Preparation method of para-aramid/PP non-woven fabric lithium ion battery diaphragm

A lithium-ion battery and para-aramid technology, which is applied in secondary batteries, battery components, circuits, etc., can solve problems such as poor performance, achieve the effects of increasing porosity, good fluidity, and avoiding pore blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A kind of preparation method of p-aramid fiber / PP non-woven fabric lithium-ion battery diaphragm, comprises the following steps:

[0028] S1, select PP non-woven fabric as the base material;

[0029] S2, preparation of pore-forming agent solution, dissolving benzoic acid in N-methylpyrrolidone, the concentration is 0.2-8mol / L, and the temperature of N-methylpyrrolidone is 60-80°C;

[0030] S3. Immerse the PP non-woven fabric in S1 into the pore-forming agent solution prepared in S2. After 1-10 minutes, take out the PP non-woven fabric, and lower its temperature to below 30°C, and clean the surface of the PP non-woven fabric to make it smooth and free. impurities;

[0031] S4, the preparation of para-aramid fiber slurry, in N 2 Under protection, add 0.5-1 weight part of CaCl to 100 weight parts of N-methylpyrrolidone 2 and 1-2 parts by weight of p-phenylenediamine, stirred at normal temperature until completely dissolved, the stirring speed is 400-500r / min; then add 2...

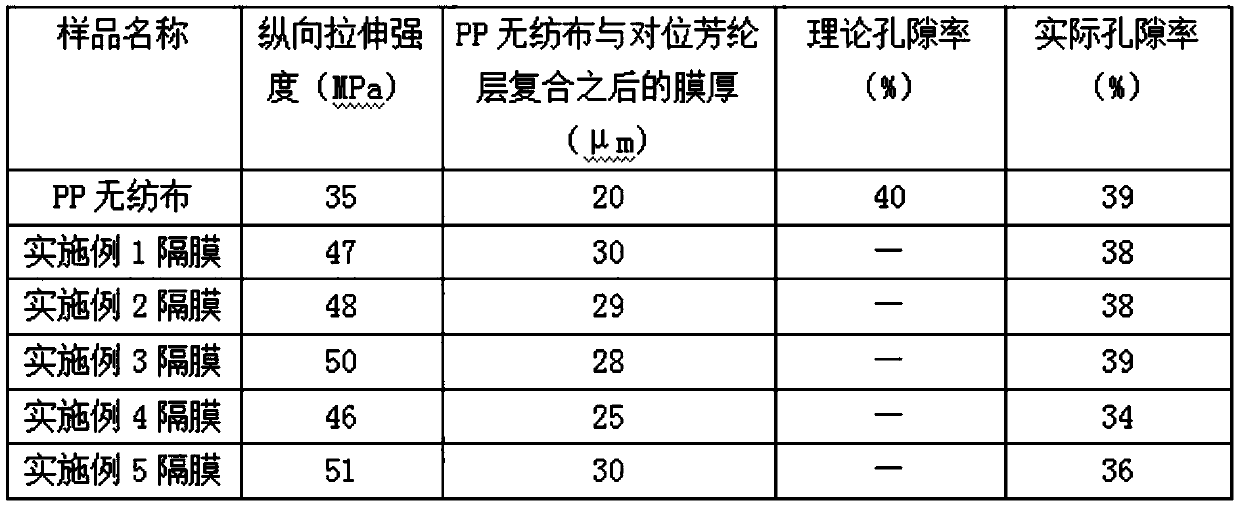

Embodiment 1

[0037] In S2, benzoic acid was dissolved in N-methylpyrrolidone at a temperature of 60°C with a concentration of 0.2mol / L; in S3, the PP non-woven fabric was immersed for 1 min, and the temperature was lowered to 30°C after taking it out; in S4 , add 0.5 parts by weight of CaCl to 100 parts by weight of N-methylpyrrolidone 2and 1 part by weight of p-phenylenediamine, stirred at normal temperature until completely dissolved, and the stirring speed was 500r / min; then added 2 parts by weight of terephthaloyl chloride, kept stirring and carried out polymerization reaction, and the reaction time was 30min; In S5, the thickness of the para-aramid slurry on the PP non-woven fabric was 40 μm; in S6, the mass fraction of sulfuric acid in the coagulation bath was 5%, the temperature of the coagulation bath was 5 °C, and the coagulation time was 6 min; in S8, 100 Sublimation of benzoic acid by heating at ℃ for 5 minutes; pressing with hot pressing roller at 100℃ for 20 minutes. The thic...

Embodiment 2

[0039] In S2, benzoic acid was dissolved in N-methylpyrrolidone at a temperature of 65°C with a concentration of 4mol / L; in S3, the PP non-woven fabric was immersed for 5min, and the temperature was lowered to 20°C after taking it out; in S4, Add 0.6 parts by weight of CaCl to 100 parts by weight of N-methylpyrrolidone 2 and 1.3 parts by weight of p-phenylenediamine, stirred at normal temperature until fully dissolved, and the stirring speed was 430r / min; then added 2.6 parts by weight of terephthaloyl chloride, kept stirring and carried out polymerization reaction, and the reaction time was 30min; In S5, the thickness of the para-aramid slurry on the PP non-woven fabric was 50 μm; in S6, the mass fraction of sulfuric acid in the coagulation bath was 8%, the temperature of the coagulation bath was 5 °C, and the coagulation time was 3 min; in S8, 110 Heating at ℃ for 6 minutes to sublimate benzoic acid; hot pressing roller at 120 ℃ for 10 minutes, during this process, accompani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com