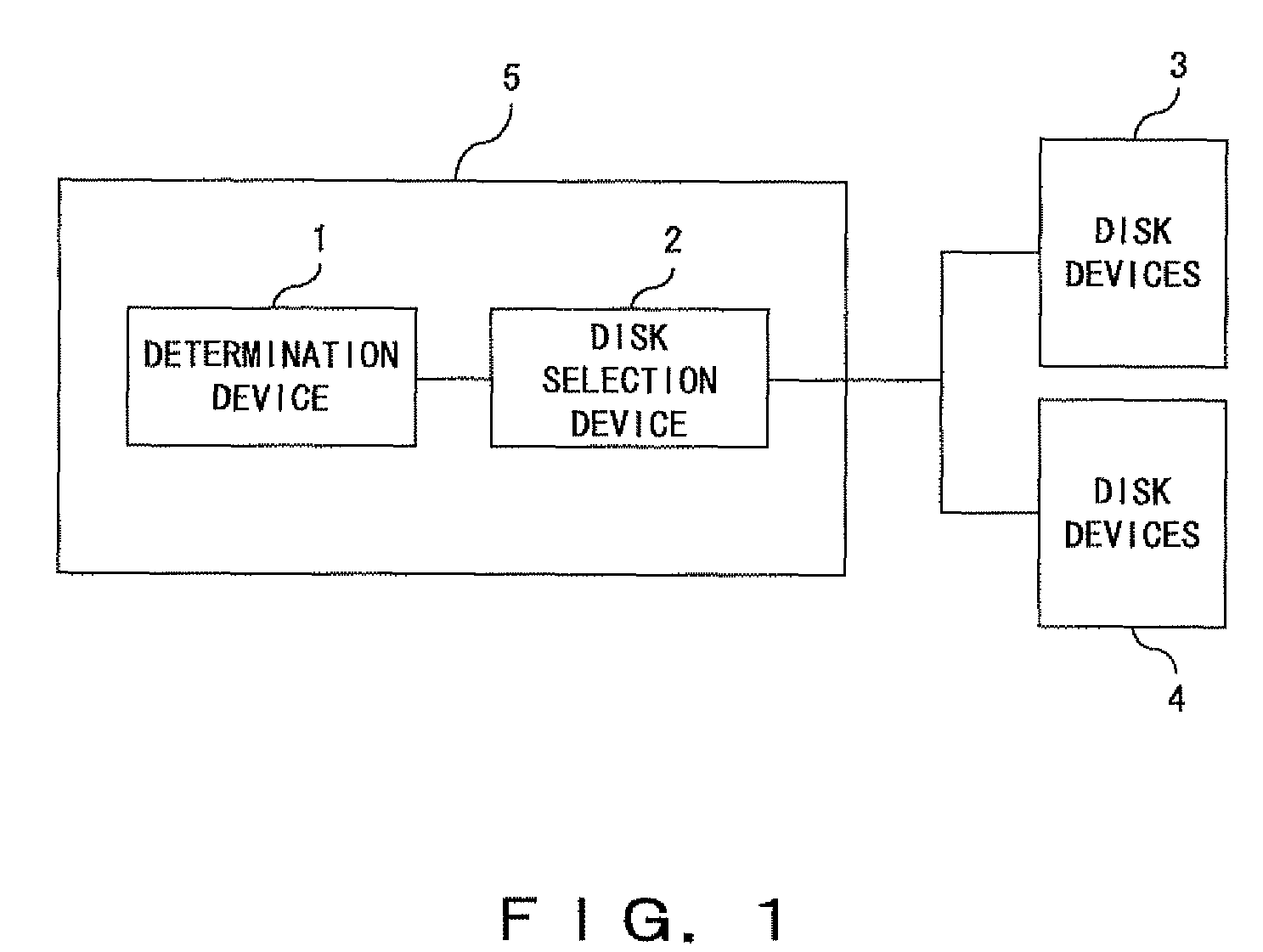

Disk selection method, raid control device, raid system, and its disk device

A response of a disk device during rebuild can be sped up. A disk array control device determines whether or not there is a normal read request during rebuild. If there is a read request during rebuild, data is read by sequentially switching a plurality of disk devices in a certain block size unit lower than a block size in which each disk device reads data during normal read.

Owner:FUJITSU LTD

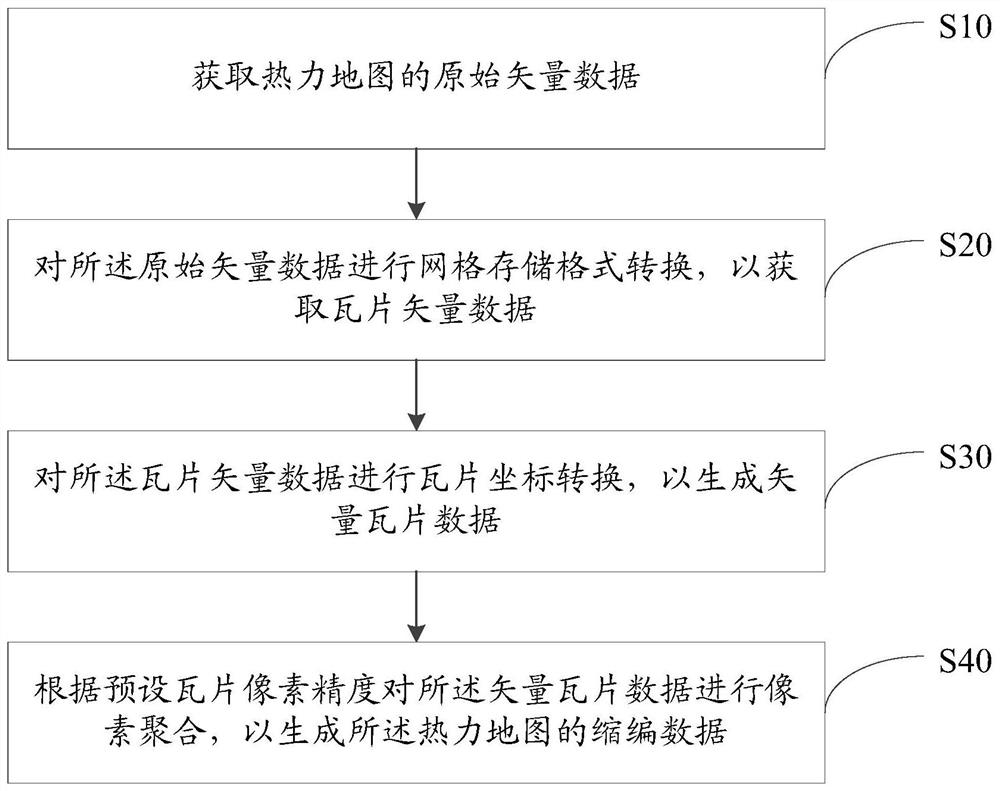

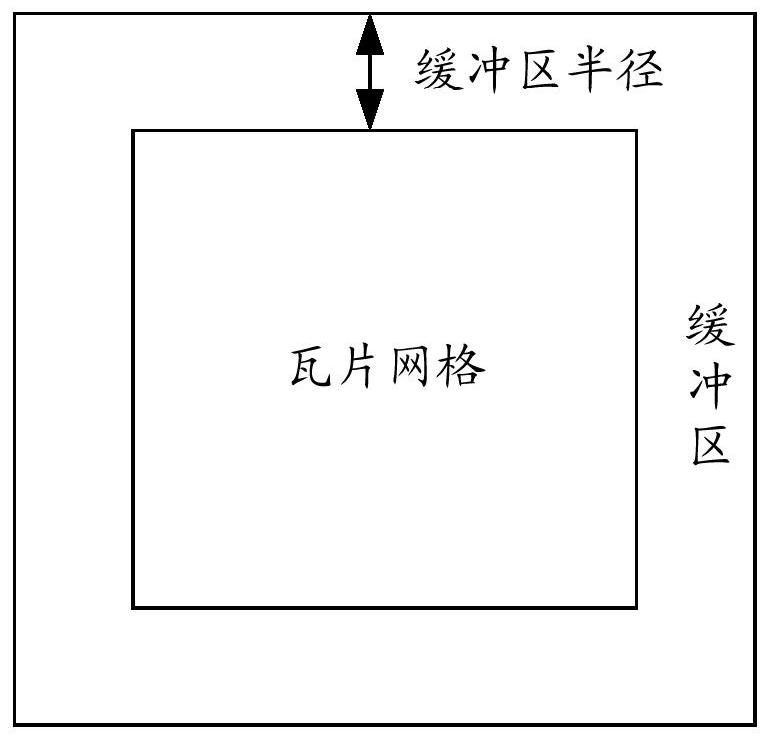

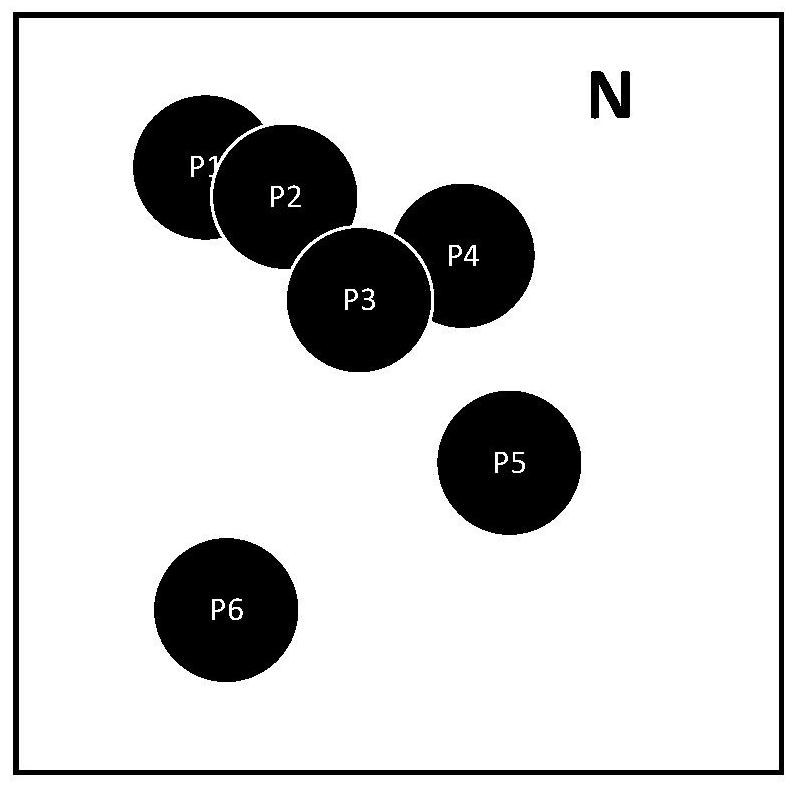

Thermodynamic diagram data abbreviation method based on vector tiles

PendingCN111915690APromote generationShortcut generationImage codingEnergy efficient computingAlgorithmEngineering

The invention relates to the technical field of data processing, in particular to a thermodynamic diagram data abbreviation method based on vector tiles. The method comprises the following steps: acquiring original vector data of a thermodynamic map; performing grid storage format conversion on the original vector data to obtain tile vector data; performing tile coordinate conversion on the tile vector data to generate vector tile data; and performing pixel aggregation on the vector tile data according to preset tile pixel precision so as to generate abbreviated data of the thermodynamic map.The vector data is converted into the vector tile data, so that the thermodynamic map can be subjected to block loading according to the tile grids, and the response speed is increased; the data volume for rendering the thermodynamic map is small; the thermodynamic map data is simple and quick to generate, high in loading performance and quick in response, and the user experience is improved.

Owner:BEIJING GEOWAY SOFTWARE

Zinc oxide/nickel composite micron rod electrode material and preparation method thereof

ActiveCN109301221ASpeed up the responseImprove electrochemical activityMaterial nanotechnologyCell electrodesEthylenediamineZinc nitrate

The invention discloses a zinc oxide / nickel composite micron rod electrode material and a preparation method thereof. The method includes, preparing a precursor by taking a mixed solution of zinc nitrate, nickel nitrate and ethylenediamine as a raw material through a homogeneous precipitation method; and then calcining the precursor in a hydrogen argon mixed reduction atmosphere to prepare the zinc oxide / nickel composite micron rod material. The material has the advantages of high initial coulomb efficiency, high reversible capacity, good cycle stability and the like when the material is usedas a lithium ion battery cathode material.

Owner:TAIZHOU UNIV

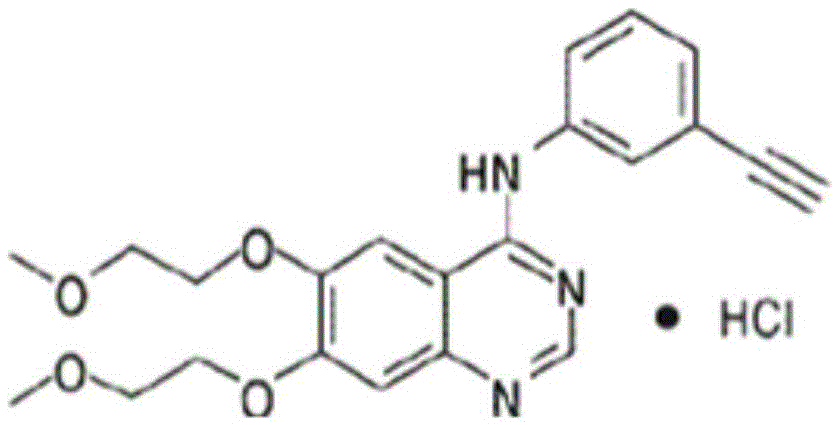

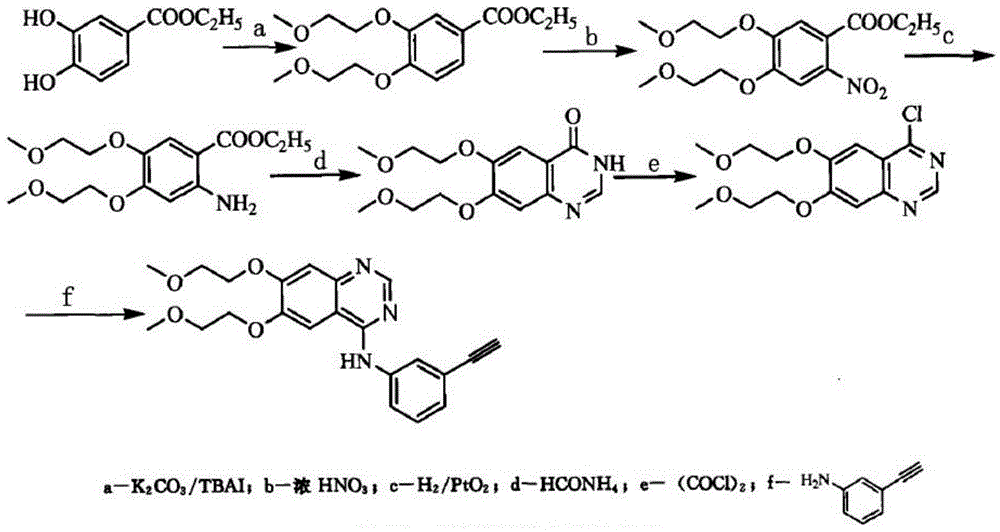

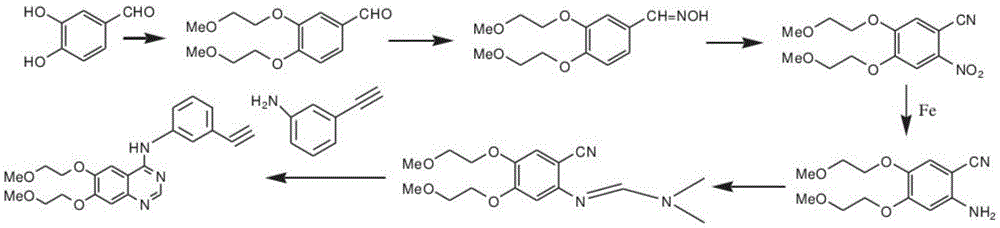

Preparation method of erlotinib hydrochloride

The invention discloses a preparation method of erlotinib hydrochloride. The preparation method comprises the following steps of using 3,4-dihydroxy benzaldehyde (compound I) as a starting raw material; converting an aldehyde group into a cyano group; undergoing six-step reactions of oxyalkylating a side chain, nitrating, hydrolyzing the cyano group, reducing a nitro group, cyclizing and performing salt formation to obtain the erlotinib hydrochloride. According to a synthetic method, the starting material is simple, low in price and easily-obtained; compared with an existing route of first closing ring, then chloridizing and finally ammonifying; the synthetic method disclosed by the invention has the advantages that steps are reduced, the yield is increased, the reaction process is easy in operation and the preparation cycle is shorter; meanwhile, the use of chlorinating agents such as phosphorus trichloride, phosphorus pentachloride, thionyl chloride, phosgene or phosphorus oxychloride with corrosivity is also avoided; the preparation method is suitable for industrial production.

Owner:SHANDONG LUOXIN PHARMA GRP HENGXIN PHARMA CO LTD

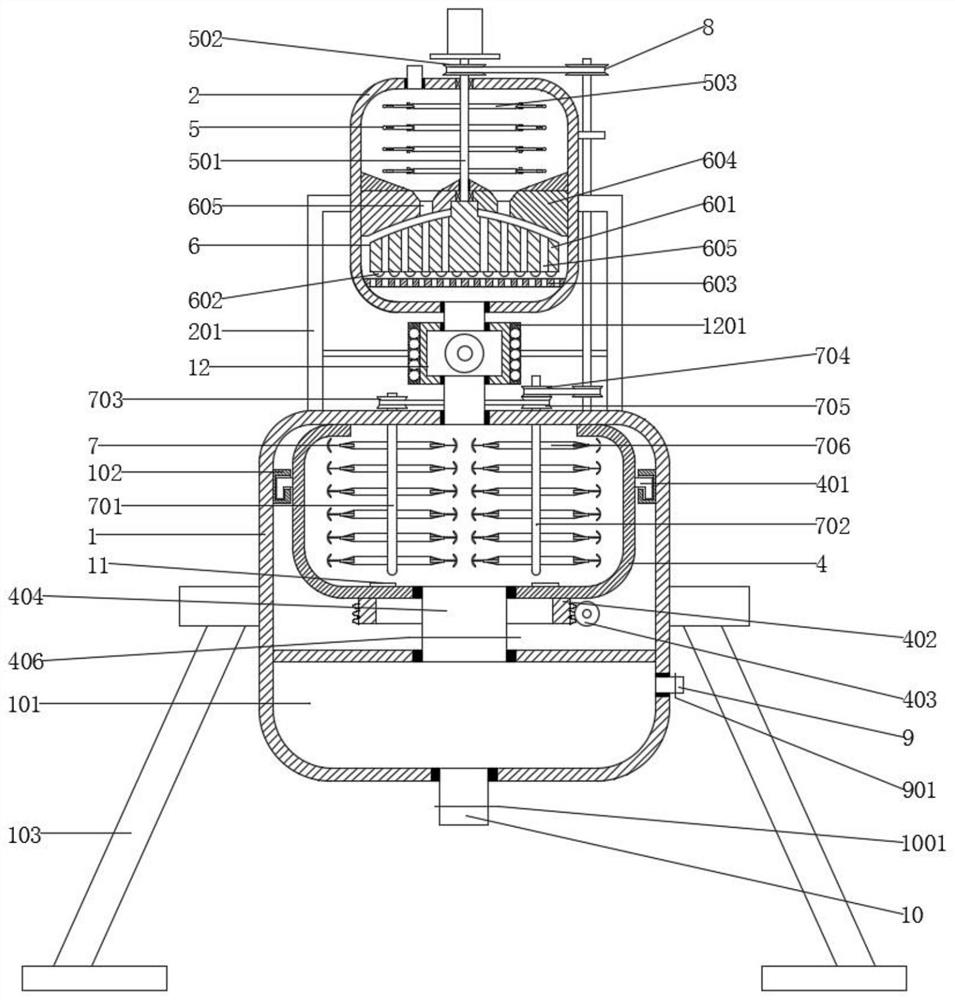

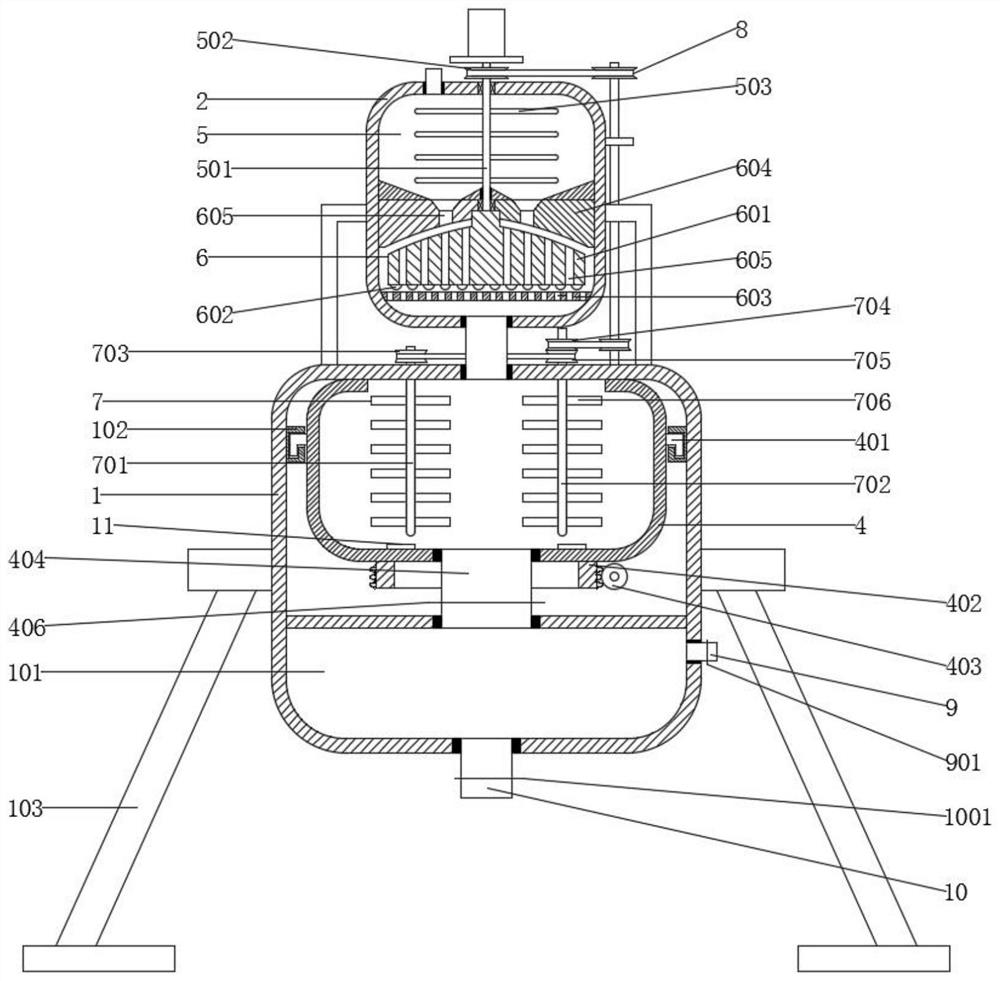

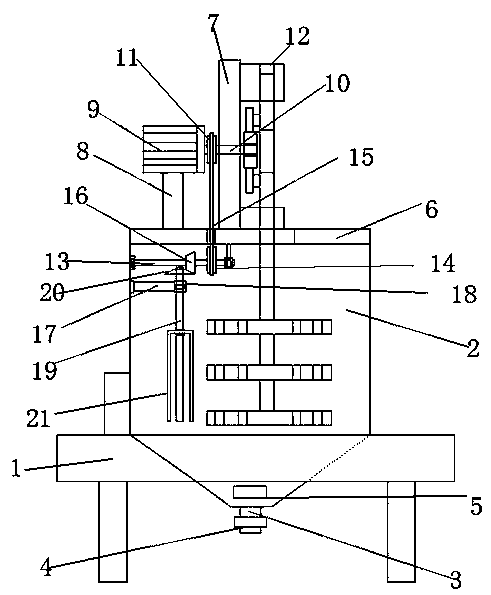

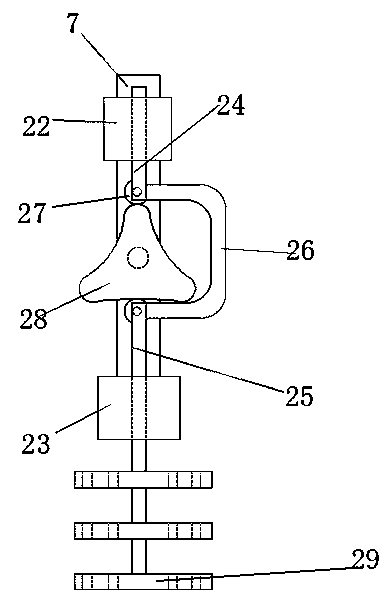

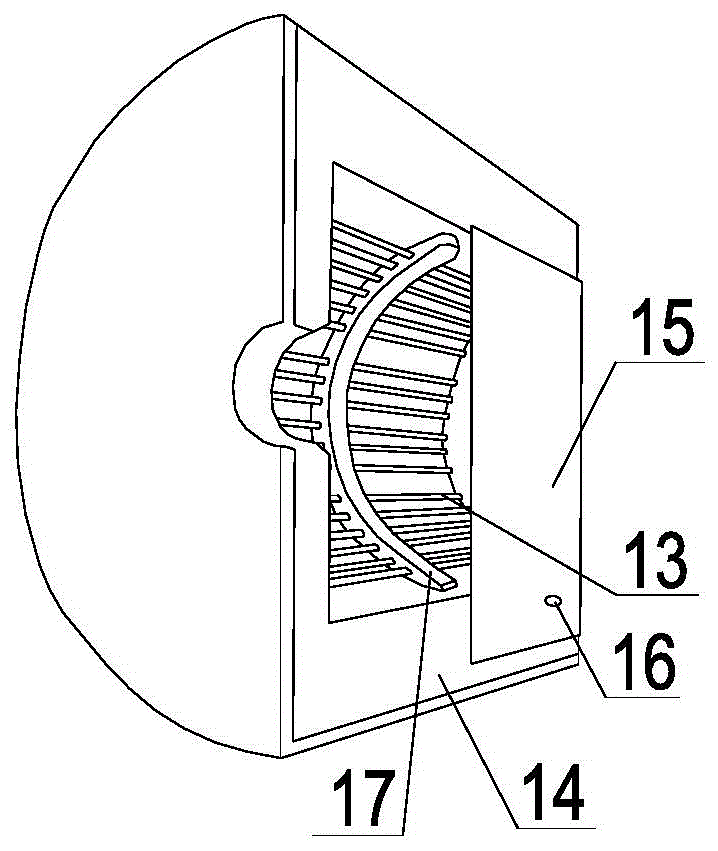

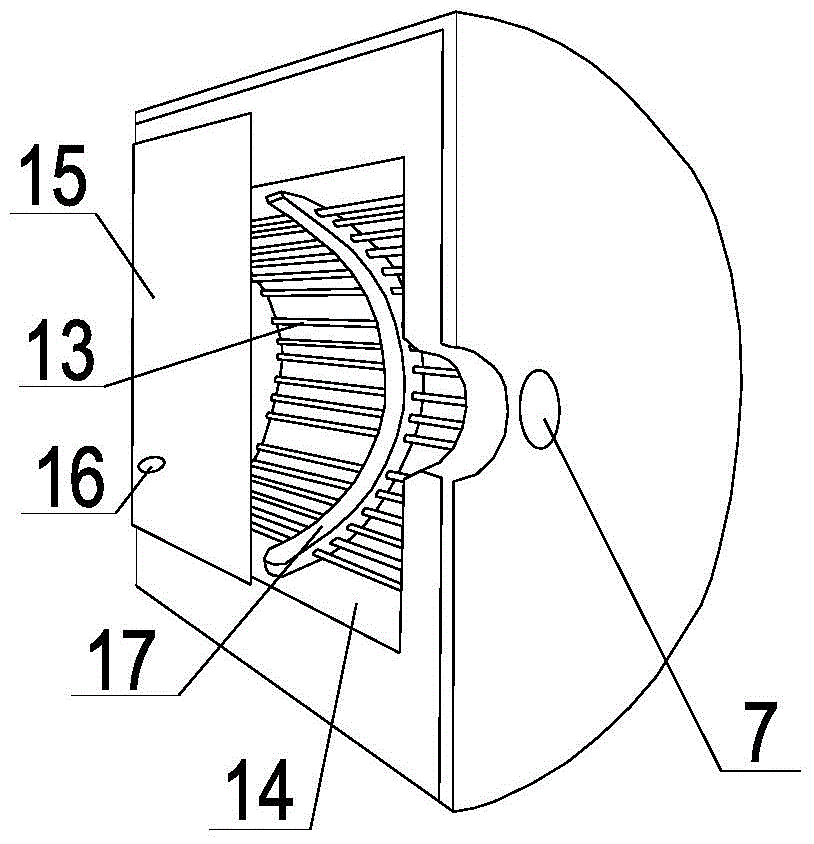

Purification equipment for protein polypeptide in peanut meal

ActiveCN111808163AThe mixed reaction is thoroughGuaranteed ExtractionPeptide preparation methodsEngineeringPeanut meal

The invention relates to the technical field of purification of protein polypeptide in peanut meal, in particular to purification equipment for protein polypeptide in peanut meal. The peanut meal is pretreated through a grinding box, condensed peanut meal is dispersed through a material dispersing mechanism, the peanut meal is ground into fine particles through a grinding mechanism, subsequent peanut meal and a solution are effectively mixed and react thoroughly, the extraction amount of the protein peptide is guaranteed, waste of peanut meal raw material is reduced, and the conversion rate isincreased; a turbine and a worm are matched to drive a reaction box to rotate, the reaction box drives the internal solution and the peanut meal to rotate and mix, and a mixing mechanism continuouslystirs the solution and the peanut meal, so that the mixing speed and the mixing uniformity are improved, the reaction time is shortened, and the mixing efficiency and the processing efficiency are improved; and a premixing box premixes the solution and peanut meal, a preheating layer preliminarily heats the solution and the peanut meal, the reaction speed is increased, the mixing time in the reaction box in the later period is shortened, and a solution box is arranged at the rear end of the grinding box, so that the interior of the premixing box is convenient to clean.

Owner:江西天禹科技协同创新有限公司

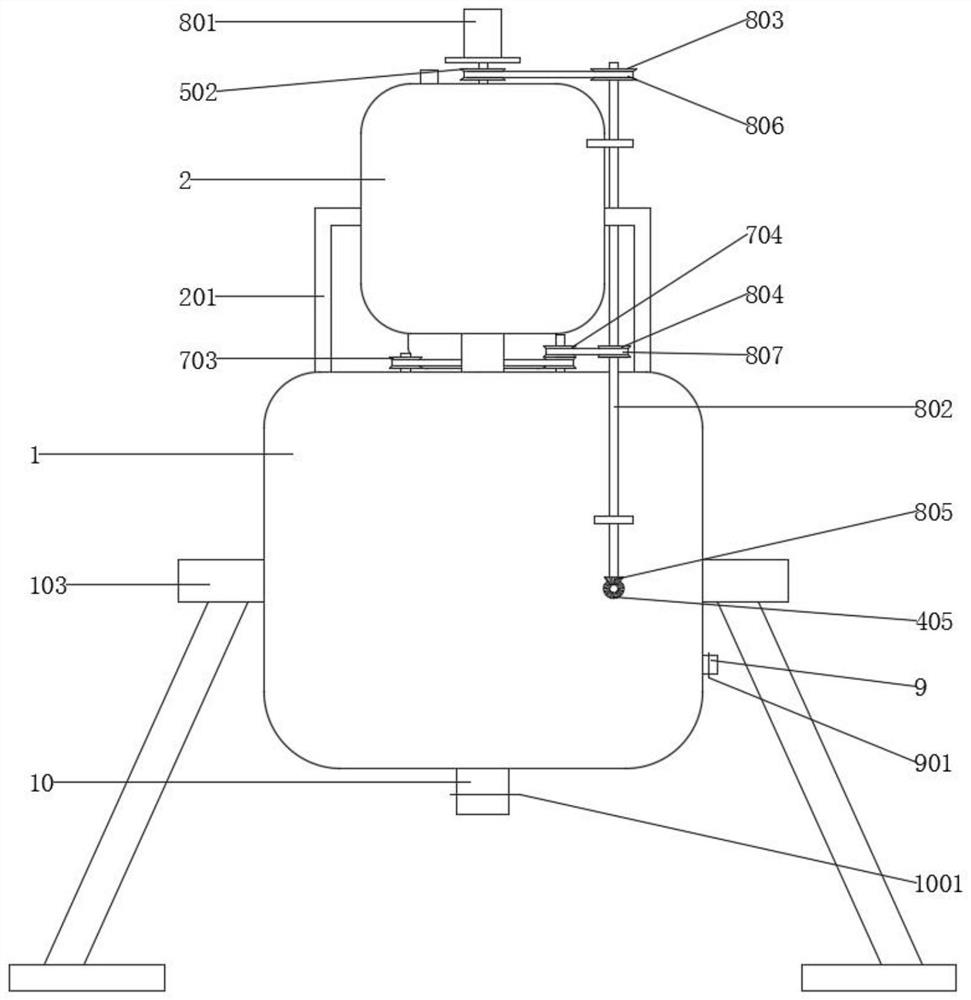

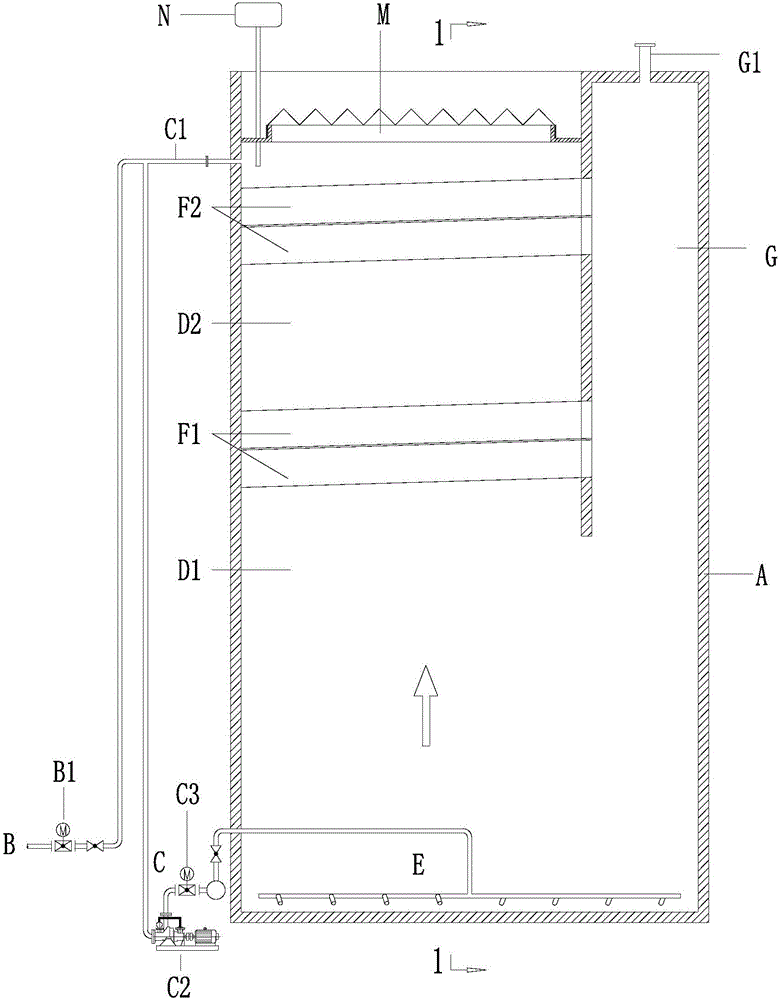

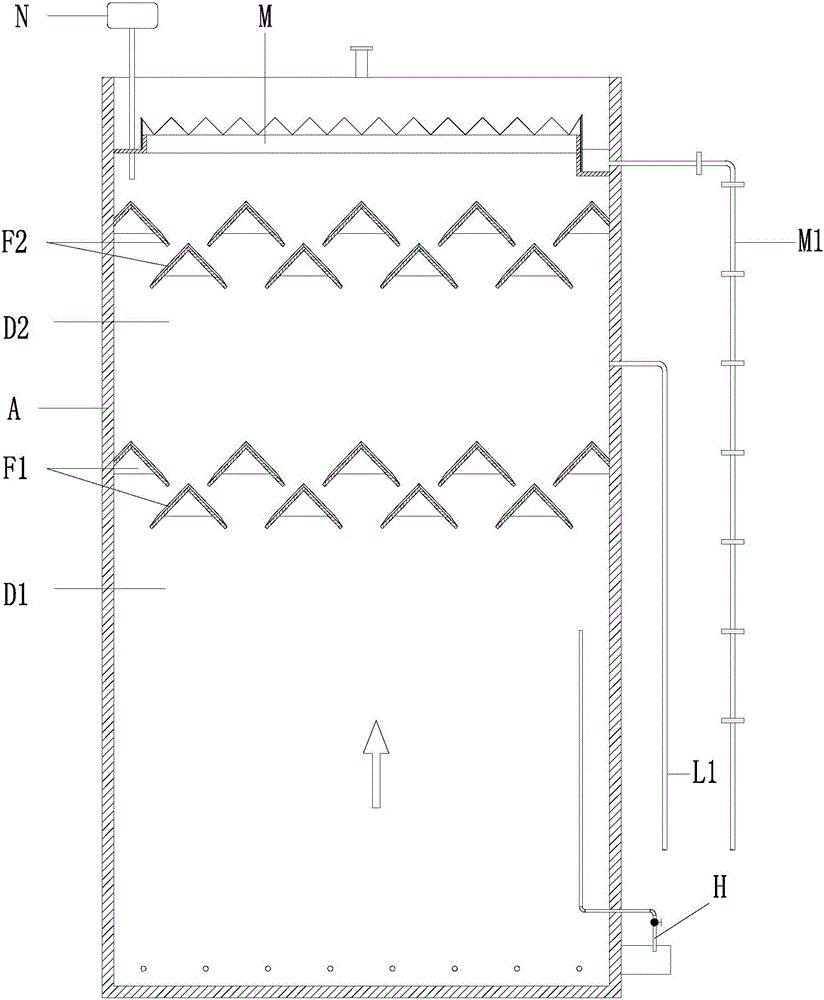

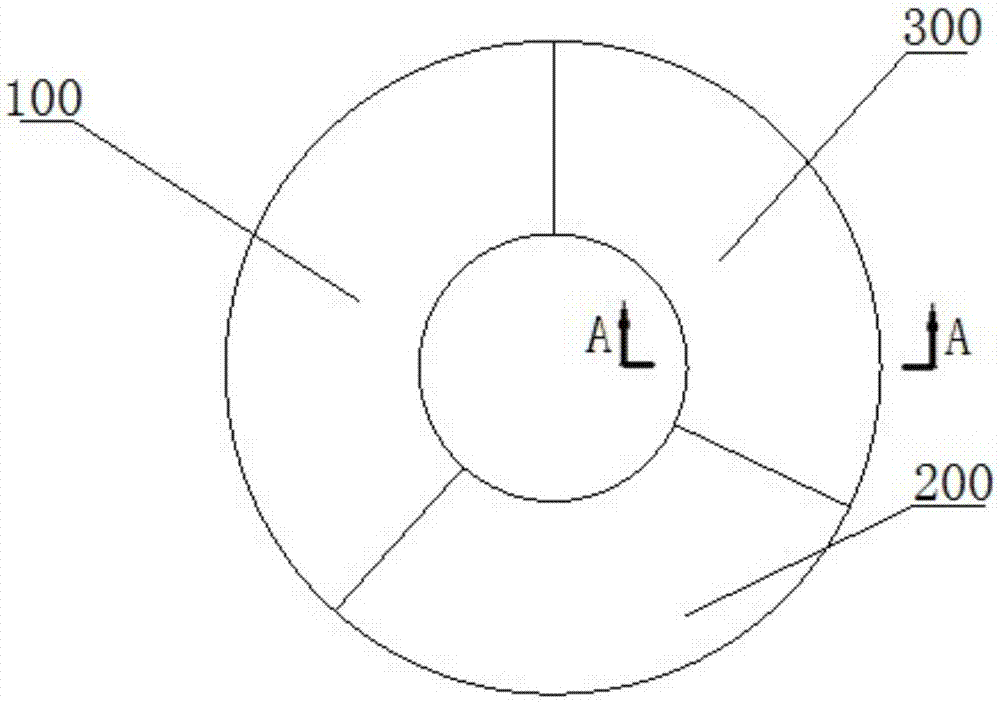

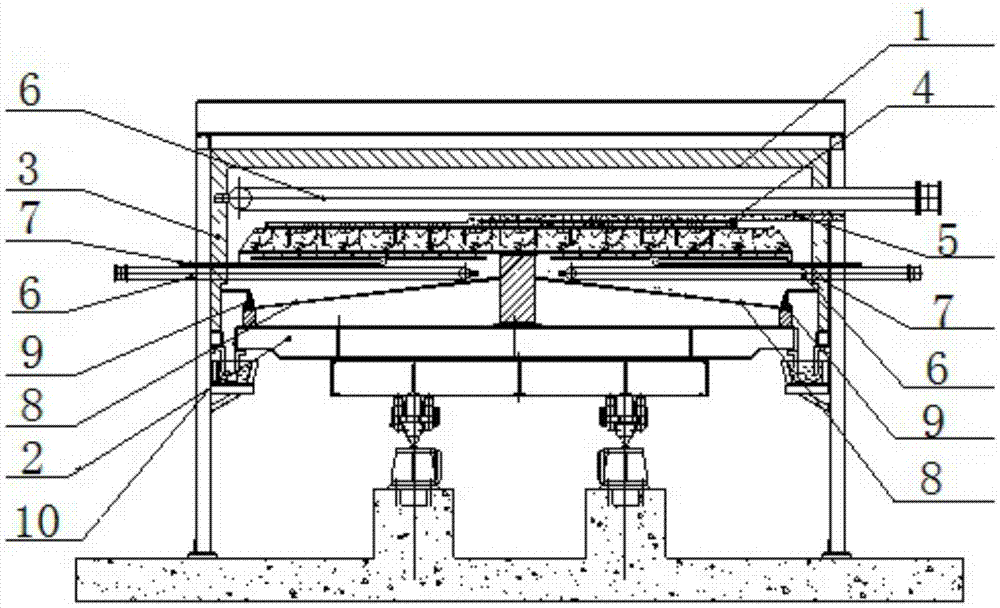

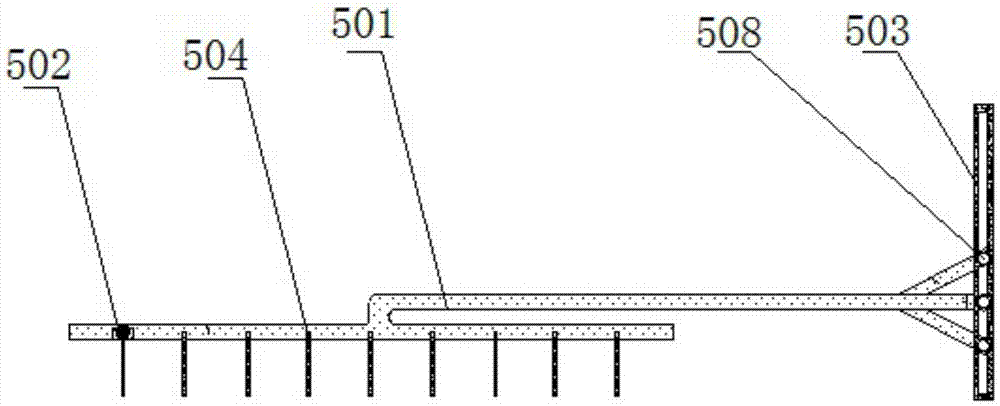

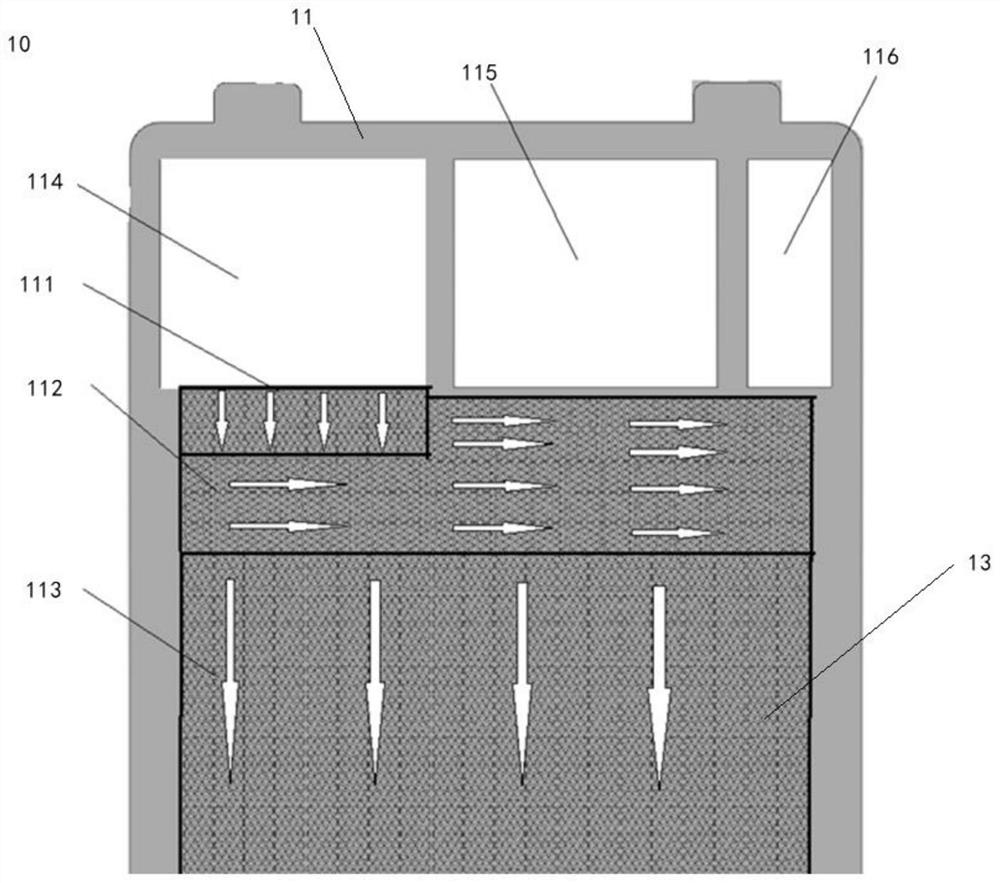

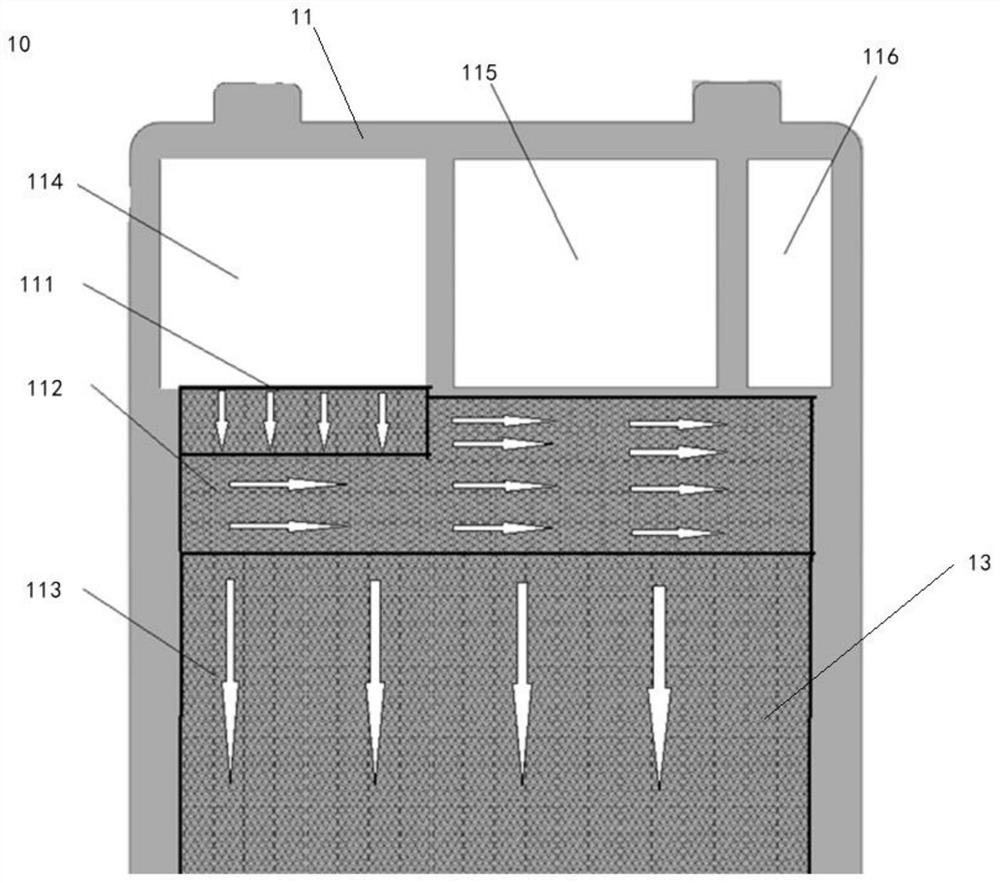

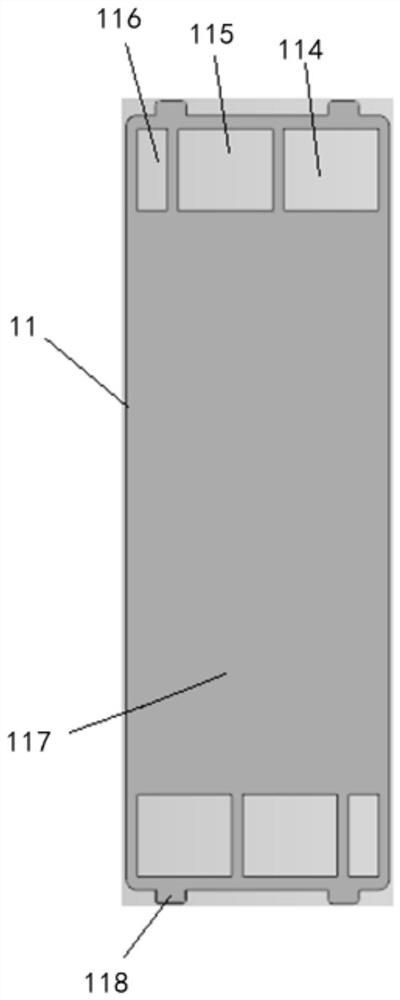

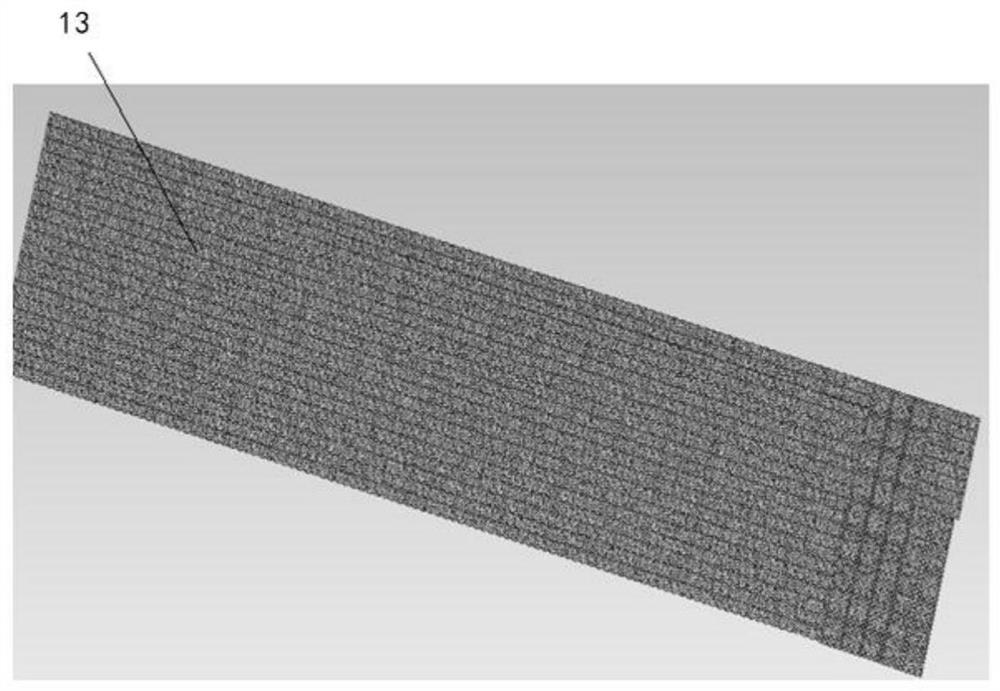

Efficient anaerobic bioreactor for treating leachate of waste incineration plant

ActiveCN105668781AReduce load shockSpeed up the responseWaste based fuelTreatment with anaerobic digestion processesAutomatic controlDistribution system

The invention relates to an anaerobic bioreactor for treating leachate of a waste incineration plant.The anaerobic bioreactor mainly comprises an anaerobic tank, a water distribution system, a reaction system, a biogas collecting system and a water discharge system.The anaerobic bioreactor has the advantages that landfill leachate directly flows into a reflux pipe, and struvite crystal generation of a reflux system and the water distribution system is avoided; water inflow is diluted while the ascending flow speed of the reactor is increased by the aid of internal reflux, anaerobic sludge is in an expansion state in the vertical direction, anaerobic microorganisms sufficiently contact with matrix to reach a good mass transfer effect, the organic pollutants in the leachate of the waste incineration plant are removed efficiently, volume load can reach 8-10kgCOD / m<3>.d, and COD removing rate reaches up to 85-95%; the reactor is low in energy consumption, high in gas production rate, beneficial to energy recycling, capable of achieving automatic control, simple in operation, stable and durable, short in construction period, small in floor space and capable of saving land resources, and the floor space of the reactor is about 40% of that of other anaerobic systems.

Owner:深圳市南科大资产经营管理有限公司

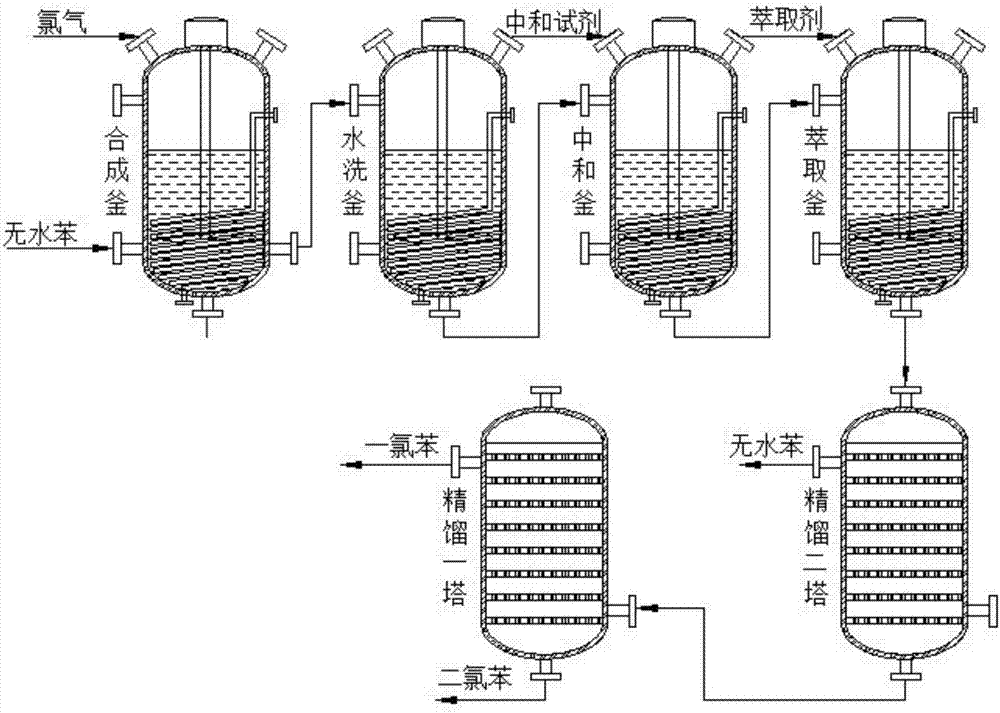

Novel chlorobenzene production process

InactiveCN109096042AHigh conversion selectivityReduce outputHalogenated hydrocarbon preparationGeneration rateChlorobenzene

The invention provides a novel chlorobenzene production process. Chlorobenzene used in the novel chlorobenzene production process comprises the following raw materials: anhydrous benzene, chlorine, acatalyst and a positioning agent. The novel production process comprises the following steps: preparing the anhydrous benzene; enabling the anhydrous benzene to flow out from the bottom of a benzene high-level tank, metering by using a flowmeter, and continuously putting into a chlorinator from the bottom of the chlorinator; buffering qualified chlorine made after gasification of liquid chlorine by using a chlorine buffer tank, introducing into the chlorinator from the bottom of the chlorinator to flow upwards together with the anhydrous benzene along flows in a same direction, carrying out areaction under the action of the catalyst and the positioning agent in the chlorinator so as to generate a chlorination liquid, and carrying out aftertreatment on the chlorination liquid, thereby obtaining chlorobenzene. By adopting the novel production process provided by the invention, the problem that a great deal of wastewater is generated from water washing and alkali washing in the conventional method can be avoided, no wastewater is generated, in addition, the catalyst is long in service life, the equipment is long in service life, the detection cycle can be prolonged, a product made byusing the process is high in purity, and due to adoption of an iron catalyst and chelate EDTA-Fe with iron as the center as the positioning agent, the process is low in wastewater generation rate andgreen, environmentally friendly and fee of pollution.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

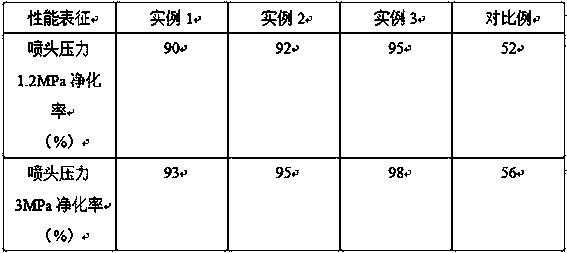

Preparation method of oil fume high-efficiency purification additive

InactiveCN109055060AStrong decontaminationImprove decontamination abilityPolymeric surface-active compoundsUsing liquid separation agentSolubilityDecomposition

The invention relates to a preparation method of an oil fume high-efficiency purification additive, and belongs to the technical field of environment-friendly cleaning. The method has the advantages that spinach leaf boiling deionized water has a certain degreasing effect due to weak basicity, glycol ether can be dissolved in water and oil due to excellent dissolving capacity, and a surfactant hasexcellent compatibility and can rapidly dissolve contacted greasy dirt into a solvent; D-limonene in citrus peels has excellent dirt-removing power, triethanolamine can produce triethanolamine oleicsoap with oleic acid, produce triethanolamine sodium sulfonate with sodium dodecyl benzene sulfonate, and rapidly emulsification decomposition on greasy dirt; in addition, the reset unreacted triethanolamine can ensure that the purification additive continuously keep weak basicity, the triethanolamine can continuously perform neutral reaction with fatty acid, and the dirt-removing power is enhanced; the additive is good in water solubility, can rapidly emulsify greasy dirt, and is high in purification efficiency and low in damage to purification equipment.

Owner:何治伟

Activated carbon preparation device

ActiveCN105439142ASpeed up the responseGuaranteed anaerobicCarbon compoundsActivated carbonCarbonization

The invention relates to the technical field of organic matter pyrolysis and activated carbon, in particular to an activated carbon preparation device which comprises a sealed hearth defined by a furnace wall, a furnace top and a furnace floor. The furnace floor moves in the horizontal extension direction of the furnace wall, and a layer of overhead distributing plates is fixed above the furnace floor. The hearth comprises a drying area, a carbonization area and an activation area which are sequentially arranged in the horizontal extension direction of the furnace wall. The drying area, the carbonization area and the activation area are separated through partition plates, and gaps are reserved between the partition plates and the distributing plates to be used for materials to pass. A plurality of radiation heating pipes are arranged in the drying area, the carbonization area and the activation area. An oxidizing gas channel communicated with the outside is arranged in the activation area. A plurality of overturning devices are arranged above distributing plates of the drying area, the carbonization area and the activation area and used for overturning the materials. According to the activated carbon preparation device, continuous production is achieved, and the activation efficiency is improved.

Owner:SHENWU TECH GRP CO LTD

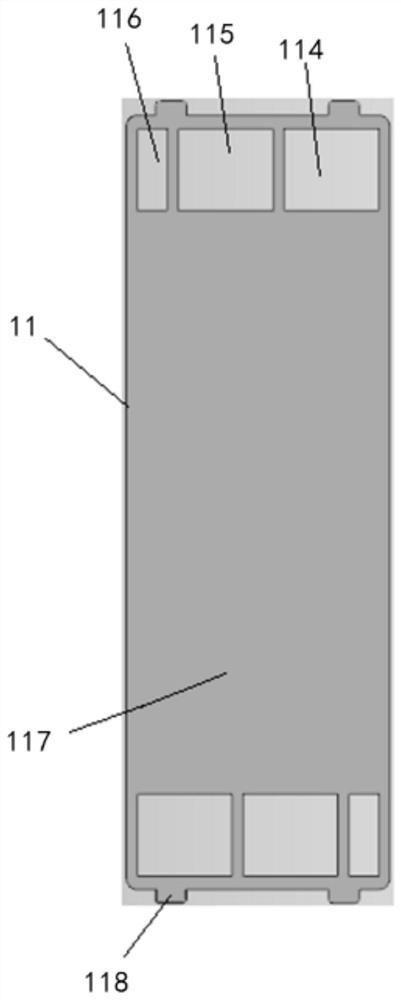

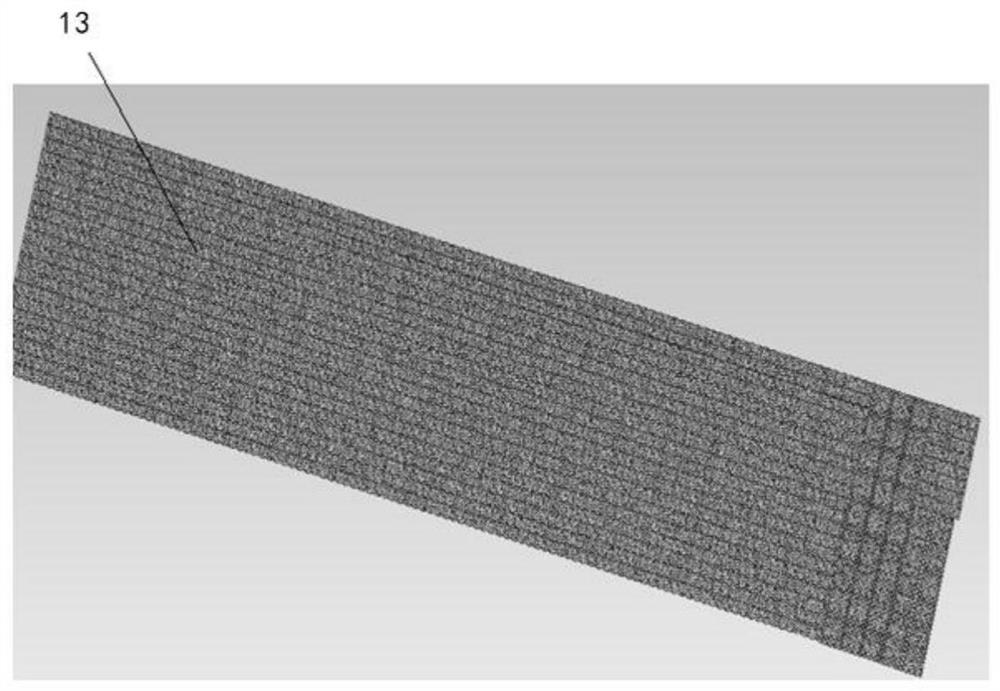

Bipolar plate structure capable of being used for fuel cell, fuel cell and fuel cell vehicle

ActiveCN112242534AIncrease flow rateHigh activityMotive system fuel cellsFuel cellsMechanical engineering

The present disclosure relates to a bipolar plate structure usable for a fuel cell, comprising: a substrate having a plurality of flow regions for a fluid thereon; a mesh structure having mesh holes,wherein the mesh structure is provided on the substrate and forms at least one of the plurality of flow regions, and protrusions are provided at connection portions of the mesh holes to increase flowresistance transverse to a direction of the protrusions.

Owner:FTXT ENERGY TECH CO LTD

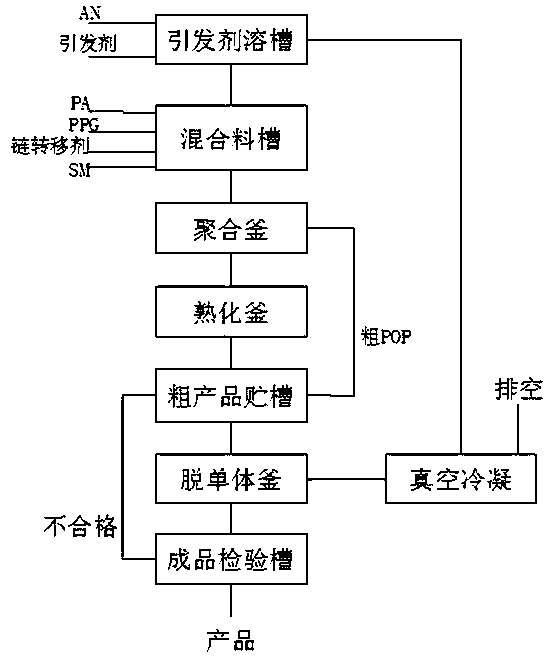

Preparation method of polymer polyol

The invention discloses a preparation method of polymer polyol. The preparation method comprises the following steps: 1) preparation of a mixture: adding acrylonitrile and azodiisobutyronitrile into an initiator dissolving tank, carrying out sufficient dissolving to obtain a mixture A, adding basic polyether and intermediate polyether into a mixture tank, adding styrene, acrylonitrile, the mixtureA and a chain transfer agent, and carrying out uniform mixing to obtain a mixture B; 2) graft polymerization: feeding the mixture B into a polymerization kettle for a polymerization reaction; 3) curing: allowing reacted materials in the polymerization kettle to overflow into a curing kettle for curing, and enabling the cured materials to enter a crude product storage tank; 4) monomer removal: conveying crude polymer polyol into a monomer removal kettle, carrying out vacuum treatment for 4-6 hours, and removing residual monomers and moisture; and 5) finished product inspection: sampling and analyzing a product in a finished product inspection tank. The method has the advantages of advanced and mature process, high conversion rate, good product quality and small influence on the environment.

Owner:LIAONING FANGDA ENG DESIGN CO LTD

Rectifying separation method for chlorinated benzene production

InactiveCN107445793AHigh conversion selectivityNot easy to cause confusionHalogenated hydrocarbon separation/purificationEnvironmental resistanceSeparation technology

The invention discloses a rectifying separation method for chlorinated benzene production. The rectifying separation method comprises the following specific steps: feeding chlorine and excessive anhydrous benzene into a chlorinator filled with an iron ring catalyst; controlling the reaction temperature at the boiling point of benzene, namely, setting the temperature to 80-90 DEG C; starting a stirrer for constant-speed and constant-temperature stirring to generate chloride liquid; washing an obtained chlorinated benzene solution by a washing tower, neutralizing by a neutralizing kettle, extracting in an extraction kettle, and distilling by a two-stage rectifying tower to obtain a finished product. The rectifying separation method for the chlorinated benzene production disclosed by the invention is a universal method of the rectifying separation technology for the chlorinated benzene production at home, and has the following main advantages: high-temperature continuous chlorination is realized; the conversion selectivity of chlorinated benzene is high, the slender chlorination reactor does not tend to cause material mixing return, and a small amount of benzene dichloride is generated; a distillation process is adopted for separation, the technology is mature and reliable, useful matters are recycled, the synthesis cost is saved, the economic benefits are increased, and the method conforms to the scientific concept of greenness, environmental protection and zero pollution.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

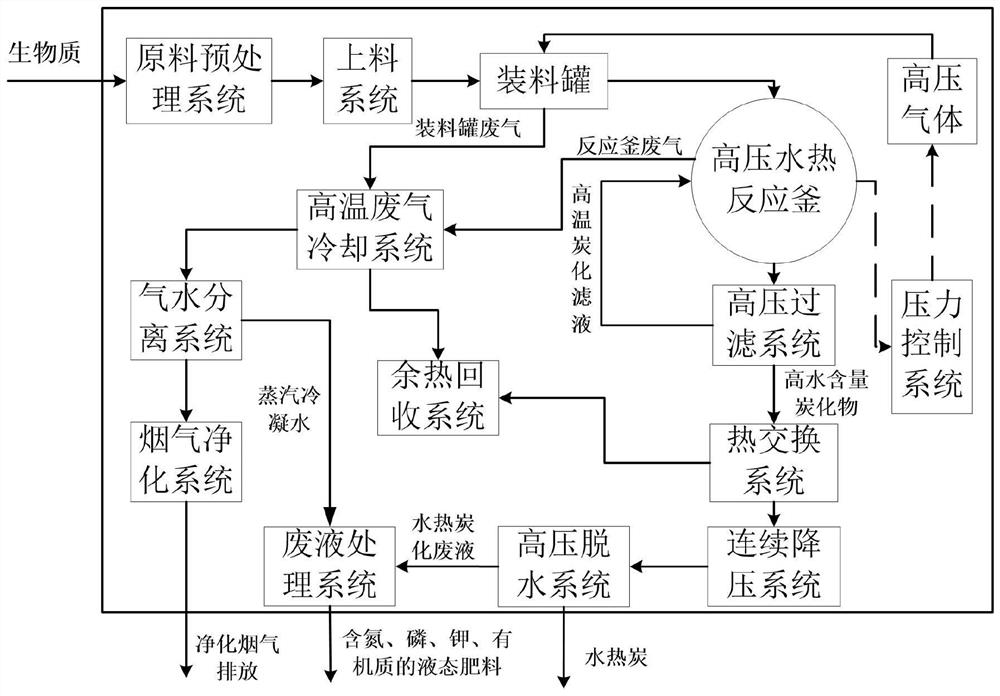

Continuous hydrothermal carbonization method

The invention discloses a continuous hydrothermal carbonization method which comprises the following steps: (1) pretreating a biomass raw material to obtain biomass solid particles, and conveying the biomass solid particles to a charging tank by a feeding system; (2) controlling the pressure of the charging tank and the high-pressure hydrothermal reaction kettle by using a pressure control system, and adding the normal-pressure biomass solid particles in the feeding system into the high-pressure hydrothermal reaction kettle, so that the hydrothermal carbonization reaction is continuously carried out; (3) completing carbonization of biomass solid particles by using the high-pressure hydrothermal reaction kettle; (4) carrying out primary solid-liquid separation on the carbonized product to obtain a high-temperature carbonized filtrate and a high-water-content carbide, and returning the high-temperature carbonized filtrate to the high-pressure hydrothermal reaction kettle to continuously participate in the carbonization reaction; and (5) treating the high-water-content carbide to obtain biomass hydrothermal carbon and carbonized waste liquid. The carbonization efficiency is improved, the carbonization energy consumption is reduced, and the method is suitable for wide popularization and application.

Owner:UNIV OF SCI & TECH BEIJING

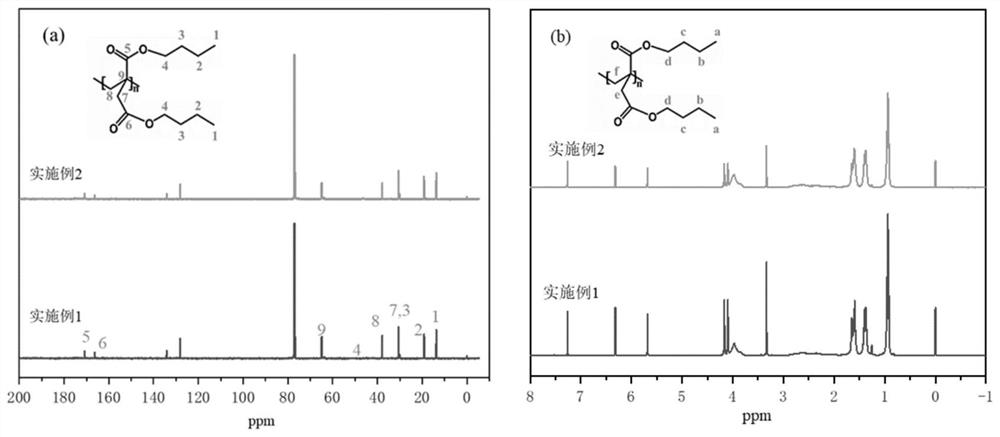

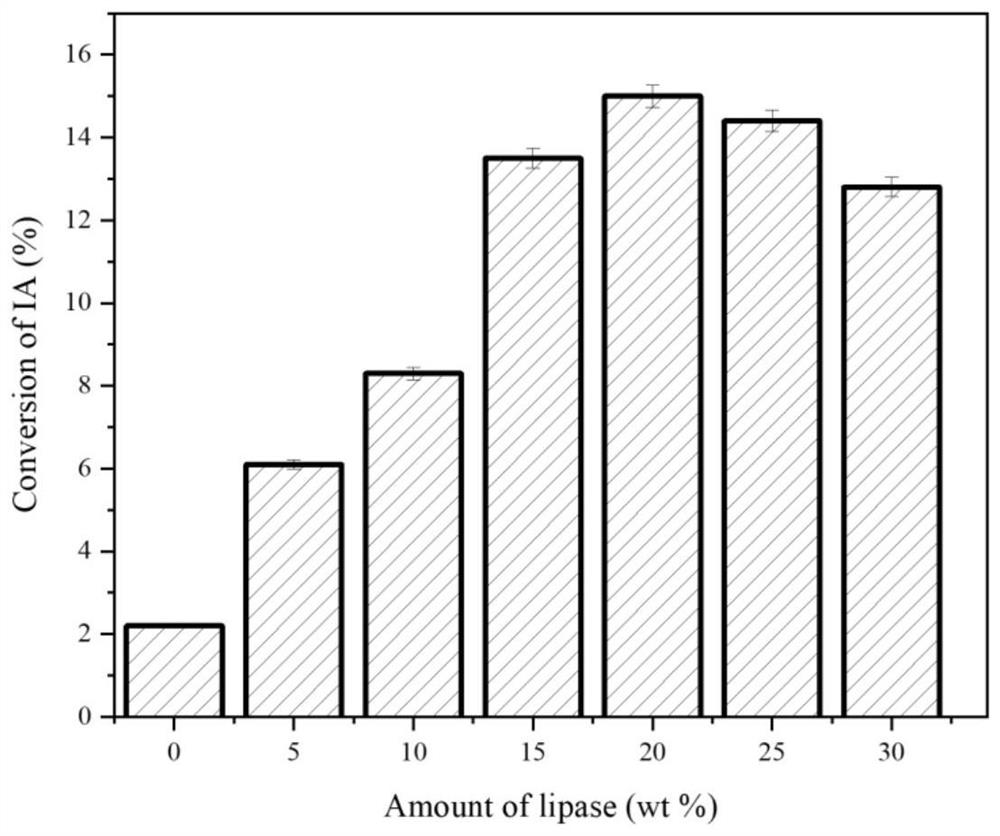

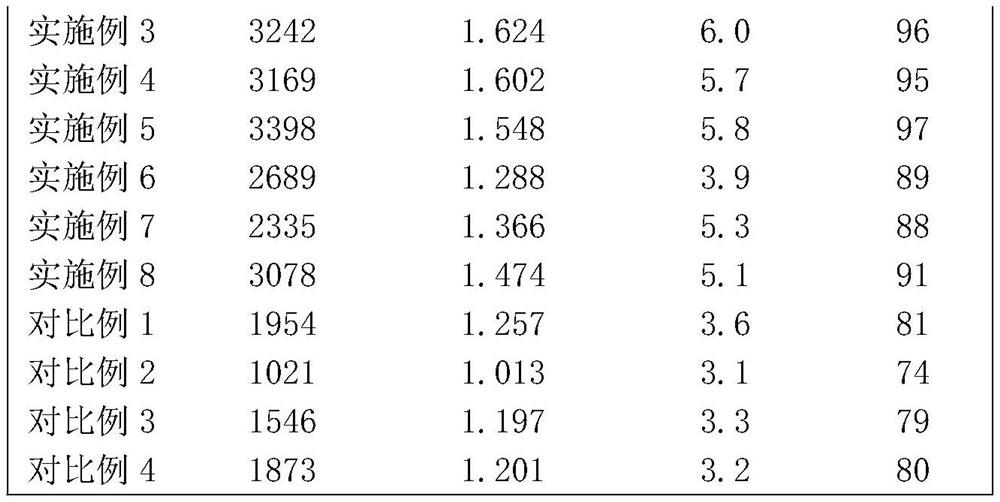

A green slow-burning pyrotechnic agent binder and preparation method thereof

ActiveCN113666792BSimple preparation processReduce reaction energy consumptionNon-explosive fillers/gelling/thickening agentsExplosive ingredient compoundingEngineeringCompatibilization

The invention discloses a green slow-burning pyrotechnic agent binder and a preparation method thereof, belonging to the fields of biocatalysis and binders. The green slow-burning pyrotechnic agent binder is an ester-based homopolymer; the ester-based homopolymer is obtained through homopolymerization using dibasic acid homopolymer dibutyl ester as a monomer. The invention can synthesize the ester monomer which is difficult to synthesize through the biological enzyme catalysis, and the reaction process is mild, and no acid waste water is generated. Afterwards, the ester-based homopolymer is prepared by low-temperature self-homopolymerization, the process is environmentally friendly, the reaction progress is accelerated, the output is increased, and the product has good thermal stability. The pyrotechnic composition binder prepared by the invention has good compatibility with the pyrotechnic composition, can improve the combustion performance of the pyrotechnic composition, reduce the burning speed of the pyrotechnic composition, and simultaneously reduce solid particles and toxic and harmful gases produced by combustion.

Owner:BEIJING UNIV OF CHEM TECH +1

Bipolar plate structure that can be used for fuel cells, fuel cells and fuel cell vehicles

The present disclosure relates to a bipolar plate structure usable in a fuel cell, comprising: a substrate having a plurality of flow areas for fluid; and a mesh structure having mesh holes, the mesh The lengthwise dimension of the holes is larger than the widthwise dimension, and the mesh structure is disposed on the substrate to form at least one of the plurality of flow regions.

Owner:FTXT ENERGY TECH CO LTD

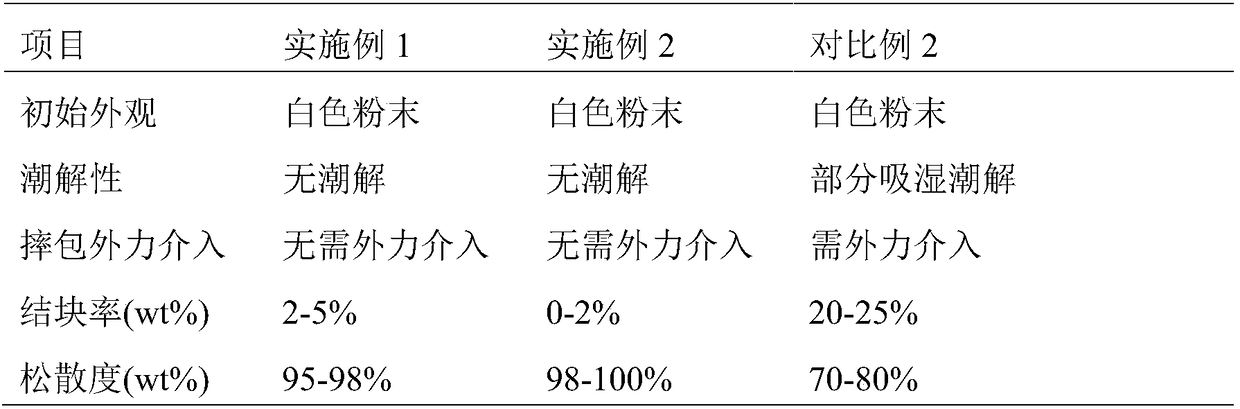

Preparation method of monopotassium phosphate granules for flame retardance

ActiveCN109133021AImprove qualitySuppress generationPhosphorus compoundsPhosphoric acidPotassium hydroxide

The invention provides a preparation method of monopotassium phosphate granules for flame retardance. The preparation method mainly comprises the following steps: preparing phosphoric acid and a potassium hydroxide solution with moderate concentrations as raw materials, and carrying out purification pretreatment on the phosphoric acid; carrying out first neutralization reaction on an atomized potassium hydroxide solution as a raw material; adding a potassium carbonate solution and residual phosphoric acid for carrying out second neutralization reaction; carrying out decoloration impurity removal treatment on reaction liquid; carrying out resin coating modification treatment on monopotassium phosphate; carrying out spraying granulation to obtain the monopotassium phosphate granules for flame retardance. According to the preparation method provided by the invention, the preparation process is combined with the post treatment step by raw material control, stepped neutralization reaction as well as modification and spray drying treatment, so that a mode of obtaining the monopotassium phosphate by concentrating crystals in the prior art is avoided, and procedures of multi-effect concentrated heating and evaporative crystallization are omitted, so that energy consumption is effectively reduced and no waste solution is discharged.

Owner:WUHAN LIANDE CHEM CO LTD

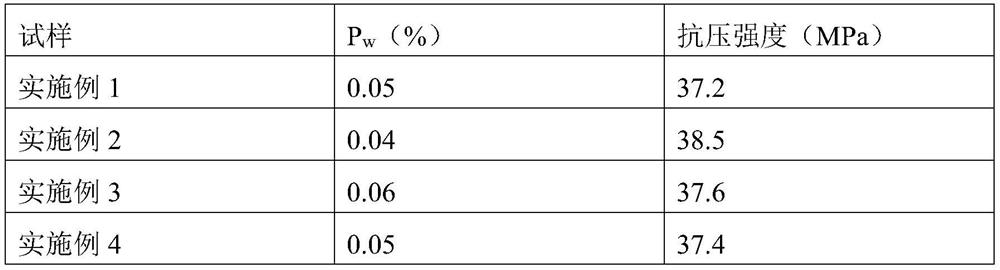

A composite cementitious material for bonding high-voltage electric porcelain and its preparation method

The invention discloses a composite cementitious material for bonding high-voltage electric porcelain, comprising the following raw materials in parts by weight: 60-80 parts of cement, 5-10 parts of quartz sand, 1-3 parts of water reducer, 5-10 parts of nano-oxidized 1-10 parts of mineral fibers, 3-10 parts of heterocyclic compounds, 5-10 parts of organic solvents and 10-50 parts of water, the present invention can prevent the further dissolution of by-products and target products in the cement hydration stage, The original structure of the inorganic gelling material is kept from being destroyed, thereby improving the later strength of the inorganic gelling material. The invention also discloses a preparation method of the inorganic gelling material. Heterocyclic compounds can form network structures and film layers in different hydration stages of cement, improving the water resistance of inorganic cementitious materials.

Owner:萍乡市鸿泰高压电瓷电气厂

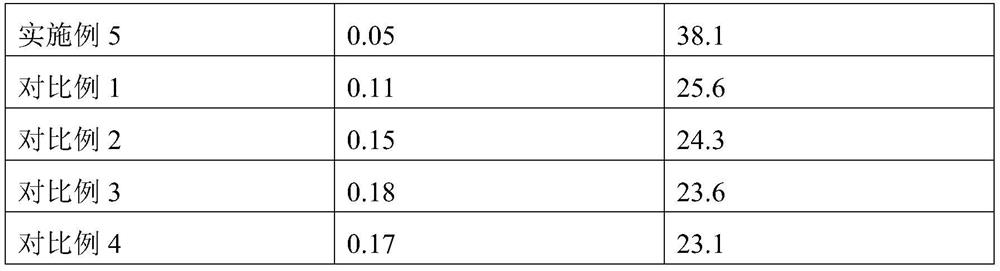

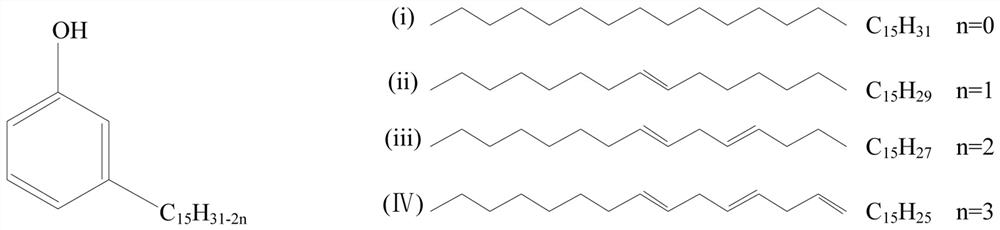

Catalytic hydrogenation preparation method of saturated cardanol

ActiveCN114621058AWide variety of sourcesLow costOrganic chemistryOrganic compound preparationPtru catalystHydrogenation reaction

The invention relates to a catalytic hydrogenation preparation method of saturated cardanol. The method comprises the following steps: feeding: sequentially adding cardanol, a solvent and a hydrogenation catalyst into a reaction kettle; nitrogen and hydrogen replacement: firstly replacing gas in the reaction kettle with nitrogen for three times, and then replacing gas in the reaction kettle with hydrogen for three times; hydrogenation reaction: heating to 60-85 DEG C under a stirring condition, pressurizing to 1.0-2.0 MPa by using hydrogen, and then continuously stirring for a period of time; and separation: recovering the hydrogenation catalyst from the solution in the kettle through a recovery device, crystallizing, centrifuging and drying to obtain saturated cardanol. The method is simple and convenient in preparation mode, energy consumption is reduced, and the prepared saturated cardanol is high in purity.

Owner:SHE COUNTY JINDONG ECONOMIC & TRADE CO LTD

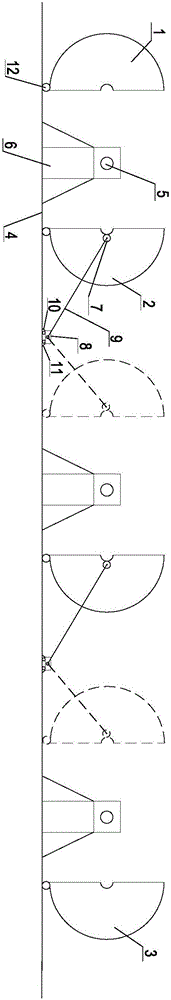

Energy-saving hydrogen decrepitation method

The invention provides an energy-saving hydrogen decrepitation method. The method has the beneficial effects that hydrogen decrepitation is carried out on prepared rare earth alloy materials by adopting a plurality of hydrogen decrepitation mechanisms arranged on a guide rail; after one hydrogen decrepitation mechanism completes reaction, a rotary heating chamber used in the hydrogen decrepitation mechanism can be put into use in the next hydrogen decrepitation mechanism, so that not only can a reaction furnace be quickly heated and plenty of heat be saved but also the powder preparation efficiency is improved; a baffle is arranged on the heating chamber of each hydrogen decrepitation mechanism and is used for insulating the heating chamber when reaction is not carried out, thus being beneficial to saving the preheating time of the heating chamber and then reducing the energy costs of enterprises; after the rear hydrogen decrepitation mechanism completes reaction, the baffle of the rotary heating chamber and a baffle of a rear end heating chamber are closed via a travel switch installed on the rotary heating chamber and a travel switch installed on the rear end heating chamber, thus the heating reaction is completed; not only can heating be carried out quickly but also the powder preparation efficiency is improved by arranging the rotary heating chambers.

Owner:SUZHOU SABO IND DESIGN

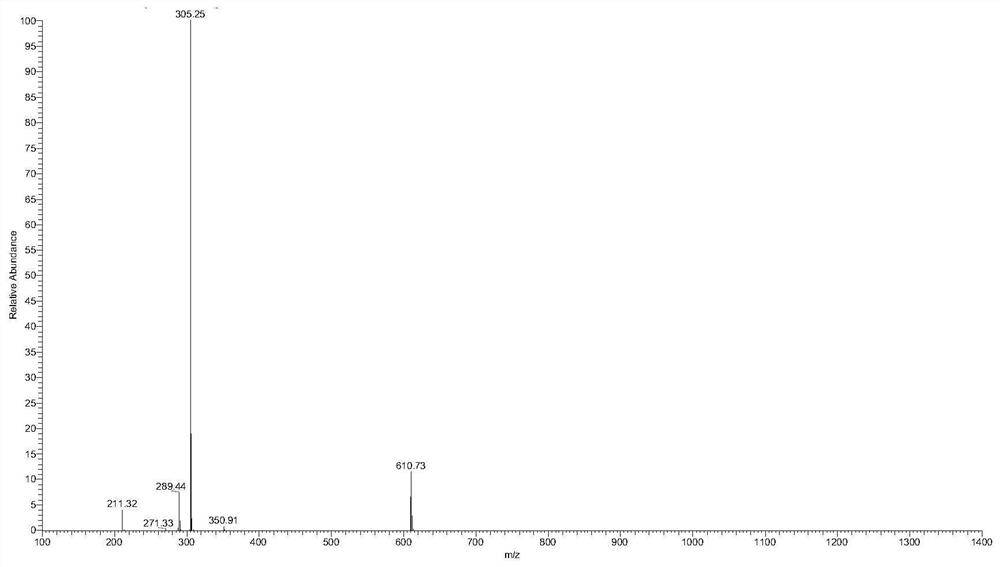

Preparation method of 1, 1, 1-tris (4-hydroxyphenyl) ethane

PendingCN113943212ASpeed up the responseHigh catalytic activityOrganic chemistryMolecular sieve catalystsPtru catalystAcetophenone

The invention relates to a preparation method of 1, 1, 1-tris (4-hydroxyphenyl) ethane, and the method comprises the following steps: taking phenol and 4-hydroxyacetophenone as raw materials, adding a water-carrying agent and a precipitating agent into a system before reaction, and taking solid superacid as a catalyst, and performing reacting and recrystallizing to obtain the 1, 1, 1-tris (4-hydroxyphenyl) ethane, wherein the solid superacid is a novel solid superacid Scat05 obtained by introducing a ZSM-5 molecular sieve into SO42- / TiO2. The precipitation agent and the water-carrying agent are added in advance, so that the reaction is carried out in a positive direction. The novel solid superacid Scat05 can effectively accelerate the reaction progress, is small in corrosion to equipment, is not easy to cause side reaction, and can be effectively separated from a product for recycling after reaction, so that the production cost and the three-waste treatment cost are saved. The operation process is simple and safe, the product yield is high, the production period is short, and the method is suitable for industrial application.

Owner:烟台海川化学制品有限公司

Method for manufacturing bamboo fibers

ActiveCN101934545BQuick removalReduce chemical pollutionWood working apparatusChemical reactionSingle fiber

The invention provides a method for manufacturing bamboo fibers. The method comprises the following steps of: 1) rolling: rolling to crack a bamboo chip to ensure that the bamboo fibers are possibly dispersed; 2) dipping: putting the bamboo chip into a reaction kettle, and mixing with a proper amount of reactant for 10 to 90 minutes to remove lignin, polysaccharide, colloid and protein on the surface of the bamboo fiber; 3) defibering: reducing the pressure instantaneously to standard atmospheric pressure to ensure that the bamboo chip is exploded in the reaction kettle and defibered to form a single-fiber bamboo chip; 4) cleaning: washing the bamboo fibers with hot water with the temperature of between 50 and 100 DEG C at least twice to remove byproducts from the surfaces of the bamboo fibers; 5) dewatering: drying the cleaned bamboo fibers to obtain a dry bamboo fiber finished product; and 6) cutting: cutting the bamboo fibers into bamboo fibers with a proper length. By adopting a physical instantaneous depressurized explosion mode and a chemical reaction reagent dipping mode, the bamboo chip is treated by steps, and the instantaneous depressurized explosion also accelerates thereacting speed of the chemical reagent and the bamboo chip to achieve the effect of quickly removing the lignin, the polysaccharide, the colloid and other substances from the surface of the bamboo chip.

Owner:宁波欣百科技有限公司

Material production device for chemical industry

InactiveCN108905927AWell mixedAvoid investmentRotary stirring mixersTransportation and packagingChemical industryEngineering

The invention discloses a material production device for chemical industry. The material production device comprises a base, a production box is arranged at the top end of the base, a discharging pipeis arranged at the bottom end of the production box, an electromagnetic valve is arranged on the discharging pipe, a vibrator which is positioned above the electromagnetic valve is arranged at the bottom end of one side of the production box, one side of the top end of the production box is provided with a feed port, a supporting column I and a supporting column II located on one side of the supporting column I are arranged at the top end of the production box, a motor is arranged at the top end of the supporting column II, an output shaft of the motor is connected to a rotating shaft, one end of the rotating shaft penetrates through the supporting column I and extends to one side of the supporting column I, the rotating shaft is sleeved with a main rotating wheel, a stirring mechanism isarranged on one side of the supporting column I, and a rotary shaft and a fixing rod positioned below the rotary shaft are arranged at the top end of the interior of the production box. The materialproduction device has the beneficial effects that mixing of materials in the production box is effectively accelerated, the reaction progress is accelerated, convenience is brought to production of the materials, meanwhile, the investment of labor force is avoided, and the investment cost is saved.

Owner:HEFEI OUYU AUTOMATION CO LTD

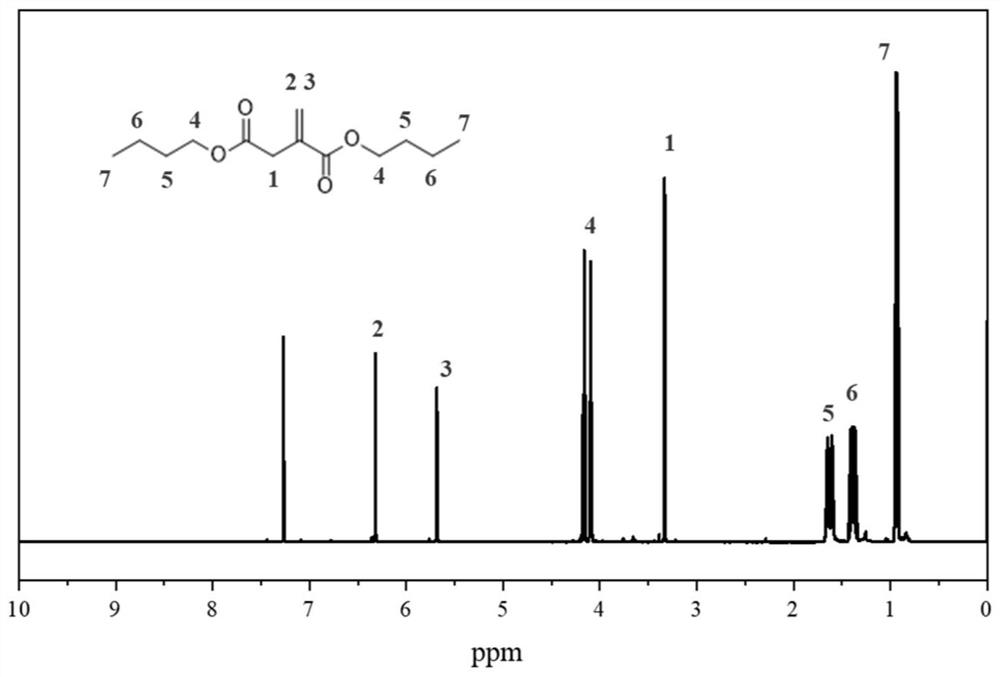

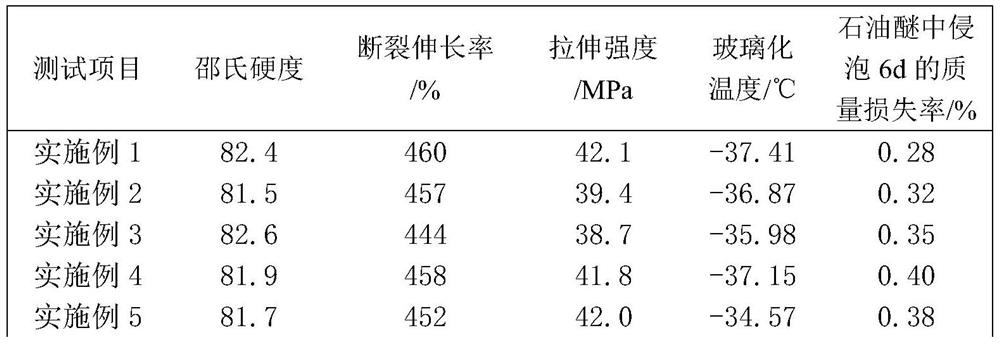

Preparation method of polyester plasticizer as well as product and application thereof

The invention discloses a preparation method of a polyester plasticizer as well as a product and application thereof. The method comprises the following steps: carrying out esterification reaction on a dihydric alcohol and binary acid mixture in a nitrogen atmosphere to obtain a prepolymer; adding lipase into the prepolymer for condensation polymerization to obtain a polyester crude product ; by taking a polyester crude product and polydimethylsiloxane as raw materials, carrying out grafting reaction under the action of a catalyst to obtain a modified polyester crude product; and separating and purifying the obtained modified polyester crude product to obtain the polyester plasticizer. The method has the advantages of greenness, environmental protection, less side reaction, less solvent consumption, small dispersion coefficient, simplicity in operation, controllable molecular weight and the like. The obtained polyester plasticizer has the characteristics of extraction resistance, migration resistance and no toxicity, and can significantly improve the mechanical properties and low temperature resistance of NBR.

Owner:BEIJING UNIV OF CHEM TECH +1

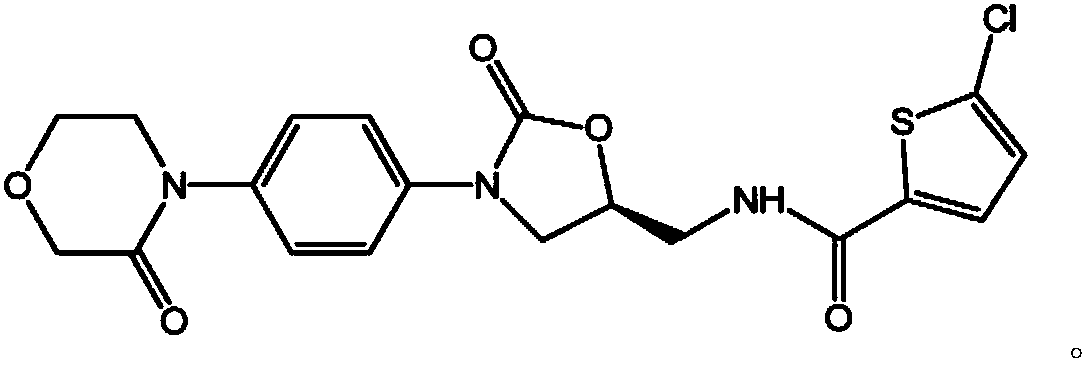

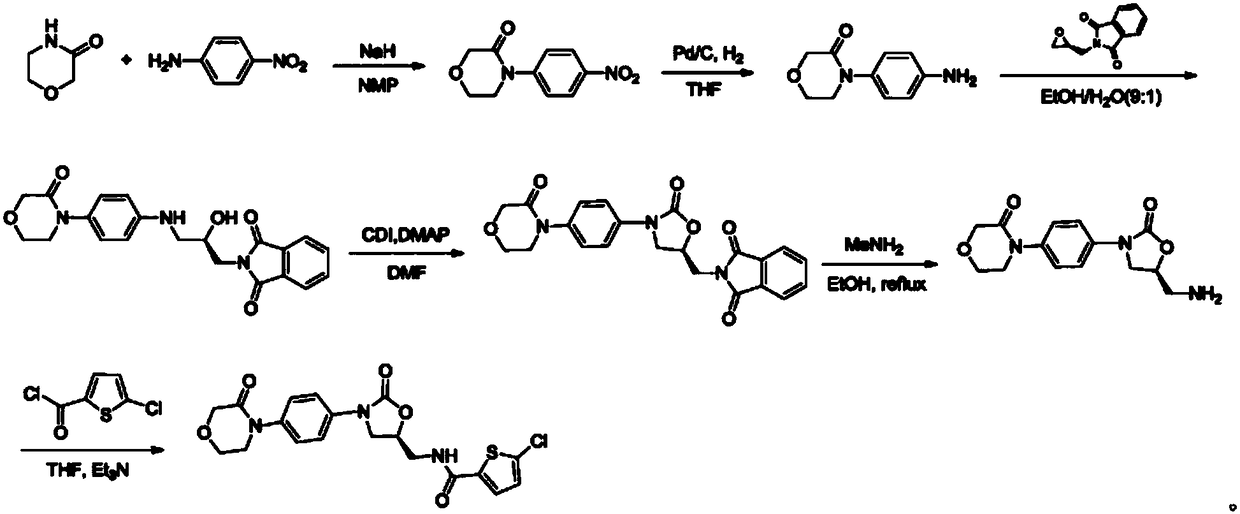

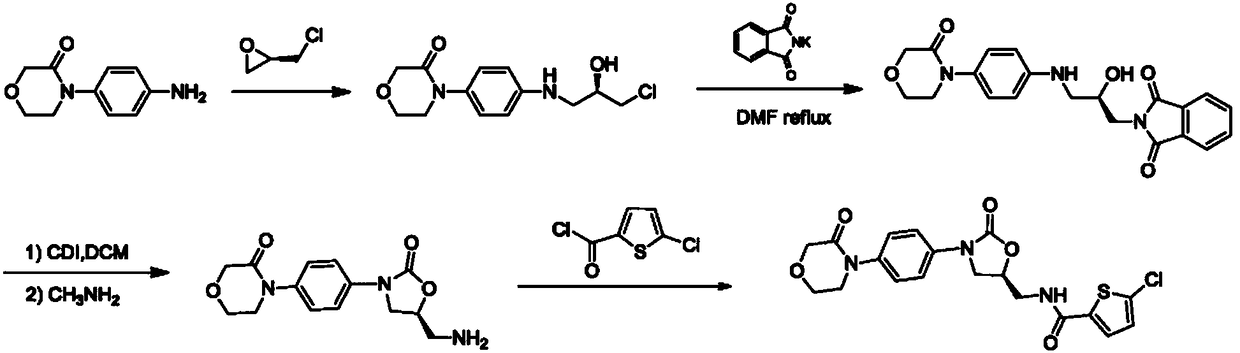

A kind of preparation method of rivaroxaban

The invention discloses a preparation method of rivaroxaban. With (S)-4-chloro-3-hydroxybutyronitrile (compound 1) as a raw material, the rivaroxaban is obtained through phthalimide potassium salt substitution, cyano hydrolysis, Hofmann rearranging cyclization, Ullmann coupling, hydrazinolysis and amidation. The rivaroxaban is introduced into a chiral center instead of (S)-epoxy chloropropane which is volatile, high in toxicity and unstable; the safety is relatively high; precious catalyst, raw materials and reagent with large environmental pollution are avoided in the total process in the total synthetic route; the overall synthesis process is small in pollution and easy to treat; the yield and the purity of various steps are high; the preparation method is environmentally friendly, low in production cost and suitable for industrial production.

Owner:SHANDONG LUOXIN PHARMA GRP HENGXIN PHARMA CO LTD

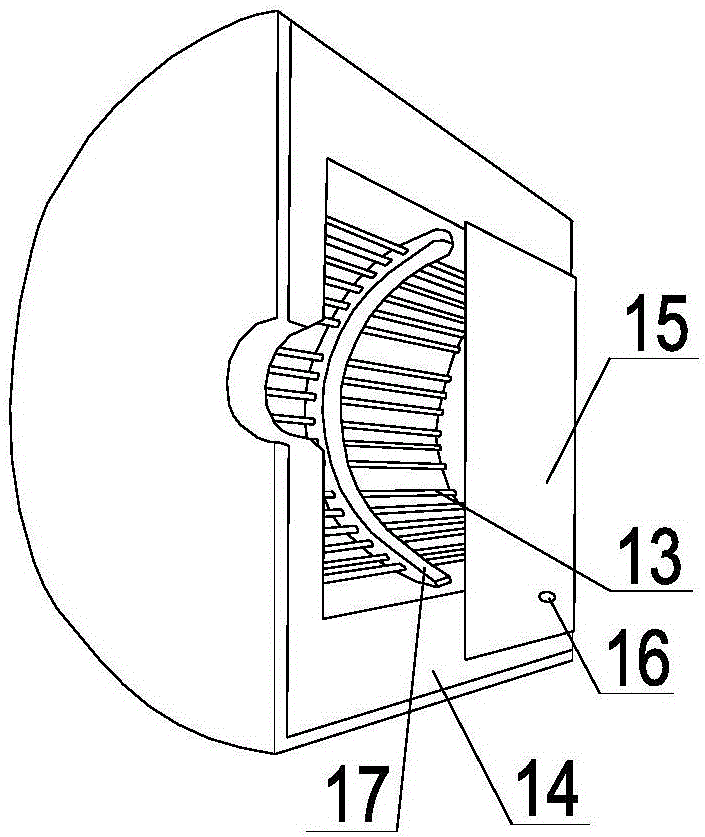

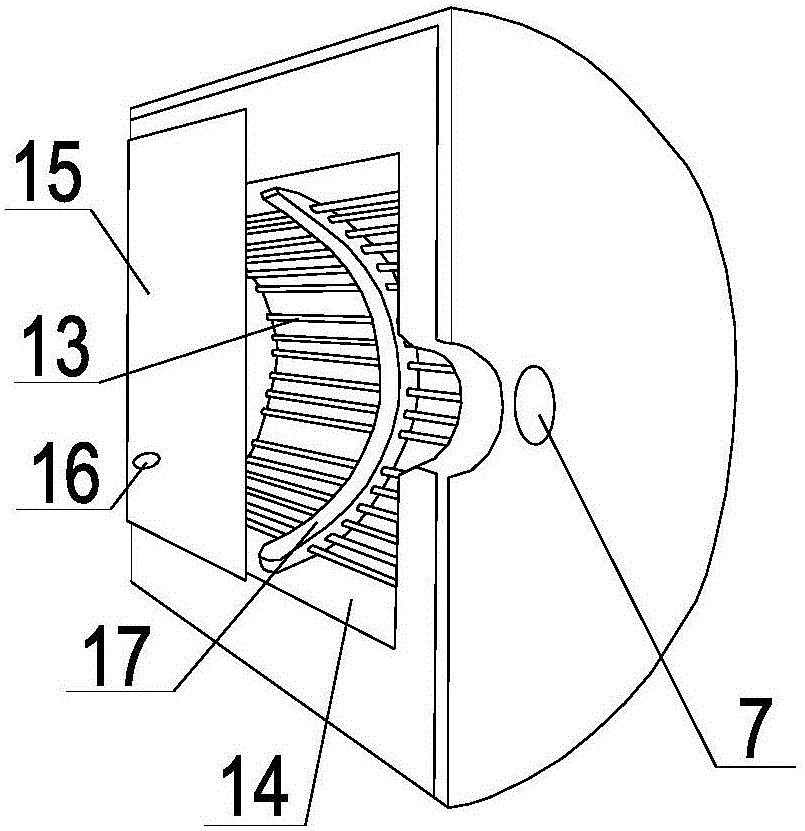

Energy-saving hydrogen decrepitation device for production of rare earth magnetic materials

ActiveCN105081335AImprove preheating efficiencySpeed up the responseManufacturing efficiencyDecrepitation

The invention provides an energy-saving hydrogen decrepitation device for production of rare earth magnetic materials. A front hydrogen decrepitation mechanism, a middle hydrogen decrepitation mechanism and a rear hydrogen decrepitation mechanism are mounted on a guide rail. The front hydrogen decrepitation mechanism comprises a front heating chamber, a reaction furnace and a rotary heating chamber. The middle hydrogen decrepitation mechanism comprises a pair of rotary heating chambers and a reaction furnace. The rear hydrogen decrepitation mechanism comprises a rotary heating chamber, a reaction furnace and a rear heating chamber. Each reaction furnace is mounted on a reaction furnace mounting frame. A steady pin is arranged on each rotary heating chamber. One end of a connecting rod is fixed to each rotary heating chamber through the corresponding steady pin. The other end of each connecting rod is mounted on a corresponding sliding support. The sliding supports are arranged on the guide rail. Each sliding support is provided with a front sliding stop pin and a rear sliding stop pin. The internal structure of the front heating chamber, the internal structures of the rotary heating chambers and the internal structure of the rear heating chamber are identical. The front heating chamber is internally provided with heating pipes. The heating pipes are arranged on a heat insulation layer. A baffle is mounted on the outer side of the heat insulation layer. A travel switch is arranged on the baffle. Through arrangement of the rotary heating chambers, the energy-saving hydrogen decrepitation device can conduct heating rapidly, and meanwhile the powder manufacturing efficiency is also improved.

Owner:SUZHOU SABO IND DESIGN

A preparation method for flame-retardant potassium dihydrogen phosphate granules

The invention provides a preparation method of monopotassium phosphate granules for flame retardance. The preparation method mainly comprises the following steps: preparing phosphoric acid and a potassium hydroxide solution with moderate concentrations as raw materials, and carrying out purification pretreatment on the phosphoric acid; carrying out first neutralization reaction on an atomized potassium hydroxide solution as a raw material; adding a potassium carbonate solution and residual phosphoric acid for carrying out second neutralization reaction; carrying out decoloration impurity removal treatment on reaction liquid; carrying out resin coating modification treatment on monopotassium phosphate; carrying out spraying granulation to obtain the monopotassium phosphate granules for flame retardance. According to the preparation method provided by the invention, the preparation process is combined with the post treatment step by raw material control, stepped neutralization reaction as well as modification and spray drying treatment, so that a mode of obtaining the monopotassium phosphate by concentrating crystals in the prior art is avoided, and procedures of multi-effect concentrated heating and evaporative crystallization are omitted, so that energy consumption is effectively reduced and no waste solution is discharged.

Owner:WUHAN LIANDE CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com