Electrode of capacitor and preparation method thereof

A technology for capacitor electrodes and capacitors, applied in hybrid capacitor electrodes, hybrid capacitor electrolytes, capacitors, etc., can solve the problems of poor dispersion of conductive polymers, increase electrode preparation costs, reduce material conductivity, etc., and achieve energy density and service life Longer length, less pulping and coating equipment, and higher power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

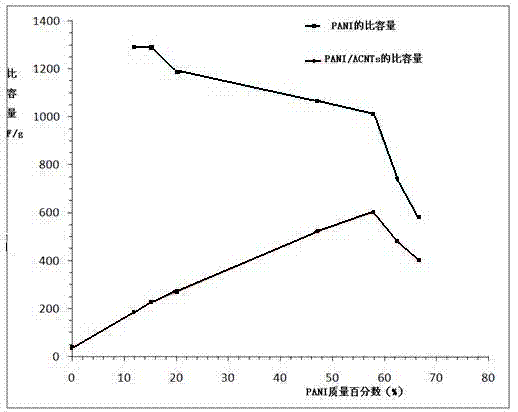

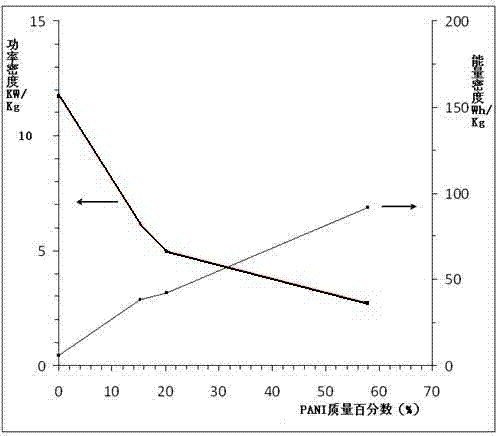

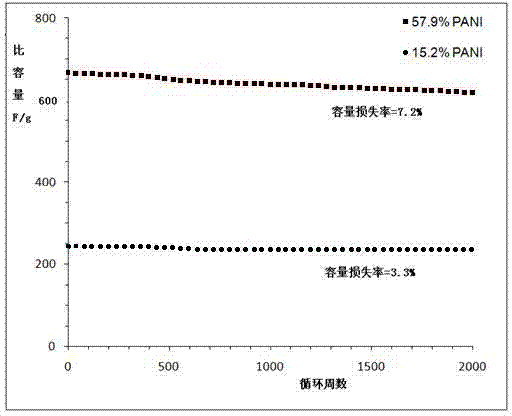

[0031] An electrode of a capacitor is composed of a conductive base material and a polyaniline / aligned carbon nanotube composite material, and the polyaniline / aligned carbon nanotube composite material is directly grown on one or both sides of the conductive base material. The polyaniline / aligned carbon nanotube composite material is composed of single-wall or multi-wall aligned carbon nanotubes with a length of 20-150 μm and a diameter of 1-50 nm, and the thickness of the coated carbon nanotubes is not greater than 30 nm polyaniline film composition; the conductive matrix material is Al, Cu, Ti, Mg, Ni, Ta, Pt, stainless steel, mesophase microspheres, graphite, expanded graphite and other metal or non-metallic plates, foils, nets , particles or foam materials; in the polyaniline / aligned carbon nanotube composite electrode material, polyaniline accounts for 10%-80% of the total mass of the composite electrode material; preferably 50%-60%.

[0032] The steps of the preparation ...

Embodiment 1

[0039] 1) Put the Ti foil and the catalyst ferrocene into the quartz tube of the chemical vapor deposition system, in which the Ti foil is located in the high-temperature reaction zone of the quartz tube, and the catalyst ferrocene is located in the low-temperature zone at the inlet end of the quartz tube. Flow 200 mL / min of Ar and H into the quartz tube 2 After 30 min in the mixed gas, the temperature of the reaction zone was heated to 800 °C, and the temperature at the inlet end of the quartz tube was controlled at 300 °C. Adjust the intake rate, and feed the reaction gas, H 2 After reacting with the mixed gas of Ar for 30 min, the supply of reaction gas was stopped, and the quartz tube was cooled to room temperature under a protective atmosphere, and an array of carbon nanotubes oriented growth was obtained on the conductive substrate material.

[0040] 2) The conductive substrate of the surface-grown aligned carbon nanotube array obtained in step 1) is used as the working...

Embodiment 2

[0043] 1) Put the Ti foil and the catalyst ferrocene into the quartz tube of the chemical vapor deposition system, in which the Ti foil is located in the high-temperature reaction zone of the quartz tube, and the catalyst ferrocene is located in the low-temperature zone at the inlet end of the quartz tube. Flow 200 mL / min of Ar and H into the quartz tube 2 After 30 min in the mixed gas, the temperature of the reaction zone was heated to 800 °C, and the temperature at the inlet end of the quartz tube was controlled at 300 °C. Adjust the intake rate, and feed the reaction gas, H 2 After reacting with the mixed gas of Ar for 30 min, the supply of reaction gas was stopped, and the quartz tube was cooled to room temperature under a protective atmosphere, and an array of carbon nanotubes oriented growth was obtained on the conductive substrate material.

[0044] 2) The conductive substrate of the surface-grown aligned carbon nanotube array obtained in step 1) is used as the working...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com