W-shaped flame boiler disposing aperture type over-fire air spouts on stove arch

A slot-type, burn-out air technology, which is applied in the direction of combustion air/fuel supply, non-flammable liquid/gas transportation, combustion method, etc., can solve the problems of reduced boiler efficiency and low pulverized coal burnout degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

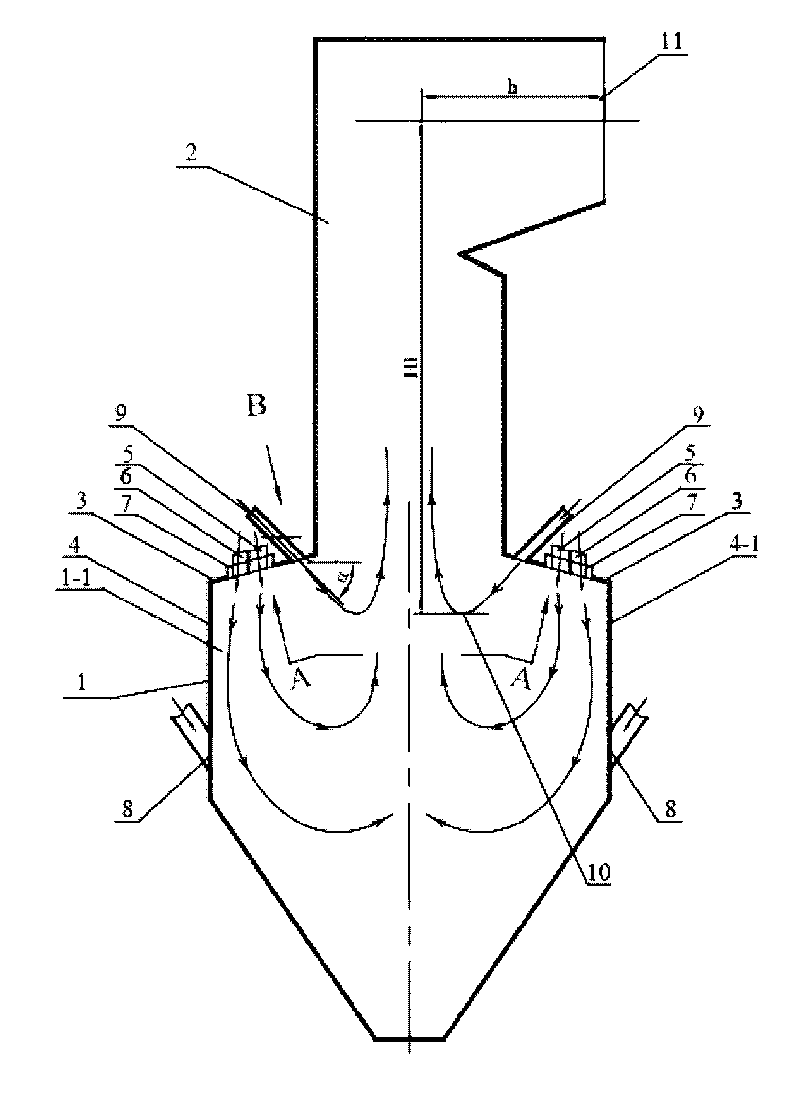

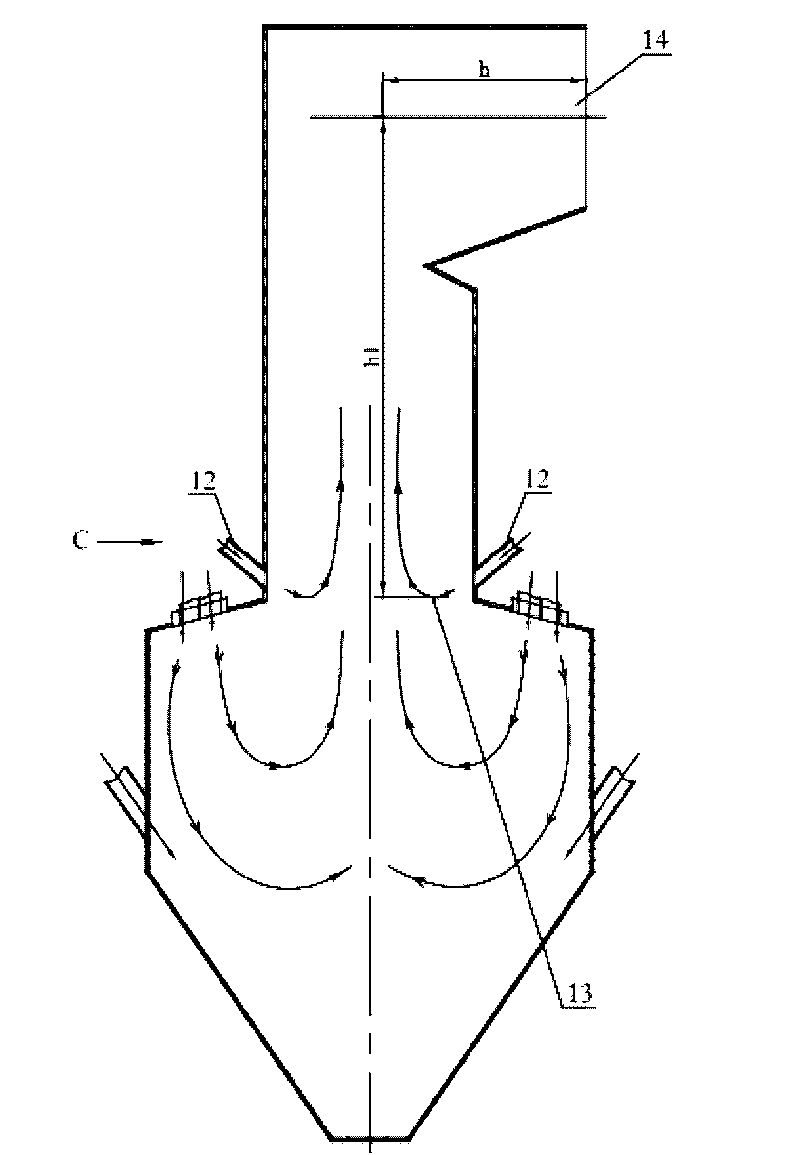

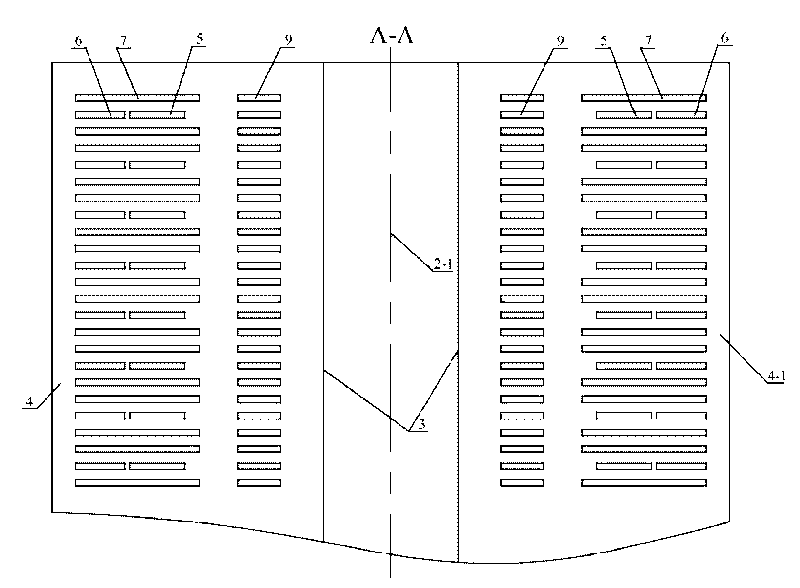

[0011] Specific implementation mode one: combine figure 1 and image 3 Describe this embodiment, the W-shaped flame boiler with slot-type overburning air nozzles arranged on the furnace arch described in this embodiment includes a furnace body composed of a lower furnace body 1, an upper furnace body 2 and two furnace arches 3 and A plurality of primary air nozzles 5, a plurality of exhaust gas nozzles 6 and a plurality of secondary air nozzles 7; the W-shaped flame boiler also includes a plurality of slit-type burn-off air nozzles 9; a plurality of secondary air nozzles 7 are divided into two groups , two groups of secondary air nozzles 7 are arranged symmetrically along the center line of the furnace body, and a group of secondary air nozzles 7 are parallelly arranged on each furnace arch 3 along its length direction, and a plurality of secondary air nozzles 7 are all connected with the lower furnace body The lower furnace of 1 is connected, and the two adjacent secondary ...

specific Embodiment approach 2

[0012] Embodiment 2: In this embodiment, the angle α between the centerline and the horizontal line of each slit-type overburning air nozzle is 25°. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0013] Specific implementation mode three: combination image 3 To describe this embodiment, the cross-section of the slit-type overburning air nozzle 9 in this embodiment is a rectangle with an aspect ratio of (5-7):1. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com