Preparing method of catalyst containing modified SAPO-34 molecular sieve and application thereof

A SAPO-34, molecular sieve technology, used in molecular sieve catalysts, hydrocarbon production from oxygen-containing organic compounds, physical/chemical process catalysts, etc., can solve the problems of high carbon deposition and low diene selectivity, and achieve large specific surface area, Low selectivity, acid-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

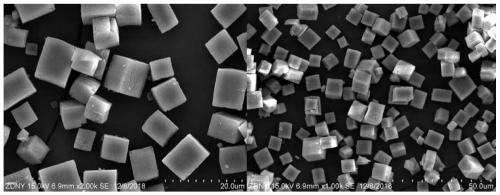

[0034] Such as figure 1 Shown, the preparation method that contains the catalyst of modified SAPO-34 molecular sieve, comprises the following steps:

[0035] 1) Mix pseudo-boehmite with water evenly, then add deionized water, 85% by weight orthophosphoric acid, triethylamine, silica sol, chromium nitrate, n-propylamine in turn, and stir at 20-30°C for 2 Mix evenly in one hour, obtain mixed reaction liquid; Al in described mixed reaction liquid 2 o 3 :P 2 o 5 : SiO 2 : Chromium Nitrate: Triethylamine: n-Propylamine: H 2 The molar ratio of O is 0.7:0.7:0.25:0.15:2.5:0.5:50;

[0036] 2) Mix the obtained mixed reaction liquid evenly, put it into a high-temperature reactor, pre-crystallize at 170°C for 8 hours, then raise the temperature to 200°C for crystallization for 8 hours, centrifuge the mixed reaction liquid to obtain a filter cake, and filter the obtained The cake is mixed with silica sol and kaolin in a certain proportion to prepare the MTO catalyst;

[0037] 3) Ca...

Embodiment 2

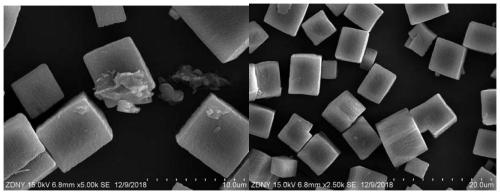

[0040] Such as figure 2 Shown, the preparation method that contains the catalyst of modified SAPO-34 molecular sieve, comprises the following steps:

[0041] 1) Mix pseudo-boehmite with water evenly, then add deionized water, 85% by weight orthophosphoric acid, triethylamine, silica sol, chromium nitrate, n-propylamine in turn, and stir at 20-30°C for 2 Mix evenly in one hour, obtain mixed reaction liquid; Al in described mixed reaction liquid 2 o 3 :P 2 o 5 : SiO 2 : Chromium salt: Triethylamine: n-Propylamine: H 2 The molar ratio of O is 1:1:0.25:0.15:2.5:0.5:50;

[0042]2) Mix the obtained mixed reaction liquid evenly, put it into a high-temperature reactor, pre-crystallize at 170°C for 8 hours, then raise the temperature to 200°C for crystallization for 8 hours, centrifuge the mixed reaction liquid to obtain a filter cake, and filter the obtained The cake is mixed with silica sol and kaolin in a certain proportion to prepare the MTO catalyst;

[0043] 3) Calcining...

Embodiment 3

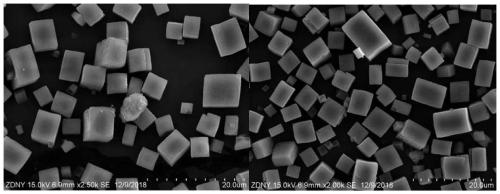

[0046] Such as image 3 Shown, the preparation method that contains the catalyst of modified SAPO-34 molecular sieve, comprises the following steps:

[0047] 1) Mix pseudo-boehmite with water evenly, then add deionized water, 85% by weight orthophosphoric acid, triethylamine, silica sol, chromium nitrate, n-propylamine in turn, and stir at 20-30°C for 2 Mix evenly for 1 hour to obtain a mixed reaction solution; in the mixed reaction solution, Al2O3: P2O5: SiO2: chromium salt: triethylamine: n-propylamine: H2O The molar ratio is 1:1:0.25:0.2:2:1:50;

[0048] 2) Mix the obtained mixed reaction liquid evenly, put it into a high-temperature reactor, pre-crystallize at 170°C for 8 hours, then raise the temperature to 200°C for crystallization for 8 hours, centrifuge the mixed reaction liquid to obtain a filter cake, and filter the obtained The cake is mixed with silica sol and kaolin in a certain proportion to prepare the MTO catalyst;

[0049] 3) Calcining the prepared catalyst ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com