Preparation method of polymer polyol

A polyol and polymer technology, applied in the field of high molecular polymer material preparation, can solve the problems of unstable process, low conversion rate, three waste discharge, etc., and achieve the effect of advanced technology and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

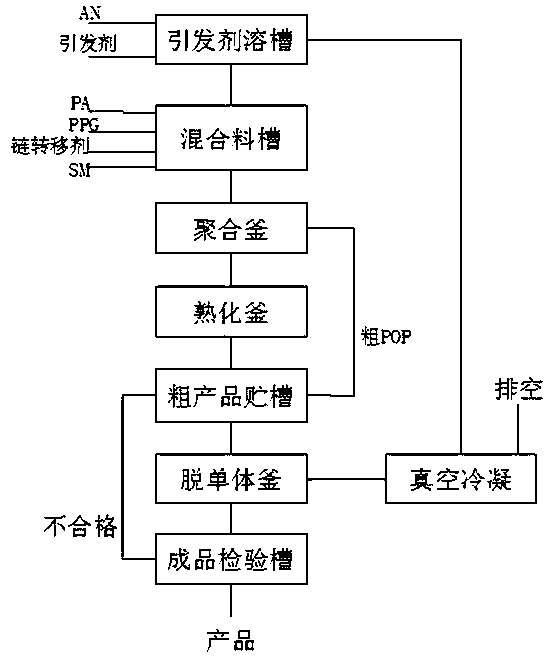

[0027] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings and specific embodiments.

[0028] see figure 1 , embodiment 1-4 prepares polymer polyol, adopts the following method:

[0029] 1) Mixture preparation: add acrylonitrile and initiator to the initiator solution tank, fully dissolve at -10~0°C to prepare mixture A; mix basic polyether and intermediate polyether (PA) Add it to the mixing tank first, then add styrene, acrylonitrile, compound A, and chain transfer agent, and mix evenly at a temperature of 5~10°C to prepare compound B.

[0030] Specifically, the mass ratio of acrylonitrile, initiator, basic polyether, intermediate polyether, styrene and chain transfer agent is: 9~13.5 : 0.3 : 55~65 : 3 : 20~30 : 0.3.

[0031] The basic polyether is polyether polyol with a molecular weight of 3005. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com