Preparation method of attapulgite clay nanorod crystal composite microsphere adsorbent

A technology of attapulgite clay and nanorod crystals, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve difficult separation, waste of attapulgite resources, and limited large-scale application, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: Prepare composite microsphere adsorbent according to the following specific steps:

[0022] a. Add 50g of attapulgite clay raw ore and 500mL of water to make slurry, pass the suspension obtained through 200-mesh gauze and let stand for 48h, pour out the upper suspension, activate the upper suspension in 400mL, 2mol / L hydrochloric acid solution for 24h, suction filter, Wash until neutral, dry to constant weight, and obtain hydrochloric acid-activated attapulgite clay nanorod crystals.

[0023] b. Weigh 0.5g of hydrochloric acid-activated attapulgite clay nanorod crystals and add them to 50mL of ethanol. After ultrasonication for 1h, transfer to the reactor. Under mechanical stirring at 300r / min, heat up to 60°C, add 1.0mL of concentrated ammonia water and 5.0mL of distilled water in sequence , stirred for 0.5h, and then added 1.0g of ethyl orthosilicate to react for 12h. The product was suction filtered, washed with ethanol, and dried to obtain an attapu...

Embodiment 2

[0025] a. Add 50g of attapulgite clay raw ore and 500mL of water to make slurry, pass the suspension obtained by passing through 200 mesh gauze for 48h, pour out the upper suspension, activate the upper suspension in 400mL, 2mol / L hydrochloric acid solution for 24h, pump Filter, wash until neutral, dry to constant weight, and obtain hydrochloric acid-activated attapulgite clay nanorod crystals.

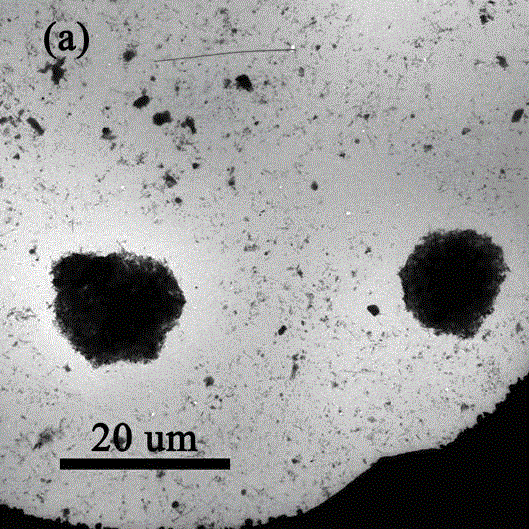

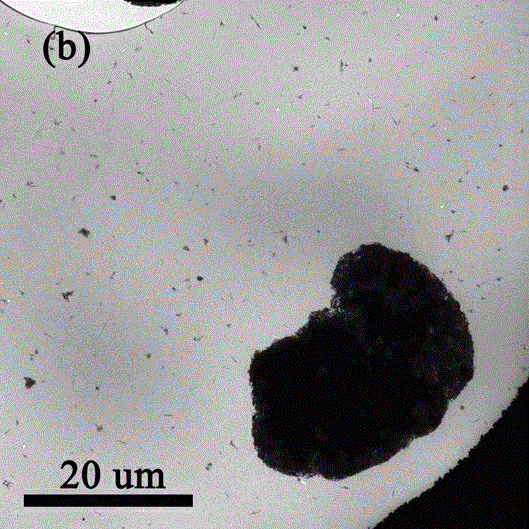

[0026] b. Weigh 0.5g of hydrochloric acid-activated attapulgite clay nanorod crystals and add them to 50mL of ethanol. After ultrasonication for 1h, transfer to the reactor. mL of distilled water, stirred for 0.5h, and then added 1.5g of ethyl orthosilicate to react for 12h. The product was suction filtered, washed with ethanol, and dried to obtain an attapulgite clay nanorod crystal composite microsphere adsorbent. from TEM Figure 1-b It can be seen that the attapulgite clay nanorod crystal composite microsphere adsorbent is formed, the diameter of the microsphere is between 10-20...

Embodiment 3

[0028] a. Add 50g of attapulgite clay raw ore and 500mL of water to make slurry, pass the suspension obtained by passing through 200 mesh gauze for 48h, pour out the upper suspension, activate the upper suspension in 400mL, 2mol / L hydrochloric acid solution for 24h, pump Filter, wash until neutral, dry to constant weight, and obtain hydrochloric acid-activated attapulgite clay nanorod crystals.

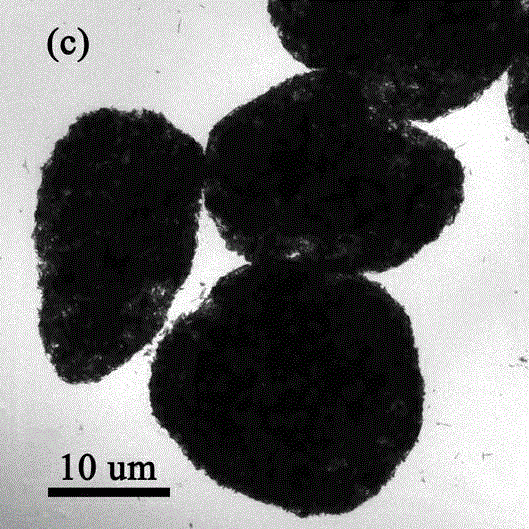

[0029] b. Weigh 0.5g of hydrochloric acid-activated attapulgite clay nanorod crystals and add them to 50mL of ethanol. After ultrasonication for 1h, transfer to the reactor. mL of distilled water, stirred for 0.5h, and then added 2.0g of ethyl orthosilicate to react for 12h. The product was suction filtered, washed with ethanol, and dried to obtain an attapulgite clay nanorod crystal composite microsphere adsorbent. from TEM Figure 1-c It can be seen that there is almost no unreacted attapulgite clay nanorod crystals in the obtained attapulgite clay nanorod crystal composite micros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com