Modified activated carbon/ferroferric oxide composite material and preparation method and application thereof

A technology of ferric tetroxide and composite materials, which is applied in the field of modified activated carbon/iron tetroxide composite materials and their preparation, and can solve problems such as the inability to use a liquid phase environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

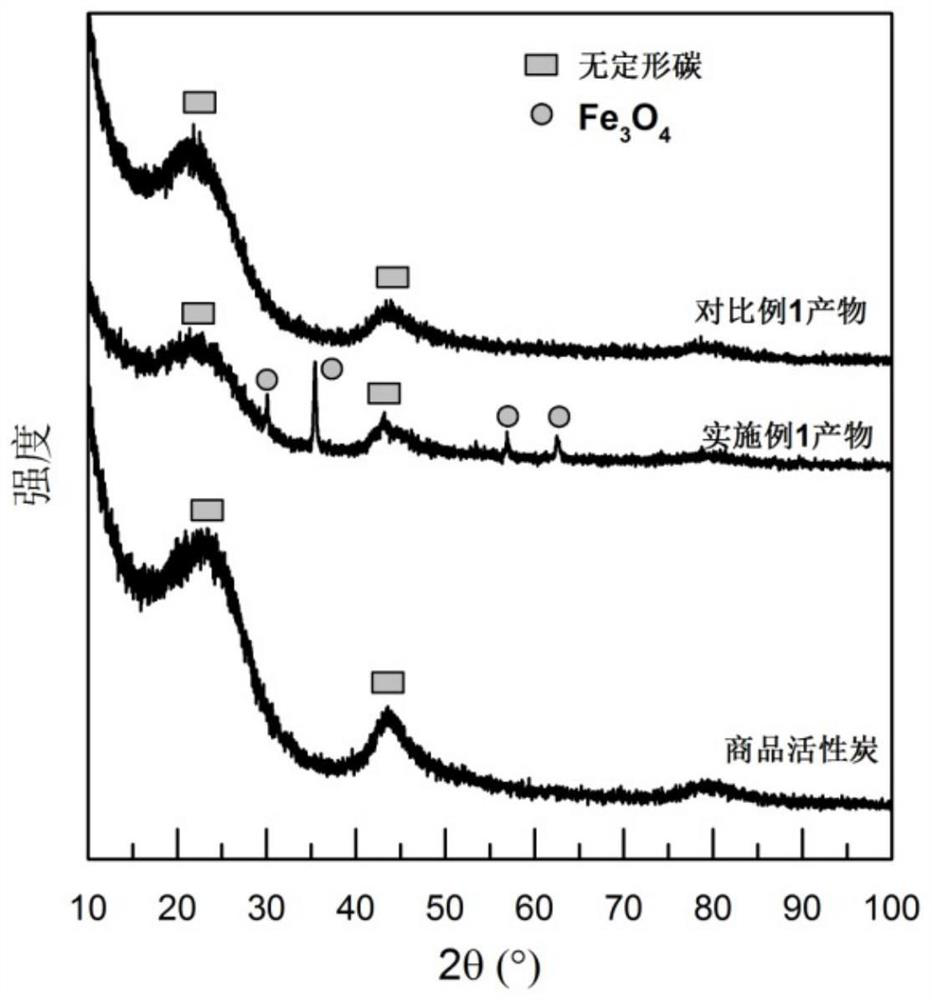

Embodiment 1

[0073] This embodiment provides a kind of preparation method of modified activated carbon / ferric oxide composite material, and described preparation method comprises the following steps:

[0074] (1) Utilize the 0.1g / mL citric acid solution of deionized water preparation 50mL, utilize described citric acid solution again to 15g commercial gac at room temperature in the shaker with the rotating speed oscillation of 180rpm, carry out the first excessive impregnation treatment 14h, After the activated carbon is adsorbed and saturated, perform vacuum filtration, wash the obtained solid to neutrality, and dry it at 90°C until the activated carbon is completely dehydrated, and the obtained solid is pickled activated carbon;

[0075] (2) Prepare 50mL of 0.1g / mL Fe(NO 3 ) 2 solution, and then use the Fe(NO 3 ) 2 Solution to step (1) obtained pickling activated carbon in the shaker at room temperature with a rotating speed of 180rpm vibration, carry out the second excessive impregna...

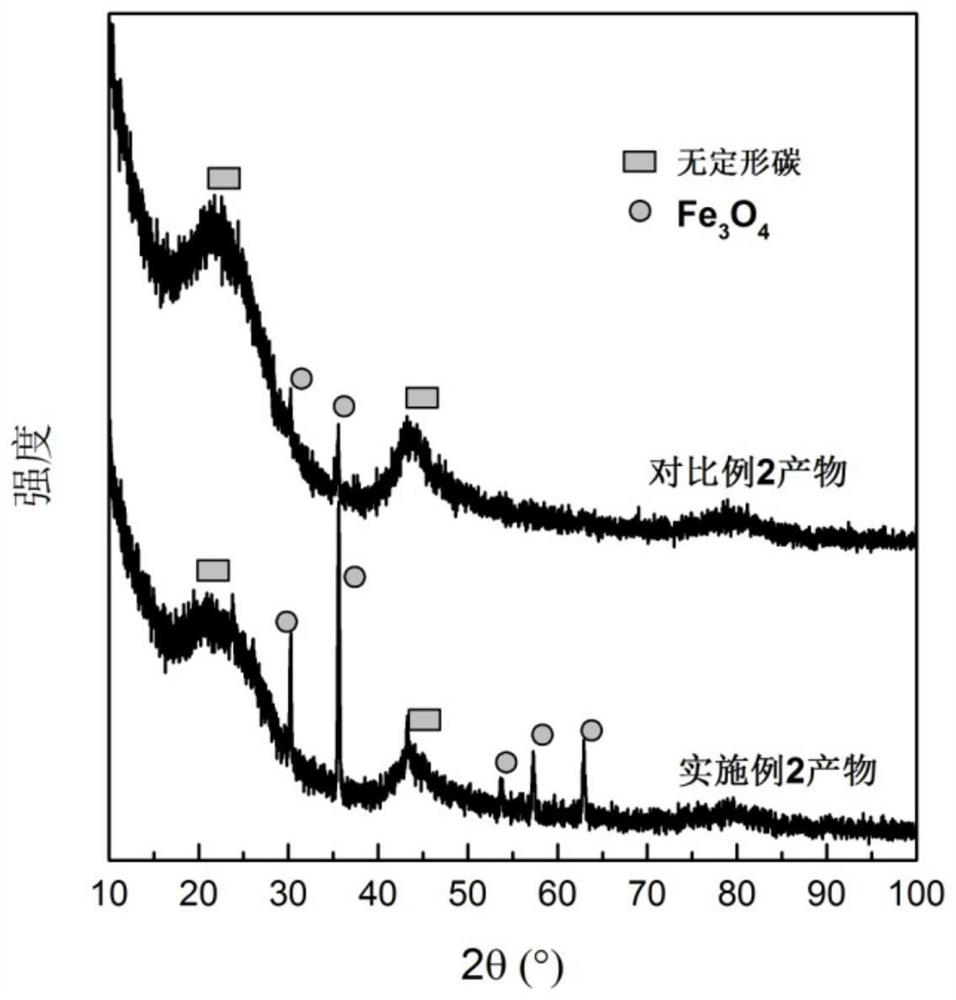

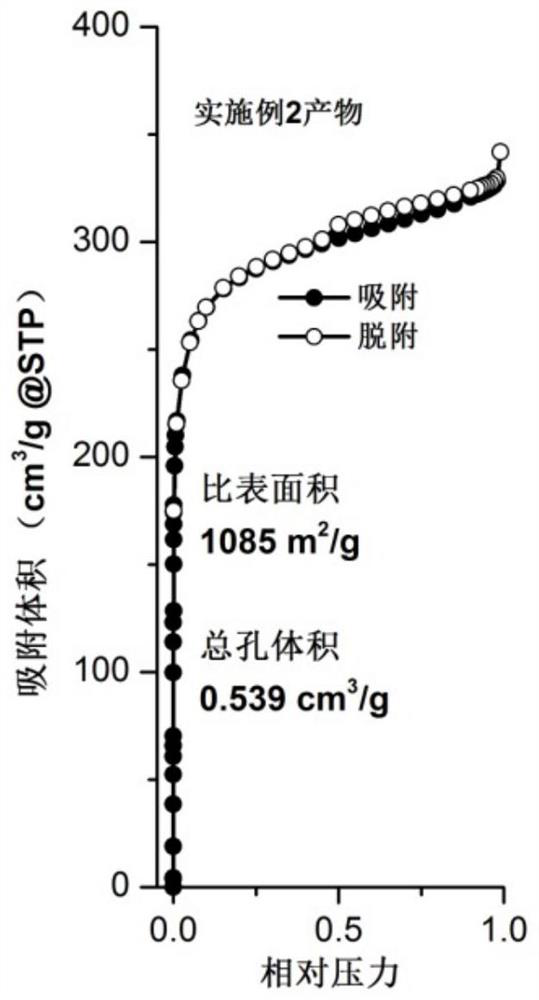

Embodiment 2

[0079] This embodiment provides a kind of preparation method of modified activated carbon / ferric oxide composite material, and described preparation method comprises the following steps:

[0080] (1) Utilize 50mL of 0.1g / mL oxalic acid solution prepared with deionized water, then use the oxalic acid solution to vibrate 15g of commercial activated carbon in a shaker at room temperature at a speed of 180rpm, carry out the first excessive impregnation treatment for 9h, and treat the activated carbon After the adsorption is saturated, carry out centrifugal dehydration, and wash the obtained solid to neutrality, and dry it at 60°C until the activated carbon is completely dehydrated, and the obtained solid is acid-soaked activated carbon;

[0081] (2) Prepare 50mL of 0.1g / mL FeCl with deionized water 2 solution, reusing the FeCl 2 The solution is to shake the acid-soaked activated carbon obtained in step (1) at room temperature in a shaker with a rotating speed of 180rpm, carry out...

Embodiment 3

[0086] This embodiment provides a kind of preparation method of modified activated carbon / ferric oxide composite material, and described preparation method comprises the following steps:

[0087] (1) Utilize deionized water to prepare 50mL of 0.1g / mL malic acid solution, then utilize said malic acid solution to vibrate 15g of commercial activated carbon in a shaker at room temperature at a speed of 180rpm, and carry out the first excessive impregnation treatment for 19h, After the activated carbon is adsorbed and saturated, carry out centrifugal dehydration, wash the obtained solid to neutrality, and dry it at 120°C until the activated carbon is completely dehydrated, and the obtained solid is pickled activated carbon;

[0088] (2) Prepare 50mL of 0.1g / mL Fe with deionized water 2 (SO 4 ) 3 solution, and reuse the Fe 2 (SO 4 ) 3 Solution to the acid-soaked activated carbon obtained in step (1) at room temperature in a shaker with a rotating speed of 180rpm, carry out the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total pore volume | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com