Method of extracting valuable element from waste water and waste slag

A technology for valuable elements and waste slag, which is applied in the field of extracting valuable elements, can solve the problems of shortage of sulfuric acid raw materials, tailings stockpiling and pollution of the environment, and achieve the effect of highlighting substantive features, simple process equipment configuration, and eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0007] Example 1, under laboratory conditions, conventional cyanide tailings are mixed with acidic waste water, the pH value is adjusted to 5-6, the influence of silicic acid skeleton and cyanide complex hydrophilic film is eliminated, and the foaming agent and The performance of collectors and minerals can reduce the impact of organic matter such as defoamers; then enter the stirring tank before flotation, add protective alkali to neutralize and precipitate impurity ions, and make the interaction between flotation agents, which is beneficial to increase the value of valuable elements. The recovery rate; add flotation agents, flotation agents are flotation oil, xanthate, black medicine, first add flotation oil, xanthate, black medicine in the stirring tank for a rough selection, then add flotation oil, xanthate Carry out two sweeps, and finally carry out a beneficiation to produce a concentrate; the flotation concentrate is roasted in two or one stages, and the flue gas is puri...

Embodiment 2

[0009] Example 2, under laboratory conditions, the cyanide tailings after bacterial oxidation were mixed with acidic wastewater, and the pH value was adjusted to 5-6 to eliminate the influence of the silicic acid skeleton and the hydrophilic film of the cyanide complex, and improve foaming The performance of the interaction between agent and collector and minerals, reducing the impact of organic matter such as defoamers; and then entering the stirring tank before flotation, adding protective alkali to neutralize the precipitated impurity ions, so that the interaction between flotation agents is beneficial to improve the efficiency. The recovery rate of valence elements; add flotation agents, flotation agents are flotation oil, xanthate, and black medicine, first add flotation oil, xanthate, and black medicine to the stirring tank for a rough selection, then add flotation oil, The xanthate is swept and separated twice, and the concentrated ore is produced by a final selection; t...

Embodiment 3

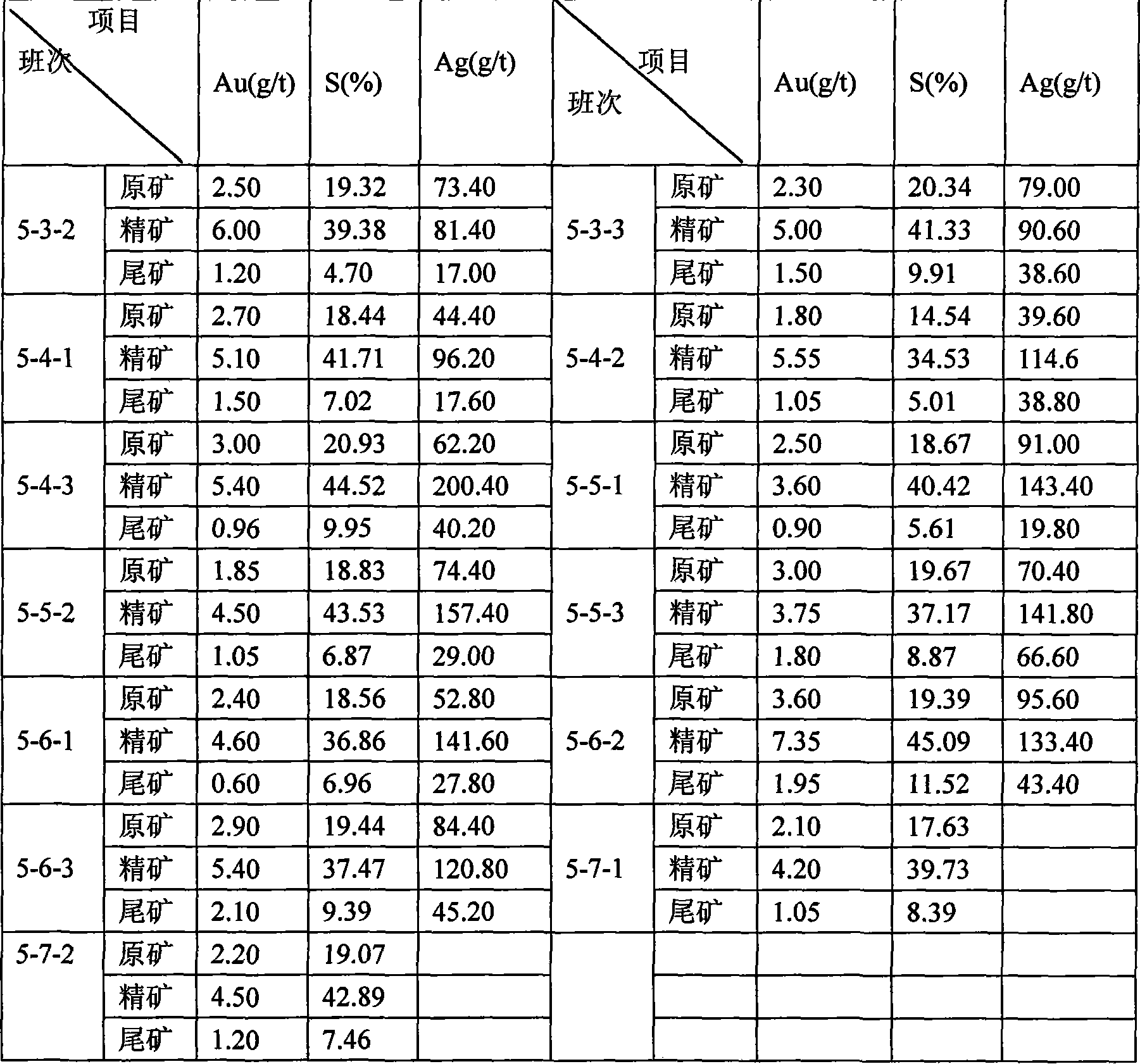

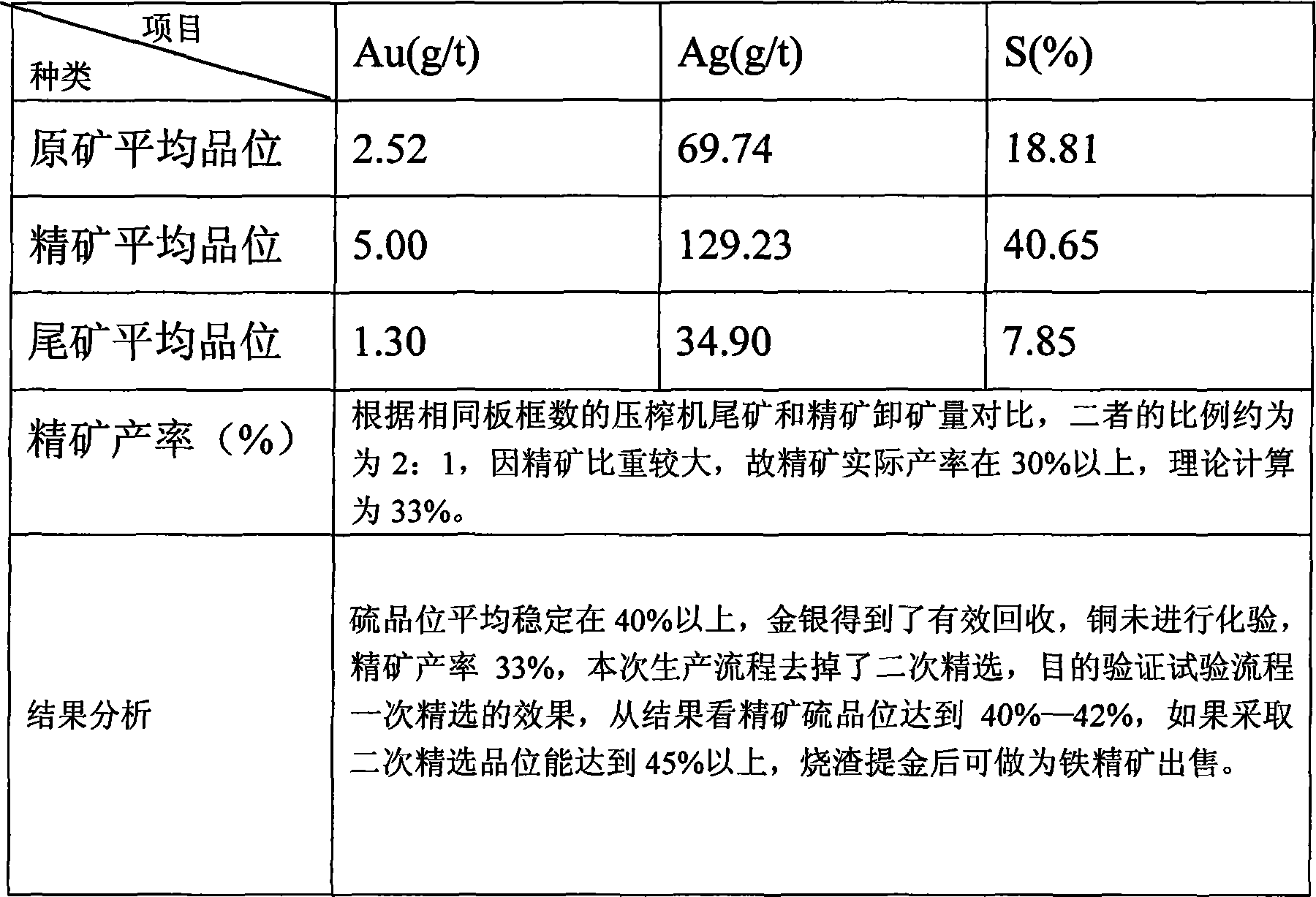

[0011] Example 3, under industrial test conditions, conventional cyanide tailings are mixed with acidic waste water, the pH value is adjusted to 5-6, the influence of silicic acid skeleton and cyanide complex hydrophilic film is eliminated, and the foaming agent is improved and collectors and minerals to reduce the impact of organic matter such as defoamers; then enter the stirring tank before flotation, add protective alkali to neutralize the precipitated impurity ions, and make the flotation agents interact, which is beneficial to improve the value The recovery rate of elements; adding flotation reagents, the flotation reagents are flotation oil, xanthate and black medicine, first add flotation oil, xanthate and black medicine to the stirring tank for a rough selection, then add flotation oil, yellow medicine Sweeping is carried out twice, and finally a concentration is carried out to produce a concentrate; the flotation concentrate is subjected to two or one stages of roasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com