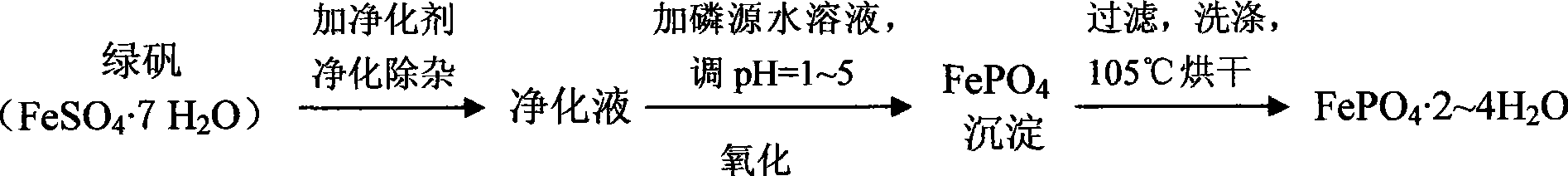

Method for preparing high purity ferric phosphate using ferrous sulfate as by-product of white titanium pigment

A technology of high-purity phosphoric acid and ferrous sulfate, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of unseen high-purity ferric phosphate, and achieve the effect of solving environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1 1. 1. 139g titanium dioxide byproduct ferrous sulfate heptahydrate is dissolved in 1kg water (equivalent to about 0.5mol L of ferrous sulfate concentration -1 ), filter to remove water-insoluble solid impurities such as sand and stones, then add 2.78g powdery sodium sulfide while stirring in the filtrate, continue to stir for 10 minutes after black precipitates appear in the solution, filter to remove black precipitates, and obtain pure ferrous sulfate solution. ②Add 60g of concentrated phosphoric acid to the pure ferrous sulfate solution, stir evenly, adjust the pH of the solution to 2 with ammonia water, add 60g of 30% hydrogen peroxide dropwise to the solution under stirring, react at 25°C for 6 hours, after the reaction is complete, filter , washed the filter cake with water for 3 times, and dried the filter cake at 105° C. to obtain white iron phosphate powder. The Fe content of the obtained product is 29.42%, and the purity is 99.5%.

Embodiment 2

[0020] Embodiment 2 1. 278g titanium dioxide by-product ferrous sulfate heptahydrate is dissolved in 1kg water (equivalent to about 1mol L of ferrous sulfate concentration -1 ), filter to remove water-insoluble solid impurities such as sand and stones, then add 5.56g powdery sodium sulfide while stirring in the filtrate, continue to stir for 10 minutes after black precipitates appear in the solution, filter to remove black precipitates, and obtain pure ferrous sulfate solution. ②Add 120g of concentrated phosphoric acid to the pure ferrous sulfate solution, stir evenly, adjust the pH of the solution to 1.8 with sodium hydroxide, feed oxygen into the solution while stirring, and react at 40°C for 10 hours. After the reaction is complete, filter, The filter cake was washed with water for 3 times, and the filter cake was dried at 105° C. to obtain white iron phosphate powder. The Fe content of the product obtained is 29.43%, and the purity is 99.5%.

Embodiment 3

[0021] Embodiment 3 1. 834g titanium dioxide by-product ferrous sulfate heptahydrate is dissolved in 1kg water (equivalent to about 3mol L of ferrous sulfate concentration -1), filter to remove water-insoluble solid impurities such as sand and stones, then add 8.34g powdery sodium sulfide while stirring in the filtrate, continue to stir for 10 minutes after black precipitates appear in the solution, filter to remove black precipitates, and obtain pure ferrous sulfate solution. ②Add 350g of concentrated phosphoric acid to the pure ferrous sulfate solution, stir evenly, adjust the pH of the solution to 2.5 with potassium hydroxide aqueous solution, pass air into the solution while stirring, and react at 70°C for 10 hours, after the reaction is complete, filter , washed the filter cake with water for 3 times, and dried the filter cake at 105° C. to obtain white iron phosphate powder. The Fe content of the product obtained is 29.38%, and the purity is 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com