Preparation method of monopotassium phosphate granules for flame retardance

A technology of potassium dihydrogen phosphate and granules, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc. It can solve the problem that evaporation crystallization does not meet the requirements of environmental protection, and the neutralization method cannot meet the requirements of flame retardant product quality, etc. problems, to achieve the effect of suppressing side reactions and the generation of impurities, ensuring particle size and fluidity, and maintaining the stability of the reaction system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] 1) Put 12.2 kg of industrial-grade wet-process phosphoric acid with a mass fraction of 85% in an aeration storage tank with an air inlet pipe installed on the top, and use compressed air to pass through the opening of the bottom pipe to the phosphoric acid in the aeration storage tank. Continue aeration at 110°C for 20 minutes; dissolve potassium hydroxide in deionized water under stirring to make a solution with a mass fraction of 35%, and send it to a raw material storage tank with a spray generating device for atomization.

[0082] 2) Place the pretreated phosphoric acid solution in a cone-shaped enamel reaction kettle with a spray feed pipe and a stirring paddle on the top, heat up to 80°C, and start stirring; preheat the 35% potassium hydroxide solution to 80°C ℃, then spray 16.1kg potassium hydroxide solution evenly into the reactor through the spray feed pipe on the upper part of the reactor through the metering pump, control the reaction contact surface at the lo...

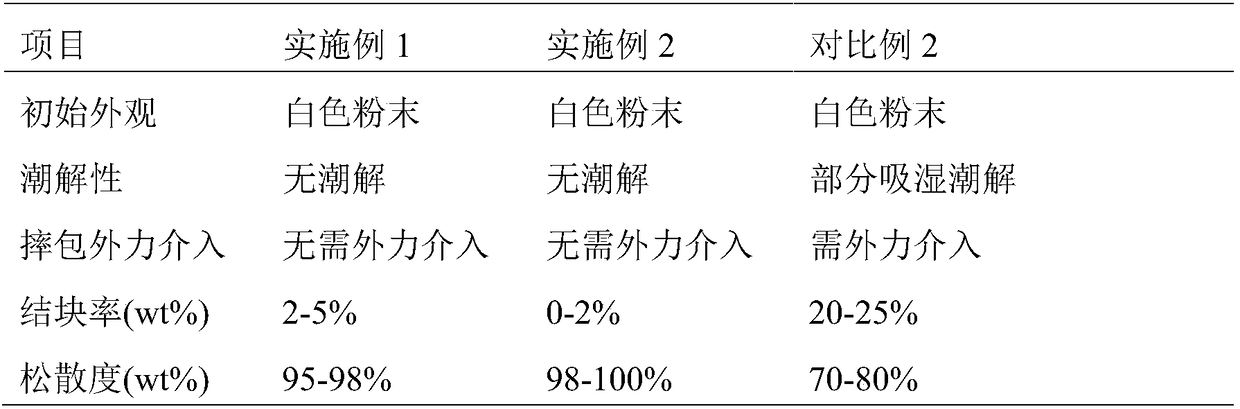

Embodiment 2

[0091] Step (1)-(6) method is the same as embodiment 1;

[0092] Step (7) post-processing:

[0093] Further, add 0.6 kg of 200-mesh silicon dioxide to the prepared potassium dihydrogen phosphate particles, stir evenly in a mixer, and vacuum-dry until the product drying loss ≤ 0.2%, to obtain phosphoric acid containing silicon dioxide anticaking agent Potassium Dihydrogen Granules.

Embodiment 3

[0095] 1) 115 kg of high-purity phosphoric acid (made by phosphorus pentoxide) with a mass fraction of 90% is placed in an aeration storage tank with an air inlet pipe installed on the top, and compressed air is used to pass through the bottom pipeline opening to the aeration storage tank. Phosphoric acid was continuously aerated for 15 minutes at 120°C; the potassium hydroxide solid accounting for 95% of the total molar amount of phosphoric acid was dissolved in deionized water under stirring to form a solution with a mass fraction of 40%, and then sent to a spray generator In the raw material storage tank of the device, ready to use.

[0096] 2) Place the phosphoric acid solution after aeration pretreatment in a conical enamel reaction kettle with a spray feed pipe and a stirring paddle on the top, heat up to 85°C, and start stirring; preheat the above potassium hydroxide solution to 85°C, then spray the preheated potassium hydroxide solution evenly into the reactor through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com