Continuous powder humidifying and forming equipment, application method and catalyst carrier preparation method

A molding equipment and powder technology, applied in the direction of catalyst carrier, catalyst activation/preparation, auxiliary molding equipment, etc., can solve the problems of affecting the microporous structure of the catalyst carrier, low production efficiency, long humidification time, etc., to shorten the process and Preparation time, improve production efficiency, good moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0075] In a third aspect, the present invention provides a method for preparing a catalyst carrier, which adopts the above-mentioned powder continuous humidification molding method, wherein the powder material is kaolin and / or pseudo-boehmite, and the liquid material is molecular sieve slurry , aluminum sol, inorganic acid solution and deionized water at least one.

[0076] Wherein, the humidification mass ratio of the powder material to the liquid material is: 1:0.01-3, and the acid content in the liquid is 0.01-20 mol / L.

[0077] The catalyst carrier preparation method provided by the present invention realizes the whole process from rapid mixing and humidification of alumina powder and liquid to extrusion molding, and eliminates the problems of sticking to the wall and difficult discharge of alumina after humidification, making alumina Having the same acidification time ensures that the molded catalyst carrier has the same pore volume as the alumina, and also improves the c...

Embodiment 1

[0099] Example 1 illustrates: the effect of using the powder continuous humidification molding provided by the present invention to prepare the catalyst carrier, and the uniformity of the catalyst carrier, the catalyst pore volume, the specific surface and the preparation time of the catalyst are analyzed.

[0100] Powder material A is a mixture of alumina powder and squash powder at a mass ratio of 80:1; liquid B is 4.2% HNO 3 Acid solution (density 1.02g / mL). Humidify the powder material A into a wet powder with a moisture content of 45% and an acid content of 0.33mmol / g. The humidified powder is extruded into a column, dried at 120°C for 2 hours, and roasted at a constant temperature of 580° After 4 hours, the catalyst carrier was obtained.

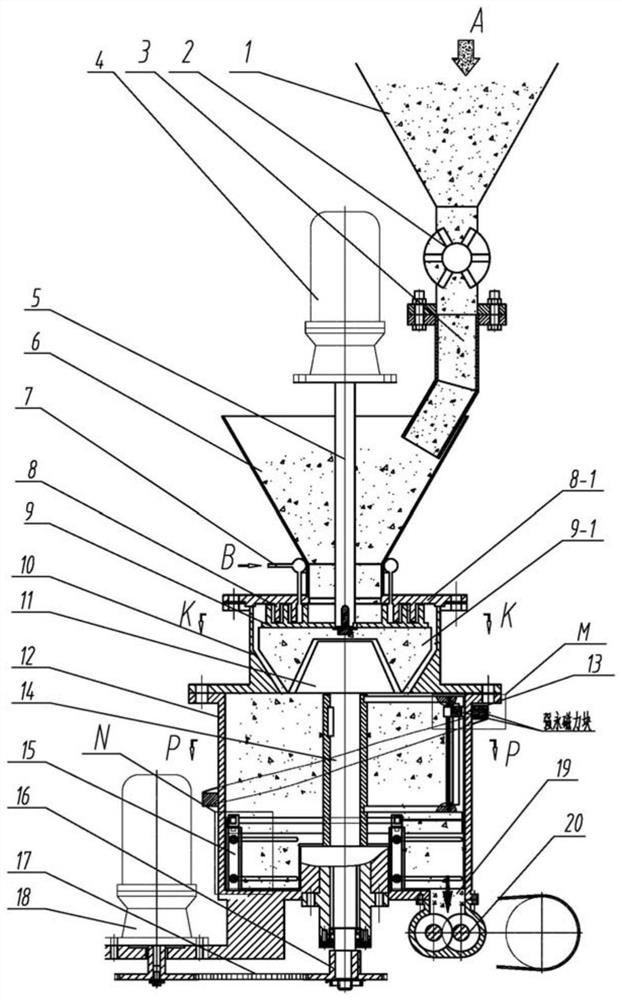

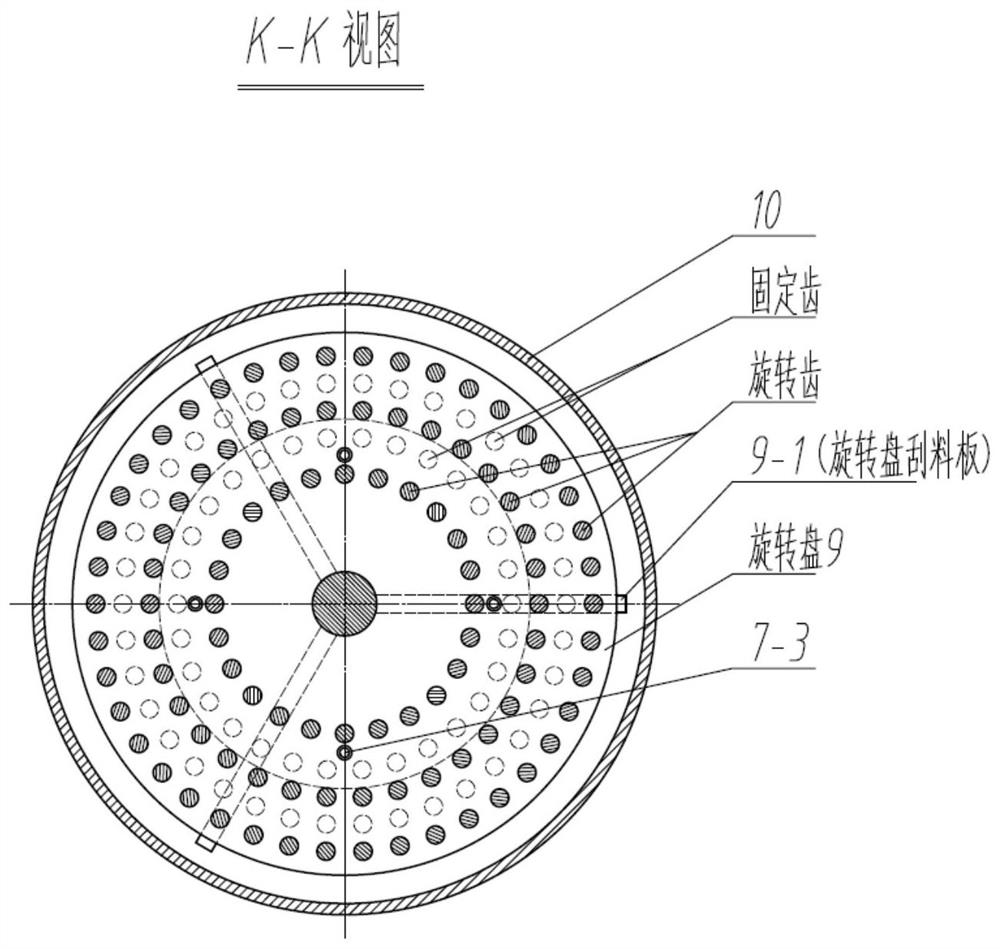

[0101] Use as attached figure 1 The shown powder continuous humidification molding equipment prepares the catalyst carrier. The powder meter 2 uses two sets of rotary valves for metering (respectively measuring alumina and sage powd...

Embodiment 2

[0129] Using the continuous humidification molding equipment in Example 1, the powder materials are pseudo-boehmite and scallop powder from Shandong Aluminum Plant, and the liquid material B is 5.7% HNO 3 Acid solution (density 1.03g / mL), humidification is pseudo-boehmite wet powder with a moisture content of 45% and an acid content of 0.32mmol / g. The powder after humidification is extruded into a columnar shape. It was dried at ℃ for 2 hours, and then calcined at a constant temperature of 580° for 4 hours to obtain a catalyst carrier.

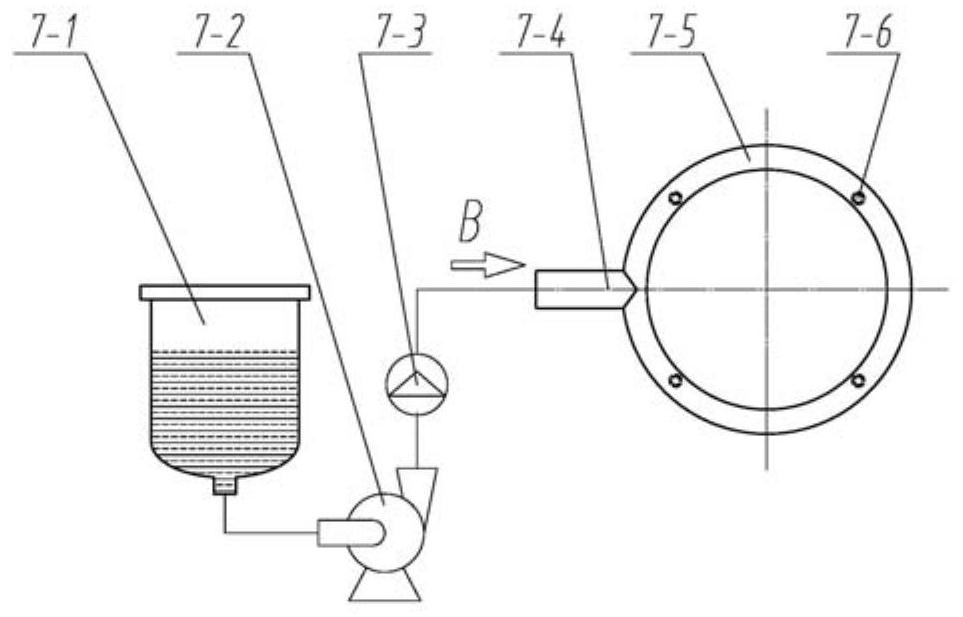

[0130] Prepare 85L5.7%HNO according to the moisture content requirements of the mixed materials 3 The solution is loaded into 7-1. The mass addition ratio of powdered pseudo-boehmite powder and safflower powder is 75:1 (the mass flow rate of powdered pseudo-boehmite is 174.87kg / h, and the mass of safflower powder is 2.33kg / h); powder: liquid mass ratio Mix according to the method of 4.14:1, the yield of mixed wet material is 220.0kg / h, the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com