Solid adsorbent regeneration process

A solid adsorbent and process technology, used in filter regeneration, petroleum industry, combustible gas purification, etc., can solve problems such as difficulty in finding outside gas, and achieve the effects of convenient secondary relocation, easy maintenance, and increased operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

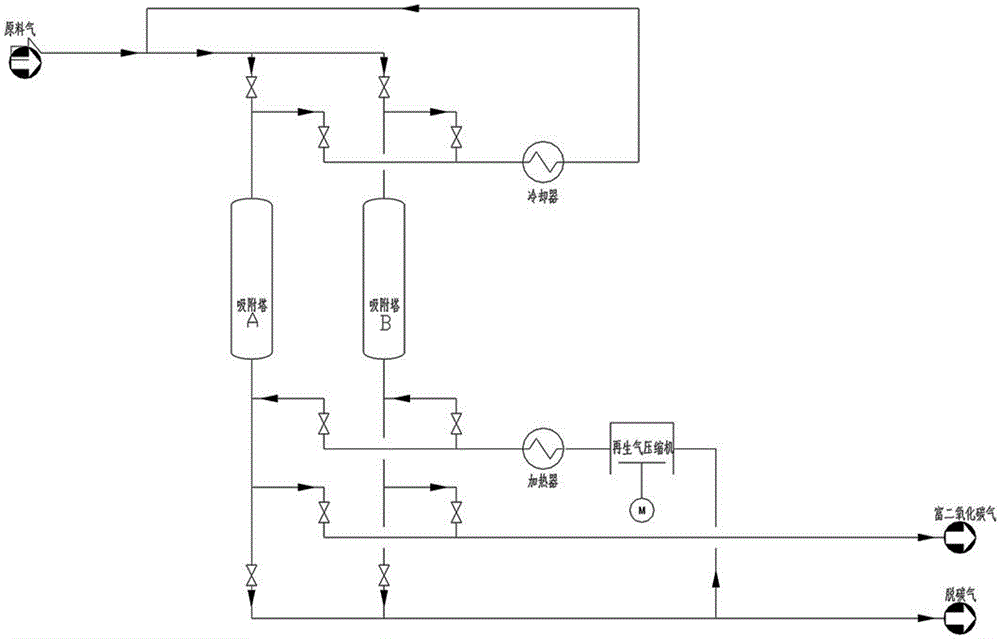

[0046] Such as figure 1 As shown, at least two adsorption towers are used to decarbonize the raw gas. The adsorption towers include a first adsorption tower that absorbs carbon dioxide and a second adsorption tower that regenerates after the adsorption is completed. The adsorption tower in this embodiment A and adsorption tower B are alternately used as the first adsorption tower. When one of the adsorption towers is used as the first adsorption tower, the other adsorption tower is the second adsorption tower. Both adsorption tower A and adsorption tower B have undergone adsorption, depressurization, heat Blowing, cold blowing several stages.

[0047] Taking adsorption tower A as the first adsorption tower and adsorption tower B as the second adsorption tower as an example, the regeneration process of the described solid adsorbent specifically includes:

[0048] A) Let the raw material gas containing carbon dioxide pass through the adsorption tower A, and the carbon dioxide i...

Embodiment 2

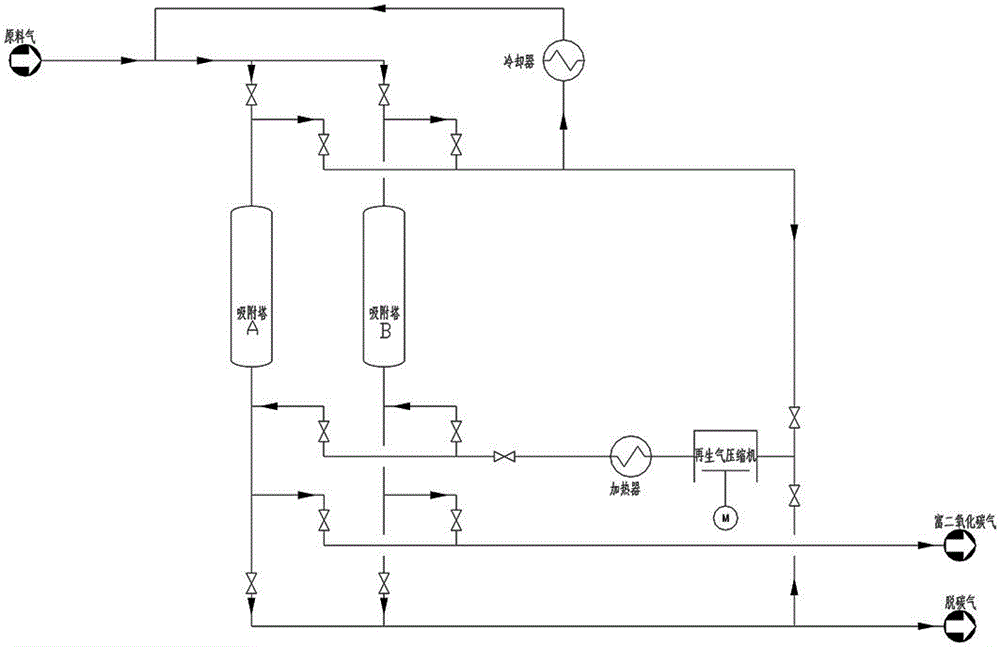

[0058] Such as figure 2 As shown, at least two adsorption towers are used to decarbonize the raw gas. The adsorption towers include a first adsorption tower that absorbs carbon dioxide and a second adsorption tower that regenerates after the adsorption is completed. The adsorption tower in this embodiment A and adsorption tower B are alternately used as the first adsorption tower. When one of the adsorption towers is used as the first adsorption tower, the other adsorption tower is the second adsorption tower. Pressing, cold blowing several stages.

[0059] Taking adsorption tower A as the first adsorption tower and adsorption tower B as the second adsorption tower as an example, the regeneration process of the described solid adsorbent specifically includes:

[0060] A) Let the raw material gas containing carbon dioxide pass through the adsorption tower A, and the carbon dioxide in the raw material gas is adsorbed by the adsorption tower A, so as to obtain the decarbonized ...

Embodiment 3

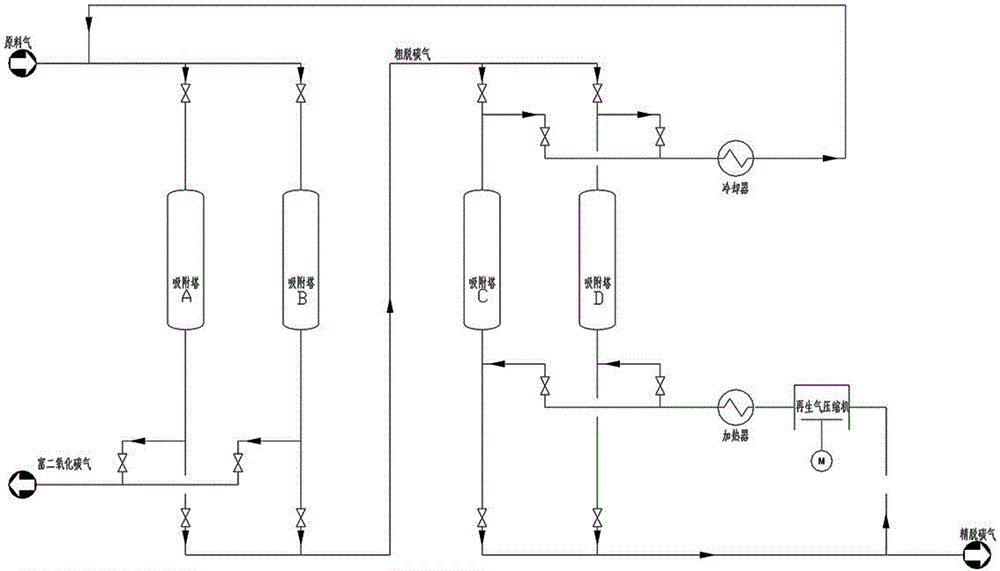

[0069] Such as image 3 As shown, at least two adsorption towers are used to decarbonize the raw gas. The adsorption towers include a first adsorption tower that absorbs carbon dioxide and a second adsorption tower that regenerates after the adsorption is completed. The adsorption tower in this embodiment A and adsorption tower B are alternately used as the first adsorption tower, and adsorption tower C and adsorption tower D are alternately used as the first adsorption tower. When one of the adsorption towers is used as the first adsorption tower, the other adsorption tower is the second adsorption tower, and Adsorption tower A and adsorption tower B constitute a stage of rough adsorption, and adsorption tower C and adsorption tower D constitute a second stage of fine adsorption. The raw material gas first undergoes a stage of rough adsorption and then undergoes a second stage of fine adsorption to achieve two-stage adsorption.

[0070] Adsorption tower A, adsorption tower B,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com