Micro-mesoporous structure beta-molecular sieve, Ni-based micro-mesoporous beta-molecular sieve catalyst and preparation method thereof

A molecular sieve and catalyst technology, used in molecular sieve catalysts, catalyst activation/preparation, chemical instruments and methods, etc., can solve the problems of single pore structure of microporous Beta molecular sieve, uneven distribution of catalyst active components, and small specific surface area. Simple operation steps, good hydrothermal stability, stable molecular structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

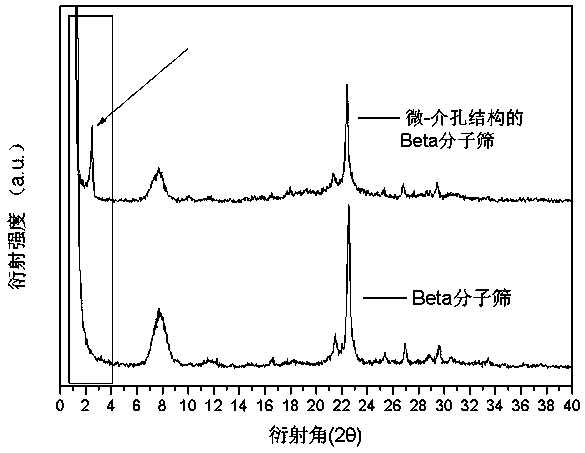

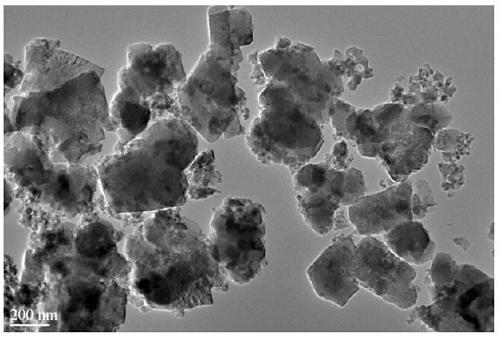

[0027] Embodiment 1: Micro-mesoporous Beta molecular sieve preparation method, comprises the following operation steps:

[0028] One, the tetraethylammonium hydroxide C of content 25% 8 h 21 Add 23.50ml of NO aqueous solution, 19ml of deionized water, and 3ml of sodium hydroxide solution with a concentration of 8mol / L, and stir evenly;

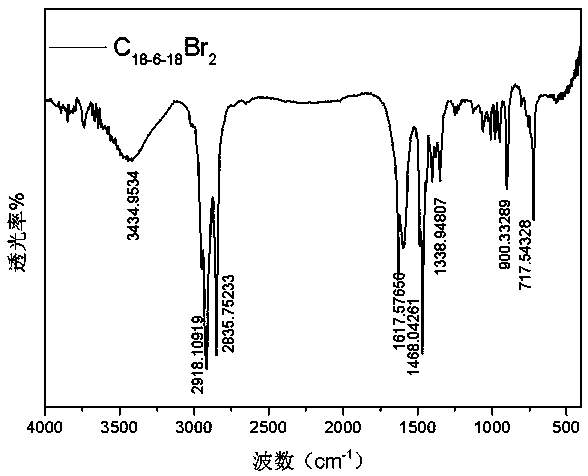

[0029] 2. At 25°C, add a mixture of acetonitrile and toluene with a volume ratio of 1:1 into a three-necked flask, heat the reaction to 75°C, and measure 0.005mol of bromooctadecane and 0.0025mol of N,N,N' ,N'-Tetramethyl-1,6-hexanediamine was added dropwise to the mixed solution in sequence, and continued to reflux and stir at the above temperature for 15 hours; After the organic solvent in the flask was rotary evaporated, the reaction product in the flask was dissolved in ethyl acetate, washed and filtered repeatedly, and finally the product was dried overnight in a vacuum oven at 48°C, and the product obtained after drying and grinding wa...

Embodiment 2

[0041] Embodiment 2: the preparation method of micro-mesoporous Beta molecular sieve, comprises the following operation steps:

[0042] One, the tetraethylammonium hydroxide C of content 25% 8 h 21 Add 23.00ml of NO aqueous solution, 18.5ml of deionized water, and 3.20ml of sodium hydroxide solution with a concentration of 8mol / L, and stir evenly;

[0043] 2. At 30°C, add a mixture of acetonitrile and toluene with a volume ratio of 1:1 into the three-necked flask, heat the reaction to 70°C, and measure 0.005mol of bromooctadecane and 0.0025mol of N,N,N' , N'-tetramethyl-1,6-hexanediamine was added dropwise to the mixed solution in sequence, and continued to reflux and stir at the above temperature for 15 hours; After the organic solvent in the flask was rotary evaporated, the reaction product in the flask was dissolved in ethyl acetate, washed and filtered repeatedly, and finally the product was dried overnight in a vacuum oven at 40°C, and the product obtained after drying ...

Embodiment 3

[0055] Embodiment 3: preparation method of micro-mesoporous Beta molecular sieve, comprises the following steps:

[0056] One, the tetraethylammonium hydroxide C of content 25% 8 h 21 Add 24.0ml of NO aqueous solution, 19.5ml of deionized water, and 2.8ml of sodium hydroxide solution with a concentration of 8mol / L, and stir evenly;

[0057] 2. At 28°C, add a mixture of acetonitrile and toluene with a volume ratio of 1:1 into the three-necked flask, heat the reaction to 72°C, and measure 0.005mol of bromooctadecane and 0.0025mol of N,N,N' , N'-tetramethyl-1,6-hexanediamine was added dropwise to the mixed solution in turn, and continued to reflux and stir at the above temperature for 15 hours; After the organic solvent in the flask was rotary evaporated, the reaction product in the flask was dissolved in ethyl acetate, washed and filtered repeatedly, and finally the product was dried overnight in a vacuum oven at 50°C, and the product obtained after drying and grinding was Te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com