Tungsten-contained mesic porous molecular sieve catalyst for synthesis of glutaral dehyde and its preparation

A technology for synthesizing glutaraldehyde and mesoporous molecular sieve, applied in molecular sieve catalysts, chemical instruments and methods, catalysts for physical/chemical processes, etc. It can achieve the effects of insensitive reaction parameters, excellent catalytic performance, and easy production control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

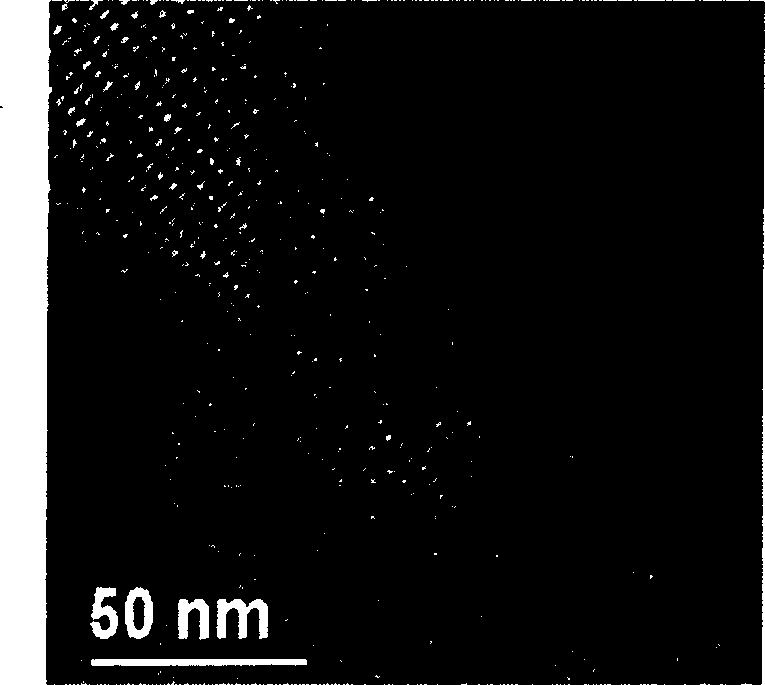

[0022] Example 1: Dissolve 1.92g NaOH in 100ml deionized water at room temperature, add 10mL aqueous solution containing 1.468g sodium tungstate and 17.5g surfactant CTAB, dissolve with hot water, and stir for 1h. 20.8 g of TEOS was added dropwise to this solution under vigorous electric stirring to obtain a white gummy mixture, and stirring was continued for 2 h. Then sealed and crystallized at 100°C for 24h. Take it out, cool it, adjust the pH value to 0 with concentrated hydrochloric acid, re-seal and crystallize at 100°C for 24 hours, filter, wash with water, and bake at 100°C for 24 hours. Calcined in an oxygen atmosphere at 700°C for more than 6 hours, granulated, sieved with 40-60 meshes, and activated at 800°C for 3 hours to obtain catalyst #1. The electron micrograph of typical W-MCM-48 catalyst is attached figure 1 And attached figure 2 .

Embodiment 2

[0023] Example 2: In a 35°C oil bath, dissolve 10.6g NaOH in 420ml deionized water, add 10mL aqueous solution containing 0.853g tungstic acid and 18.7g surfactant CTAB, dissolve with hot water, and stir for 1 hour. 20.8 g of TEOS was added dropwise to this solution under vigorous electric stirring to obtain a white gummy mixture, and stirring was continued for 3 h. Then sealed and crystallized at 80°C for 36h. Take it out, cool it, adjust the pH value to ~1 with concentrated hydrochloric acid, re-seal and crystallize at 80°C for 12 hours, filter, wash with water, and bake at 120°C for 24 hours. Calcination temperature is 200 DEG C, remaining is the same as embodiment 1, obtains 2# catalyst.

Embodiment 3

[0024] Example 3: In a 50°C oil bath, dissolve 0.2g NaOH in 20ml deionized water, add 10mL aqueous solution containing 1.75g silicotungstic acid and 10.4g surfactant CTAB, dissolve with hot water, and stir for 5 hours. 20.8 g of TEOS was added dropwise to this solution under vigorous electric stirring to obtain a white gummy mixture, and stirring was continued for 4 h. Then sealed and crystallized at 110°C for 30h. Take it out, cool it, adjust the pH value to ~7 with concentrated hydrochloric acid, re-seal and crystallize at 110°C for 18h, filter, wash with water, and bake at 110°C for 24 hours at 1300°C, as in Example 1 to obtain 3# catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com