High stability molecular sieve catalyst for preparing propylene transformed from methanol and preparation thereof

A methanol conversion and high stability technology, applied in the direction of molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of molecular sieve catalysts such as poor thermal stability and hydrothermal stability, easy coking and deactivation, etc., to achieve Good anti-coking performance, improved anti-coking performance, and increased reaction stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

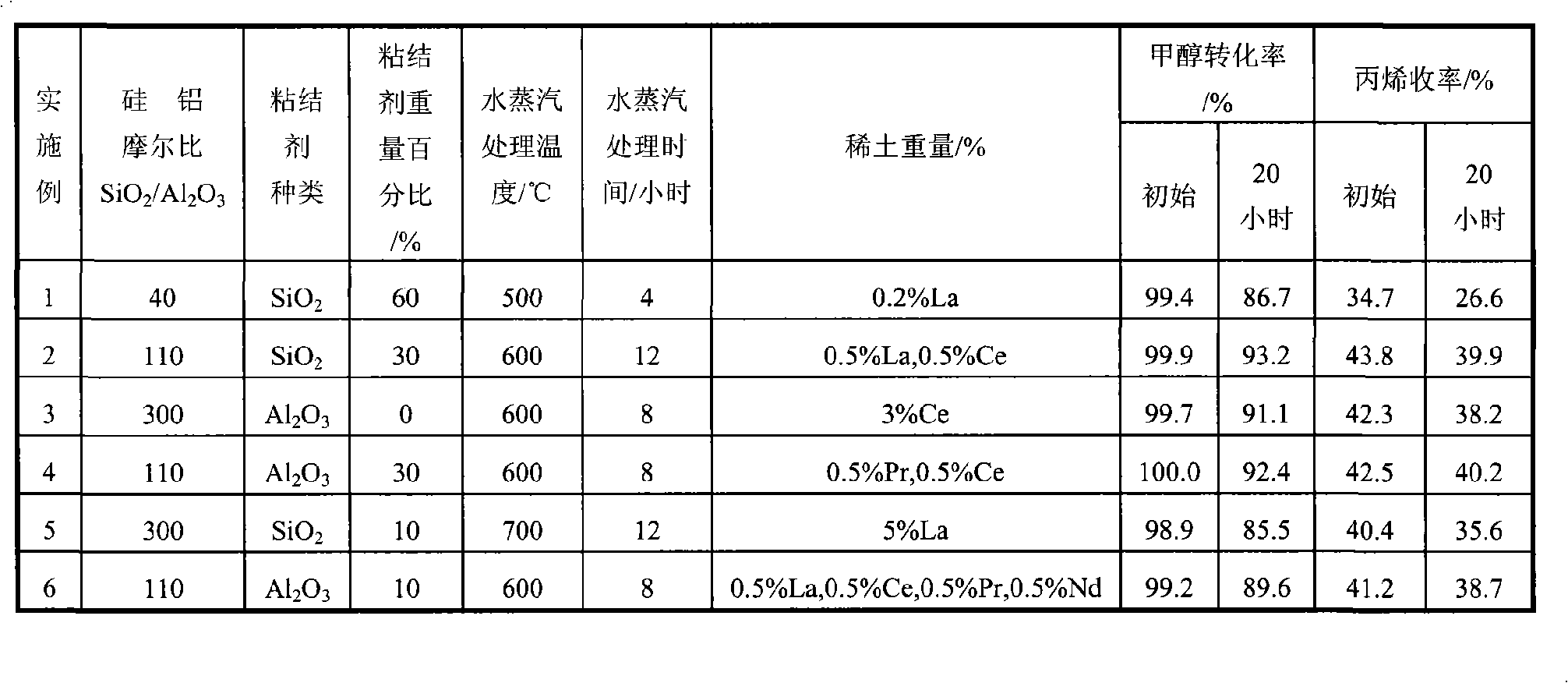

[0018] SiAl to SiO 2 / Al 2 o 3 40, 110, 300 ZSM-5 molecular sieve raw powder and 0%, 10%, 30%, 60% binder SiO in weight percentage 2 Mixed, extruded and calcined at 600°C for 8 hours. Exchange in a 0.5 mol / L hydrochloric acid solution with a volume liquid-solid ratio of 10 at a temperature of 70° C. for 5 hours. Then use at least one solution selected from lanthanum, cerium, praseodymium or neodymium nitrate or chloride at a temperature of 20 to 90°C for 4 to 8 hours, and exchange the modified molecular sieve precursor at a temperature of 500, 600, 700 ℃, space velocity 0.2 hours -1 Under steam treatment for 8 hours. The desired modified molecular sieve catalyst was prepared by rinsing with oxalic acid at 70°C for 5 hours at a volume-liquid-solid ratio of 10, and roasting at 600°C.

Embodiment 7

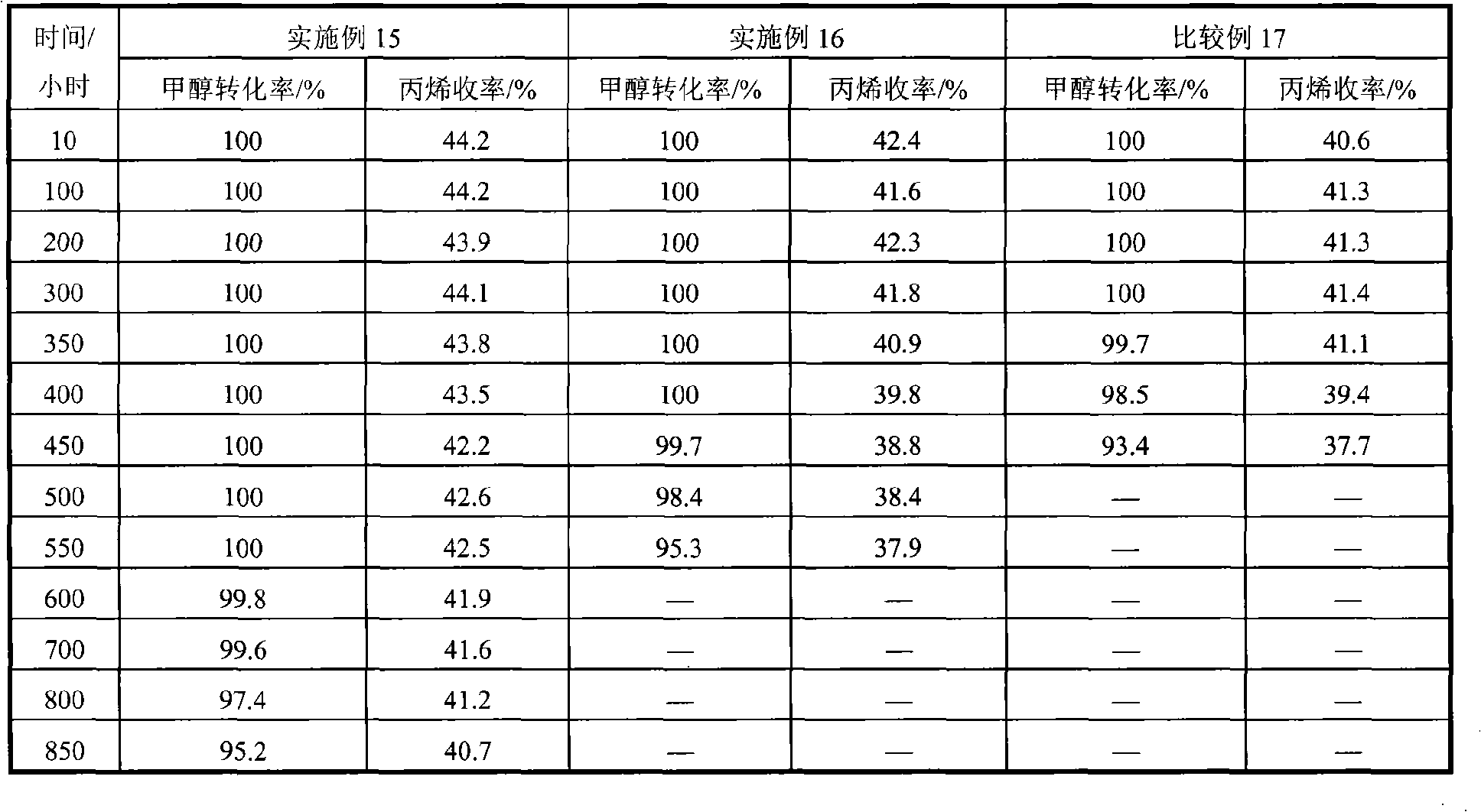

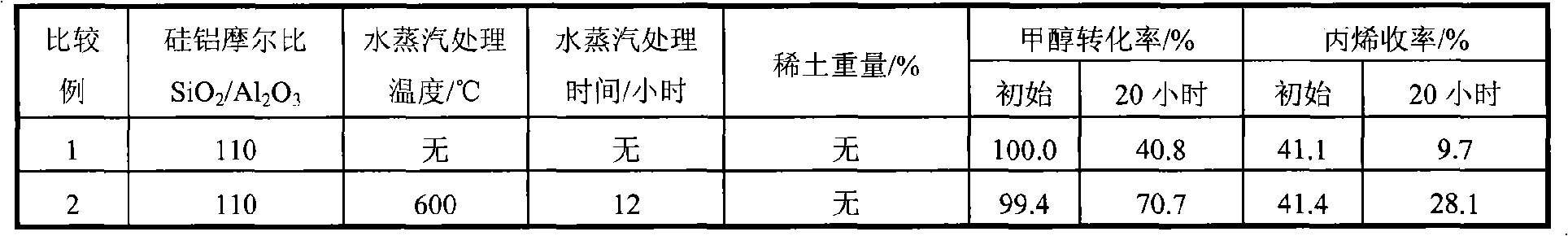

[0020] The modified molecular sieve catalysts prepared in Examples 1 to 6 and the molecular sieve precursors I and II prepared in Comparative Examples 1 and 2 were used in the methanol conversion reaction to produce propylene, using methanol as a raw material at a pre-reaction temperature of 400°C , the reaction temperature is 470°C, the reaction pressure is 0.04MPa, and the space velocity of methanol is 12 hours -1 , under the condition of water / methanol molar ratio 3, the reaction raw materials pass through Al 2 o 3 The catalyst bed and the modified ZSM-5 molecular sieve bed react to generate propylene. The reaction results are listed in Table 1 and Table 4.

Embodiment 8~15

[0022] Molar ratio of silicon to aluminum to SiO 2 / Al 2 o 3 110 ZSM-5 molecular sieve powder and 30% binder SiO in weight percent 2 Mixed, extruded and calcined at 600°C for 8 hours. 0.1, 1.0, 3.0, 5.0 mol / L hydrochloric acid, nitric acid solution at 20, 40, 70, 90°C with a volume liquid-solid ratio of 10 or 0.1, 0.5 at a temperature of 70°C with a volume liquid-solid ratio of 10 , 2.0, 3.0 mol / L ammonium nitrate, ammonium sulfate, and ammonium chloride solutions for 1, 3, 5, and 8 hours. Then treat it with cerium nitrate solution at a temperature of 70°C for 6 hours, and place the exchanged modified molecular sieve precursor at a temperature of 600°C and a space velocity of 0.2 hours -1 Under steam treatment for 8 hours. Use oxalic acid, citric acid, and maleic acid solutions to wash at 70°C for 2, 3, and 5 hours at a volume-to-solid ratio of 10, and roast at 600°C to obtain the desired modified molecular sieve catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com