Patents

Literature

57results about How to "Maintain pore structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium-ion battery pole piece and preparation method thereof

ActiveCN111725479AIncrease energy densityGood ion conductivityElectrode rolling/calenderingSecondary cellsElectrically conductiveHigh energy

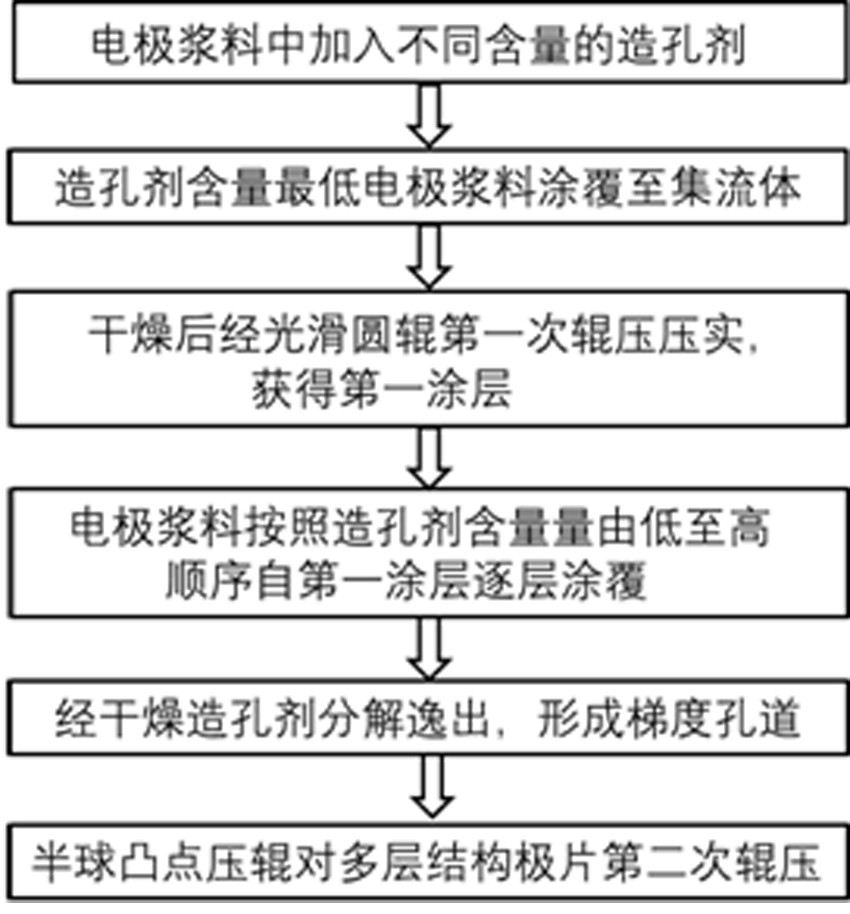

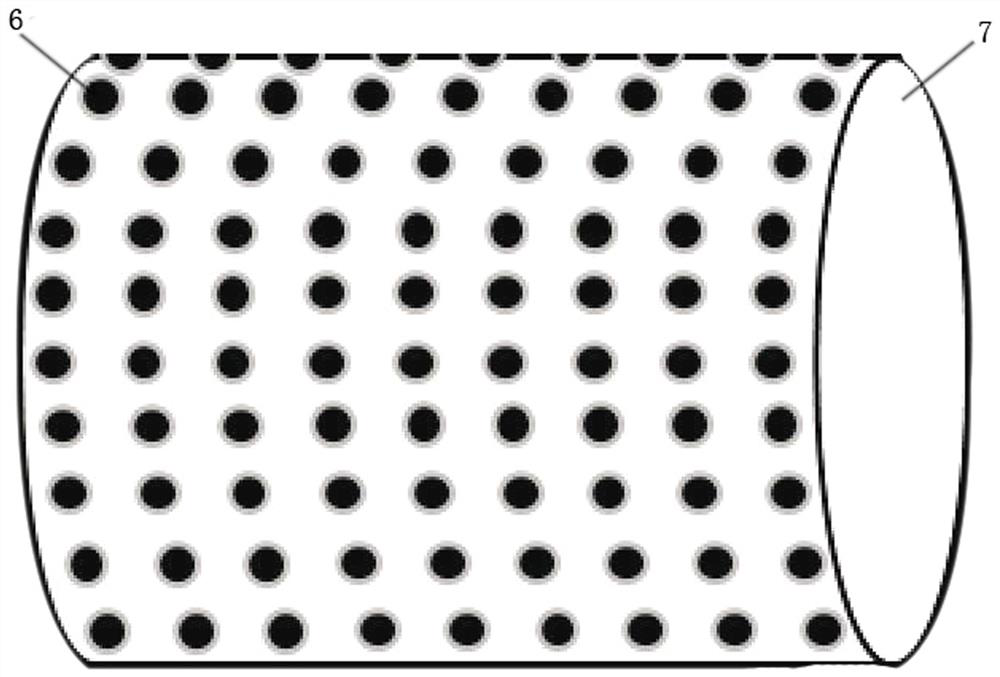

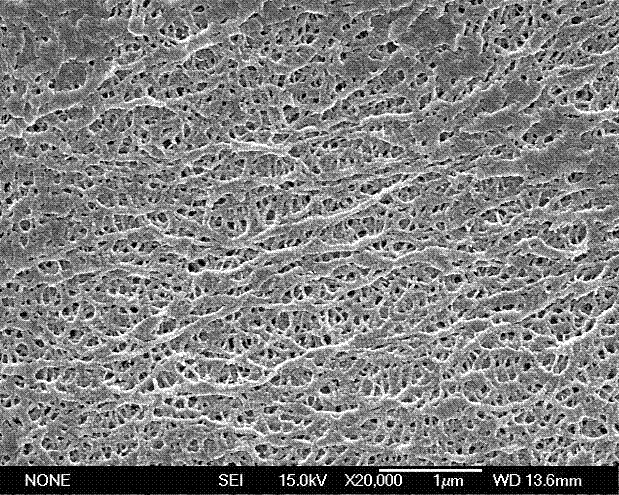

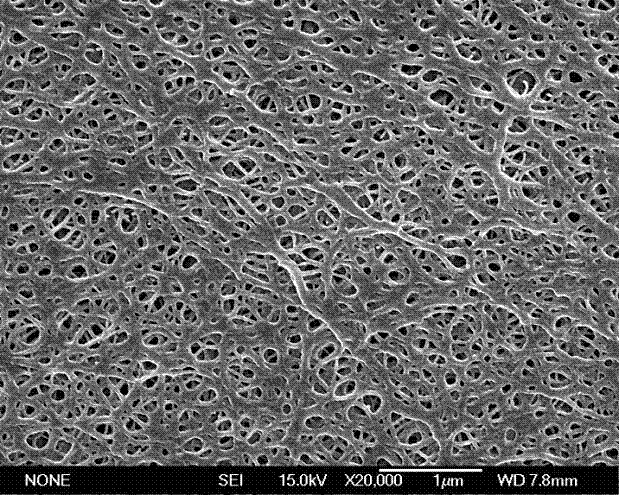

The invention belongs to the technical field of lithium-ion batteries and particularly relates to a lithium-ion battery pole piece with gradient porosity and a preparation method thereof, and the preparation method comprises the following steps: (1) mixing powder pore-forming agents with different contents with an active material, a conductive agent and a polymer binder according to the number ofdesigned pole piece layers to obtain multiple parts of electrode slurry with different pore-forming agent contents; (2) coating a current collector with the electrode slurry with the lowest pore-forming agent content, drying, and carrying out primary rolling compaction by using a compression roller to obtain a first coating; (3) applying the electrode slurry on the surface of the first coating layer by layer according to the sequence of the pore-forming agent contents from low to high; (4) heating and drying a pole piece to decompose and escape the pore-forming agents, and forming a gradient pore channel in the coating; and (5) carrying out secondary rolling on the dried multi-layer structure pole piece by adopting an embossing roller with a continuous hemispherical convex point structure.Compared with the prior art, the method has the advantages that the pole piece with the gradient porosity is prepared, high energy density is obtained through rolling, meanwhile, good rate capabilityis achieved, and the utilization rate of the active material is increased.

Owner:SHENZHEN XINYUREN TECH

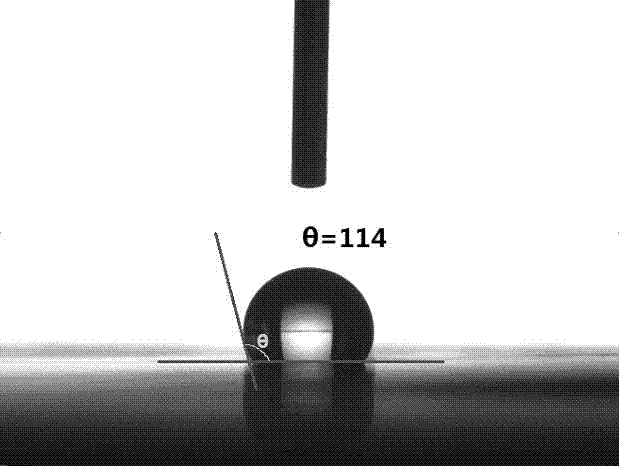

A constitution method of a lithium ion battery diaphragm surface supermolecule membrane

ActiveCN104124417AImprove mechanical propertiesMaintain pore structureSecondary cellsCell component detailsPolyolefinElectrochemistry

The invention relates to a constitution method of a lithium ion battery diaphragm surface supermolecule membrane. Organic and inorganic constitution units with high thermal stability, high mechanical strength and hydrophilic polar functional groups are adopted. An organic-inorganic composite supermolecule membrane is alternatively assembled onto the polyolefin diaphragm surface and the pore inner surface by a layer-by-layer self-assembly method based on molecule interfaces. By fine regulation and control of the thickness, the constitution, the structure and surface characteristics of the supermolecule membrane at the molecule level, the thermal stability, mechanical strength and the ionic conductivity of the diaphragm are improved, thus enhancing the safety and electrochemical properties of the lithium ion battery.

Owner:SHANGHAI UNIV

Preparation method of high-performance zinc-polyaniline secondary battery

InactiveCN106935916AImprove adsorption capacityIncrease profitFinal product manufactureSecondary cellsCarbon compositesGlass fiber

The invention discloses a preparation method of a high-performance zinc-polyaniline secondary battery. The preparation method comprises the following steps: preparation of a positive plate: adopting home-made graphite paper as a positive current collector, and preparing polyaniline on the graphite paper; preparation of a negative plate: adopting a home-made zinc / carbon composite material as a negative active material, mixing the zinc / carbon composite material with a conductive agent, a binder and a solvent to form a sizing agent, coating the sizing agent on the current collector, drying, roll forming and cutting into slices to prepare the cathode plate; assembling: putting the positive plate, a membrane and the negative plate into a battery shell in a laminated manner, after a pole lug is welded with a pole column, sealing the battery and injecting an electrolyte, and adding glass fiber paper for capping. The zinc-polyaniline secondary battery prepared in the invention is high in safety performance, low in preparation cost, high in utilization rate of positive and negative active substances and excellent in cycle performance.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Preparation method of nitrogen-doped hollow porous carbon

InactiveCN106672935ALow priceEliminate hazardsCarbon preparation/purificationPorous carbonSupercapacitor

The invention relates to a preparation method of nitrogen-doped porous carbon. The preparation method specifically comprises the following steps of firstly, preparing a manganese dioxide precursor, preparing a mixing solution containing a certain ratio of aniline and pyrrole monomers, dispersing a manganese dioxide powder into the mixing solution, cooling the dispersing liquid to the temperature below 10 DEG C, adding an acid solution into the dispersing liquid, reacting for a period of time at low temperature, and separating, so as to obtain a product; finally, carbonizing at high temperature under the protection atmosphere, so as to obtain the nitrogen-doped hollow porous carbon material. The preparation method has the characteristics that the synthesis technology is simple, the safe, green and pollution-free effects are realized in the synthesis process, the byproducts can be recycled, the preparation method is suitable for industrial production, and the like; the property of the nitrogen-doped porous carbon is excellent, the specific surface area is higher, and the nitrogen-doped porous carbon can be widely applied to the fields of energy storage, catalysis, adsorption, such as supercapacitors.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

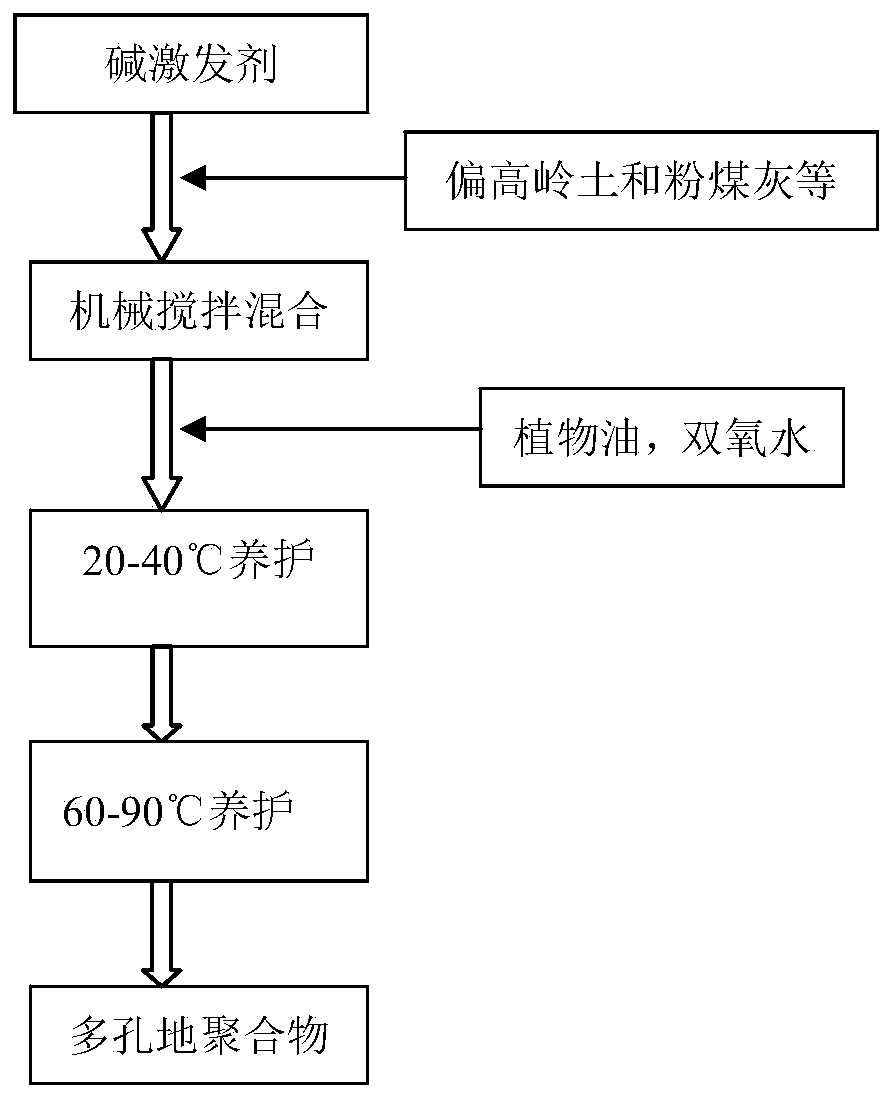

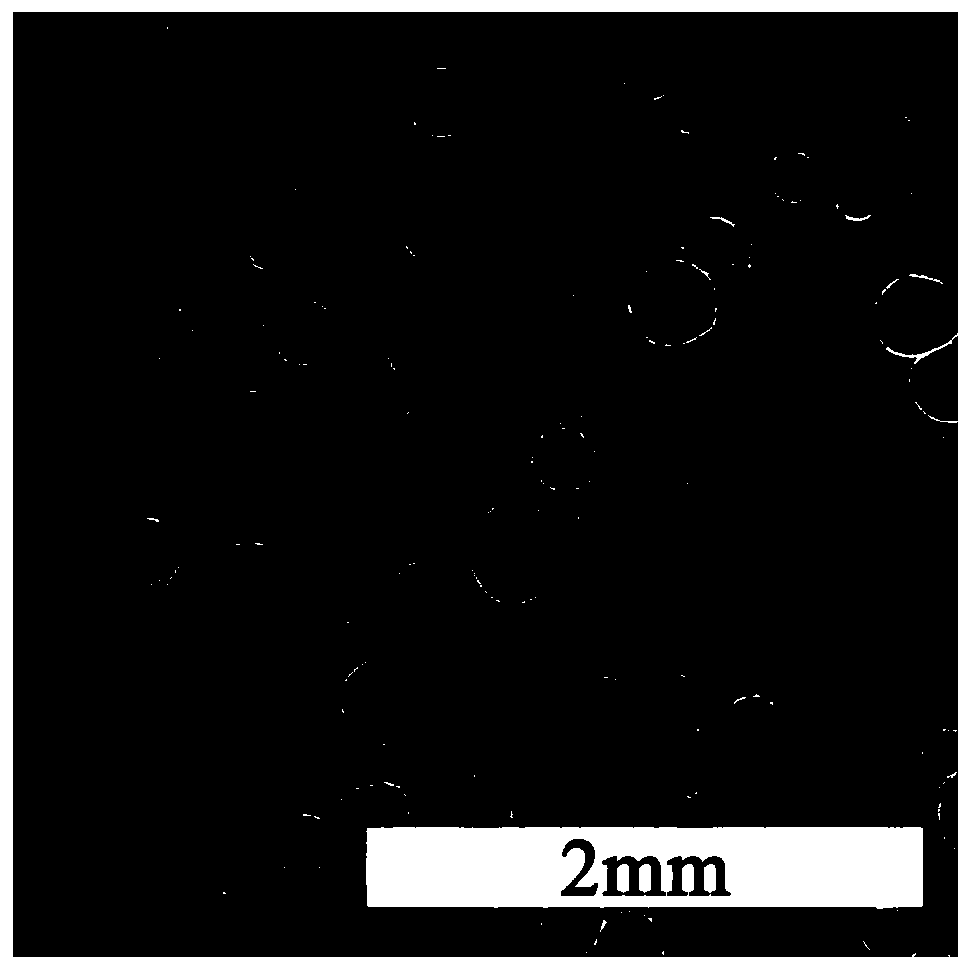

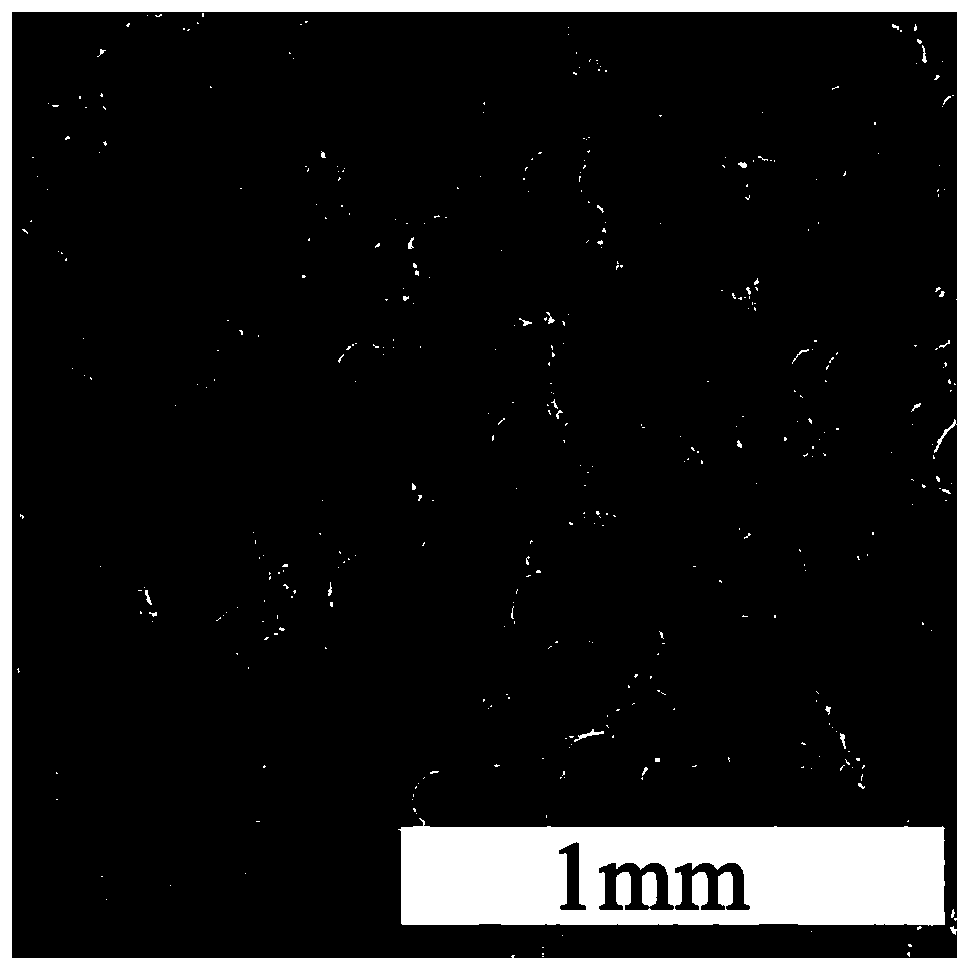

Method for efficiently preparing porous geopolymer by using vegetable oil

ActiveCN109704663AEasy to operateImprove pore structureCement productionCeramicwarePorosityVegetable oil

The invention relates to the technical field of manufacturing novel porous inorganic non-metallic materials new materials, in particular to a method for efficiently preparing porous geopolymer by using vegetable oil. At first, alkali activator is prepared; and then a homogeneously mixed geopolymer slurry / pulp is prepared by using the alkali activator; and then a foamed slurry is prepared by usingthe geopolymer slurry / pulp; finally, the foamed slurry is put into a mold for curing, and the final product is obtained after demoulding treatment. The porous geopolymer which is uniform and completeand controllable in porosity is prepared, the vegetable oil is used as the novel foam stabilizer, so as to not only effectively reduce the cost of preparation of the porous geopolymer, but also the method can be used as a method for efficiently utilizing the vegetable oil.

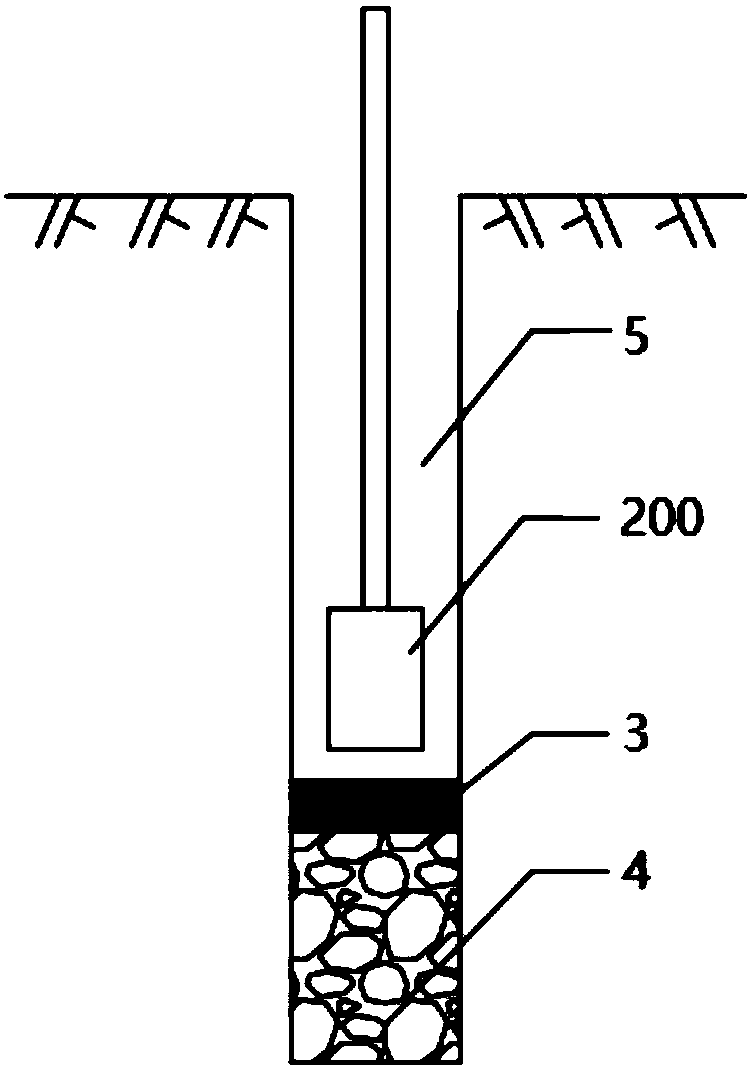

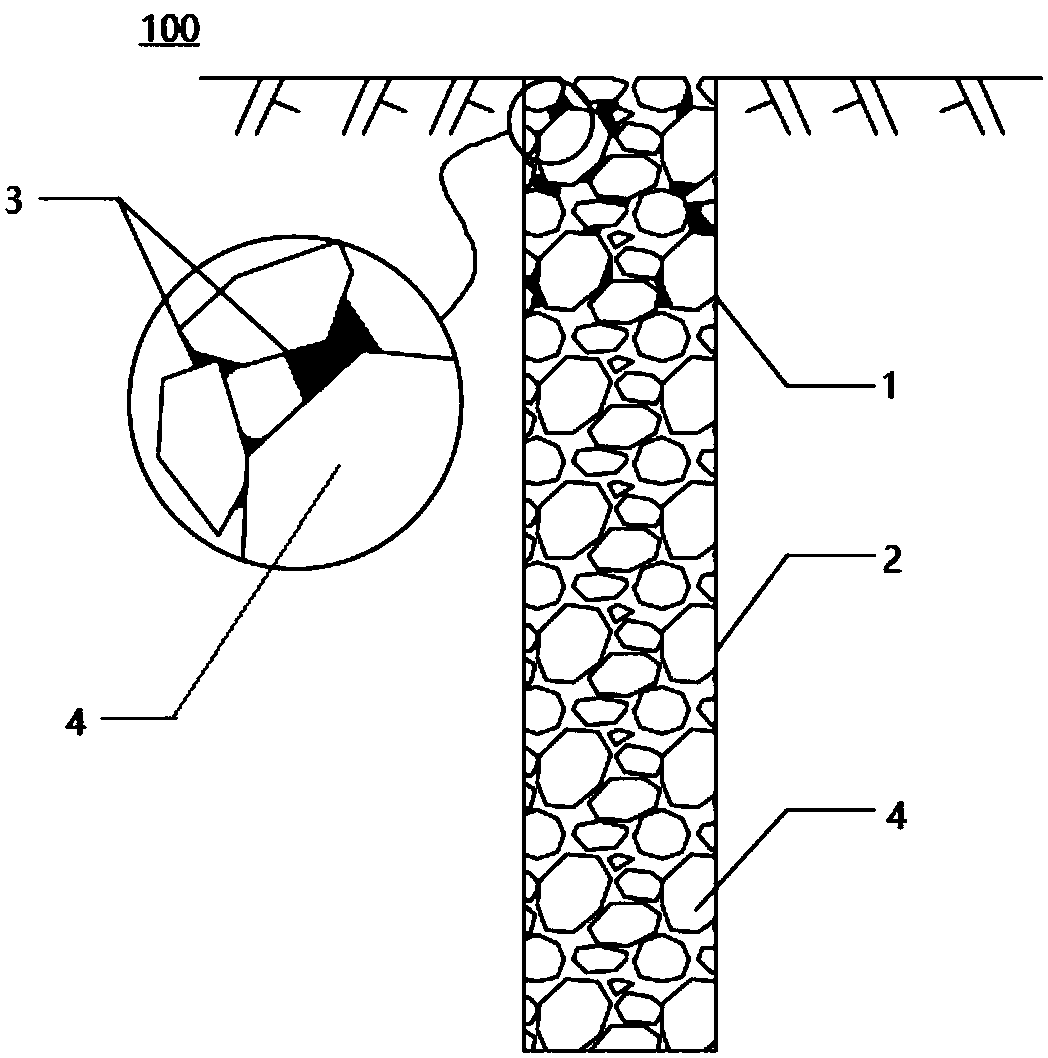

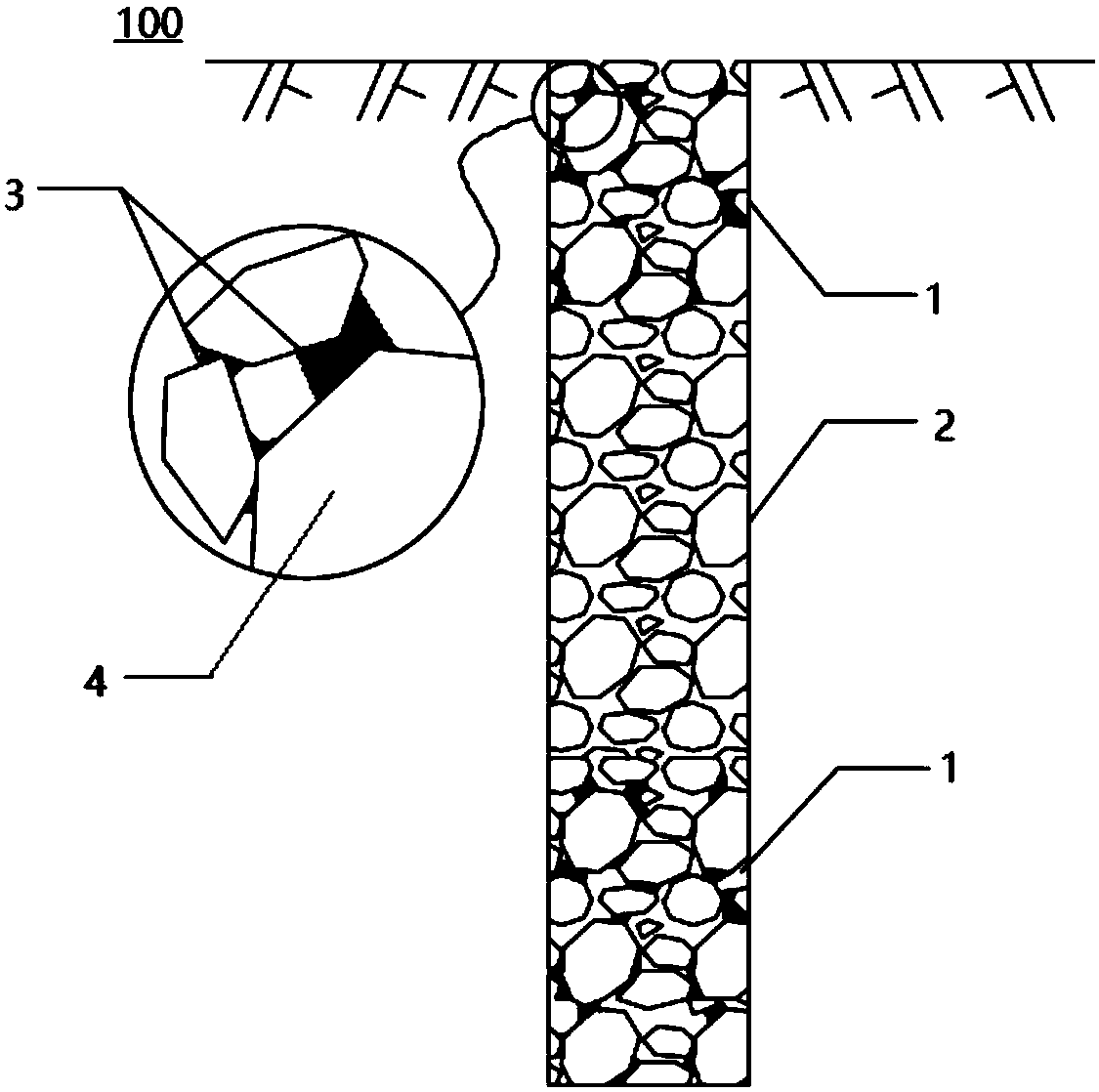

Structured cemented gravel pile and construction method thereof

The invention discloses a structured cemented gravel pile and a construction method thereof. The structured cemented gravel pile comprises a cemented gravel material pile body and a gravel material pile body. The construction method of the structured cemented gravel pile comprises the following steps of 1, an on-site in-situ test is performed according to design requirements to determine the porosity ratio of a gravel material in the compact accumulation process and the expansion degree and viscosity of a self-compacting cement-based material used for forming a cemented gravel material; 2, construction is carried out on the ground to form a pile hole; 3, the gravel material is backfilled into the pile hole to form the gravel material pile body, and the gravel material pile body is vibratedby adopting a vibrator until the porosity ratio of the gravel material reaches a preset value; and 4, the self-compacting cement-based material is poured into the pile hole so as to bond a part of the gravel material in the gravel material pile body to form the cemented gravel material pile body. According to the structured cemented gravel pile, the water permeability of the gravel pile is kept,the strength and the rigidity of the structured cemented gravel pile are increased, and the capability of supporting the horizontal load of the structured cemented gravel pile is improved.

Owner:TSINGHUA UNIV +1

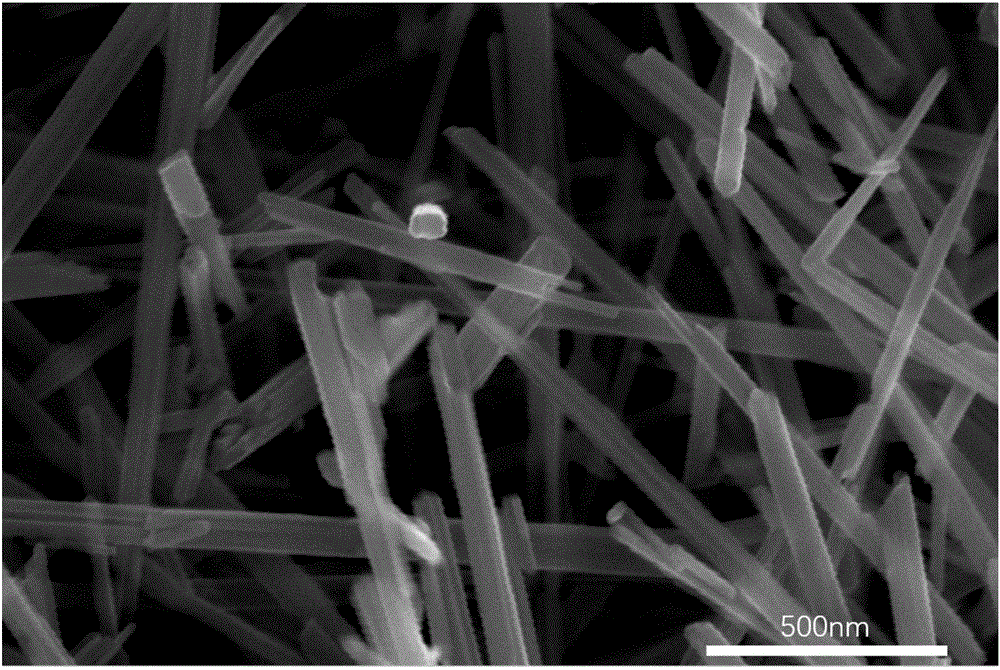

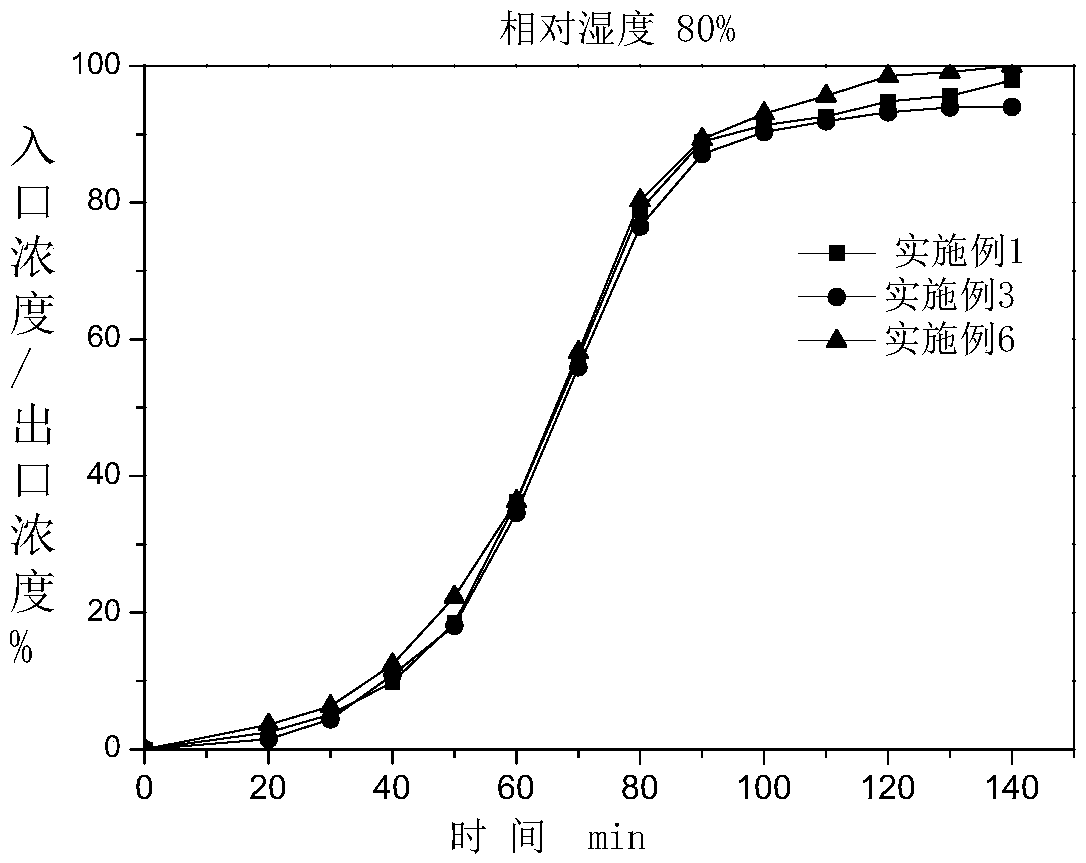

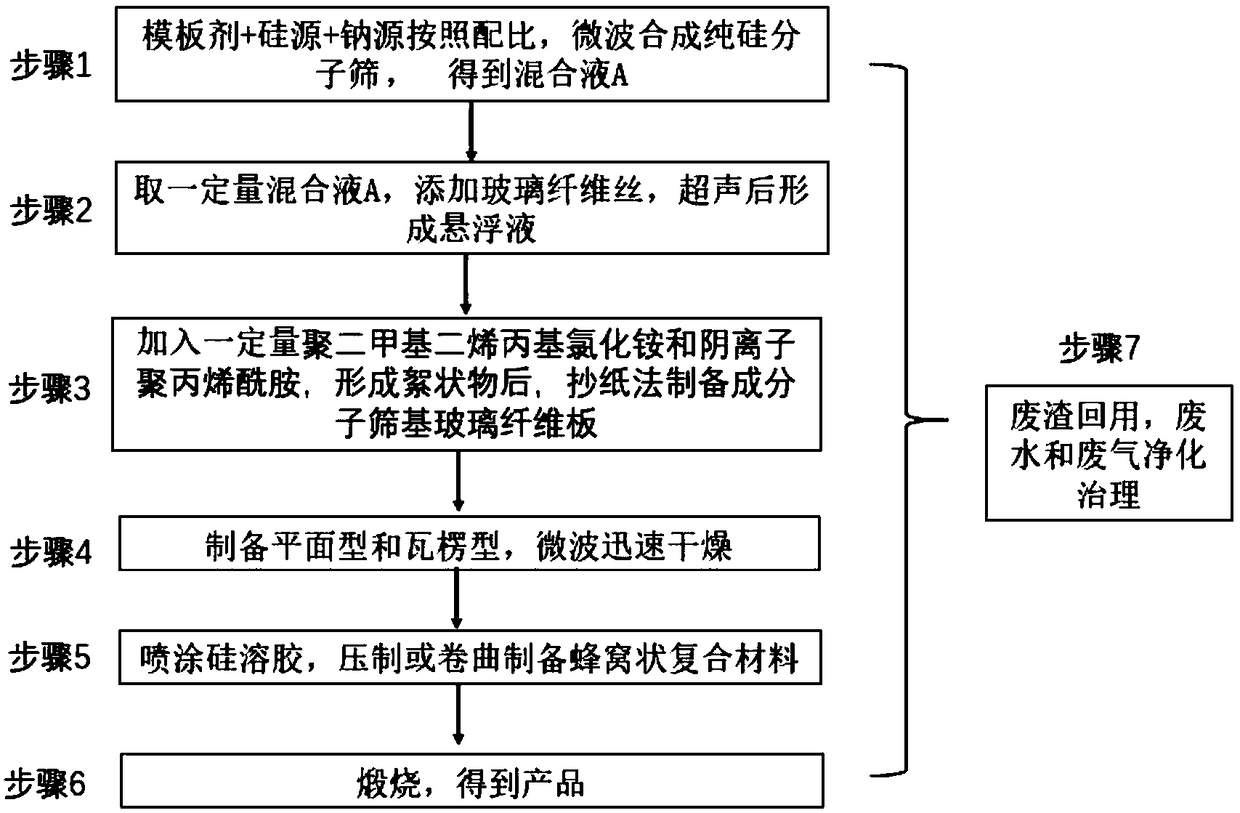

Hydrophobic molecular sieve-based composite material and preparation method thereof

ActiveCN109317119AEfficient synthesisMaintain pore structureGas treatmentOther chemical processesGlass fiberAdditive ingredient

The invention discloses a hydrophobic molecular sieve-based composite material and a preparation method thereof. The composite material is mainly prepared from pure silicon-based ZSM-5, is doped witha small amount of SiO2, and belongs to a pure silicon-based material. The preparation method is characterized in that a molecular sieve-based glass fiber board is made by a microwave-assisted synthesizing technology and a papermaking technology, made into a corrugated shape by hot pressing. The composite material prepared by the method has the advantages of high effective ingredient content, highadsorption performance, high hydrophobic property, high hydrothermal stability, low energy consumption, simple process steps, high material machining operability and the like, and can be widely applied to treatment equipment for organic waste gases such as industrial VOCs (Volatile Organic Compounds).

Owner:BEIJING LONGTAO ENVIRONMENTAL TECH CO LTD

Fe-SAPO-34 molecular sieve with high skeleton ion content and preparation method thereof

ActiveCN103708498AEvenly distributedIncrease contentMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesMolecular sieveIon content

The invention provides a Fe-SAPO-34 molecular sieve with high skeleton ion content and a preparation method thereof, overcoming the problems that the prepared metal-modified SAPO-34 molecular sieve reported in literature is low in skeleton metal content and low in catalytic activity when being applied to reaction for preparing olefin by employing methanol. The invention provides a synthetic method of the Fe-SAPO-34 molecular sieve with high skeleton ion content. The method has the characteristics that the prepared SAPO-34 molecular sieve is high in skeleton ion atom content and good in catalytic activity, and has a good industrial application prospect.

Owner:CHINA TIANCHEN ENG +1

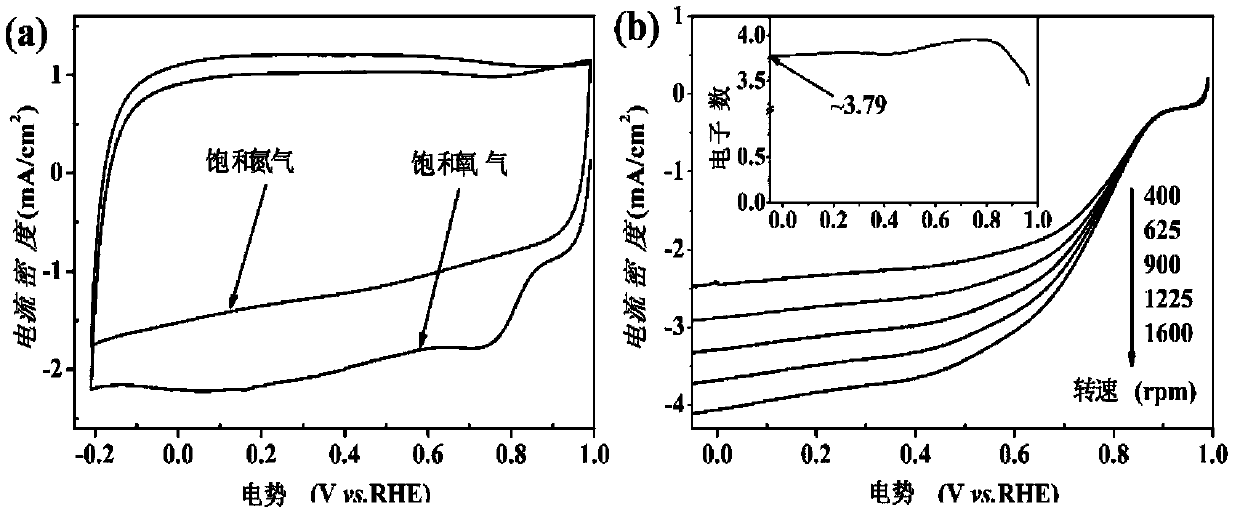

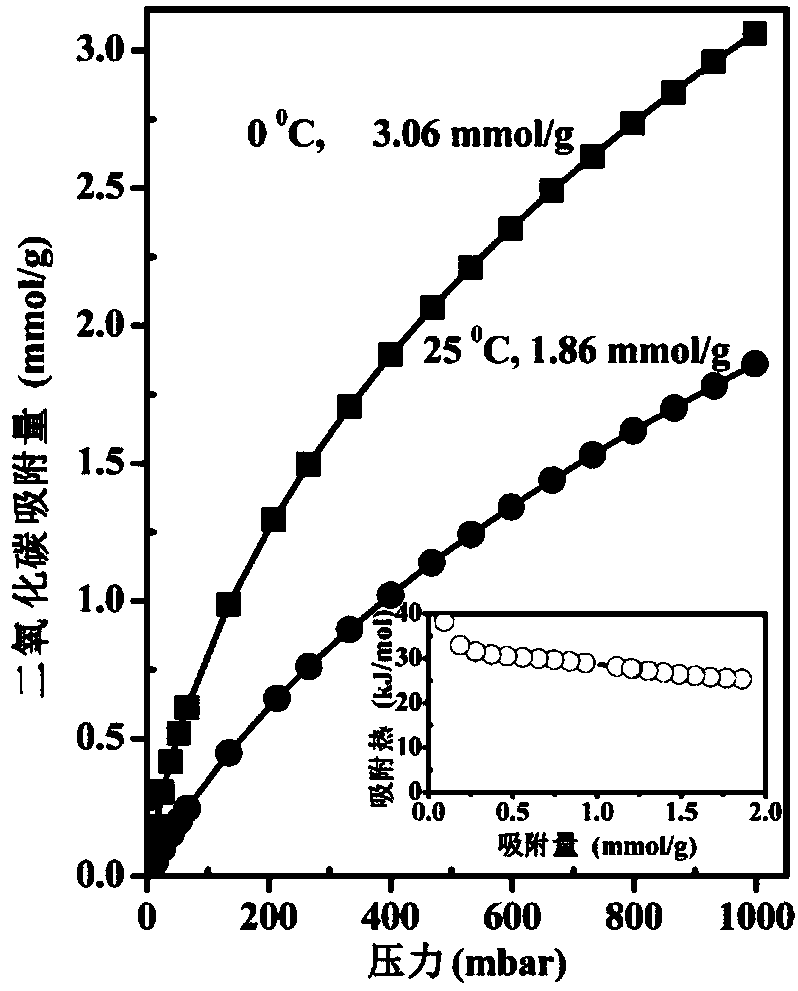

Method for preparing pyridine nitrogen element-enriched carbon material and application thereof

InactiveCN107651687AAbundant and renewable sourcesEasy to makeMaterial nanotechnologyCarbon compoundsPotassium hydroxideBiological activation

The invention provides a method for preparing a pyridine nitrogen element-enriched carbon material. The method for preparing the pyridine nitrogen element-enriched carbon material comprises a synthesis step and an activation step. The synthesis step is that high-pressure hydrothermal carbonization synthesis is carried out on a mixed solution formed by a carbon source and a solvent to obtain a carbide, wherein the carbon source is aquatic plant Enteromorpha; the activation step is that the carbide, melamine and potassium hydroxide are warmed up under a nitrogen atmosphere according to a certainratio, andcooled, washed and dried to obtain the pyridine nitrogen element-enriched carbon material. The carbon material obtained by the method has the advantages that the carbon source is abundant and renewable, and has a pore structure and nitrogen elements, and is favorable for the synthesis of the pyridine nitrogen element-enriched carbon material; the preparation process is simple and suitable for industrial application, and the process parameters are easy to control; and the carbon material has high nitrogen content, micron aperture and high specific surface area. The invention also discloses the application of the carbon material. The carbon material has a very broad application scope in the fields of carbon dioxide adsorption, electrocatalytic reaction and electrode material production.

Owner:XIANGTAN UNIV

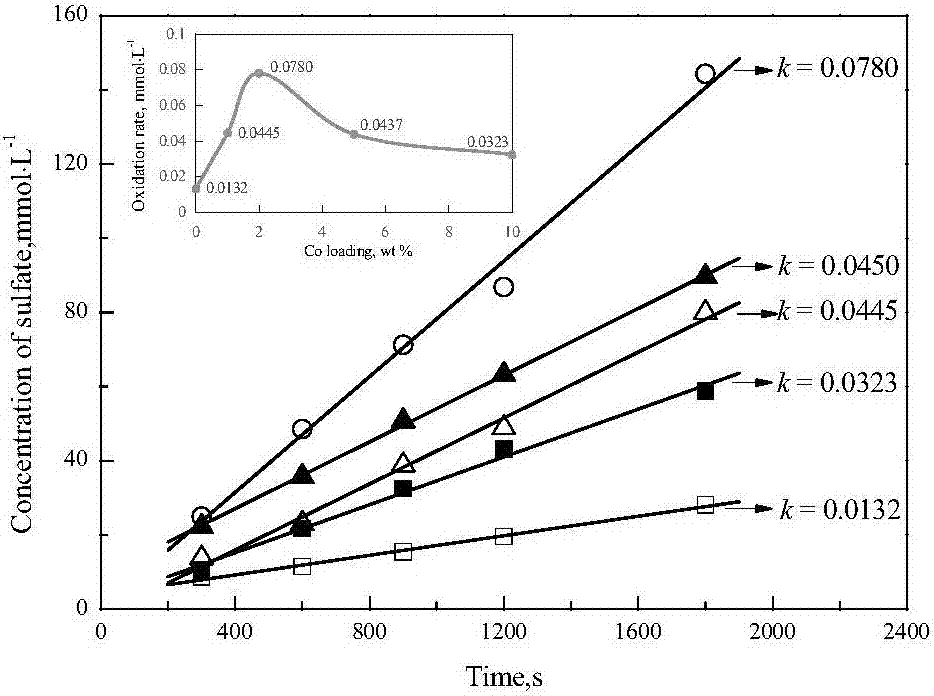

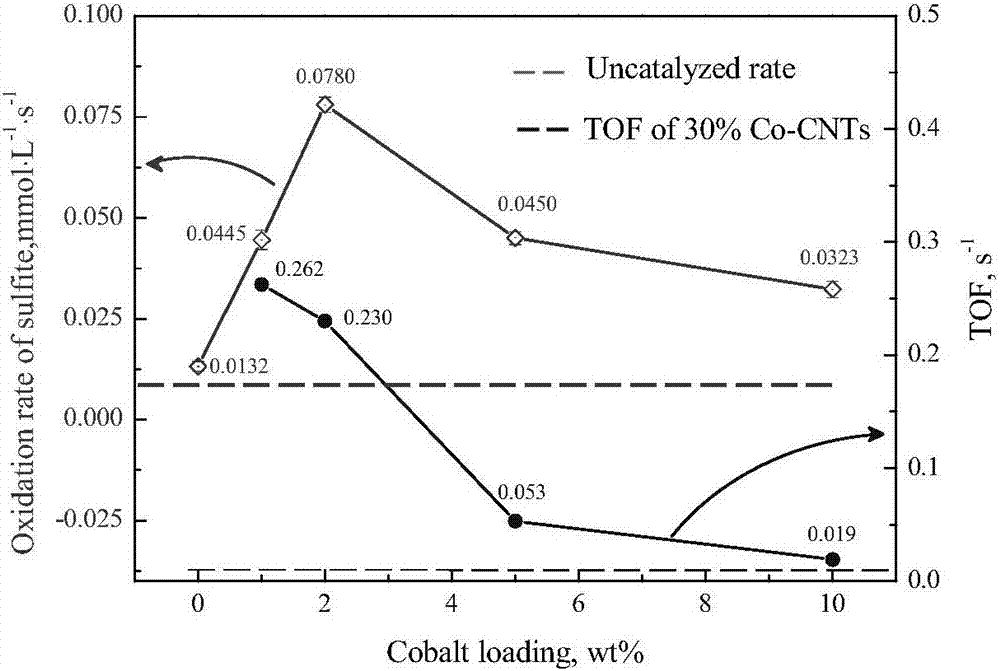

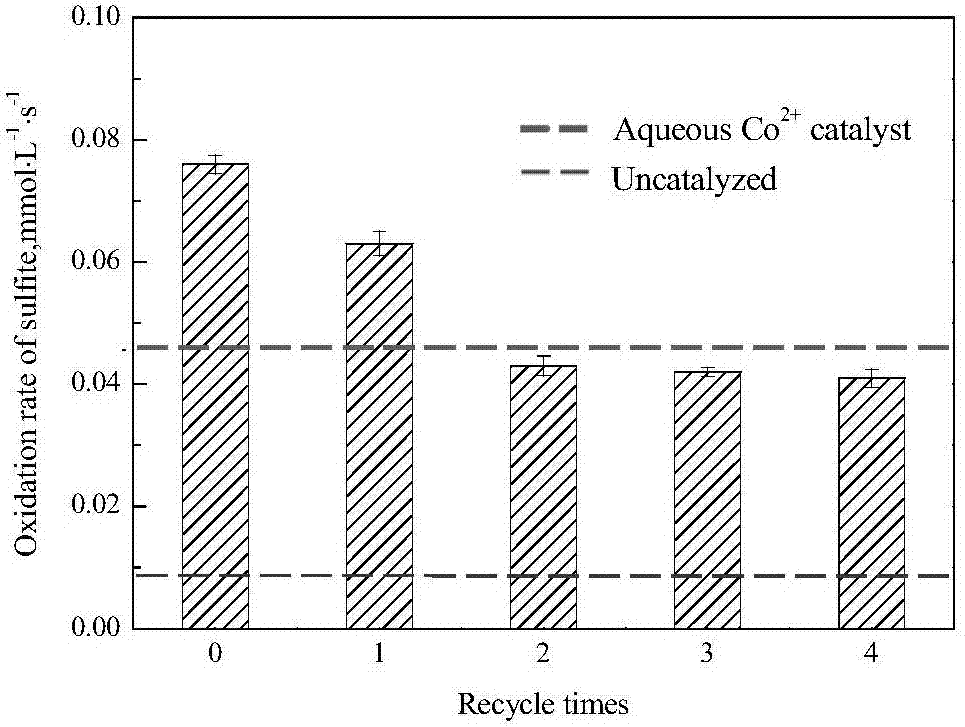

SBA15 catalyst loading cobalt base

ActiveCN107185581AIncrease oxidation rateSmall sizeMolecular sieve catalystsMagnesium sulfatesAlcoholRotary evaporator

The invention discloses an SBA15 catalyst loading a cobalt base. The loading amount of the cobalt base is 2%wt, and the cobalt base is highly dispersed inside pore canals of SBA15. The preparing method of the SBA15 catalyst comprises the steps of firstly weighing, by weight, 2 parts of solid powder of SBA15 and 0.1973 part of cobalt nitrate particles, dissolving the solid powder and cobalt nitrate particles into 100 parts (by weight) of absolute ethyl alcohol, and placing thee mixture into a beaker and conducting magnetic stirring for 5 h; secondly conducting still standing and crystallization for 24h; then placing the material obtained in the last step in a vacuum rotary evaporator to conduct evaporation drying for 2h, wherein the temperature is 60 DEG C; finally roasting the material in a muffle furnace at the temperature of 450 DEG C for 5h. The SBA15 catalyst loading the cobalt base is used for promoting oxidization of magnesium sulfite in a magnesia desulfurization process, the cost is lowered, and the catalysis efficiency is improved at the same time.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Preparation method for aerogel type sewage cleaning agent

ActiveCN105800724AImprove brittlenessHigh porosityWater/sewage treatment by sorptionHalloysiteCellulose

The invention provides a preparation method for an aerogel type sewage cleaning agent.The preparation method comprises the steps that firstly, furfural, water soluble phenol-formaldehyde resin, sea-foam stone powder, halloysite nanotubes, nano crystalline cellulose, polyvinylpyrrolidone and water are mixed, mixed liquid A is obtained, ammonium hydroxide is dropwise added into the mixed liquid A, and then sol A is obtained through a reaction; secondly, butyl titanate and absolute ethyl alcohol are mixed to obtain mixed liquid B, a hydrochloric acid solution, absolute ethyl alcohol and water are mixed to obtain mixed liquid C, the mixed liquid C is dropwise added into the mixed liquid B, and after a reaction, sol B is obtained; thirdly, the sol A, the sol B and phenoxy resin are mixed evenly to obtain mixed sol, solvent replacement is conducted after the mixed sol is aged, and mixed gel is obtained; fourthly, supercritical fluid is adopted to dry the mixed gel, and the aerogel type sewage cleaning agent is obtained.The aerogel type sewage cleaning agent prepared through the method is good in adsorption effect, high in adsorption capacity, short in cleaning time and high in efficiency, and the cleaning time is short.

Owner:中山市高平织染水处理有限公司

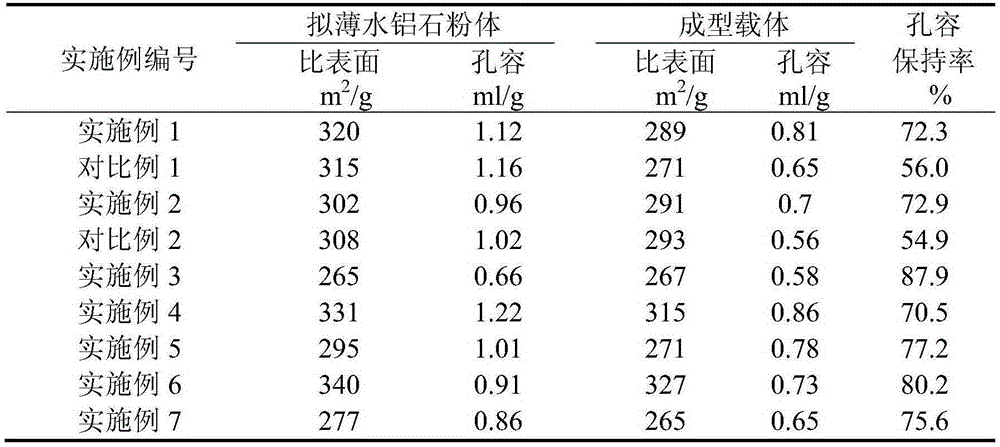

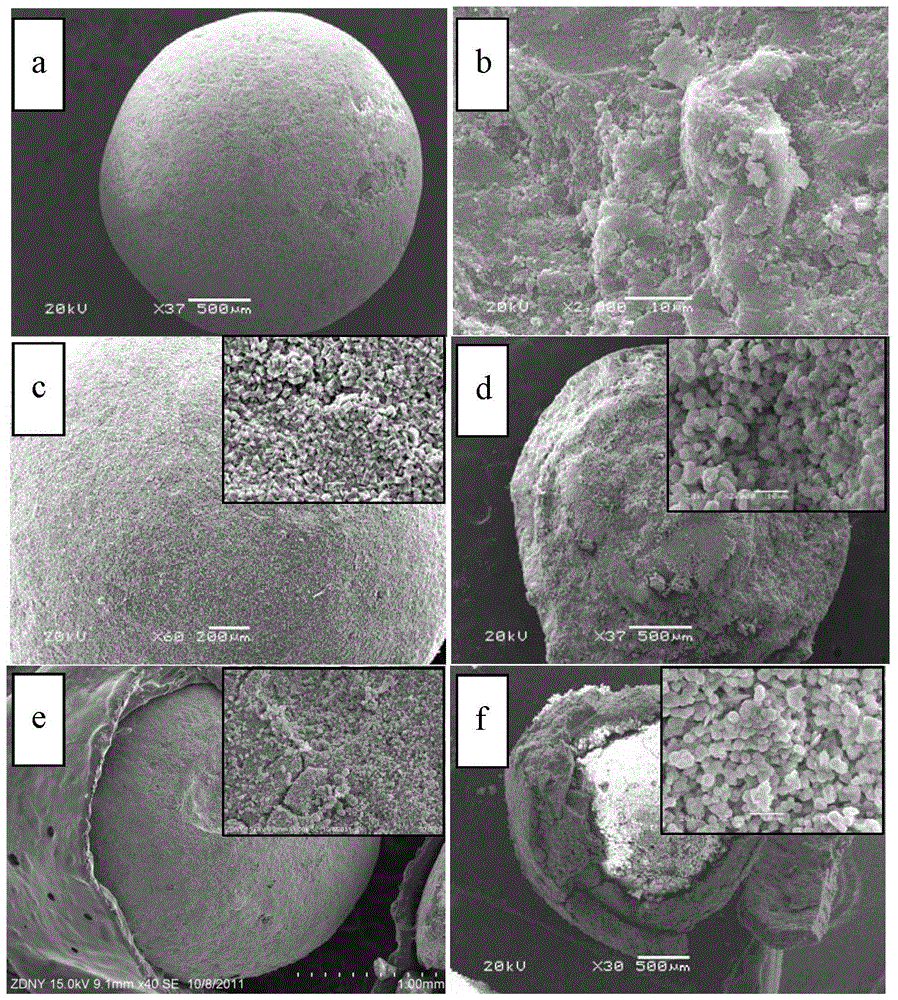

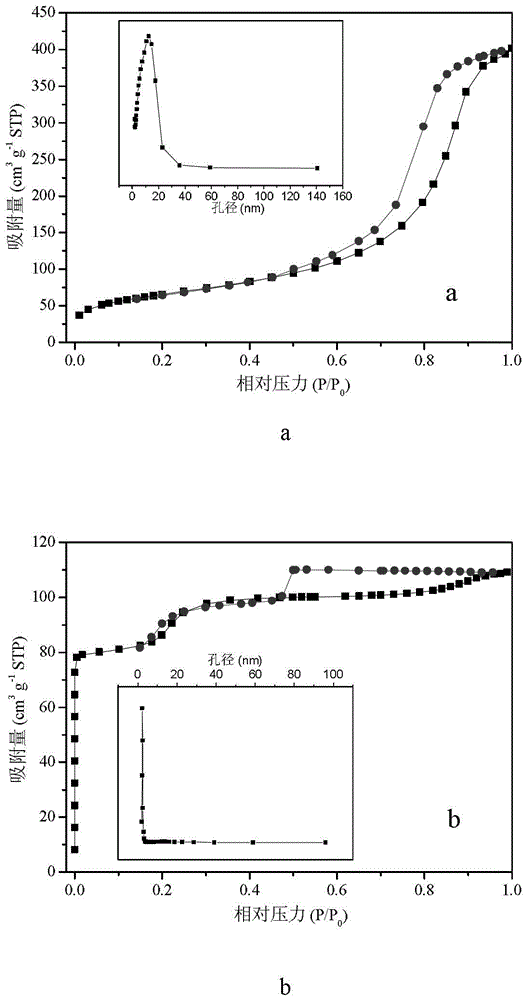

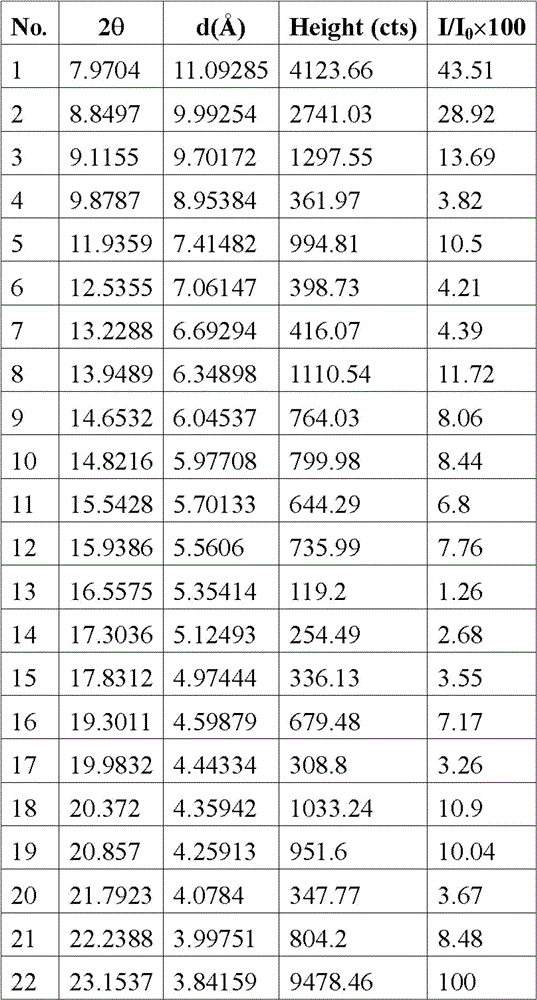

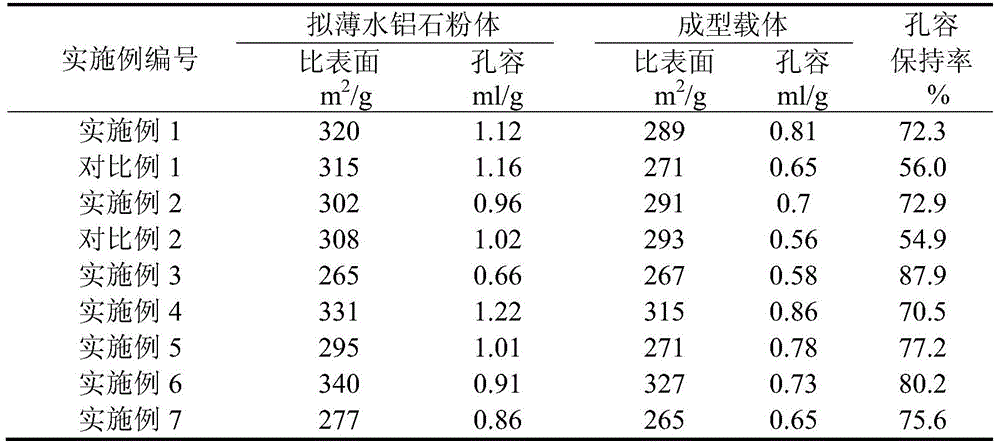

Aluminium-salt-assisted hydro-thermal synthesis method for pseudo-boehmite

ActiveCN105271328AMaintain pore structureHigh pore volume retentionAluminium oxides/hydroxidesAluminium sulfateSynthesis methods

A disclosed aluminium-salt-assisted hydro-thermal synthesis method for pseudo-boehmite comprises the steps: 1) adding a certain amount of aluminium sulfate, urea and a surfactant into proper amount of deionized water, fully dissolving and adding active aluminium oxide in batches, and stirring uniformly to obtain a solid-liquid mixture; 2) performing homogenization and refinement on the obtained solid-liquid mixture, and then transferring into a high-pressure reaction kettle for hydrothermal reaction; and 3) after the reaction is finished, performing solid-liquid separation on the obtained reaction product, fully washing and drying, so as to obtain the pseudo-boehmite powder. The prepared pseudo-boehmite possesses the characteristics of high purity, high pore volume and specific surface area, and especially high pore-volume retention rate during molding, and also the technology is simple in operation, low in cost, free of waste discharge and easy for industrial amplification.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Recyclable water purifying agent preparation method

ActiveCN105797694AImprove adsorption capacityPlay a foaming roleWater/sewage treatment by irradiationOther chemical processesHalloysiteCellulose

The invention provides a recyclable water purifying agent preparation method. The method includes: step 1, mixing polyether polyol, isocyanate, sodium dodecyl benzene sulfonate, carboxymethyl cellulose, dibutyltin dilaurate, aluminium hydroxide and ferroferric oxide magnetic powder to obtain a foam material; step 2, mixing butyl titanate, sepiolite powder, halloysite nanotubes, nanocrystalline cellulose, polyvinylpyrrolidone, ferroferric oxide magnetic powder and absolute ethyl alcohol to obtain a mixed liquid A; mixing a hydrochloric acid solution, absolute ethyl alcohol and water to obtain a mixed liquid B; dropwise adding the mixed liquid B into the mixed liquid A, and reacting to obtain sol; subjecting the sol to silver loading treatment; step 3, mixing the foam material, the silver-loaded sol and phenoxy resin to obtain a mixed foam material; ageing and cleaning to obtain wet sponge; step 4, drying and grinding the wet sponge to obtain a recyclable water purifying agent. The recyclable water purifying agent prepared according to the method is effective in adsorption, high in adsorption capacity, high in efficiency and recyclability.

Owner:南京兰庭绿色建筑技术有限公司

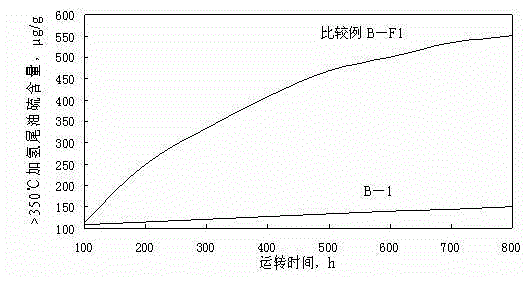

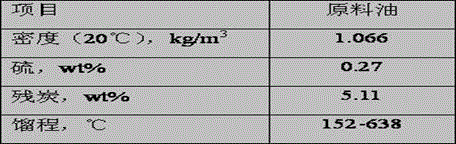

Coal tar hydrogenation catalyst, and preparation method and application thereof

ActiveCN104588109ALow costEvenly dispersedOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oils refiningPtru catalystAluminium hydroxide

The invention discloses a coal tar hydrogenation catalyst, and a preparation method and application thereof. The catalyst comprises iron oxyhydroxide, organic polybasic carboxylic acid, macroporous alumina, a molecular sieve and pseudo-boehmite. The preparation method comprises the following steps: adding organic polybasic carboxylic acid into an iron oxyhydroxide filter cake and carrying out beating to obtain slurry; preparing aluminum hydroxide colloid, wherein the macroporous alumina and the molecular sieve are added before, during or after preparation of the aluminum hydroxide colloid so as to obtain the aluminum hydroxide colloid containing the macroporous alumina and the molecular sieve; adding the iron oxyhydroxide slurry before ageing of the aluminum hydroxide colloid; then carrying out filtering, washing, drying and molding; and carrying out drying so as to obtain the coal tar hydrogenation catalyst. The method provided by the invention adopts cheap iron oxyhydroxide as an active metal component, so cost is low. The catalyst prepared in the invention is especially applicable as a fluidized bed coal tar hydrogenation catalyst and has high hydrogenation activity, proper cracking activity and good stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

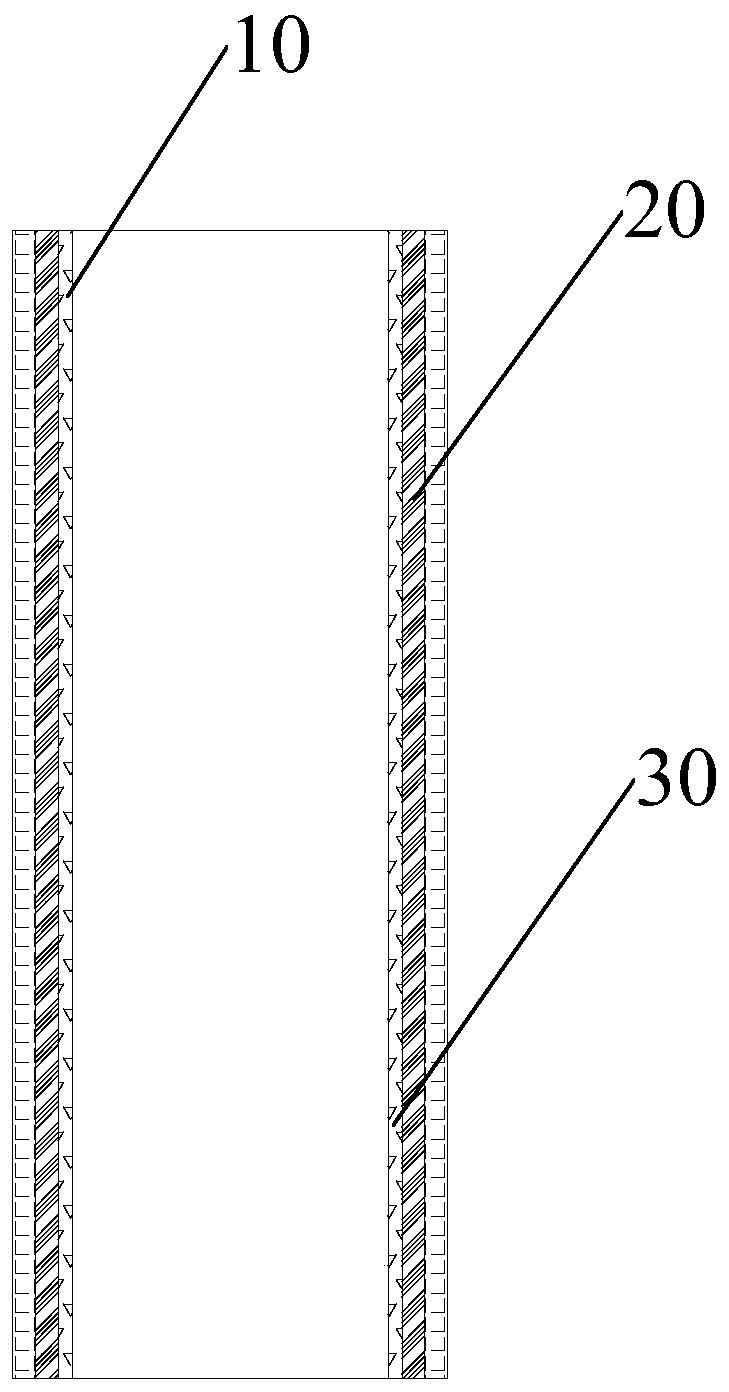

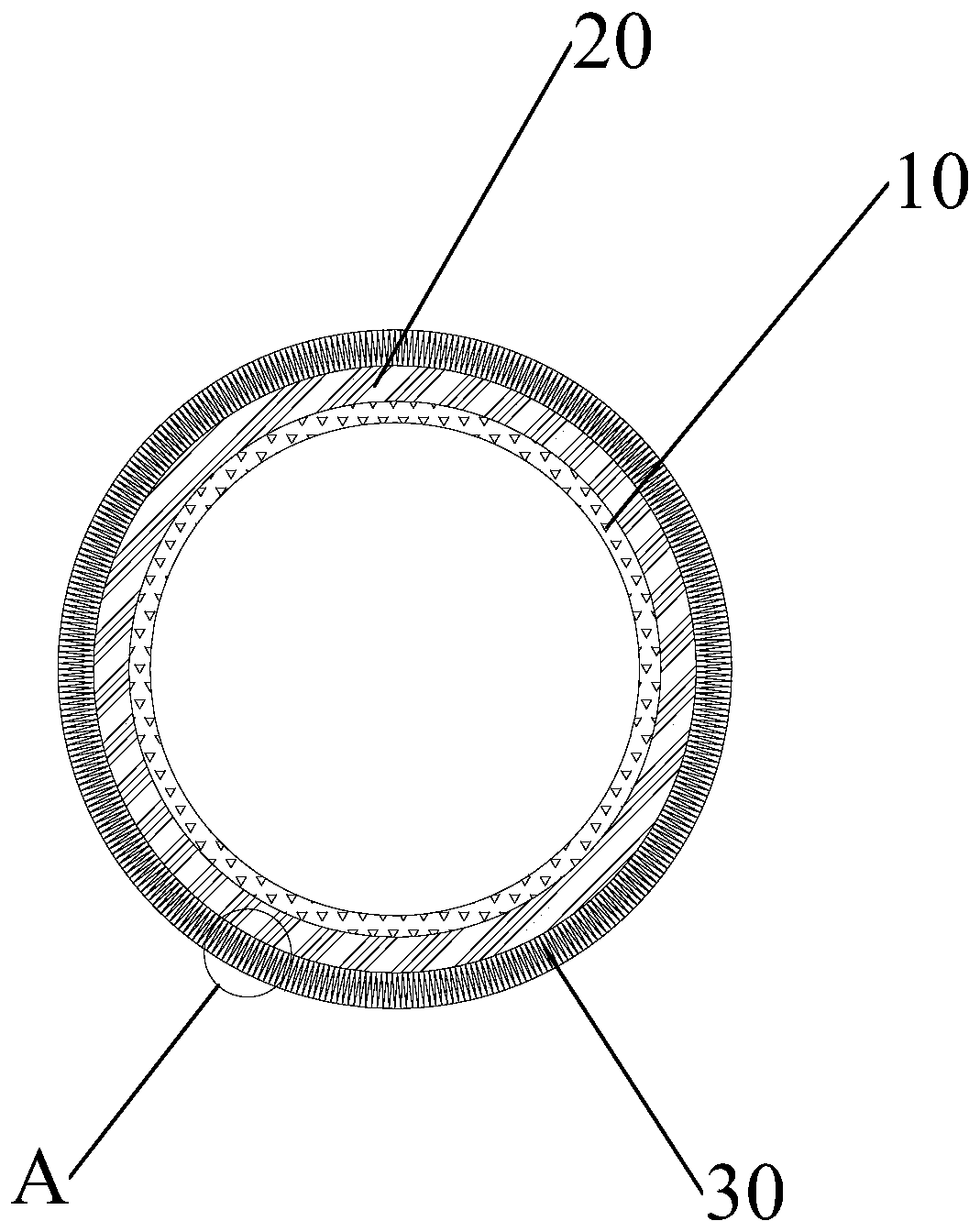

Rigid gas-liquid coalescing filter element, and preparation method and device thereof

PendingCN109847490AMaintain pore structureImprove rigidityDispersed particle filtrationFiltration separationInlet channelAdhesive

The invention provides a rigid gas-liquid coalescing filter element, and a preparation method and device thereof. The filter element comprises a coalescing layer which surrounds the outer side of a central air inlet channel and is used for coalescing and separating liquid drops flowing in from the air inlet channel, and the filter element also comprises a liquid discharging layer which surrounds the outer side of the coalescing layer and is used for providing a liquid discharging channel for condensed liquid drops, wherein the coalescing layer is formed by drying and solidifying a first flexible material containing an adhesive, the liquid discharging layer is formed by drying and solidifying a second flexible material containing an adhesive, the first flexible material containing the adhesive is obtained by carrying out vacuum suction to enable an adhesive solution to pass through the first flexible material, and the second flexible material containing the adhesive is obtained by carrying out vacuum suction to enable an adhesive solution to pass through the second flexible material. According to the invention, the strength of the gas-liquid coalescing filter element can be improved, and requirements of a high-pressure working condition can be met.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

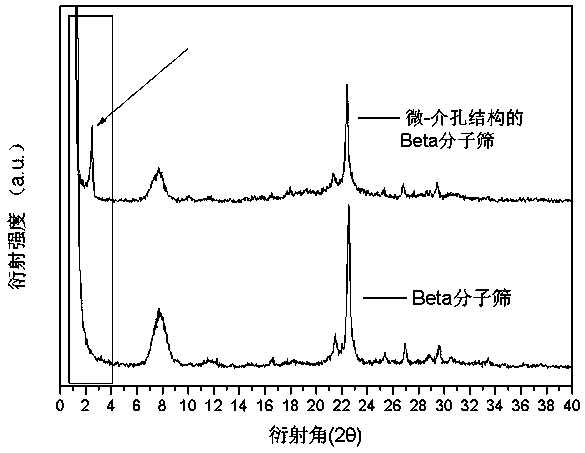

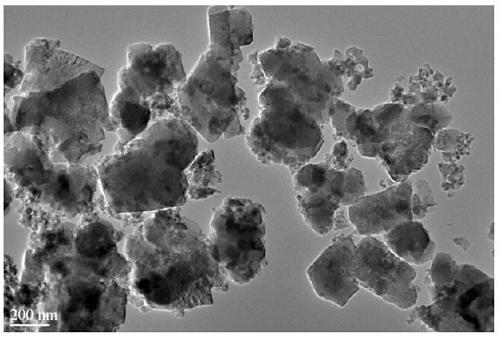

Micro-mesoporous structure beta-molecular sieve, Ni-based micro-mesoporous beta-molecular sieve catalyst and preparation method thereof

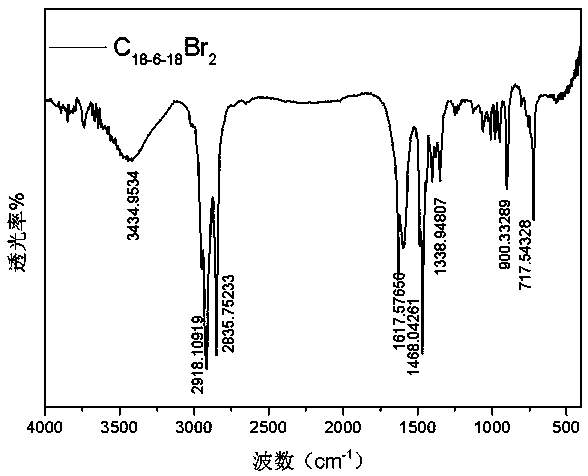

InactiveCN109231232AMaintain pore structureGood hydrothermal stabilityHydrogenMolecular sieve catalystsDiamineMolecular sieve

The invention relates to a molecular sieve and a catalyst, in particular to a micro-mesoporous structure beta-molecular sieve, an Ni-based micro-mesoporous beta-molecular sieve catalyst and a preparation method thereof. The micro-mesoporous structure beta-molecular sieve solves the problems of narrow pore passage and small specific surface area of the existing microporous Beta molecular sieve andthe problems of diffusion limitation of an Ni-based molecular sieve catalyst. The method comprises the following steps of preparing a template agent C18-6-18Br2 through reaction between bromooctadecane and N,N,N',N'-tetramethyl-1,6-hexamethylene diamine according to the mol ratio of 2:1 in acetonitrile and toluol (1:1 v / v); then, performing hydro-thermal synthesis of the micro-mesoporous beta-molecular sieve by tetra-ethylalnmonium hydroxide water solution, the template agent and other chemical raw materials; next, loading nickel nitrate hexahydrate onto the molecular sieve to obtain the Ni-based micro-mesoporous beta-molecular sieve catalyst. The method has the advantages that the self made template agent is used for synthesizing the micro-mesoporous beta-molecular sieve; the cost is low;the synthesized micro-mesoporous beta-molecular sieve has good pore passage communication performance; by using the prepared Ni-based micro-mesoporous beta-molecular sieve catalyst, the ethanol conversion rate and hydrogen gas selectivity are obviously improved.

Owner:TAIYUAN UNIV OF TECH

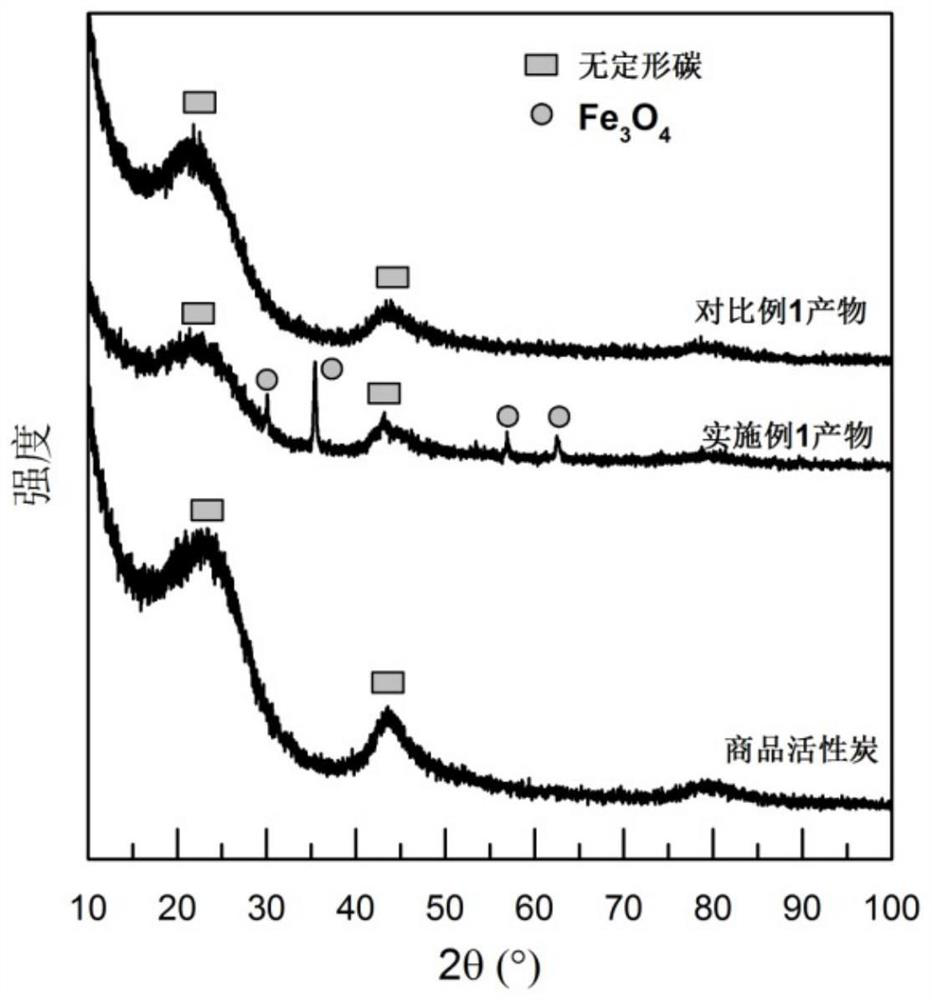

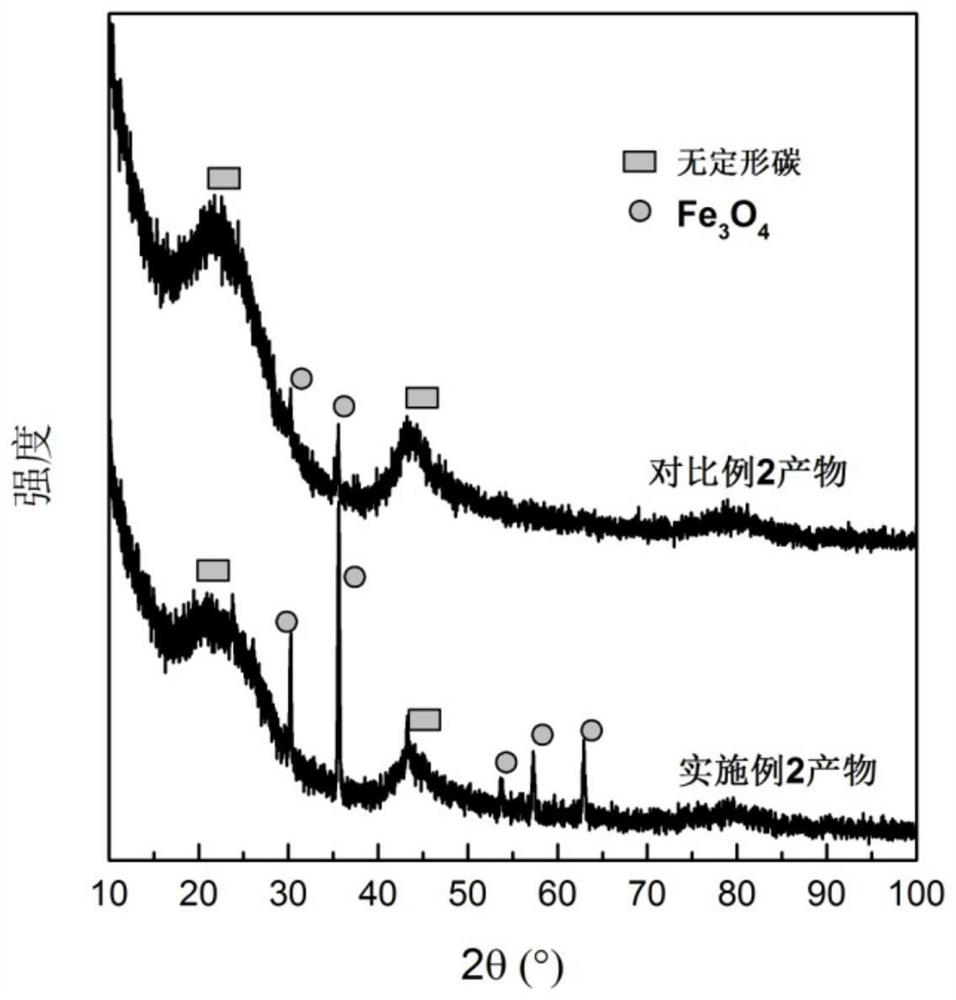

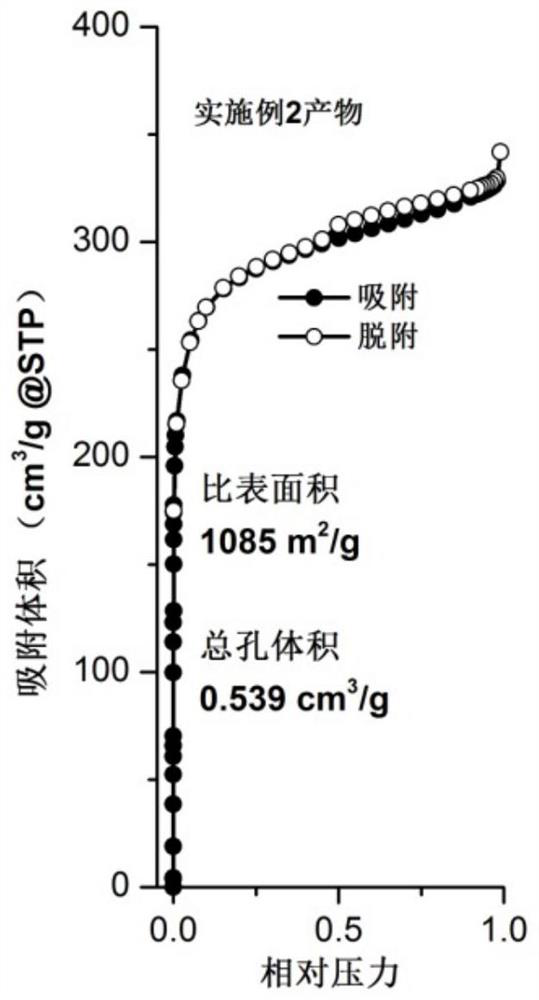

Modified activated carbon/ferroferric oxide composite material and preparation method and application thereof

ActiveCN112086298AAvoid destructionImprove adsorption capacityCarbon compoundsOther chemical processesChemistryComposite material

The invention provides a modified activated carbon / ferroferric oxide composite material and a preparation method and application thereof. The preparation method comprises the following steps: 1, usingan organic acid solution for conducting first dipping treatment on activated carbon, and conducting solid-liquid separation after the activated carbon is adsorbed to be saturated, wherein the obtained solid is pickled activated carbon; (2) carrying out second dipping treatment on the pickled activated carbon obtained in the step (1) by using an iron salt solution, and carrying out solid-liquid separation after the pickled activated carbon is adsorbed to be saturated, wherein the obtained solid is iron-loaded pickled activated carbon; (3) roasting the iron-loaded pickling activated carbon obtained in the step (2) to obtain a modified activated carbon / ferroferric oxide composite material; wherein iron ions in the ferric salt solution in the step (2) comprise Fe < 2 + > and / or Fe < 3 + >. The modified activated carbon / ferroferric oxide composite material can be used as an adsorption material, a superparamagnetic material, a Fenton-like catalyst or a supercapacitor electrode material.

Owner:自然资源部天津海水淡化与综合利用研究所

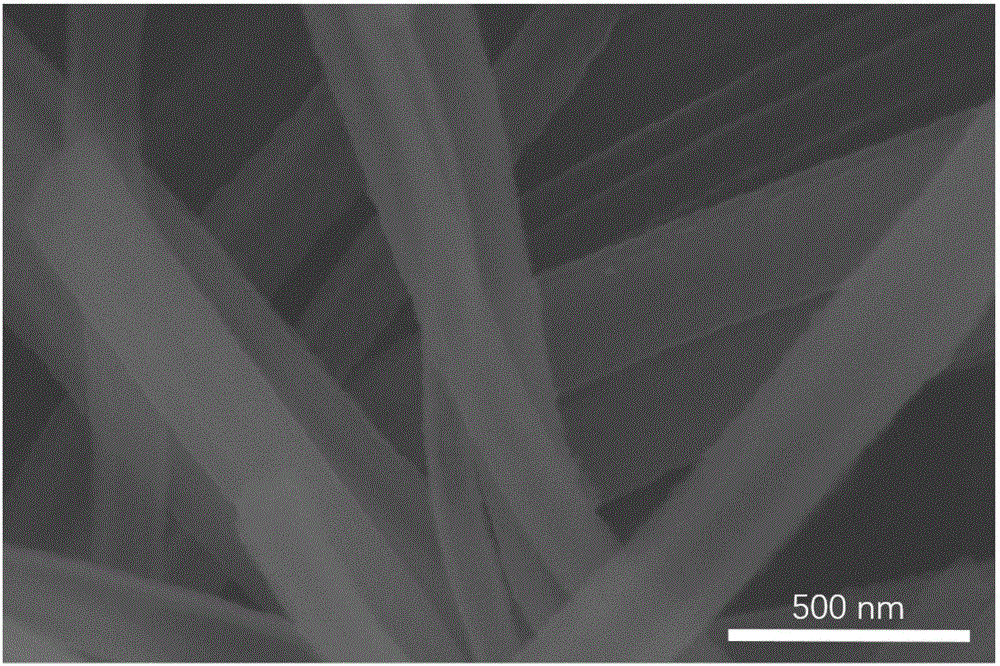

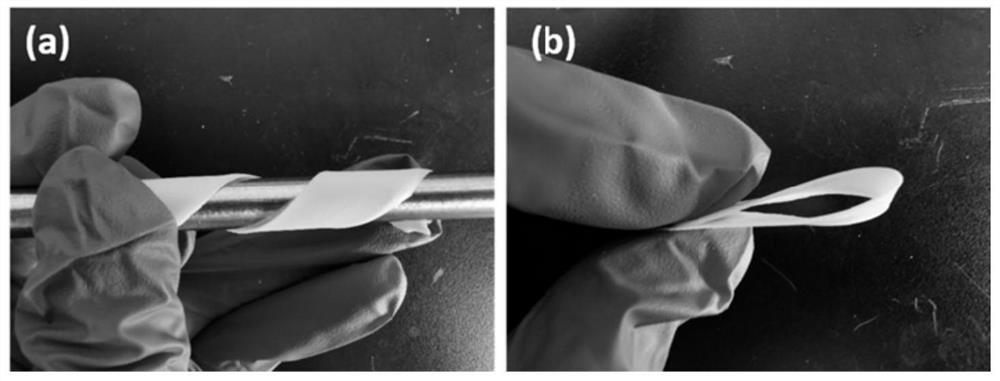

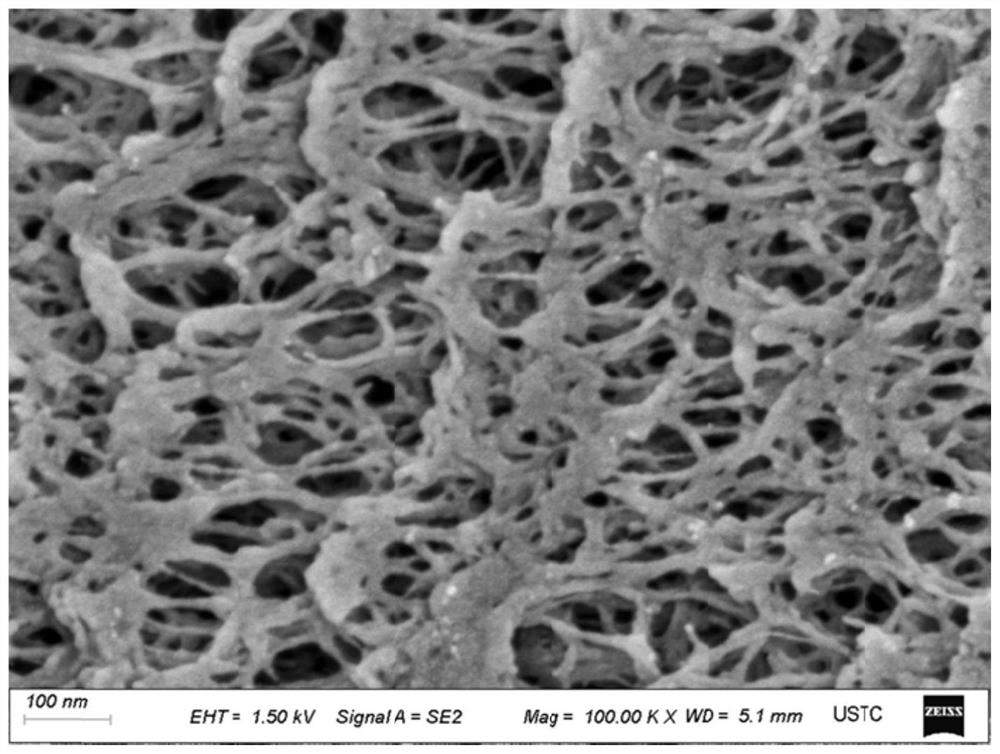

Flexible linear high-temperature-resistant polyimide aerogel battery diaphragm, preparation method thereof and lithium ion battery

InactiveCN113462012AUniform porositySmall average pore sizeSecondary cellsCell component detailsImidePtru catalyst

The invention provides a preparation method of a flexible linear high-temperature-resistant polyimide aerogel battery diaphragm, which comprises the following steps: A) mixing a diamine monomer and a dianhydride monomer in an organic solvent to obtain a polyamide acid solution; B) adding a bis(trimethoxysilylpropyl) amine cross-linking agent into the polyamide acid solution for chemical cross-linking, and then adding a dehydrating agent and a catalyst to obtain a polyimide solution; C) coating the surface of a base material with the polyimide solution to obtain a polyimide wet gel film, and then aging; and D) placing the aged film in an organic solvent for solvent exchange, and then carrying out supercritical fluid drying to obtain the polyimide aerogel battery diaphragm. The invention also provides a flexible linear high-temperature-resistant polyimide aerogel battery diaphragm and a lithium ion battery.

Owner:UNIV OF SCI & TECH OF CHINA

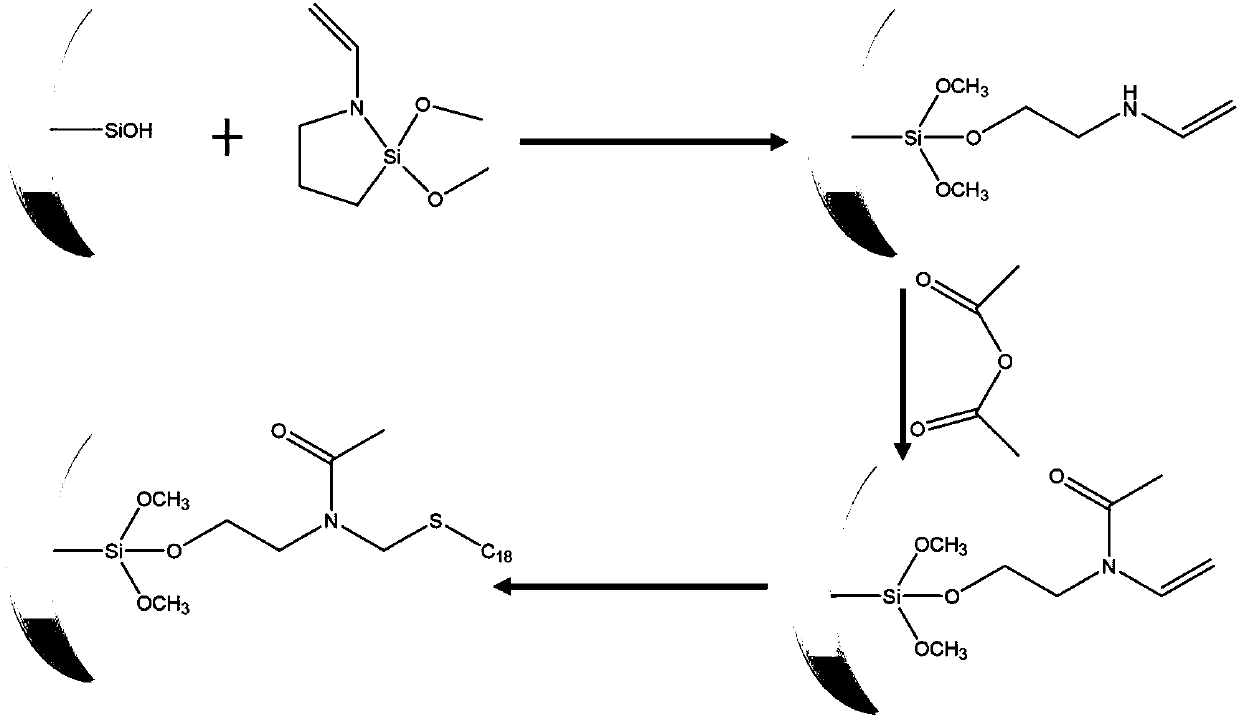

Novel silica gel matrix surface modification method and application of surface-modified silica gel matrix

ActiveCN109865507AAvoid non-specific adsorptionEfficient separationOther chemical processesSolid sorbent liquid separationVolumetric Mass DensitySilica gel

The invention discloses a novel silica gel matrix surface modification method and application of a surface-modified silica gel matrix. The novel silica gel matrix surface modification method is basedon a five-membered heterocyclic silylating reagent which has an unstable heterocyclic structure, and hydrolysis ring-opening is performed on the reagent and silanol groups, wherein the reactivity is high, and the bonding density is improved significantly; in addition, hydrophilic groups are formed by ring-opened heteroatoms, so that non-specific adsorption of analytes by unreacted silanol groups is avoided effectively. Compared with conventional chlorosilane modification, the novel silica gel matrix surface modification method has high bonding efficiency, mild reaction conditions and no cross-linking, the pore structure of silica gel can be ensured, and therefore the separation efficiency can be improved effectively by a chromatographic stationary phase prepared from the silica gel matrix;and the chromatographic stationary phase can be widely applied to separation of alkaline analytes and biological samples.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Tungsten-contained mesic porous molecular sieve catalyst for synthesis of glutaral dehyde and its preparation

InactiveCN1680033AMaintain pore structureEvenly dispersedMolecular sieve catalystsCarbonyl compound preparation by oxidationCyclopentenePtru catalyst

A multi-phase W-contained catalyst for preparing glutaraldehyde from cyclopentene through selective oxidizing by the aqueous solution of hydrogen peroxide is prepared through synthesizing the meso-porous MCM-48 all-silicon molecular sieve while adding the tungstic acid precursor to introduce the tungsten oxide with high catalytic oxidizing activity to the skeleton of MCM-48 molecular sieve. Its advantage is high selectivity and output rate of glutaraldehyde.

Owner:FUDAN UNIV

Preparing method of catalyst containing modified SAPO-34 molecular sieve and application thereof

InactiveCN109772448AReduce acidityLow selectivityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveSilicon

A preparing method of a catalyst containing a modified SAPO-34 molecular sieve is disclosed. The method includes S01) fully mixing an aluminum source and water, then adding deionized water, a phosphorus source, a first template, a silicone source, a chromium salt and a second template in order, and stirring the mixture at 20-30 DEG C for 1-2 h to fully mix the materials to obtain a mixed reactionliquid, with the mole ratio of the aluminum source, the phosphorus source, the silicon source, the chromium salt, the first template, the second template and the water being (0.7-1.5):(0.7-1.5):(0.1-0.4):(0.1-0.4):(0.5-2.5):(0.5-2.5):(50-70). The invention also discloses application of the method in MTO reactions. The method can reduce carbon deposition of the catalyst, can improve diffusion ability of the catalyst and can improve diene selectivity.

Owner:CHIA TAI ENERGY MATERIALS DALIAN

Antibacterial water absorption stable resin

InactiveCN110183810AReduce the amount of solutionEasy to stretch freelyAbsorption capacityFreeze-drying

The invention relates to an antibacterial water absorption stable resin and belongs to the field of macromolecule chemical aids. The antibacterial water absorption stable resin is prepared from strawas a raw material, actions of molecules are enhanced through processes such as crushing, alkali immersion and acid immersion, the water absorption capacity is increased, meanwhile, due to freeze drying, a pore structure of the resin can be well maintained, and a very good retention function is achieved for water-soluble biologically extracted antibacterial components, so that the water absorptioncapacity can be stably increased, and the resin can be used as a carrier for taking an antibacterial effect into play; due to processes of ultrasonic degreasing, centrifugation, ultrasonic treatment and extraction, and the like on wheat bran and green walnut peel, very good antibacterial and sterilization functions can be achieved; meanwhile, herba leonuri and radix paeoniae rubra are smashed andsubjected to backflow extraction, so that the herba leonuri and the radix paeoniae rubra have good moisture absorption and can be well adsorbed by the resin material after being dried; and when the resin is adopted for water absorption, an antibacterial function of a macromolecule substance can be brought into play, and the antibacterial effect can be improved progressively. By adopting the resin,the problems that a conventional common water absorption resin is poor in antibacterial effect and poor in stability after water absorption can be solved.

Owner:陈习红

Method used for preparing iron-based hydrogenation catalyst from iron-containing waste residue raw material

ActiveCN105709738AImprove hydrogenation activitySolve pollutionMetal/metal-oxides/metal-hydroxide catalystsPtru catalystFerrous salts

The invention discloses a method used for preparing an iron-based hydrogenation catalyst from an iron-containing waste residue raw material. The method comprises following steps: the iron-containing waste residue raw material is smashed and sieved so as to obtain an iron-containing waste residue with a particle size larger than 150 meshes; the iron-containing waste residue is treated with an acidic solution; an obtained solution is filtered so as to obtain a ferrous salt-containing solution; an alkaline suspension liquid I containing iron oxide hydroxide and an acidic suspension liquid II are prepared respectively; parallel flow precipitation, aging, drying, moulding, and drying are carried out so as to obtain the iron-based hydrogenation catalyst. According to the method, cheap iron oxide hydroxide is taken as an active metal ingredient, cost is low, and hydrogenation activity and stability are relatively high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of attapulgite clay nanorod crystal composite microsphere adsorbent

ActiveCN104069801BGuaranteed adsorption effectLarge specific surface areaOther chemical processesAlkali metal oxides/hydroxidesActivated attapulgiteSorbent

The invention relates to a preparation method for an attapulgite clay nanorod crystal composite microsphere adsorbent. According to the method, hydrochloric acid activated attapulgite clay nanorod crystals, concentrated ammonia liquor, ethyl orthosilicate, water and a solvent--absolute ethyl alcohol are reacted at a certain temperature, and through hydrolytic condensation and bonding of ethyl orthosilicate, a loose microsphere is formed by the attapulgite clay nanorod crystals. A loose microsphere composite material is formed by bonding each single attapulgite clay nanorod crystal with silica produced after hydrolytic condensation of ethyl orthosilicate, so the preparation method is simple; and the prepared microsphere composite material has good adsorption performance and has good application prospects in the field of sewage treatment.

Owner:LANZHOU UNIVERSITY

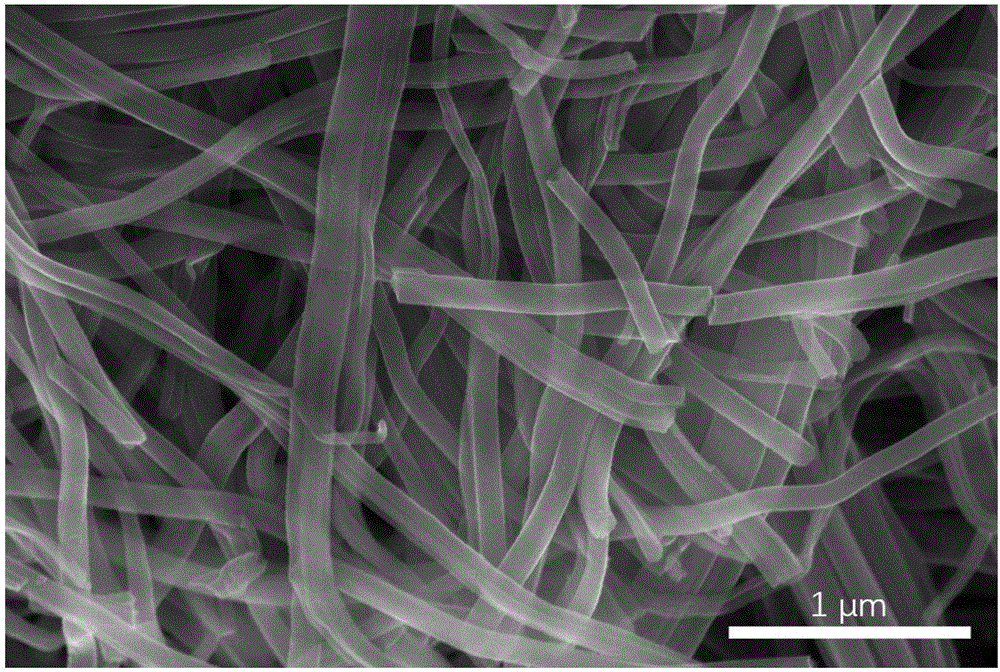

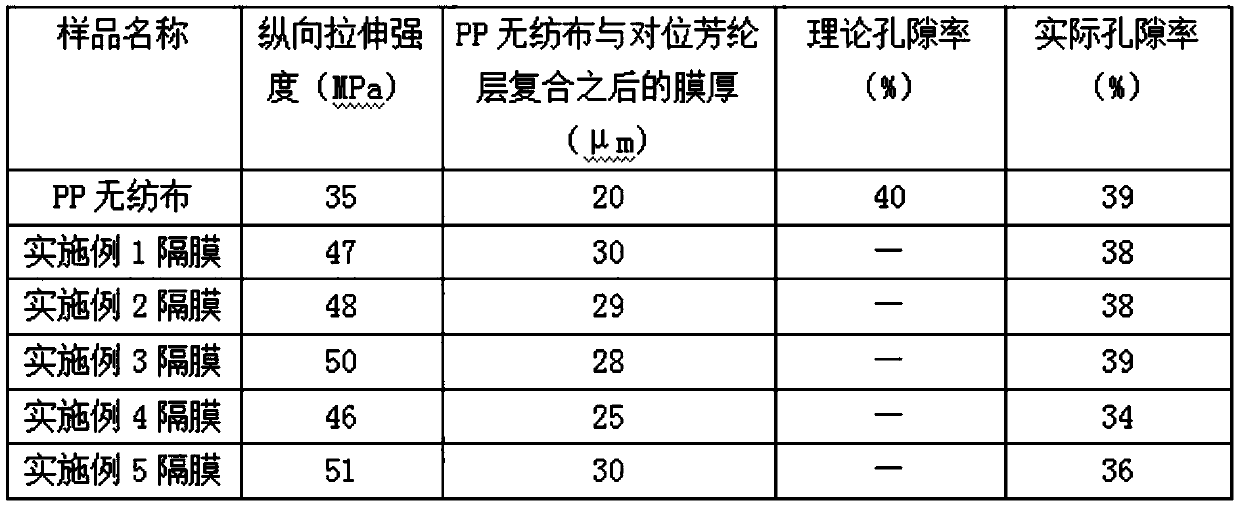

Preparation method of para-aramid/PP non-woven fabric lithium ion battery diaphragm

ActiveCN110620205AImprove liquidityImprove adhesionFinal product manufactureSecondary cellsPorosityPhysical chemistry

The invention provides a preparation method of a para-aramid / PP non-woven fabric lithium ion battery diaphragm and relates to the technical field of a para-aramid / PP non-woven fabric lithium ion battery diaphragm. The method is advantaged in that PP non-woven fabric is selected as a substrate material, pores in the PP non-woven fabric are occupied by pore forming agent, then the PP non-woven fabric is immersed into para-aramid pulp, curing is conducted in a sulfuric acid coagulating bath, the pore forming agent is heated and sublimated, the pores are vacated, and the diaphragm thickness film is determined through hot pressing. Compared with the prior art, the method is advantaged in that the PP non-woven fabric is directly coated with the para-aramid polymerization solution for reinforcement, the process is completed in one step, and influence of external factors is small; the porosity of the para-aramid / PP non-woven fabric lithium ion battery diaphragm is effectively improved due to occupation of the pore-forming agent; the sulfuric acid solution is adopted as a coagulating bath, so the high porosity of the PP non-woven fabric layer is not only maintained, but also the pore structure of the PP non-woven fabric layer is maintained, and uniformity and consistency of diaphragm pores of the para-aramid fiber layer are realized.

Owner:山东精恒科技有限公司

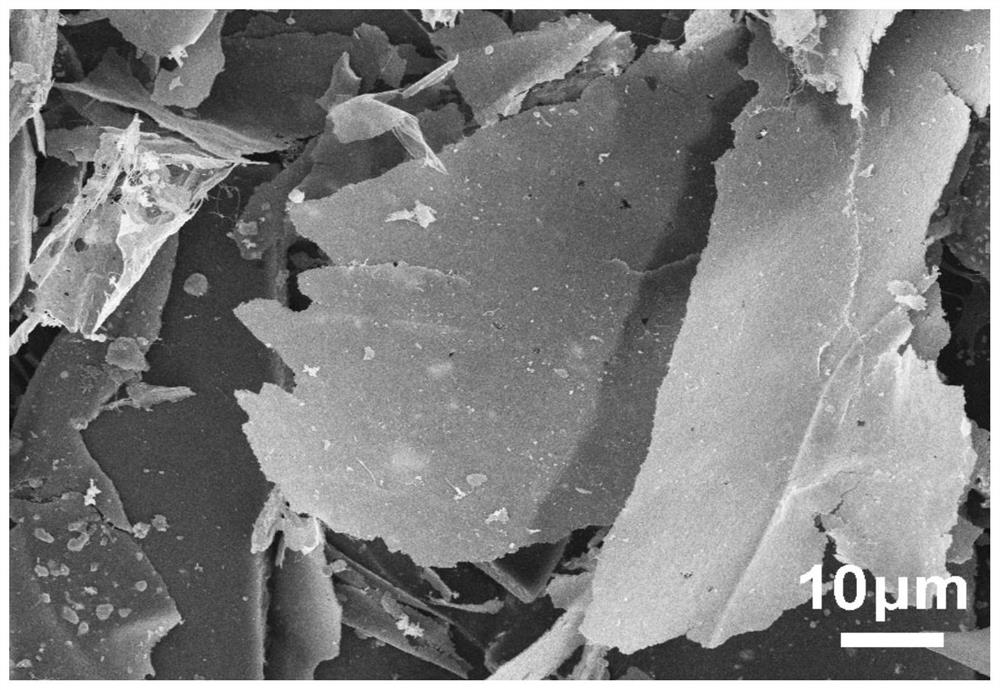

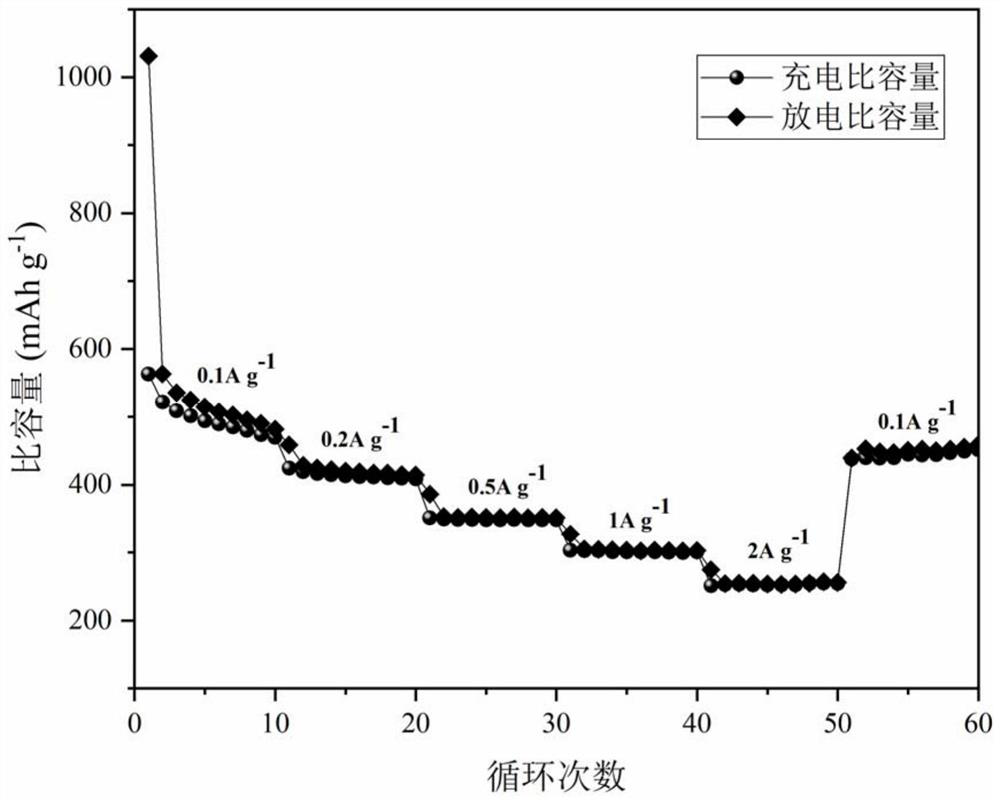

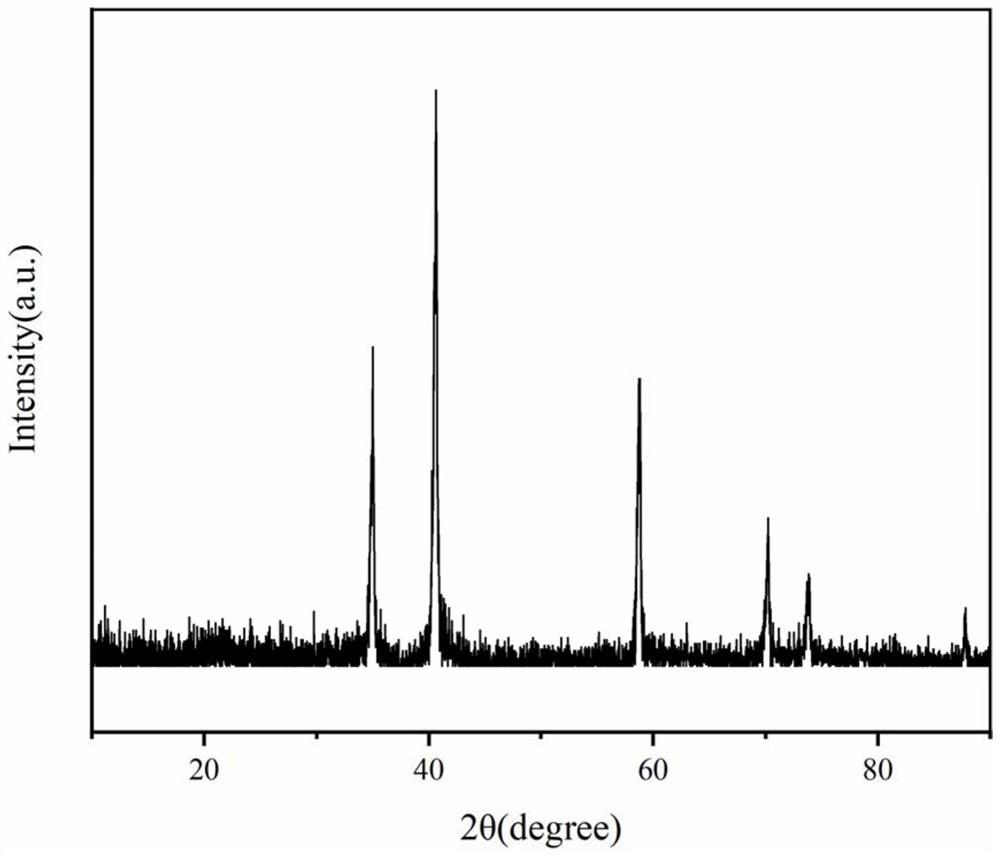

Preparation method of sodium alginate-based dual-network carbon aerogel negative electrode material for lithium ion battery

ActiveCN113140717AAlleviate the problem of easy reunionRich pore structureNegative electrodesSecondary cellsElectrical batteryMaterials science

The invention discloses a preparation method of a sodium alginate-based dual-network carbon aerogel negative electrode material for a lithium ion battery, and belongs to the technical field of lithium ion battery negative electrode materials. The method comprises the following steps: firstly, preparing a certain amount of sodium alginate powder and agar powder into precursor hydrogel by adopting a sol-gel method; preparing a Mn (NO3) 2 solution and ZnCl2 particles into a mixed solution according to a certain proportion, and immersing the precursor hydrogel into the mixed solution for 6-9 hours to obtain dual-network hydrogel; washing the prepared hydrogel with deionized water for multiple times, and freeze-drying to obtain fluffy double-network aerogel; and finally, carrying out high-temperature carbonization under the protection of inert gas to obtain the sodium alginate-based dual-network carbon aerogel negative electrode material. The operation method is simple and easy to implement, the used raw materials are low in cost and wide in source, the prepared material is good in mechanical performance, conductivity and stability in the charging and discharging process when used for the negative electrode of the lithium ion battery, meanwhile, the pore structure can be kept, and excellent electrochemical performance is achieved.

Owner:BEIJING UNIV OF CHEM TECH

A kind of preparation method of high-strength binder-free hierarchical porous composite ZSM-5 catalyst

ActiveCN103657706BKeep shapeMaintain pore structureMolecular sieve catalystsPentasil aluminosilicate zeoliteAdhesiveGas phase

The invention discloses a preparation method of a high-strength binding-agent-free multi-orifice compound ZSM-5 (Zeolite Socony Mobil-5) catalyst. The preparation method is characterized in that the high-strength binding-agent-free multi-orifice compound ZSM-5 molecular sieve based catalyst is prepared by a gas-phase synthesis method under a vapor or water and organic amine mixed steam atmosphere after aluminum is immersed by an aluminum source and organic amine ions are immersed by adopting mesoporous silica as a precursor, wherein the ratio of silicon to aluminum can be freely regulated within a certain range.

Owner:中科催化新技术(大连)股份有限公司

Preparation method of granular sewage purifying agent

InactiveCN105921122AImprove brittlenessHigh porosityOther chemical processesAlkali metal oxides/hydroxidesCelluloseSolvent

The invention provides a preparation method of a granular sewage purifying agent. The preparation method comprises the steps that 1, formaldehyde, dihydroxybenzene, sepiolite powder, nano-sized halloysite tubes, nanocrystalline cellulose, polyvinylpyrrolidone and water are mixed to obtain a mixed solution A, a sodium hydroxide solution is dropwise added into the mixed solution A, and reacting is conducted to obtain sol A; 2, butyl titanate and absolute ethyl alcohol are mixed to obtain a mixed solution B, a hydrochloric acid solution and absolute ethyl alcohol are mixed with water to obtain a mixed solution C, the mixed solution C is dropwise added into the mixed solution B, and reacting is conducted to obtain sol B; 3, the sol A, the sol B and phenoxy resin are mixed to be uniform to obtain mixed sol, and the mixed sol is aged and then subjected to solvent exchange to obtain mixed gel; 4, drying is conducted by adopting a supercritical fluid, smashing is conducted until the grain size is in a millimeter level, and then the granular sewage purifying agent is obtained. The granular sewage purifying agent prepared through the method is good in adsorption effect, high in adsorption capacity, short in purifying time and high in efficiency.

Owner:CHANGSHA XIAORU INFORMATION TECH CO LTD

A method for aluminum salt-assisted hydrothermal synthesis of pseudo-boehmite

ActiveCN105271328BMaintain pore structureHigh pore volume retentionAluminium oxides/hydroxidesSynthesis methodsHigh pressure

A disclosed aluminium-salt-assisted hydro-thermal synthesis method for pseudo-boehmite comprises the steps: 1) adding a certain amount of aluminium sulfate, urea and a surfactant into proper amount of deionized water, fully dissolving and adding active aluminium oxide in batches, and stirring uniformly to obtain a solid-liquid mixture; 2) performing homogenization and refinement on the obtained solid-liquid mixture, and then transferring into a high-pressure reaction kettle for hydrothermal reaction; and 3) after the reaction is finished, performing solid-liquid separation on the obtained reaction product, fully washing and drying, so as to obtain the pseudo-boehmite powder. The prepared pseudo-boehmite possesses the characteristics of high purity, high pore volume and specific surface area, and especially high pore-volume retention rate during molding, and also the technology is simple in operation, low in cost, free of waste discharge and easy for industrial amplification.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

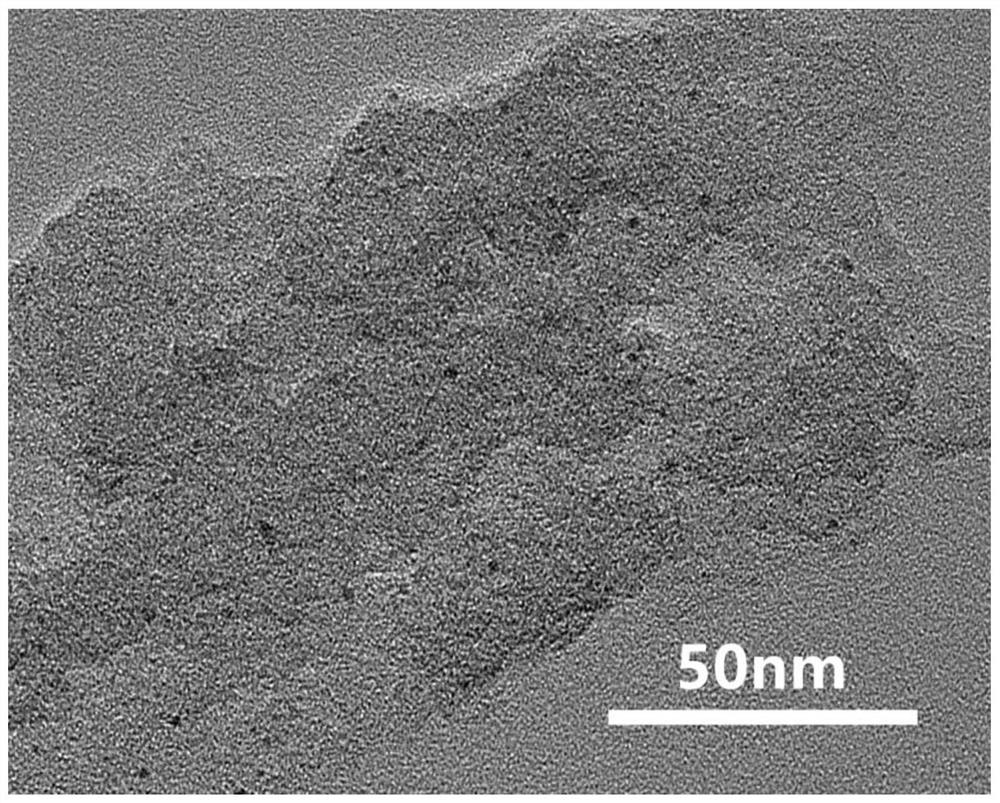

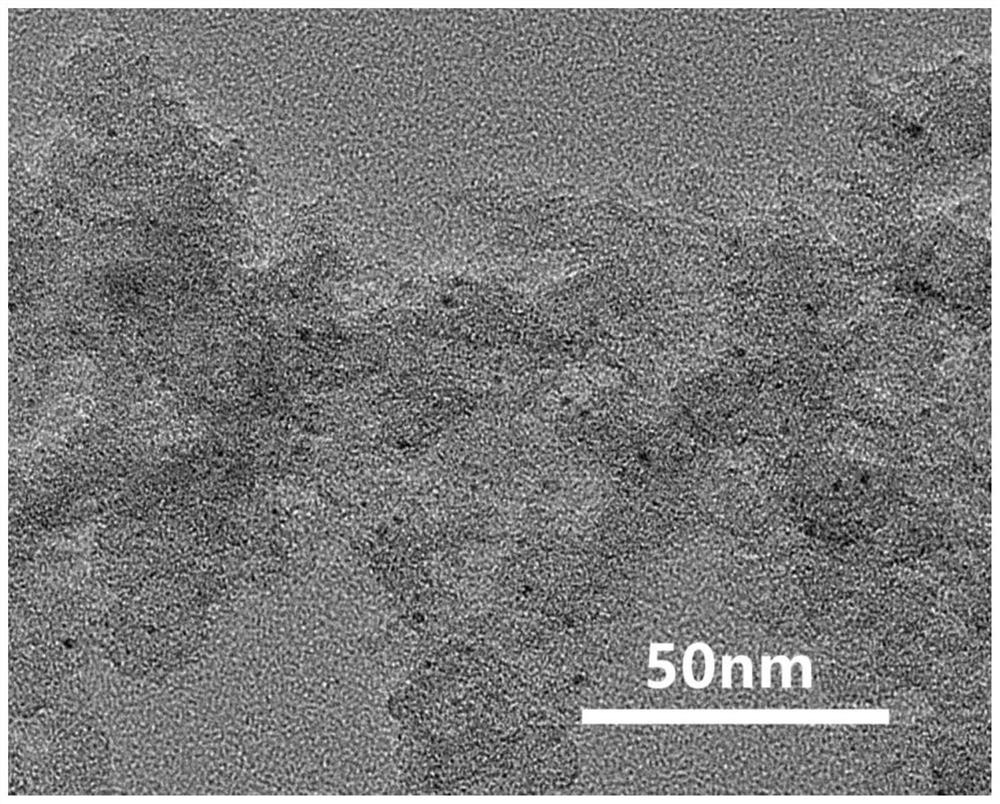

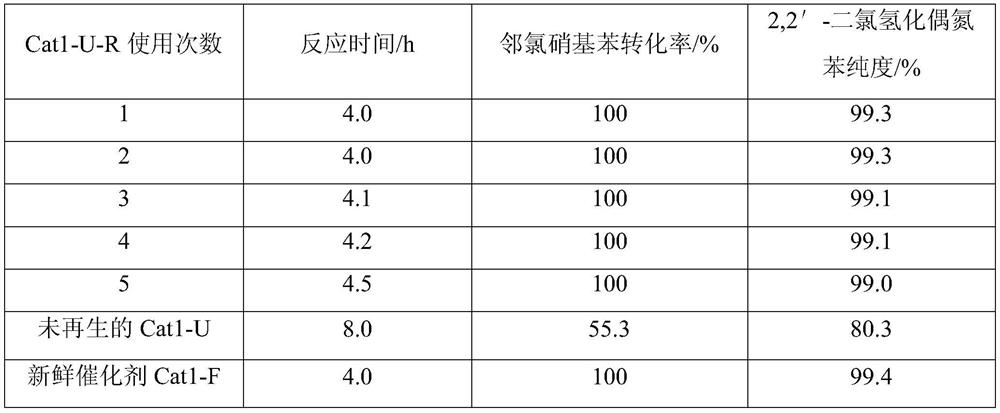

Regeneration method and application of chloronitro aromatic hydrocarbon selective hydrogenation catalyst

PendingCN113333034AEnsure complete removalMaintain pore structureOrganic compound preparationCatalyst regeneration/reactivationTitanium oxideCarbonization

The invention relates to the technical field of catalysts, and particularly discloses a regeneration method of a chloronitro aromatic hydrocarbon selective hydrogenation catalyst. The regeneration method comprises the following steps: impregnating a part of the deactivated catalyst by adopting a titanium oxide precursor and a stabilizing solution, carbonizing, mixing the carbonized catalyst and the deactivated catalyst, adding the mixture into a regeneration kettle filled with a treatment solution, and decomposing organic impurities under the action of ultraviolet irradiation and microwaves; and carrying out microwave washing on the treated catalyst under the interaction effect of the organic acid and the organic solvent, so as to realize dredging of pore channels and recovery of active metal sites. According to the treatment method, organic impurities adsorbed in the catalyst can be effectively removed, and the catalytic performance is recovered. The method has the advantages of being simple, efficient, environmentally friendly and the like, the structure of the catalyst and the active metal loading state can be kept while it is guaranteed that organic impurities are removed, the activity of the catalyst is effectively recovered, and the use cost of the catalyst is reduced.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com