Flexible linear high-temperature-resistant polyimide aerogel battery diaphragm, preparation method thereof and lithium ion battery

A polyimide, battery separator technology, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as limited porosity, achieve a small average pore size, ensure uniformity and integrity, and uniform pores. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The invention provides a method for preparing a flexible linear high-temperature-resistant polyimide airgel battery diaphragm, comprising the following steps:

[0043] A) mixing diamine monomers and dianhydride monomers in an organic solvent to obtain a polyamic acid solution;

[0044] B) adding a bis(trimethoxysilylpropyl)amine crosslinking agent to the polyamic acid solution for chemical crosslinking, and then adding a dehydrating agent and a catalyst to obtain a polyimide solution;

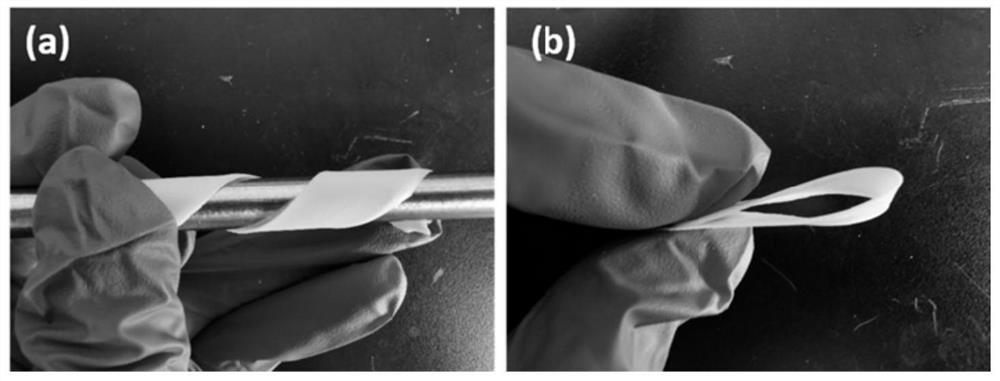

[0045] C) coating the polyimide solution on the surface of the substrate to obtain a polyimide wet gel film, and then aging;

[0046] D) placing the aged film in an organic solvent for solvent exchange, and then performing supercritical fluid drying to obtain a polyimide airgel battery separator.

[0047] In the present invention, the polyamic acid solution is firstly prepared, and the diamine monomer is dissolved in an organic solvent, ultrasonically oscillated or rapidly stirred until...

Embodiment 1

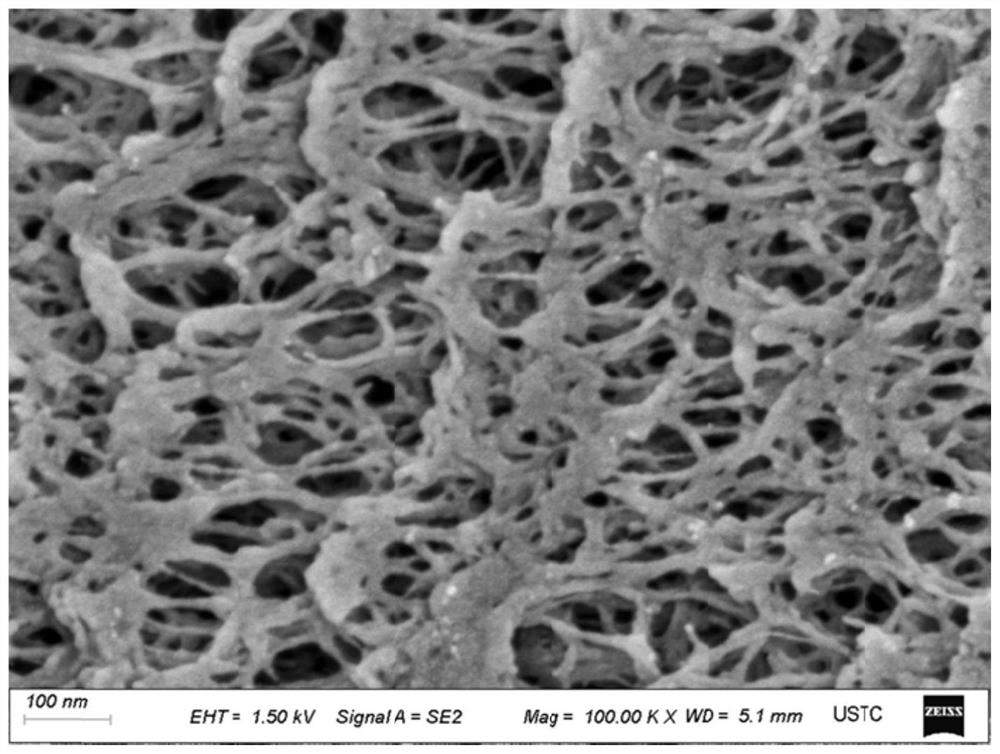

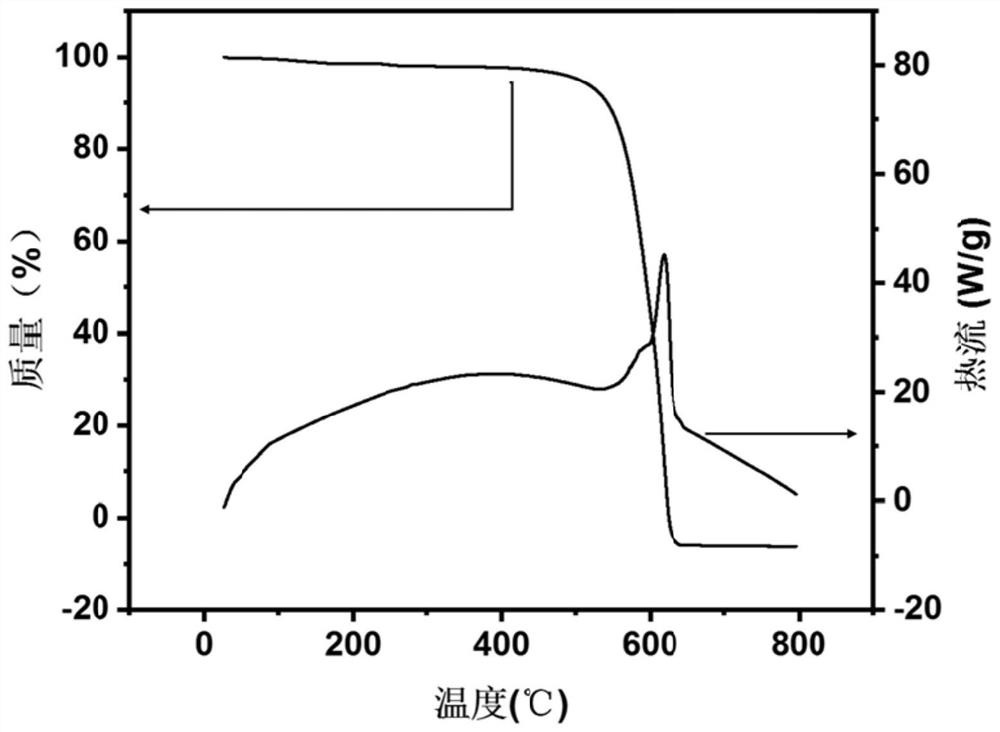

[0083] In this embodiment, polyimide airgel film is first prepared, and the specific steps are as follows:

[0084] 1) Preparation of polyamic acid solution: Dissolve diamine monomer 4,4'-diaminodiphenyl ether (ODA) in N-methylpyrrolidone (NMP), ultrasonically shake or stir rapidly at room temperature until dissolved, and then Add dianhydride monomer 3,3',4,4'-biphenyltetracarboxylic dianhydride (BPDA), and stir rapidly to prepare a polyamic acid solution. After the BPDA is dissolved, stir rapidly to prepare a polyamic acid solution. The molar ratio of ODA and BPDA is 1:1.03; the solid content is 15%.

[0085] 2) Preparation of polyimide solution: Add a certain amount of cross-linking agent BTMSPA to the polyamic acid solution obtained in step 1), the molar ratio of cross-linking agent to ODA is 1:45; stir rapidly for about half an hour. Then add dehydrating agent acetic anhydride and catalyst, the molar ratio of acetic anhydride, pyridine and BPDA is 8:8:1, oscillate or sti...

Embodiment 2

[0100] 1) Preparation of polyamic acid solution: Dissolve diamine monomer 4,4'-diaminodiphenyl ether (ODA) in N-methylpyrrolidone (NMP), ultrasonically shake or stir rapidly at room temperature until dissolved, and then Add dianhydride monomer 3,3',4,4'-biphenyltetracarboxylic dianhydride (BPDA), and stir rapidly to prepare a polyamic acid solution. After the BPDA is dissolved, stir rapidly to prepare a polyamic acid solution. The molar ratio of ODA and BPDA is 1:1.03; the solid content is 15%.

[0101] 2) Preparation of polyimide solution: Add a certain amount of cross-linking agent BTMSPA to the polyamic acid solution obtained in step 1), the molar ratio of cross-linking agent to ODA is 1:45; stir rapidly for about half an hour. Then add dehydrating agent acetic anhydride and catalyst, the molar ratio of acetic anhydride, pyridine and BPDA is 8:8:1, oscillate or stir evenly, and eliminate bubbles by ultrasonic to obtain polyimide solution. The solids content was 15%.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com