Novel silica gel matrix surface modification method and application of surface-modified silica gel matrix

A technology of surface modification and silica gel matrix, which is applied in the field of chromatographic separation. It can solve the problems of low bond and efficiency and non-specificity of silanol materials, and achieve high bond and density, increase bond and density, and high-efficiency separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Preparation of reversed-phase C18 chromatography packing material

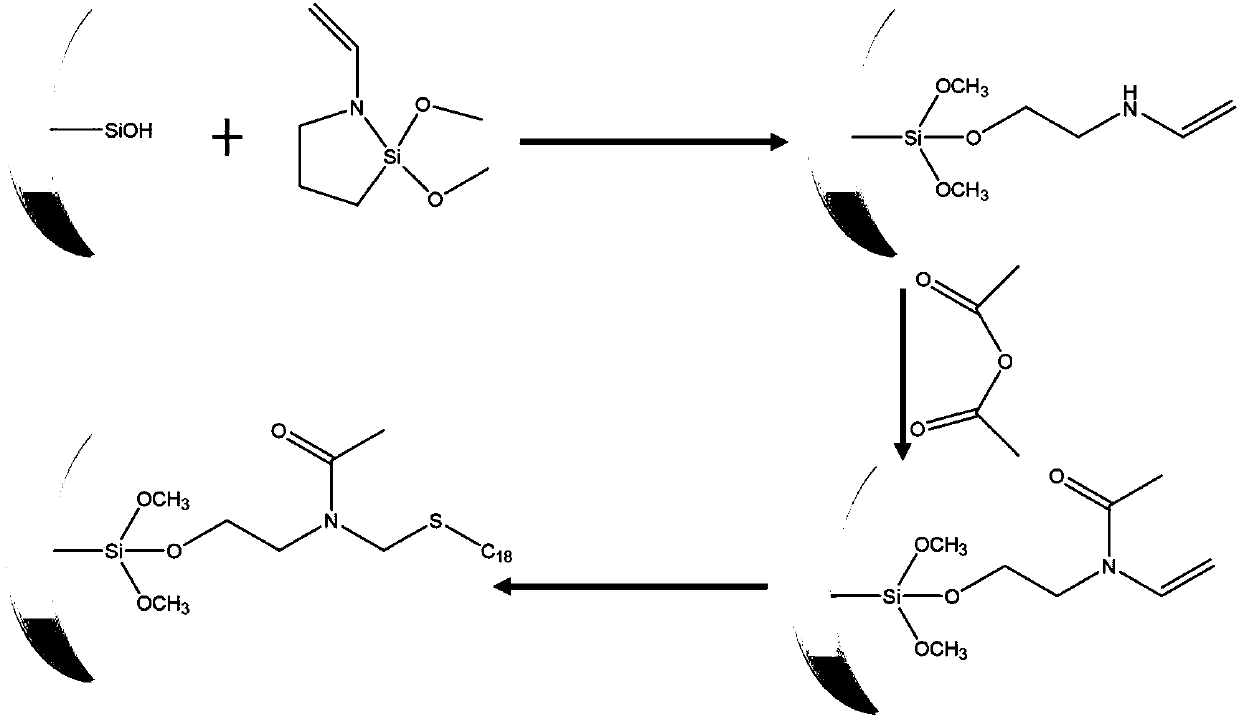

[0027] like figure 1 As shown, it is prepared according to the following process:

[0028] (1) Surface activation of silica gel: Disperse 1 g of silica gel in 1M hydrochloric acid, reflux at constant temperature for 12 hours under stirring; then wash with distilled water until neutral; finally dry at 70°C.

[0029] (2) High-density bonding of silylating agents: disperse the activated silica gel in 50% N-propenyl-aza-2,2-dimethoxysilapentane in dichloromethane solution (v / v); At a constant temperature of 25°C, the stirring time was 2h.

[0030] (3) Click reaction: Accurately weigh 20 mg of silica gel, 3 mg of AIBN, 20 mg of mercaptooctadecyl, and 750 μL of ethanol, mix well, and react at a constant temperature of 60° C. for 12 hours. After the reaction is completed, rinse with ethanol for 1 h, filter, and dry at 50°C to obtain a modified reversed-phase C18 chromatographic filler. 2. The effect of ...

Embodiment 2

[0039] like figure 1 As shown, the reversed-phase C18 chromatographic filler was prepared according to the following process:

[0040] (1) Surface activation of silica gel: Disperse silica gel in 1M sulfuric acid, reflux at constant temperature for 12 hours under stirring; then wash with distilled water until neutral; finally dry at 70°C.

[0041] (2) High-density bonding of silylating reagents: disperse the activated silica gel in 50% N-propenyl-aza-2,2-dimethoxysilapentane in dichloromethane solution (v / v); Stir for a certain period of time at a constant temperature of 25°C.

[0042] (3) Click reaction: Accurately weigh 20mg of silica gel, 3mg of AIBN, 20mg of HSC 18 , 750 μL ethanol, after mixing evenly, react at a constant temperature of 60°C for 12h. After the reaction was completed, wash with ethanol for 1 h.

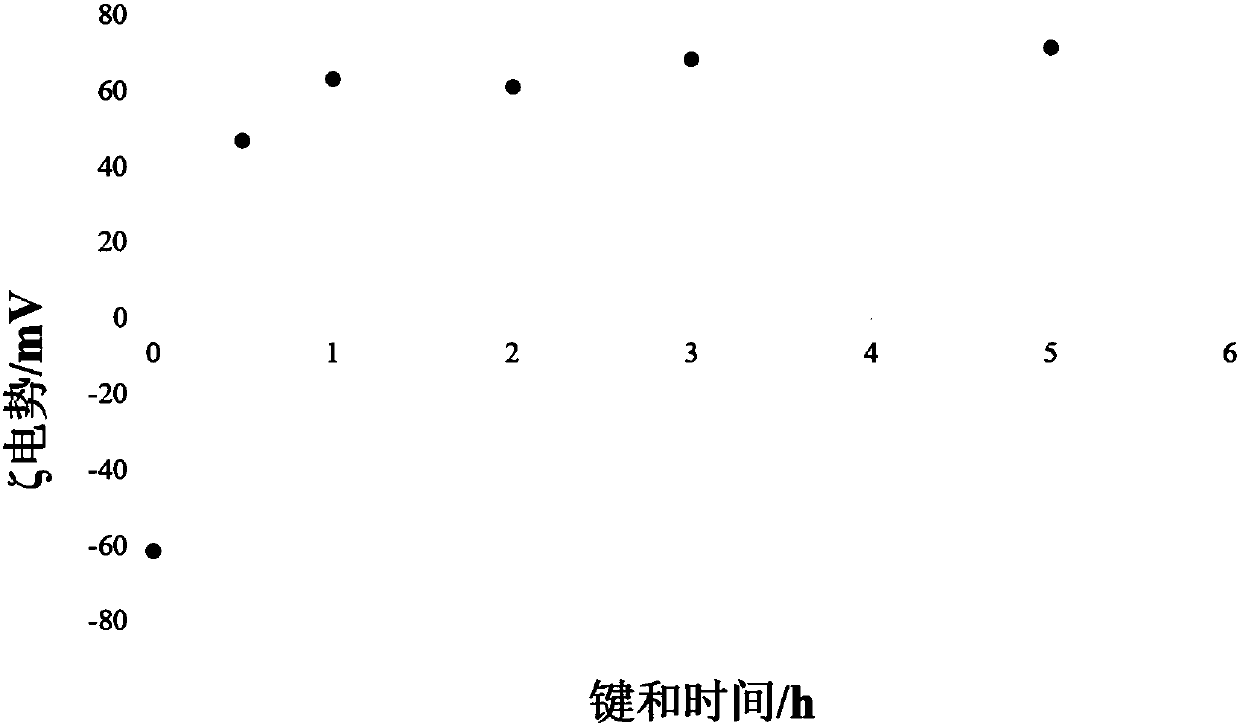

[0043] The chromatographic filler prepared by the above process has similar bond and efficiency to the material prepared in Example 1, and the zeta potential ...

Embodiment 3

[0045] like figure 1 As shown, the reversed-phase C18 chromatographic filler was prepared according to the following process:

[0046](1) Surface activation of silica gel: Disperse silica gel in 1M hydrochloric acid, reflux at constant temperature for 12 hours under stirring; then wash with distilled water until neutral; finally dry at 70°C.

[0047] (2) High-density bonding of silylating reagents: disperse the activated silica gel in 30% N-propenyl-aza-2,2-dimethoxysilapentane in dichloromethane solution (v / v); Stir for a certain period of time at a constant temperature of 25°C.

[0048] (3) Click reaction: Accurately weigh 20mg of silica gel, 3mg of AIBN, 20mg of HSC 18 , 750 μL ethanol, after mixing evenly, react at a constant temperature of 60°C for 12h. After the reaction was completed, wash with ethanol for 1 h.

[0049] The chromatographic filler prepared by the above process has similar bond and efficiency to the material prepared in Example 1, and the zeta potenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com