Separating and recycling method of nickel, cobalt, copper manganese and zinc in electroplating sludge

A technology for separation and recovery of electroplating sludge, which is applied in the field of separation and recovery of cobalt and zinc, copper, manganese and nickel in electroplating sludge. The effect of short technological process, good social and economic benefits, and small investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

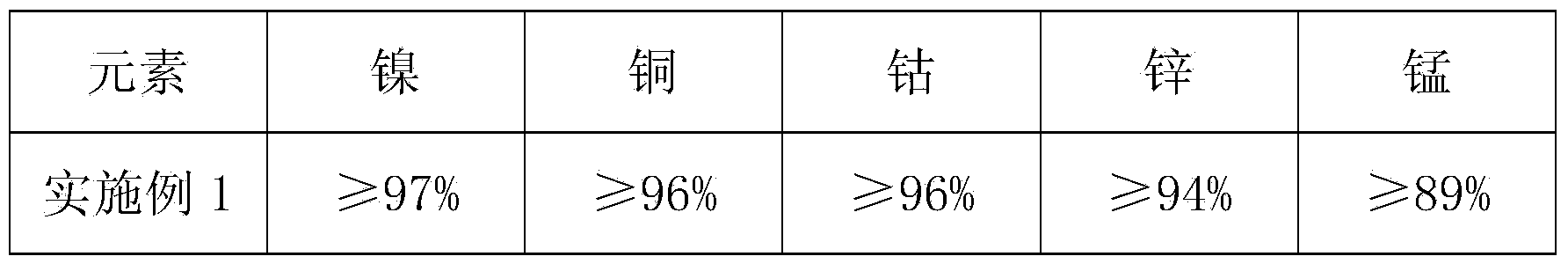

Embodiment 1

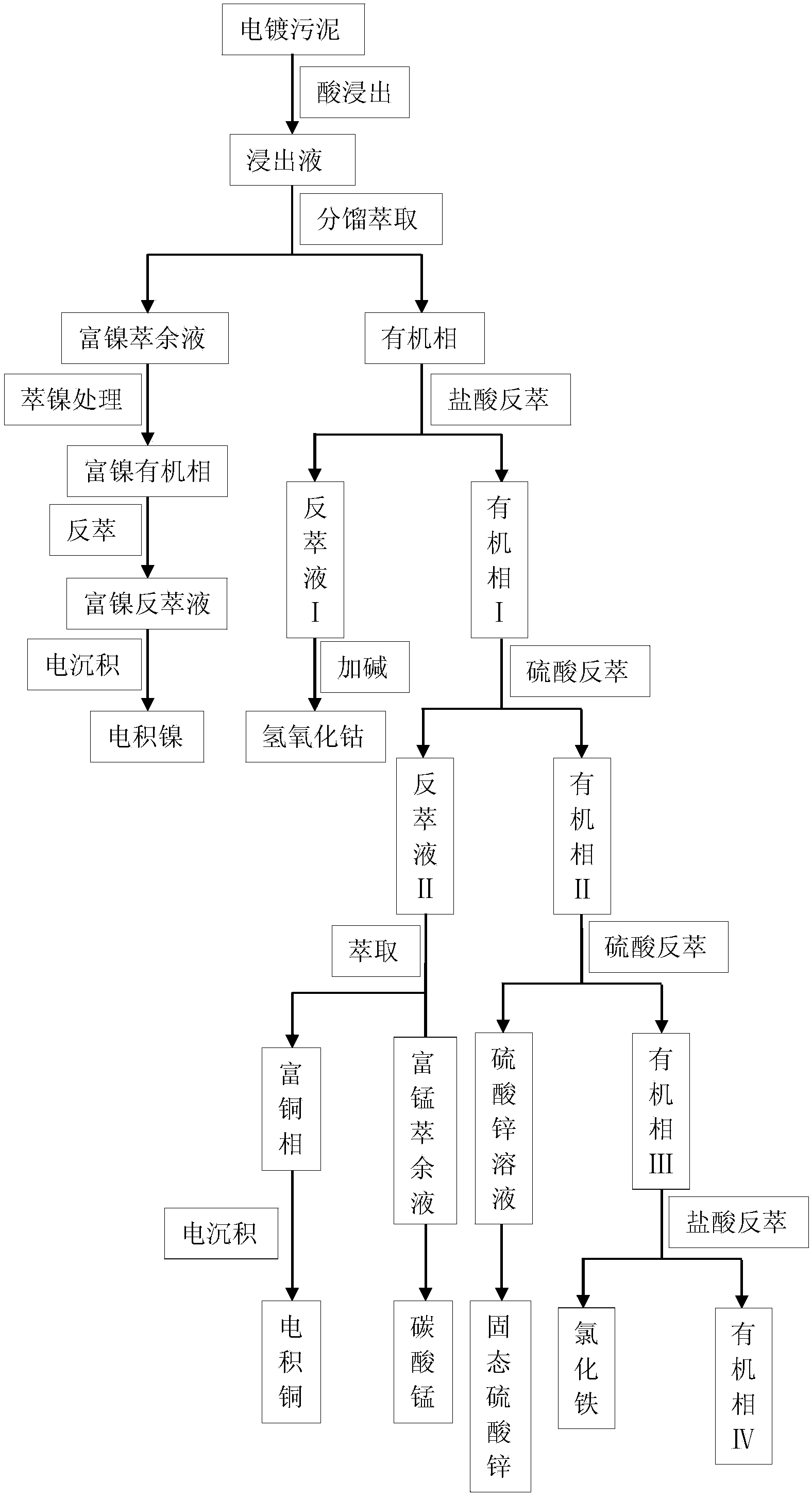

[0048] A method for separating and recovering nickel, cobalt, copper, manganese and zinc in electroplating sludge is realized through the following steps:

[0049] Step 1, performing acid leaching treatment on the electroplating sludge, and filtering to obtain leachate and filter residue; wherein, the acid leaching treatment specifically refers to the iron removal operation on the electroplating sludge by using the yellow sodium iron vanadium method;

[0050] Step 2, using the P507 kerosene extraction system to carry out fractional distillation and extraction of the leaching solution to obtain an organic phase and a nickel-rich raffinate;

[0051] Step 3, the organic phase is carried out step by step stripping:

[0052] (1), the organic phase is back-extracted with hydrochloric acid with a concentration of 0.5 to 2 mol / L to obtain an organic phase I and a back-extraction solution I containing cobalt, calcium and magnesium;

[0053] (2), be that 1~2mol / L sulfuric acid is carri...

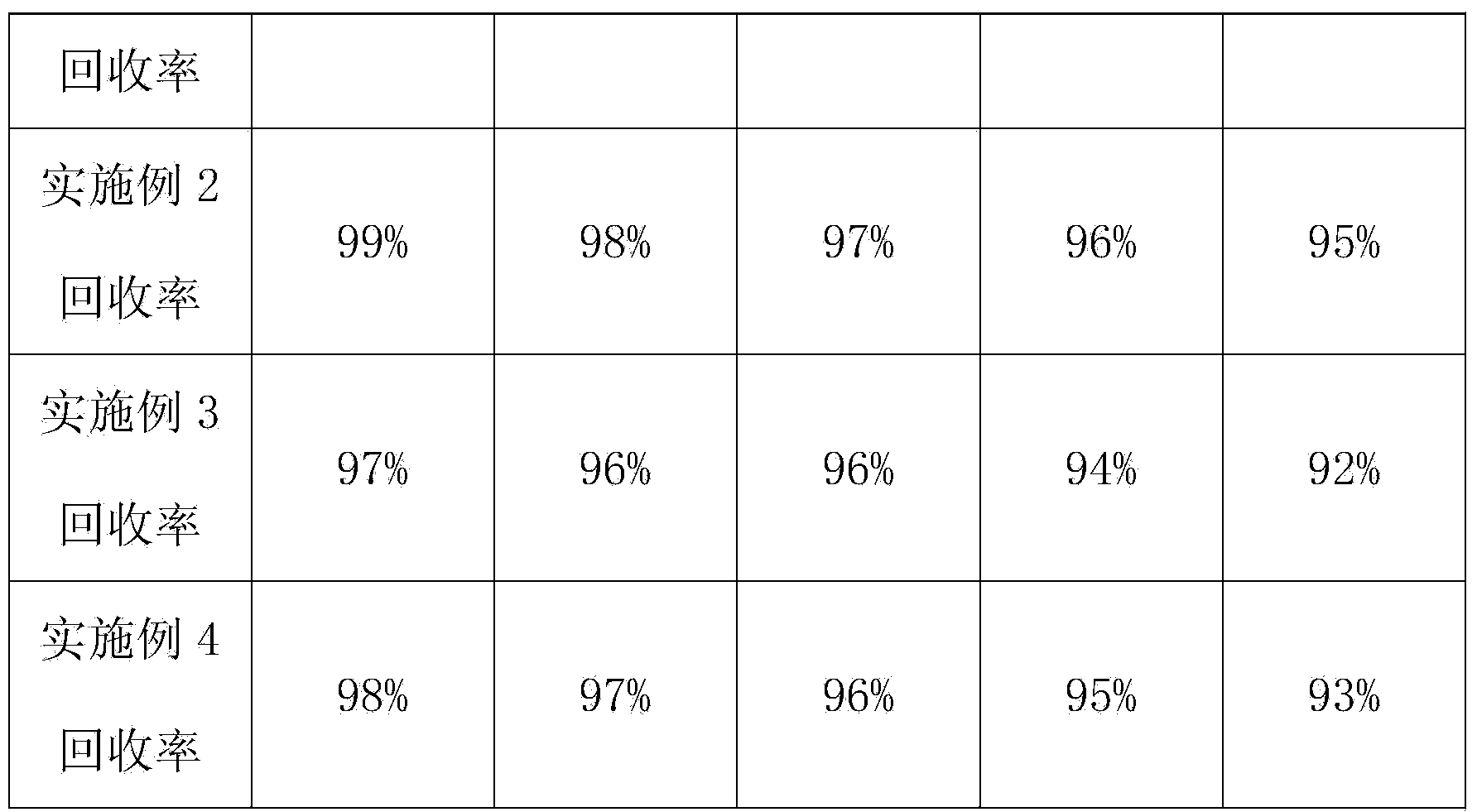

Embodiment 2

[0070] Compared with Example 1, this Example 2 is different in that the concentration of the stripping liquid used in the step-by-step back-extraction of Step 3 is different, and the rest of the steps and parameters are the same as in Example 1. Specifically, the specific content of Step 3 of Embodiment 2 is as follows:

[0071] Step 3, the organic phase is carried out step by step stripping:

[0072] (1), the organic phase is back-extracted with hydrochloric acid with a concentration of 1mol / L to obtain an organic phase I and a back-extraction solution I containing cobalt, calcium and magnesium;

[0073] (2), with a concentration of 1.2mol / L sulfuric acid, the organic phase I is back-extracted to obtain the organic phase II and copper- and manganese-containing stripping solution II;

[0074] (3), be that 2.5mol / L sulfuric acid is carried out stripping to organic phase II with concentration, obtain organic phase III and zinc sulfate solution;

[0075] (4) Back-extracting the...

Embodiment 3

[0077] Compared with Example 1, this Example 3 is different in that the concentration of the stripping liquid used in the step-by-step stripping in Step 3 is different, and the rest of the steps and parameters are the same as in Example 1. Specifically, the specific content of Step 3 of Embodiment 3 is as follows:

[0078] Step 3, the organic phase is carried out step by step stripping:

[0079] (1), the organic phase is back-extracted with hydrochloric acid with a concentration of 0.8mol / L to obtain an organic phase I and a back-extraction solution I containing cobalt, calcium and magnesium;

[0080] (2), with a concentration of 1.1mol / L sulfuric acid, the organic phase I is back-extracted to obtain the organic phase II and copper- and manganese-containing stripping solution II;

[0081] (3), be that 2.3mol / L sulfuric acid is carried out stripping to organic phase II with concentration, obtain organic phase III and zinc sulfate solution;

[0082] (4) Back-extracting the org...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com