Preparation method of sodium alginate-based dual-network carbon aerogel negative electrode material for lithium ion battery

A lithium-ion battery and sodium alginate technology, which is applied in the direction of battery electrodes, negative electrodes, electrical components, etc., can solve the problems of easy agglomeration of particles, limiting the electrochemical performance of lithium batteries, poor conductivity, etc., and achieve the effect of alleviating easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

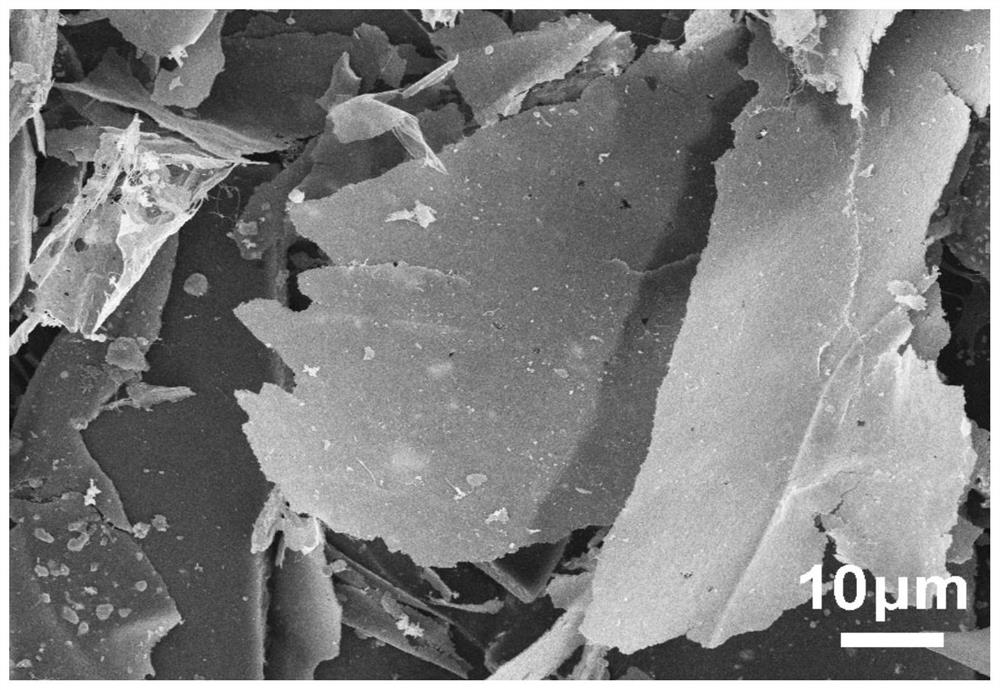

[0028] Weigh 0.4g of sodium alginate powder and 0.4g of agar powder, add them into 40mL of deionized water, and stir at high speed in a water bath at 80°C for 40 minutes to fully dissolve them in deionized water and form a uniform viscous solution; The viscous solution was transferred to a disposable plastic cup and left to cool for 2 hours to obtain a preformed hydrogel; measure 6mL Mn(NO 3 ) 2 Solution in 60mL deionized water, weigh 0.272g ZnCl 2 Dilute the particles in 60mL of deionized water, stir to make it evenly mixed, and record it as solution A. Gently cut the disposable plastic cup, take out the preformed hydrogel, soak it in solution A for 8 hours, then wash it repeatedly with deionized water for 6 times, and finally place the sodium alginate / agar double network hydrogel on the Freeze in a low-temperature refrigerator for 12 hours and then transfer to a freeze dryer for freeze-drying for 48 hours to obtain a fluffy sodium alginate / agar double network airgel.

[0...

Embodiment 2

[0032] Weigh 0.4g of sodium alginate powder and 0.4g of agar powder, add them into 40mL of deionized water, and stir at high speed in a water bath at 80°C for 40 minutes to fully dissolve them in deionized water and form a uniform viscous solution; The viscous solution was transferred to a disposable plastic cup and left to cool for 2 hours to obtain a preformed hydrogel; measure 6mL Mn(NO 3 ) 2 Solution, weigh 0.408g ZnCl 2 Dilute the particles in 60mL of deionized water, stir to make it evenly mixed, and record it as solution A. Gently cut the disposable plastic cup, take out the preformed hydrogel, soak it in solution A for 8 hours, then wash it repeatedly with deionized water for 6 times, and finally place the sodium alginate / agar double network hydrogel on the Freeze in a low-temperature refrigerator for 12 hours and then transfer to a freeze dryer for freeze-drying for 48 hours to obtain a fluffy sodium alginate / agar double network airgel.

[0033] Put the airgel obta...

Embodiment 3

[0036] Weigh 0.4g of sodium alginate powder and 0.2g of agar powder, add them to 40mL of deionized water, and stir at high speed in a water bath at 80°C for 40 minutes to fully dissolve them in deionized water and form a uniform viscous solution; The viscous solution was transferred to a disposable plastic cup, and left to cool for 2 hours to obtain a preformed hydrogel; measure 6mL Mn(NO 3 ) 2 Solution, weigh 0.68g ZnCl 2 Dilute the particles in 60mL of deionized water, stir to make it evenly mixed, and record it as solution A. Gently cut the disposable plastic cup, take out the preformed hydrogel, soak it in solution A for 8 hours, then wash it repeatedly with deionized water for 6 times, and finally place the sodium alginate / agar double network hydrogel on the Freeze in a low-temperature refrigerator for 12 hours and then transfer to a freeze dryer for freeze-drying for 48 hours to obtain a fluffy sodium alginate / agar double network airgel.

[0037] Put the airgel obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com