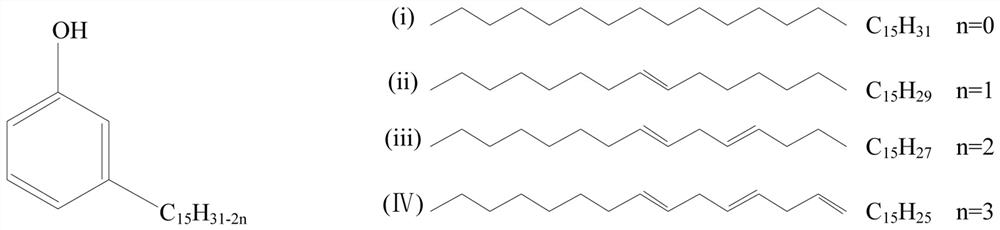

Catalytic hydrogenation preparation method of saturated cardanol

A technology for catalytic hydrogenation and cardanol, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as self-polymerization, and achieve the effects of reducing hydrogenation time, good reusability, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

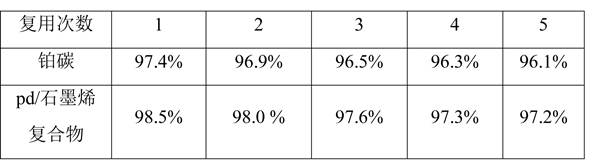

Examples

Embodiment 1

[0032] (1) Feeding:

[0033] Cardanol, methanol and platinum carbon were sequentially added to the reaction kettle according to the mass ratio of 1:1.5:0.05.

[0034] (2) Nitrogen and hydrogen replacement:

[0035] First, replace the gas in the reactor with nitrogen three times, and then replace the gas in the reactor with hydrogen three times.

[0036] (3) Hydrogenation reaction:

[0037] When heated to 60°C at a heating rate of 1°C / min under stirring, pressurize hydrogen to 1.0Mpa, and continue to heat to 70°C at a heating rate of 1°C / min while the pressure remains unchanged. At this time, the pressure was increased to 1.5MPa by introducing hydrogen, and continued to heat to 85°C at a heating rate of 0.5-1°C / min under this pressure. Then, the pressure was increased to 2.0MPa by introducing hydrogen, and stirring was continued for 1.5 hours.

[0038] (4) Separation:

[0039] After the solution in the kettle reclaims the hydrogenation catalyst through the filter, it is tra...

Embodiment 2

[0041] (1) Feeding:

[0042] According to the mass ratio of 1:1.3:0.02, cardanol, ethanol and platinum carbon were sequentially added to the reaction kettle.

[0043] (2) Nitrogen and hydrogen replacement:

[0044] First, replace the gas in the reactor with nitrogen three times, and then replace the gas in the reactor with hydrogen three times.

[0045] (3) Hydrogenation reaction:

[0046] When heated to 60°C at a heating rate of 1°C / min under stirring, pressurize hydrogen to 1.0Mpa, and continue to heat to 70°C at a heating rate of 1°C / min while the pressure remains unchanged. At this time, the pressure was increased to 1.5MPa by introducing hydrogen, and continued to heat to 85°C at a heating rate of 0.5-1°C / min under this pressure. Then, the pressure was increased to 2.0MPa by introducing hydrogen, and stirring was continued for 1.5 hours.

[0047] (4) Separation:

[0048] After the solution in the kettle reclaims the hydrogenation catalyst through the filter, it is tra...

Embodiment 3

[0050] (1) Feeding:

[0051] Cardanol, methanol and platinum carbon were sequentially added to the reaction kettle in a mass ratio of 1:1.1:0.01.

[0052] (2) Nitrogen and hydrogen replacement:

[0053] First, replace the gas in the reactor with nitrogen three times, and then replace the gas in the reactor with hydrogen three times.

[0054] (3) Hydrogenation reaction:

[0055] When heated to 60°C at a heating rate of 1°C / min under stirring, pressurize hydrogen to 1.0Mpa, and continue to heat to 70°C at a heating rate of 1°C / min while the pressure remains unchanged. At this time, the pressure was increased to 1.5MPa by introducing hydrogen, and continued to heat to 85°C at a heating rate of 0.5-1°C / min under this pressure. Then, the pressure was increased to 2.0MPa by introducing hydrogen, and stirring was continued for 1.5 hours.

[0056] (4) Separation:

[0057]After the solution in the kettle reclaims the hydrogenation catalyst through the filter, it is transferred to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com