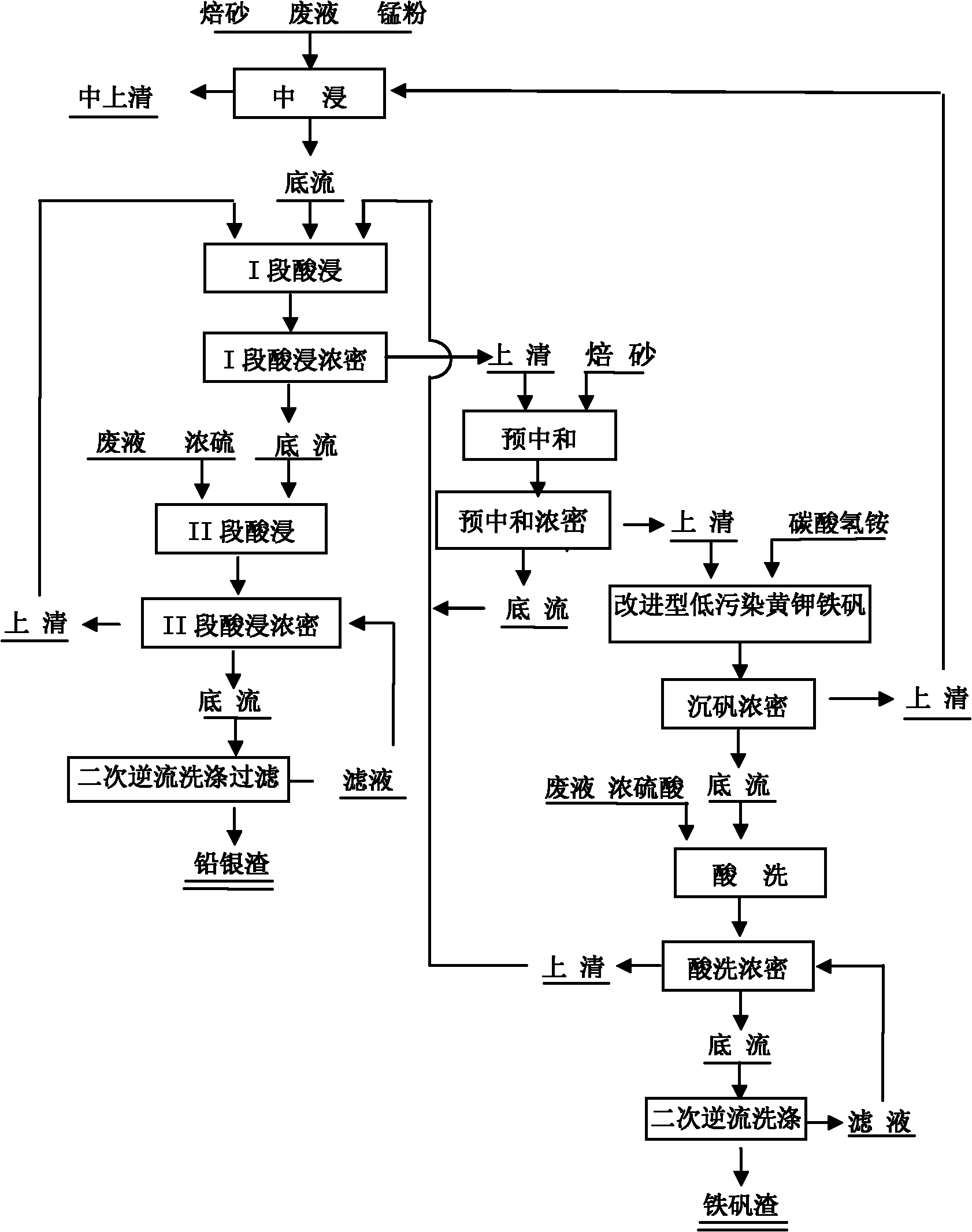

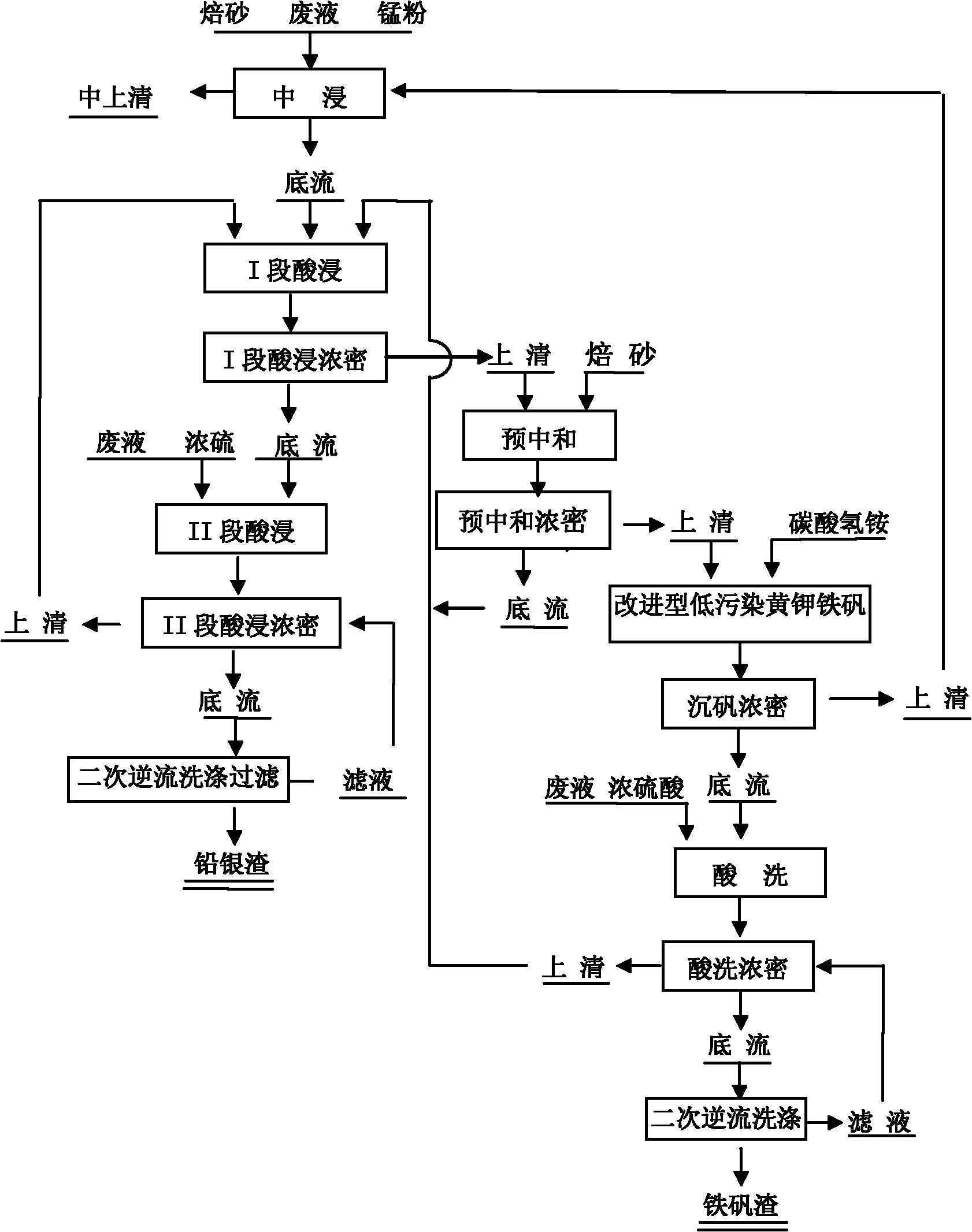

Process for smelting zinc with wet method of high temperature and high acid-jarosite iron removing-iron vitriol slag pickling by two stages

A jarosite, high-temperature, high-acid technology is applied in the field of two-stage high-temperature, high-acid-low-pollution jarosite iron removal-jarosite slag pickling wet zinc smelting process, which can solve the problem of low metal recovery rate, two High zinc content in slag, low leaching rate and other problems, to achieve high metal recovery rate, lower acid content in slag, and high zinc leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The second-stage high-temperature, high-acid-low-pollution jarosite iron removal-jaosite slag pickling wet zinc smelting process includes the following steps:

[0030] (1) Neutral leaching

[0031] The neutral leaching process is equipped with a head tank (oxidation tank), five leaching tanks connected in series and connected by an overflow tank, and two ¢21m thickeners.

[0032] Waste electrolyte, overflow of improved low-pollution jarosite separation thickener, manganese dioxide slurry, cadmium-poor solution, and anode slime are made into a uniform oxidation solution in the head tank. The oxidation solution is pumped to the first leaching tank, and quantitative calcined sand is added. A pH meter is installed at the overflow of the first leaching tank to automatically adjust the flow rate of the oxidizing solution. The pulp in the first leaching tank overflows into the second leaching tank, the zinc oxide in the calcined sand is completely dissolved, and the div...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com