A carbon nanotube-doped copper-aluminum composite metal oxide denitration catalyst and its preparation method and application

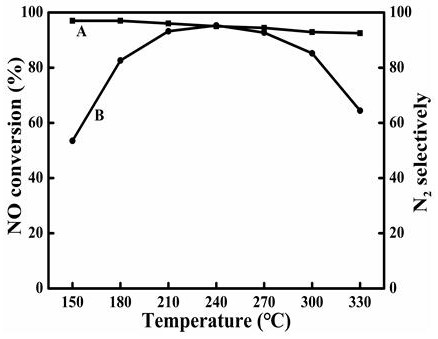

A technology of denitrification catalyst and carbon nanotubes, which is applied in the field of CuAl-LDO/CNTs denitration catalyst, catalyst and its preparation, can solve the problems of poor water resistance and sulfur resistance, narrow active window, etc., so as to slow down the poisoning effect and enhance the resistance The effect of water resistance to sulfur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

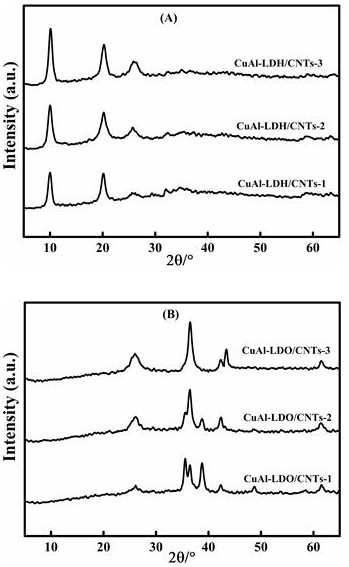

Embodiment 1

[0036] (1) Take 20ml respectively and the concentration is 0.5 mol L -1 Aqueous solution of aluminum nitrate nonahydrate and 20ml concentration of 1.0 mol L -1 Add the copper nitrate trihydrate aqueous solution to the beaker, and stir with a magnetic stirrer for 10min to make it evenly mixed, and transfer the prepared salt solution to the dropping funnel 1 for later use;

[0037] (2) Take 200ml and make the concentration 1.00 mol L -1 aqueous sodium hydroxide solution, which is transferred to the dropping funnel 2 for later use;

[0038] (3) Take 8ml and the concentration is 30 g L -1The oxidized carbon nanotube dispersion liquid is placed in a beaker, and the sodium hydroxide aqueous solution and the mixed salt solution are dropped into the above dispersion liquid at the same time under magnetic stirring, and the pH value during the titration process is monitored in real time with an acidity meter, and the titration speed is controlled to make the whole reaction During the...

Embodiment 2

[0042] (1) Take 20ml respectively and the concentration is 0.5 mol L -1 Aqueous solution of aluminum nitrate nonahydrate and 30ml concentration of 1.0 mol L -1 Add the copper nitrate trihydrate aqueous solution to the beaker, and stir it with a magnetic stirrer for 10 min to make it evenly mixed, and transfer the prepared salt solution to the dropping funnel 1 for later use;

[0043] (2) Take 200ml and make the concentration 1.00 mol L -1 aqueous sodium hydroxide solution, which is transferred to the dropping funnel 2 for later use;

[0044] (3) Take 25ml and the concentration is 30 g L -1 The oxidized carbon nanotube dispersion liquid is placed in a beaker, and the sodium hydroxide aqueous solution and the mixed salt solution are dropped into the above dispersion liquid at the same time under magnetic stirring, and the pH value during the titration process is monitored in real time with an acidity meter, and the titration speed is controlled to make the whole reaction proce...

Embodiment 3

[0048] (1) Weigh 20ml respectively to a concentration of 0.5 mol L -1 The concentration of aluminum nitrate nonahydrate aqueous solution and 40ml is 1 mol L -1 Copper nitrate trihydrate was mixed into the beaker, and stirred with a magnetic stirrer for 10 min to make it evenly mixed, and the prepared salt solution was transferred to the dropping funnel for later use

[0049] (2) Take 200ml and make the concentration 1.00 mol L -1 aqueous sodium hydroxide solution, which is transferred to the dropping funnel for use;

[0050] (3) Take 60ml of concentration to be 30 g L -1 The oxidized carbon nanotube dispersion liquid is placed in a beaker, and the sodium hydroxide aqueous solution and the mixed salt solution are dropped into the above dispersion liquid at the same time under magnetic stirring, and the pH value during the titration process is monitored in real time with an acidity meter, and the titration speed is controlled to make the whole reaction During the process, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com