Technology for recycling sulfur and valuable metal from copper oxidative pressure leaching residues

A valuable metal, leaching slag technology, applied in the improvement of process efficiency, chemical instruments and methods, solid separation and other directions, can solve the problems of great comprehensive recovery, waste of secondary resources, low copper leaching rate, etc. The effect of detoxification treatment, improving utilization rate and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

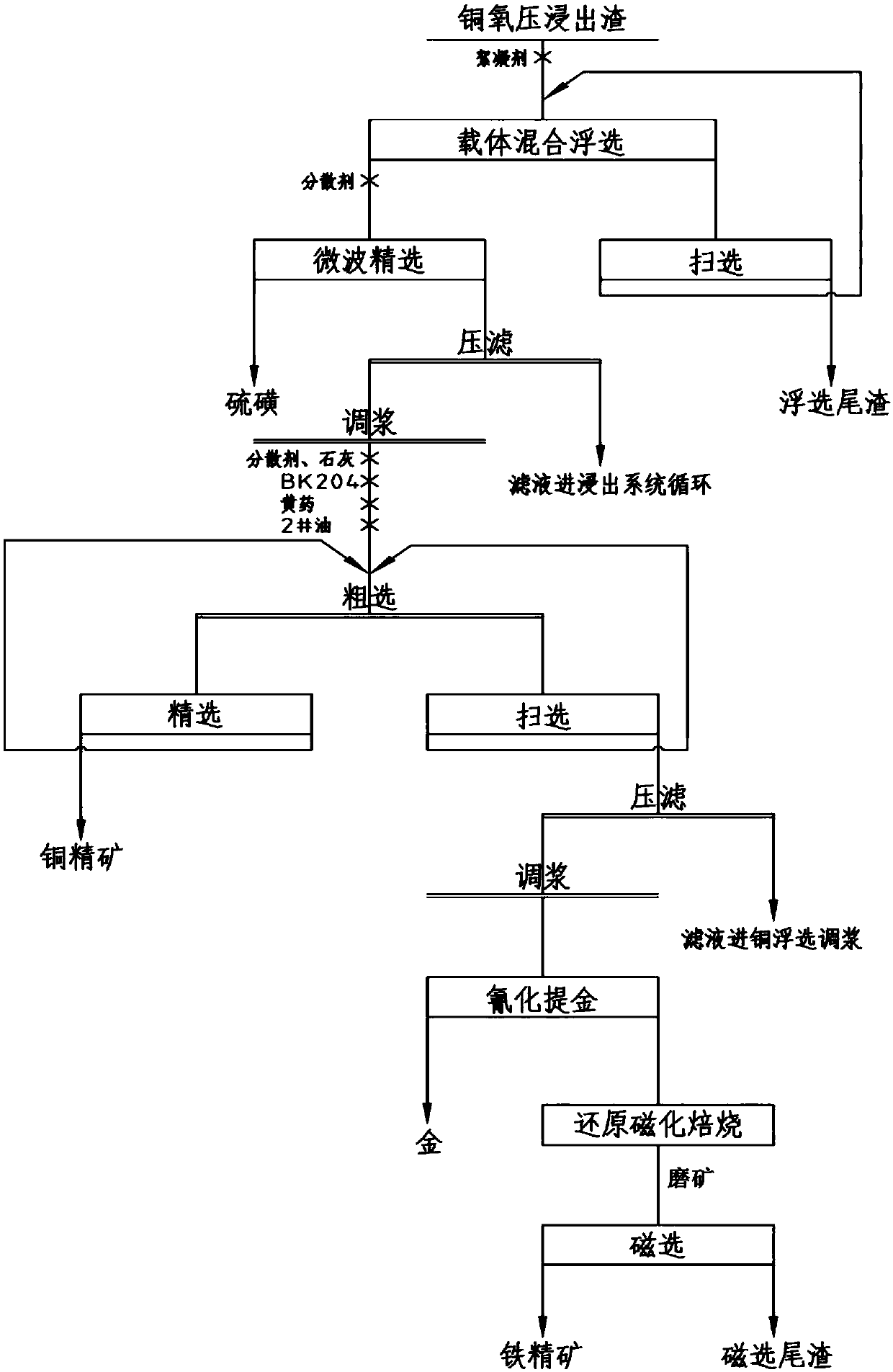

[0032] The invention provides a process for recovering sulfur and valuable metals from copper oxygen pressure leaching slag, comprising:

[0033] (1) Copper oxygen pressure leaching slag contains 4.5% copper, gold 83g / t, iron 32%, sulfur 23%; add polyacrylamide to the copper oxygen pressure leaching slag as a flocculant, the dosage is 65g / t, for rapid carrier Mixed flotation to obtain mixed flotation concentrate and mixed flotation tailings;

[0034] (2) Mixed flotation tailings go through 3 stages of scavenging operations, and the scavenging tailings are flotation tailings, and lignin is added to the mixed flotation concentrate at a dosage of 50g / t, and 3 stages of beneficiation operations are carried out. Microwave treatment is carried out in the beneficiation operation. The microwave power of the three stages of beneficiation is 800W, 1200W, 1600W, and the microwave power of the middle mine is 1800W, so as to obtain sulfur concentrate and beneficiation tailings;

[0035] (...

Embodiment 2

[0041] The invention provides a process for recovering sulfur and valuable metals from copper oxygen pressure leaching slag, comprising:

[0042] (1) Copper oxygen pressure leaching slag contains 2.3% copper, gold 43g / t, iron 38%, sulfur 18%; starch is added to the copper oxygen pressure leaching slag as a flocculant, the dosage is 83g / t, and rapid carrier mixed flotation is carried out. election to obtain mixed flotation concentrate and mixed flotation tailings;

[0043] (2) Mixed flotation tailings go through 3 stages of scavenging operations, and the scavenging tailings are flotation tailings, and water glass is added to the mixed flotation concentrate at a dosage of 70g / t, and 3 stages of beneficiation operations are carried out. Microwave treatment is carried out in the beneficiation operation. The microwave power of the three stages of beneficiation is 1000W, 1200W, and 1400W, and the microwave power of the middle mine is 2000W to obtain sulfur concentrate and beneficiat...

Embodiment 3

[0050] The invention provides a process for recovering sulfur and valuable metals from copper oxygen pressure leaching slag, comprising:

[0051] (1) Copper oxygen pressure leaching slag contains 3.1% copper, gold 32g / t, iron 43%, sulfur 26%; add polyacrylamide to the copper oxygen pressure leaching slag as a flocculant, the dosage is 45g / t, for rapid carrier Mixed flotation to obtain mixed flotation concentrate and mixed flotation tailings;

[0052] (2) Mixed flotation tailings go through 3 stages of scavenging operations, and the scavenging tailings are flotation tailings, and lignin is added to the mixed flotation concentrate at a dosage of 120g / t, and 3 stages of beneficiation operations are carried out. Microwave treatment is carried out in the beneficiation operation. The microwave power of the three stages of beneficiation is 1200W, 1200W, 1600W, and the microwave power of the middle mine is 1800W, so as to obtain sulfur concentrate and beneficiation tailings;

[0053]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com