Hydrophobic molecular sieve-based composite material and preparation method thereof

A composite material and molecular sieve-based technology, which is applied in the field of hydrophobic molecular sieve-based composite materials and their preparation, can solve the problems of low utilization rate, high cost, low content of effective components of adsorption materials, etc., and achieves shortened manufacturing time and good hydrophobicity. , strong hydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

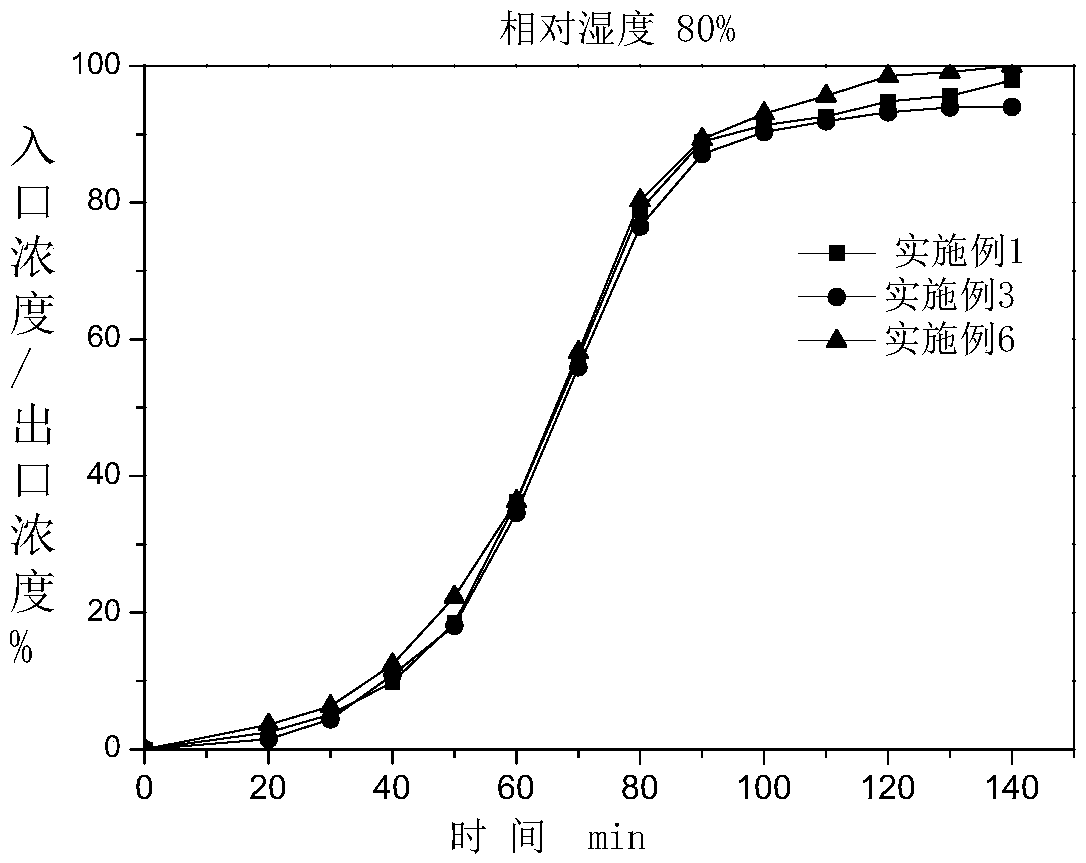

Embodiment 1

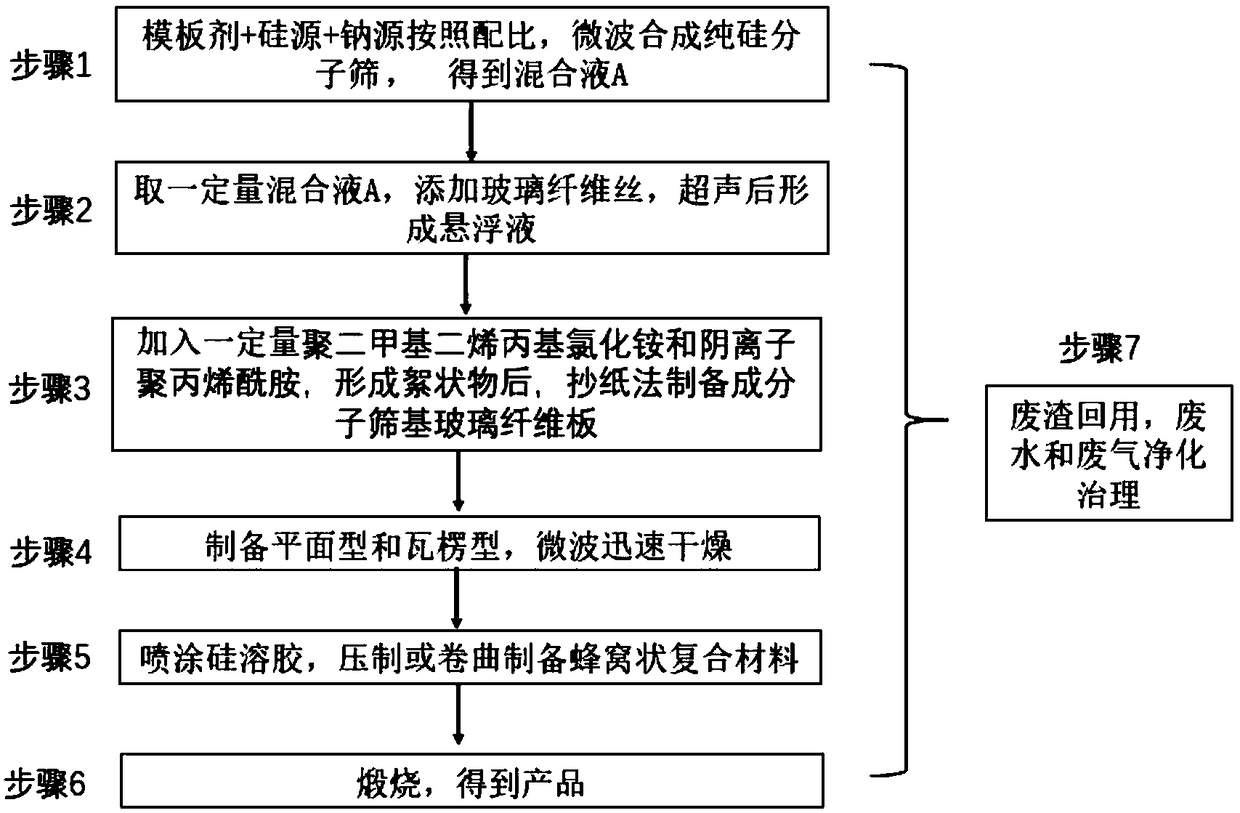

[0028] A preparation method of a hydrophobic molecular sieve-based composite material:

[0029] Step 1: Cyclohexylamine: Sodium Hydroxide: Silicon Dioxide: Water = 0.8~1.2: 0.8~1.2: 40~45: 380~390 according to the molar ratio respectively, after accurate weighing, put it in the crystallization reaction kettle and stir After uniformity, airtight, microwave heating, after 60 minutes of treatment, move to 180°C oven, keep for 60 minutes, and cool to room temperature. Keep the obtained material in the still, and the mixed solution in the still is recorded as mixed solution A;

[0030] Step 2: Weigh 100 g of the mixed solution A in a beaker, and add 5 to 10 grams of glass fiber monofilaments with a diameter of 2 to 15 microns into the mixed solution A, and ultrasonically treat it for 10 to 20 minutes to form a suspension;

[0031] Step 3: Weigh 1 to 5 g of polydimethyldiallyl ammonium chloride, slowly add the suspension in step 2, and continue to sonicate for 3 to 8 minutes, then ...

Embodiment 2

[0037] A preparation method of a hydrophobic molecular sieve-based composite material:

[0038] Step 1: According to the molar ratio of tetraethylammonium hydroxide: sodium hydroxide: silicon dioxide: water = 1.2: 1.2: 45: 380, after accurate weighing, put it in the crystallization reaction kettle, stir it evenly, seal it, and use Microwave heat treatment, after 30 minutes of treatment, move to 180°C oven, keep for 120 minutes, and cool to room temperature. Keep the obtained material in the still, and the mixed solution in the still is recorded as mixed solution A;

[0039] Step 2 to step 7 are the same as step 2 to step 7 in embodiment 1;

Embodiment 3

[0041] A preparation method of a hydrophobic molecular sieve-based composite material:

[0042] Step 1: According to the molar ratio of tetraethylammonium hydroxide: sodium hydroxide: silicon dioxide: water = 1.0: 1.0: 40: 390, after accurate weighing, put it in the crystallization reaction kettle, stir it evenly, seal it, and use Microwave heat treatment, after treatment for 120 minutes, move to 180°C oven, keep for 30 minutes, and cool to room temperature. Keep the obtained material in the still, and the mixed solution in the still is recorded as mixed solution A;

[0043] Step 2 to step 7 are the same as step 2 to step 7 in embodiment 1;

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com