SBA15 catalyst loading cobalt base

A catalyst, cobalt-based technology, applied in the field of magnesium oxide desulfurization, can solve problems that have not been explored

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A cobalt-based SBA15 catalyst, the cobalt-based loading is 2%wt, and the cobalt-based is highly dispersed inside the SBA15 pores.

[0029] Its preparation method is as follows:

[0030] First, weigh 2g of SBA15 solid powder and 0.1973g of cobalt nitrate particles, dissolve the two in 100ml of absolute ethanol, and place them in a beaker for magnetic stirring for 5h; secondly, let stand and crystallize for 24h; then, place Vacuum rotary evaporator was evaporated and dried for 2 hours at a temperature of 60°C; finally, it was roasted in a muffle furnace at 450°C for 5 hours.

[0031] The catalyst is mainly used to promote the oxidation of magnesium sulfite in the process of magnesium oxide desulfurization.

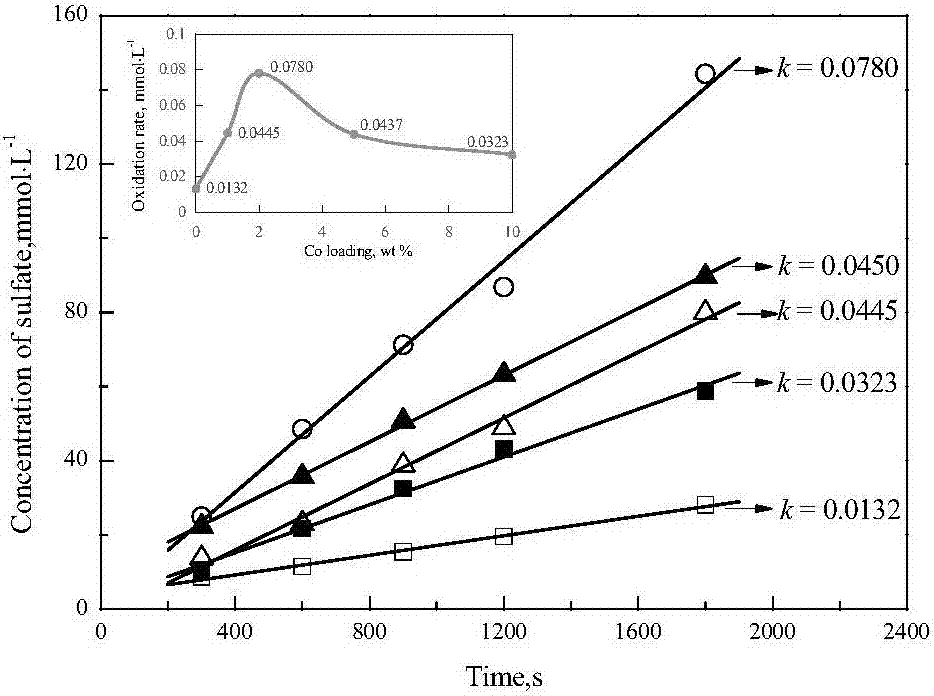

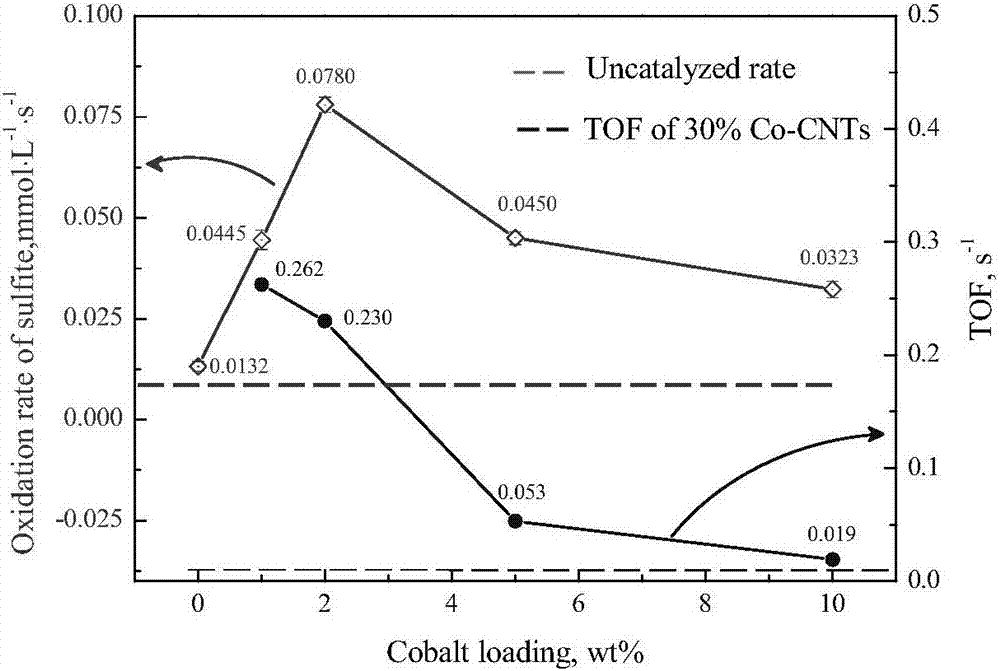

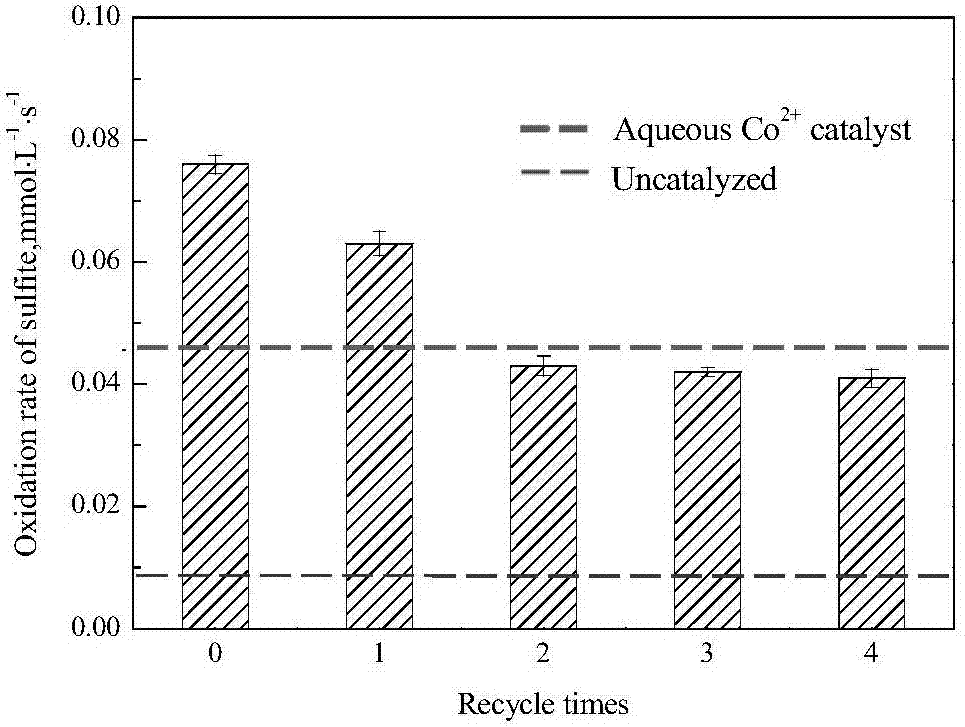

[0032] Such as figure 1 with 2 Shown is the effect of cobalt loading and loading on catalytic performance. The cobalt-based loading has a great influence on the catalyst performance. As the loading increases, the oxidation rate of magnesium sulfite increases rapid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com