Control method for relay network connection of two gas chambers

A control method and technology of gas cabinets, applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve problems such as the inability to recycle gas, achieve simple and reliable principles, low technical requirements, and improve resistance to accident risks effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below based on specific embodiments and in conjunction with the accompanying drawings.

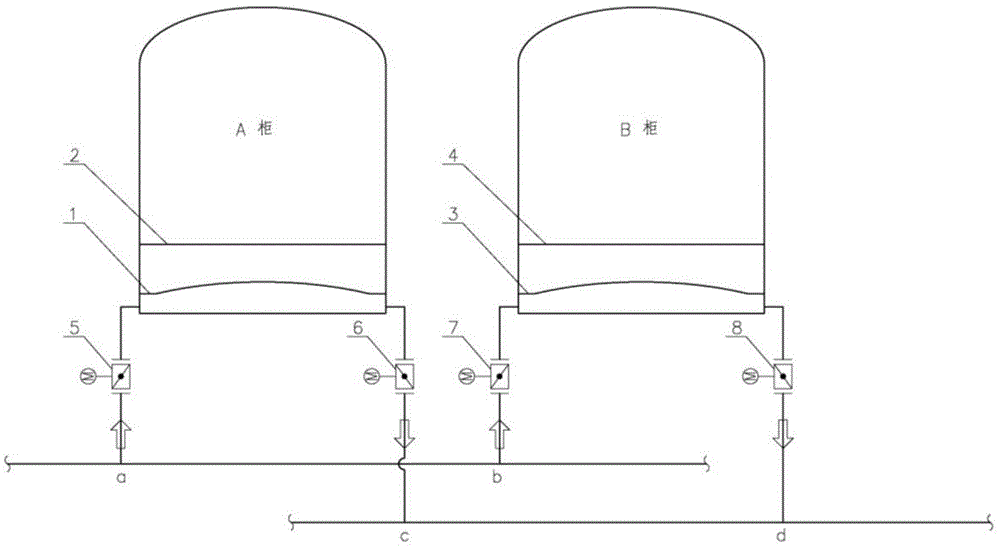

[0018] refer to figure 1 As shown, the control method for two gas cabinets relayed into the cabinet provided by the present invention specifically includes the following steps:

[0019] 1) Define the near-end cabinet and the far-end cabinet

[0020] Set the first gas cabinet as cabinet A, the second gas cabinet as cabinet B, the inlet access point of the pipeline network of cabinet A as a, the inlet access point of the pipeline network of cabinet B as b, and the outlet access point of the pipeline network of cabinet A is c, the access point of the pipe network outlet of cabinet B is d, and the pipe network resistance △P from point a to the inlet of cabinet A a and the pipe network resistance △P from point b to the inlet of cabinet B b As equal, compare the gas pressure P at points a and b in the intake pipe network a ,P ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com