A constitution method of a lithium ion battery diaphragm surface supermolecule membrane

A technology of lithium-ion batteries and supramolecular membranes, which is applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as decreased ion conductivity, increased lithium ion migration resistance, and blockage of diaphragm pores, achieving increased mechanical performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

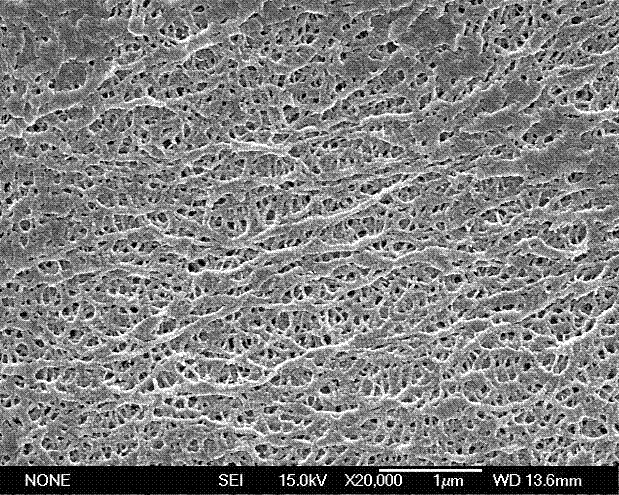

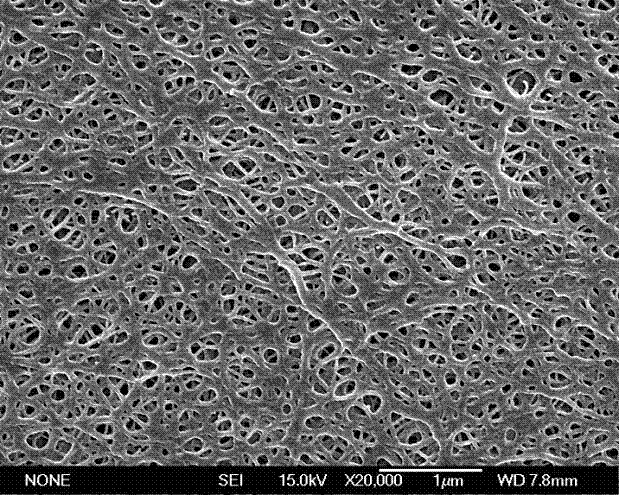

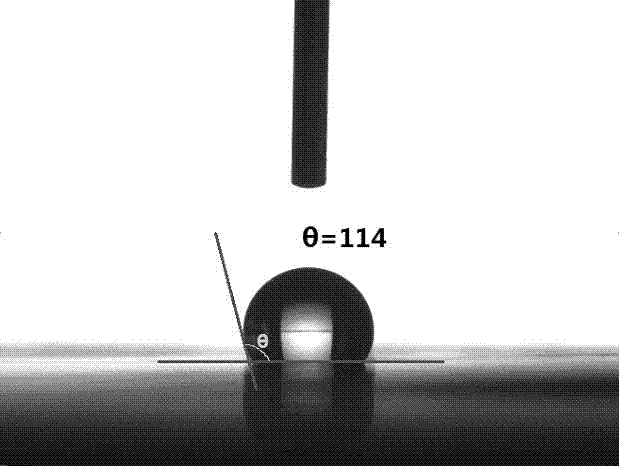

[0028] Embodiment 1: The polyolefin membrane is treated with plasma first, so that its surface has carboxyl groups. Then soak in PEI aqueous solution with a concentration of 1 mg / ml for 20 minutes, and then wash with deionized water for 3 times, each time for 1 minute. Next, soak in a water / methanol mixed solution of PAA polyanion compound with a concentration of 0.03 mg / ml for 10 minutes, and then soak in a water / methanol mixed solvent for 3 times, each time for 1 minute. Finally, the polyolefin separator was placed in ZrO with amino groups on the surface at a concentration of 1 mg / ml. 2 Soaked in the sol for 10min, and then soaked in deionized water for 3 times, each time for 1min, so that the PAA and ZrO 2 One cycle of assembly, repeat the above steps to assemble multiple cycles of PAA and ZrO 2 Afterwards, soak the polyolefin membrane in HA or ALG aqueous solution with a concentration of 0.05 mg / ml for 10 minutes, and then soak it in deionized water for 3 times, each tim...

Embodiment 2

[0029] Example 2: The polyolefin separator was first treated with plasma, then soaked in PEI aqueous solution with a concentration of 1 mg / ml for 20 minutes, and then soaked with deionized water for 3 times, each time for 1 minute. Next, put SiO with a carboxyl group concentration of 10mg / ml on the surface 2Soak in the sol for 10 minutes, and then soak in deionized water for 3 times, 1 minute each time. Finally, put the polyolefin separator into the PAH polycation compound aqueous solution with a concentration of 1 mg / ml and soak it for 10 minutes, and then soak it in deionized water for 3 times, each time for 1 minute, thus completing the SiO 2 And PAH one cycle of assembly, multiple cycles of assembly repeat the above steps. Subsequently, the modified polyolefin separator was immersed in a solution of chemical crosslinking solvent EDC (1-ethyl-3-carbodiimide hydrochloride) and NHS (N-hydroxysuccinimide) at a concentration of 0.1M 24h.

Embodiment 3

[0030] Example 3: The polyolefin separator was treated with plasma first, then soaked in PEI aqueous solution with a concentration of 0.5 mg / ml for 20 minutes, and then soaked with deionized water for 3 times, each time for 1 minute. Next, put Al with a carboxyl group concentration of 1mg / ml on the surface 2 o 3 Soak in the sol for 10 minutes, and then soak in deionized water for 3 times, 1 minute each time. This completes the PEI and Al 2 o 3 One cycle of assembly, repeat the above steps to assemble multiple cycles of PEI and Al 2 o 3 Afterwards, soak the polyolefin membrane in PAH or CS aqueous solution with a concentration of 0.1 mg / ml for 10 minutes, and then soak it in deionized water for 3 times, each time for 1 minute. Finally, soak the modified polyolefin separator in a solution of chemical crosslinking solvent EDC (1-ethyl-3-carbodiimide hydrochloride) and NHS (N-hydroxysuccinimide) at a concentration of 0.1M 24h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com