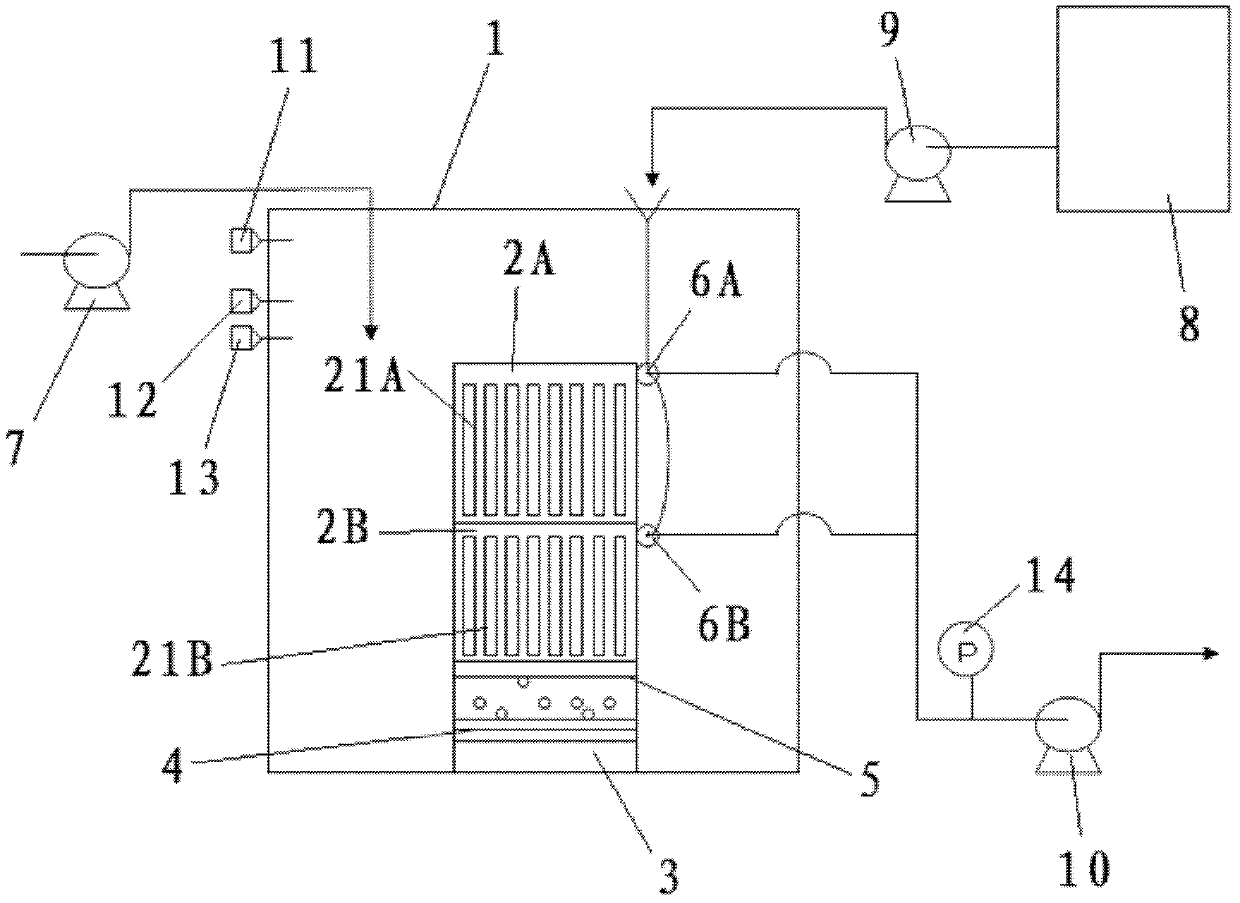

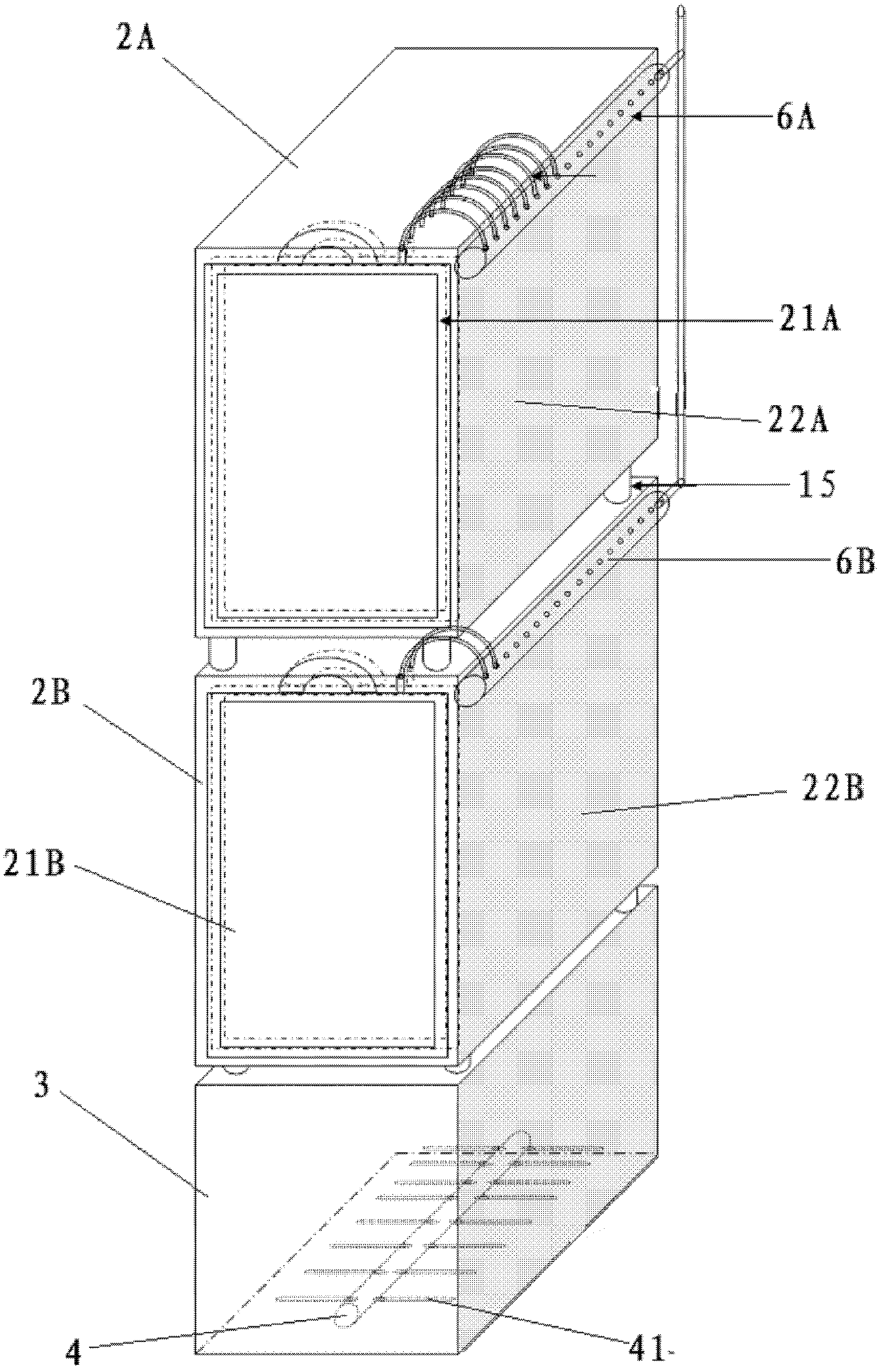

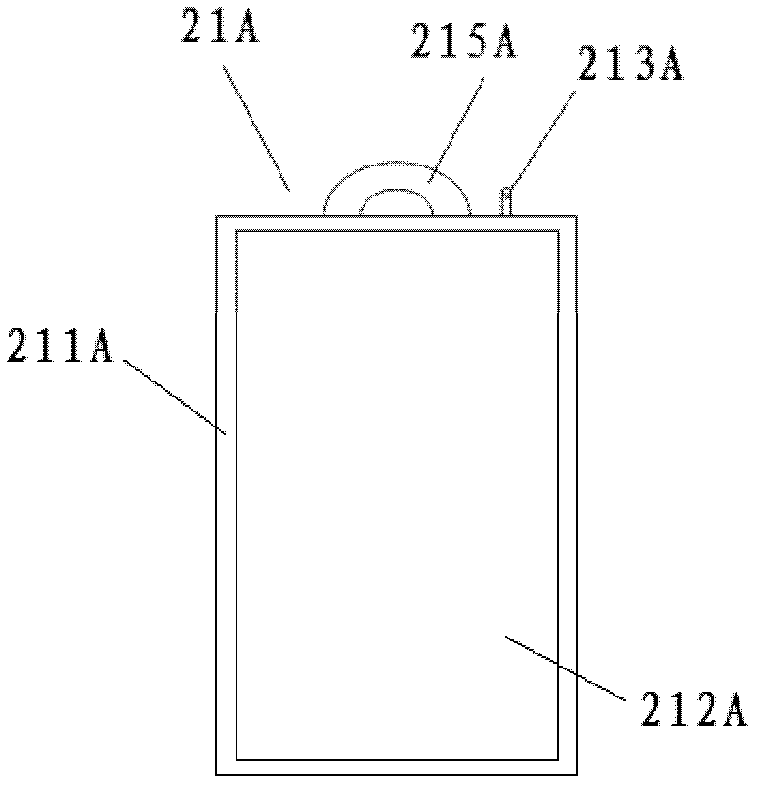

High-flux contamination-resisting type flat membrane bioreactor and flat MBR (Membrane Bioreactor) device

A flat membrane assembly device, anti-pollution technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc. The effect of improving membrane fouling, saving air consumption, and saving aeration volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0053] The domestic sewage of a residential area is treated by the flat-panel MBR device of the present invention, with a treatment capacity of 5,000 tons per day. The influent water quality and effluent water quality are shown in Table 1. The flat-panel MBR device has been in operation for 6 months, and the transmembrane pressure difference (TMP) has increased from 2kPa to 15kPa, and the membrane pressure difference has risen steadily. The flat-panel MBR device has been continuously operated for 6 months without cleaning.

[0054] Table 1 Water quality before and after treatment

[0055]

example 2

[0057] Tobacco sewage treatment and reuse project, the treatment capacity is 2000m 3 / hour, raw water COD cr 2000-4000mg / L, BOD 150-400mg / L, SS 200-450mg / L. After treatment, the effluent COD cr Less than 50mg / L, turbidity less than 1NTU. The flat-panel MBR device has been in operation for one month, the transmembrane pressure (TMP) has risen from 8kPa to 12.6kPa, the membrane pressure difference has risen steadily, and the operation is stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com