Lithium-ion battery pole piece and preparation method thereof

A lithium ion battery and pole piece technology, which is applied in the field of lithium ion battery pole pieces with gradient porosity and its preparation, can solve the problems of poor pore-making effect and difficult penetration of pore-forming agents, and achieves good ion conduction rate, The effect of increased energy density and good hole-making effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

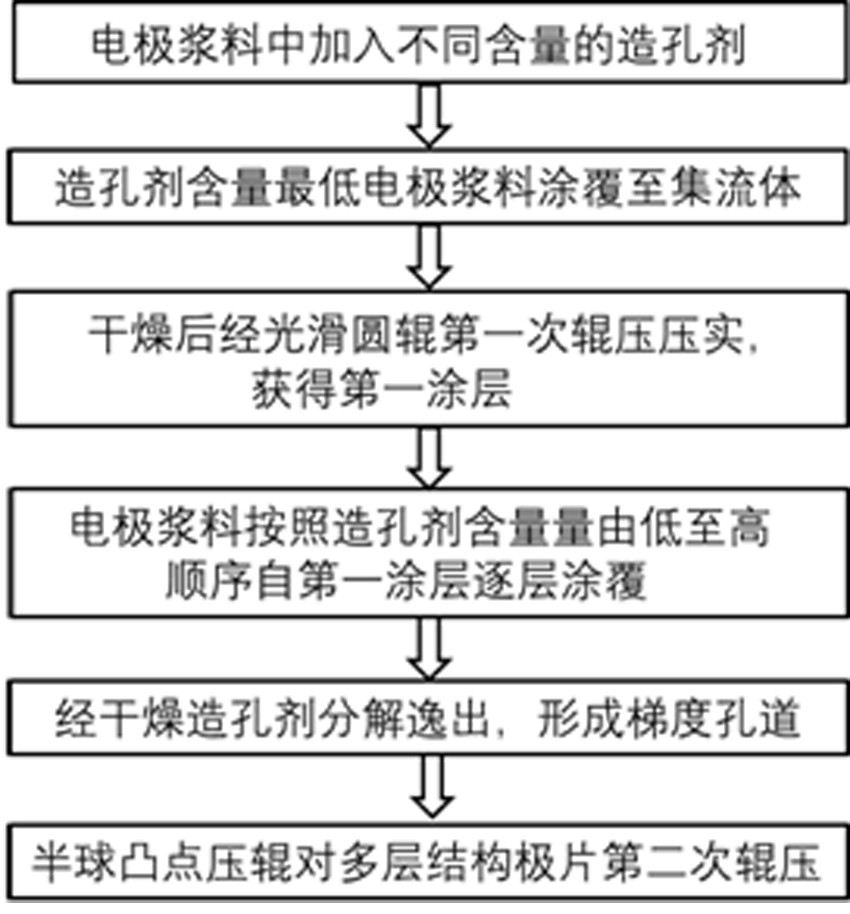

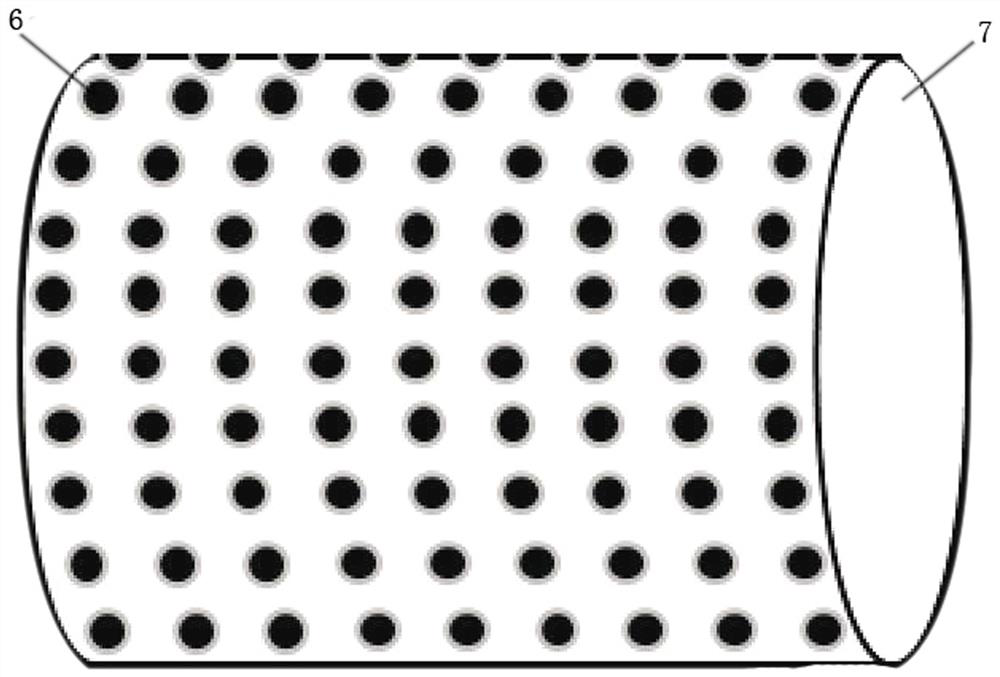

[0059] see Figure 1-Figure 3 , the present invention prepares a lithium ion battery pole piece with gradient porosity according to the following method:

[0060] (1) Mix NMC, conductive agent Super-P, and polyvinylidene fluoride PVDF at a mass ratio of 9.4:0.3:0.3 to prepare a mixture, and then mix the mixture with N-methylpyrrolidone at a mass ratio of 2:1, Prepare electrode slurry;

[0061] (2) Divide the above-mentioned electrode slurry into two parts, and add uniform and delicate ammonium carbonate powder as a pore-forming agent, adjust the stirring speed to fully mix and disperse, wherein the pore-forming agent and active material in the first part of slurry The mass ratio is 0.3:1, and the mass ratio of the pore-forming agent to the active material in the second slurry is 0.6:1.

[0062] (3) Coat the above-mentioned first electrode slurry on one side of the current collector aluminum foil, and after drying, the pore-forming agent decomposes and escapes, and no other s...

Embodiment 2

[0065] The present invention prepares a kind of lithium-ion battery pole piece with gradient porosity according to the following method:

[0066] (1) Mix LFP, conductive agent Super-P, and polyvinylidene fluoride PVDF at a mass ratio of 9.6:0.2:0.2 to prepare a mixture, and then mix the mixture with N-methylpyrrolidone at a mass ratio of 2:1, Prepare electrode slurry;

[0067] (2) Divide the above-mentioned electrode slurry into two parts, and add uniform and delicate ammonium bicarbonate powder as a pore-forming agent, adjust the stirring speed to fully mix and disperse, wherein the pore-forming agent and active material in the first part of the slurry The mass ratio of the pore forming agent and the active material in the second slurry is 0.8:1.

[0068] (3) Coat the above-mentioned first electrode slurry on one side of the current collector aluminum foil, and after drying, the pore-forming agent decomposes and escapes, and no other substances remain; Rolling, the rolling ...

Embodiment 3

[0071] The present invention prepares a kind of lithium-ion battery pole piece with gradient porosity according to the following method:

[0072] (1) Mix graphite, conductive agent Super-P, and adhesive LA133 at a mass ratio of 8.6:0.7:0.7 to prepare a mixture, and then mix the mixture with water solvent at a mass ratio of 3:1 to prepare electrode slurry material;

[0073] (2) Divide the above-mentioned electrode slurry into three parts, and add uniform and delicate ammonium bicarbonate powder as a pore-forming agent, adjust the stirring speed to fully mix and disperse, wherein the pore-forming agent and the active material in the first part of the slurry The mass ratio of the pore-forming agent to the active material in the second slurry is 0.4:1, and the mass ratio of the pore-forming agent to the active material in the third slurry is 0.7:1.

[0074] (3) Apply the first electrode slurry above to the copper foil side of the current collector. After drying, the pore-forming ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Coating surface density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com