Structured cemented gravel pile and construction method thereof

A construction method and technology of crushed stone piles, which are applied in basic structure engineering, soil protection, construction, etc., can solve problems such as cement slurry polluting sea water, semi-rigid piles cannot meet foundation deformation, and construction progress is slow, so as to improve resistance Capability of horizontal load, increased strength and stiffness, less pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

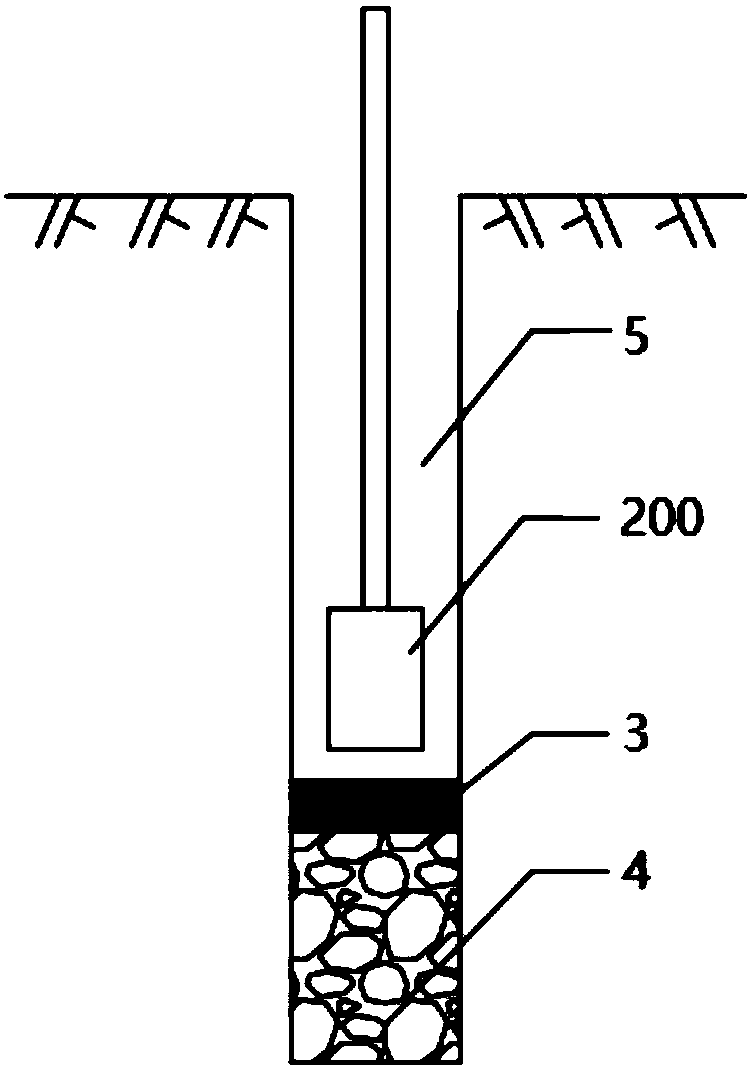

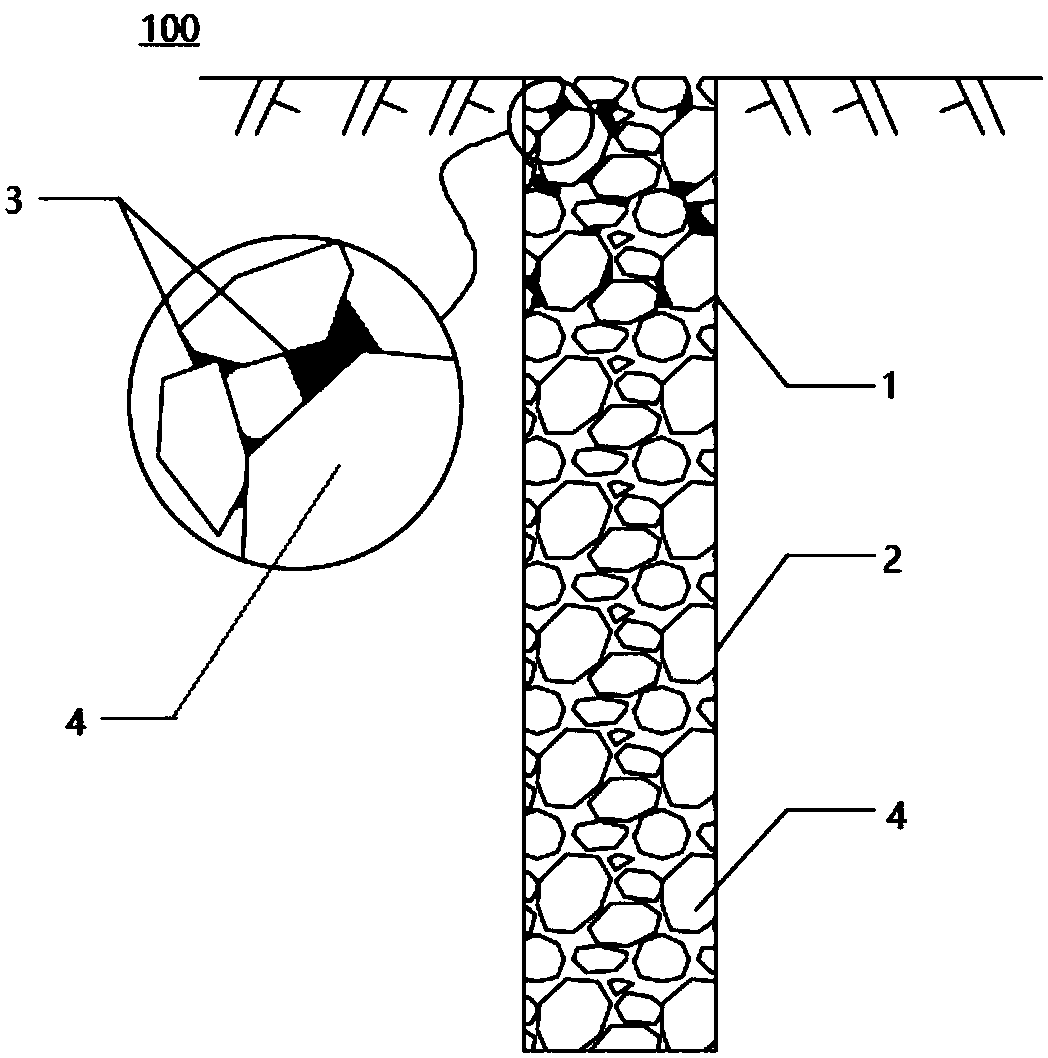

[0046] Such as figure 2 As shown, the construction result of this embodiment is a structured cemented crushed stone pile 100 with a single-stage cemented crushed stone pile body 1, with a diameter of 500 mm, and the cemented crushed stone pile body 1 is located at the top of the pile. The length of the stone pile 1 is 2m, the particle size of the crushed stone 4 is 30-80mm, the self-compacting cement-based material 3 adopts the self-compacting cement paste, the expansion of the self-compacting cement paste is 260mm, and the V-shaped funnel time is 2.57s .

[0047] The specific construction steps are as follows:

[0048] S1: Perform on-site in-situ tests according to design requirements to determine that the void ratio of the compacted aggregate 4 is 0.3, and the expansion degree of the self-compacting cement-based material 3 used to form the cemented aggregate pile 1 is 260mm, V-shaped funnel Passing time is 2.57s;

[0049] S2: Pile hole 5 is formed during construction;

[0050] S3...

Embodiment 2

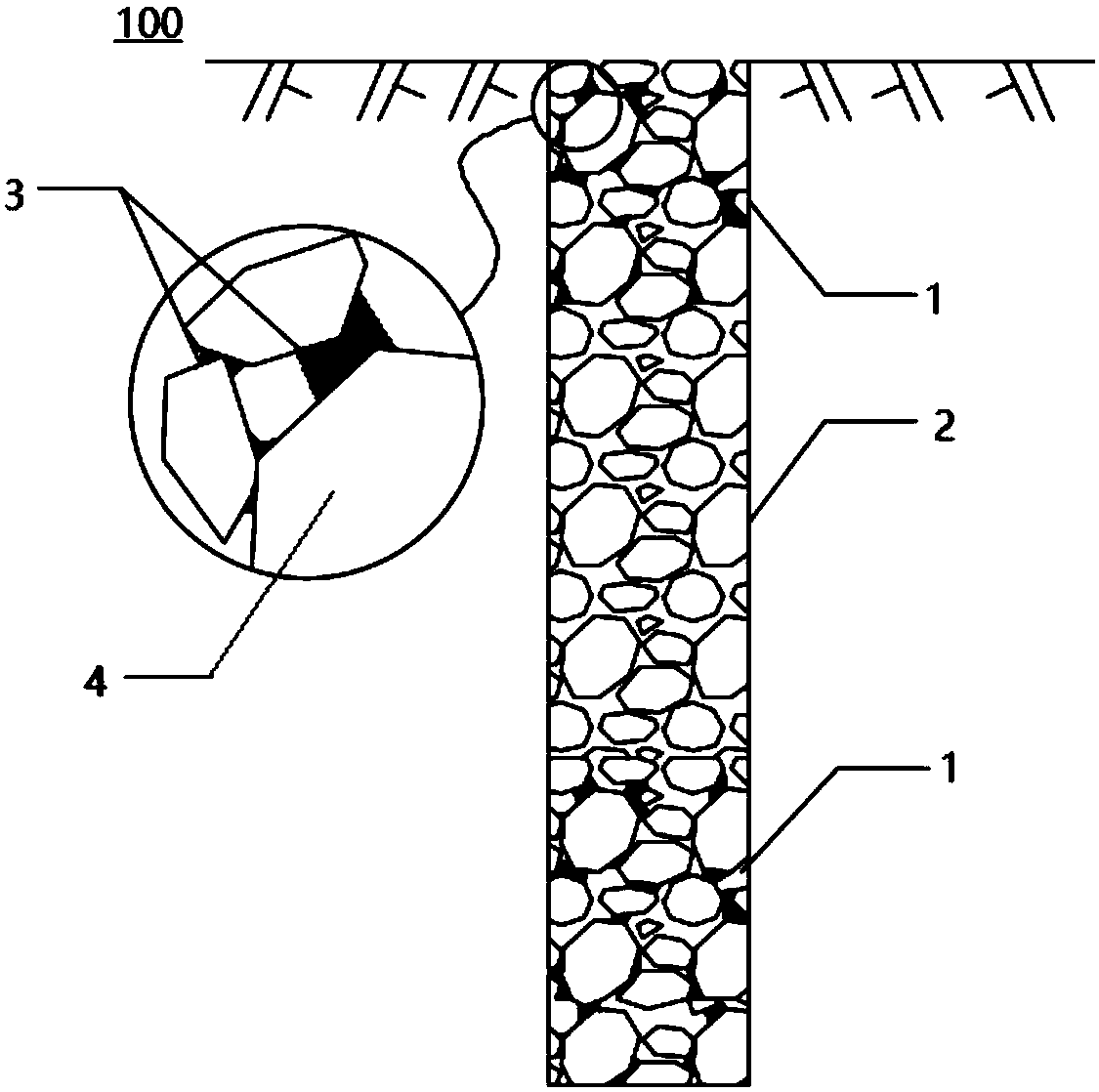

[0053] Such as image 3 As shown, the construction result of this embodiment is a structured cemented gravel pile 100 with a multi-section cemented crushed stone pile body 1. The structured cemented crushed stone pile 100 is applied to sea reclamation projects, and the multi-section cemented crushed stone pile body 1 Located at the top of the pile and the bottom of the pile, the diameter of the pile is 500mm, the length of the cemented gravel at the top of the pile is 2m, the length of the cemented gravel at the bottom of the pile is 2.5m, and the particle size of the gravel 4 is 30 -50mm, self-compacting cement-based material 3 adopts underwater self-protecting self-compacting cement paste, the expansion degree of underwater self-protecting self-compacting cement paste is 280mm, and the V-shaped funnel time is 2.0s.

[0054] The specific construction steps are as follows:

[0055] S1: Perform on-site in-situ tests according to design requirements to determine that the void ratio o...

Embodiment 3

[0062] Such as Figure 4 As shown, the construction result of this embodiment is a structured cemented gravel pile group. According to the calculation of the engineering structure, the structured cemented gravel pile group includes a variety of structured cemented gravel piles 100, and part of the pile tops are poured Cemented gravel pile body 1 is formed, the middle of the pile body of part of the pile is poured to form cemented gravel pile body 1, the top of the pile of part of the pile body is poured to form cemented gravel pile body 1, and the pile body of some piles includes multiple cemented gravel piles Pile body 1.

[0063] The structured cemented crushed stone piles 100 of this embodiment are arranged in groups, and the position of the cemented crushed stone pile body 1 of each pile in the pile group realizes the optimal design of structural performance through structural calculation, thereby improving the stability of the entire reinforced foundation.

[0064] According t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com