Preparation method for biological porous magnesium alloy

A technology of porous magnesium and magnesium alloys, which is applied in the field of preparation of biological porous magnesium alloys, can solve problems such as environmental pollution and harmful substance residues, and achieve high controllability, high processing efficiency, and favorable quality control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

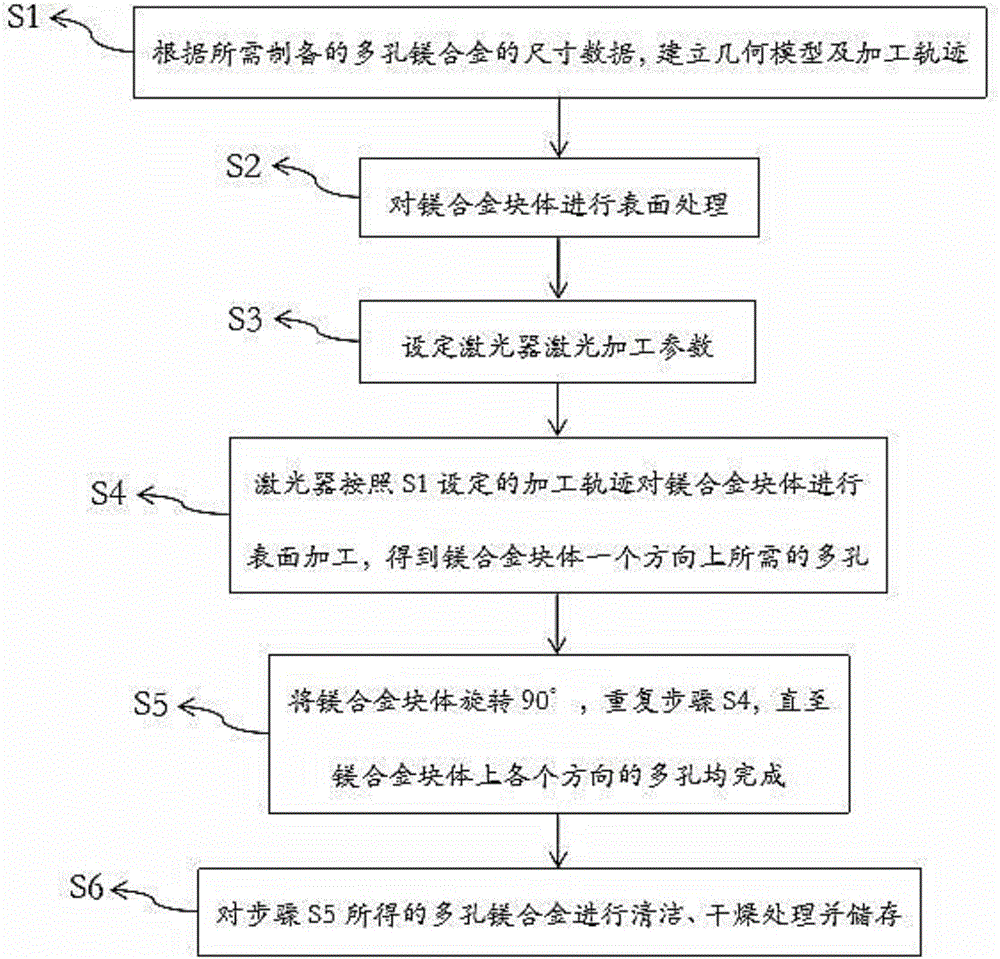

[0039] The present invention is aimed at the deficiencies in the prior art, see figure 1 As shown, a method for preparing a bioporous magnesium alloy is provided, and the bioporous magnesium alloy is obtained by melting layer by layer with a laser, which avoids the occurrence of the above adverse situations. Specifically include the following steps:

[0040] S1. According to the shape of the porous magnesium alloy to be prepared, establish the geometric model of the porous magnesium alloy formed by the multi-layer structure, and use the computer to calculate the established geometric model to obtain the dimensional data, the number of layers to be processed and the processing trajectory . The dimensional data includes the pore diameter required by the porous magnesium alloy, the regularity of spatial arrangement and the size of the gap between the pores. The pore diameter of the porous magnesium alloy prepared in the present invention is φ20-500 μm.

[0041] S2, performing s...

Embodiment 1

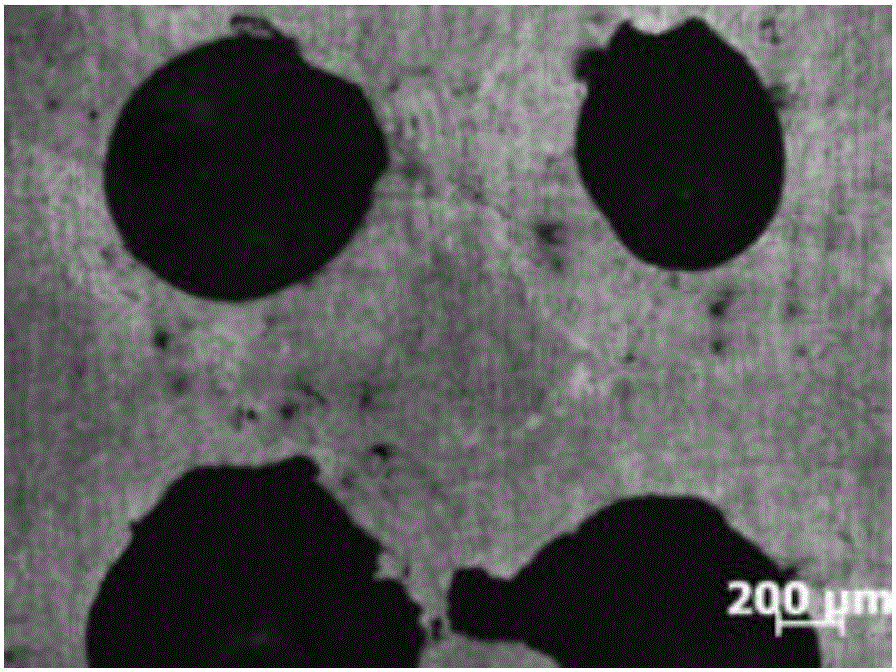

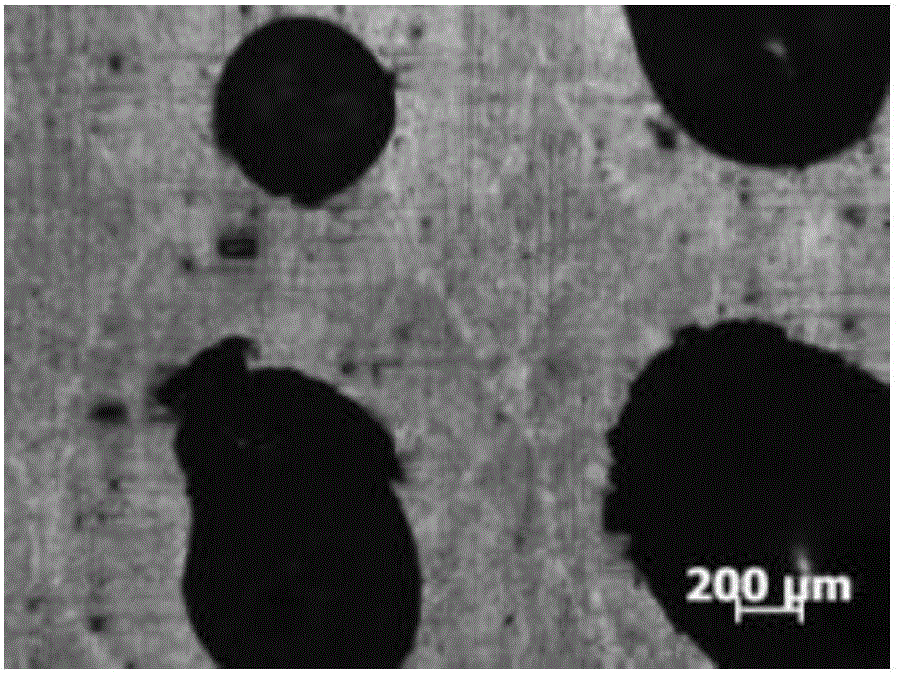

[0049] S1. According to the shape of the porous magnesium alloy to be prepared, establish the geometric model of the porous magnesium alloy formed by the multi-layer structure, and use the computer to calculate the established geometric model to obtain the dimensional data, the number of layers to be processed and the processing trajectory . The dimensional data includes the required pore size of the porous magnesium alloy, the regularity of spatial arrangement and the size of the gap between the pores. The pore size of the porous magnesium alloy prepared in this example is φ20 μm.

[0050] S2, performing surface treatment on the magnesium alloy block. The porous magnesium alloy prepared by the invention is mainly used in the medical industry, so the original raw material of the magnesium alloy block is a biomedical magnesium alloy. The surface treatment step is specifically to use sodium hydroxide solution as a cleaning agent to clean the surface of the biomedical magnesium ...

Embodiment 2

[0056] The difference between this example and Example 1 is that the pore diameter of the prepared porous magnesium alloy is φ100 μm, the laser used is a solid-state laser with a wavelength of 900 nm, and the laser processing parameters are set as follows: laser spot φ100 μm, laser energy 150 W, scanning The spacing is 0.4mm, the pulse width is 0.6ms, and the frequency is 40Hz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com