Vertical eddy current reinforced separation device and granulation fluidized bed for efficient solid-liquid separation

A technology for strengthening separation and solid-liquid separation, applied in the field of water treatment, can solve the problems of low efficiency of large particles, inability to grow into large particles, low solid-liquid separation efficiency, etc. water quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

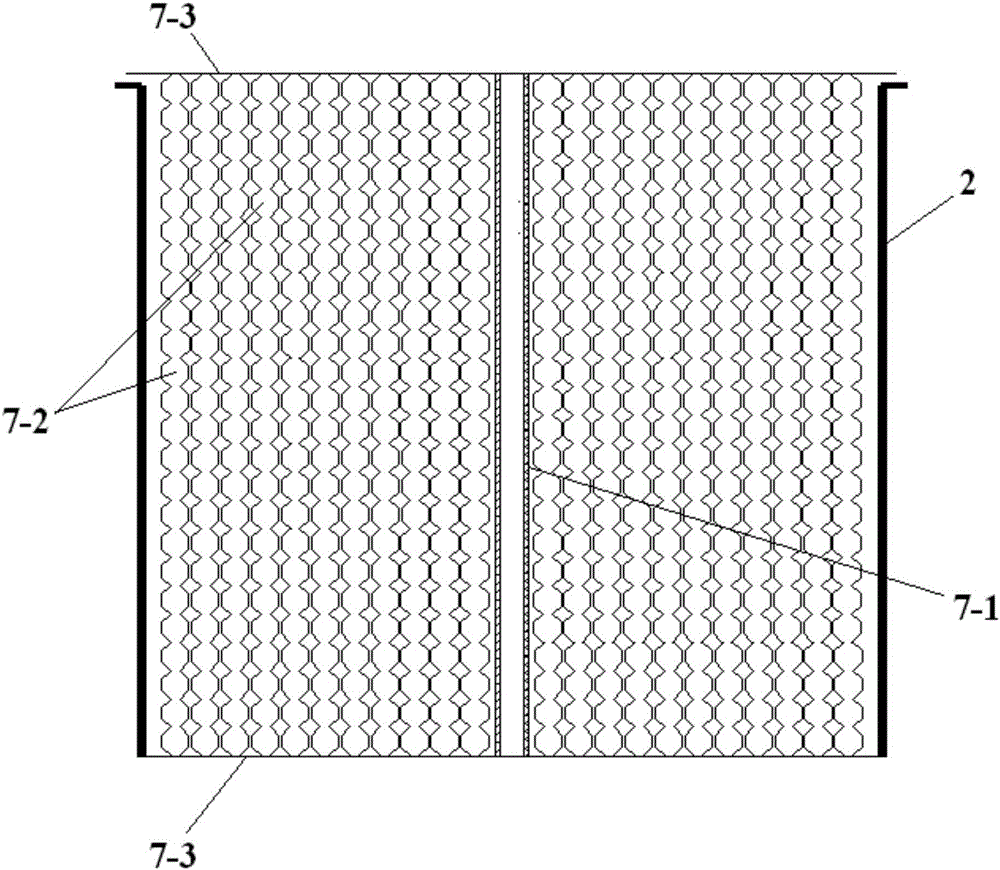

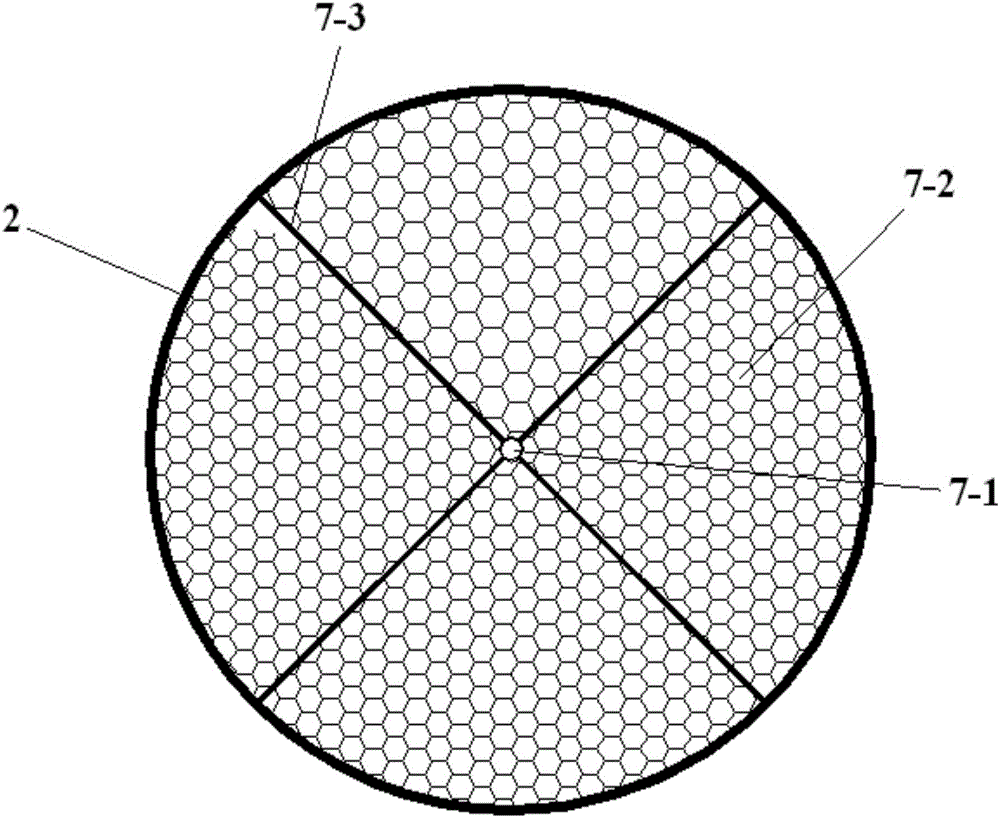

[0039] Comply with the above technical solutions, such as figure 1 and figure 2 As shown, this embodiment provides a vertical vortex enhanced separation device, including a stirring shaft sleeve 7-1 arranged in the center, and a plurality of bellows vertically fixed together are arranged around the stirring shaft sleeve 7-1 7-2, the two ends of the bellows 7-2 are sandwiched between a pair of cross frame 7-3, and the center of the cross frame 7-3 is installed at the two ends of the stirring shaft sleeve 7-1.

Embodiment 2

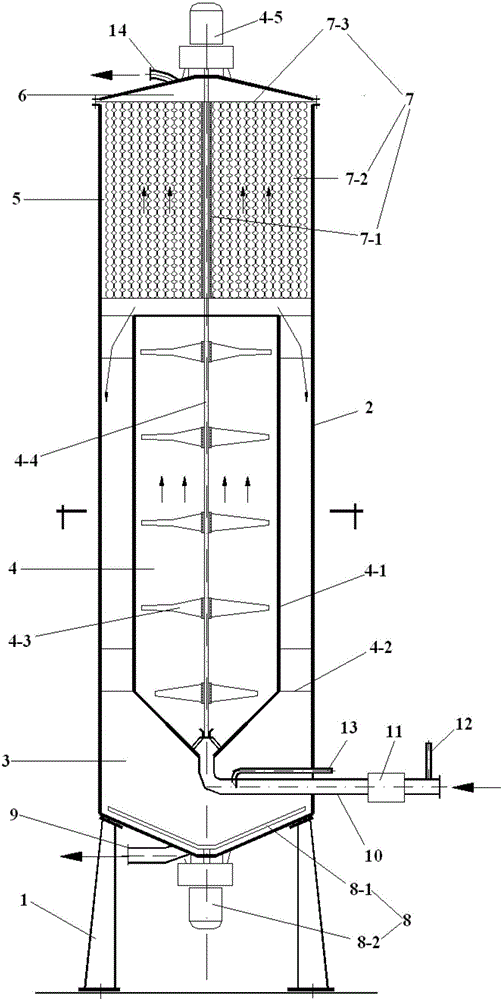

[0041] Comply with the above technical solutions, such as Figure 1 to Figure 4 As shown, the present embodiment provides a granulation fluidized bed with high-efficiency solid-liquid separation, including a base frame 1, and a tank body 2 is fixedly installed on the base frame 1, and the tank body 2 is sequentially arranged from bottom to top Mud thickening zone 3, granulation zone 4, separation zone 5 and catchment zone 6;

[0042] A vertical vortex enhanced separation device 7 is installed in the separation zone 4 , and the vertical vortex enhanced separation device 7 can make the water in the separation zone 5 generate a vertical vortex.

[0043] The vertical vortex strengthening separation device 7 includes a stirring shaft sleeve 7-1 arranged at the center, and a plurality of bellows 7-2 vertically fixed together are arranged around the stirring shaft sleeve 7-1, and the bellows 7-2 The two ends are clamped between a pair of cross frame 7-3, the center of the cross fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com