Preparation method of pigment-level titanium dioxide powder by cyclic hydrochloric acid micro emulsion method

A microemulsion, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of comprehensive recovery and utilization of vanadium-titanium magnetite resources, environmental pollution of blast furnace slag, and high energy consumption, and achieve comprehensive solutions. The effect of recycling difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

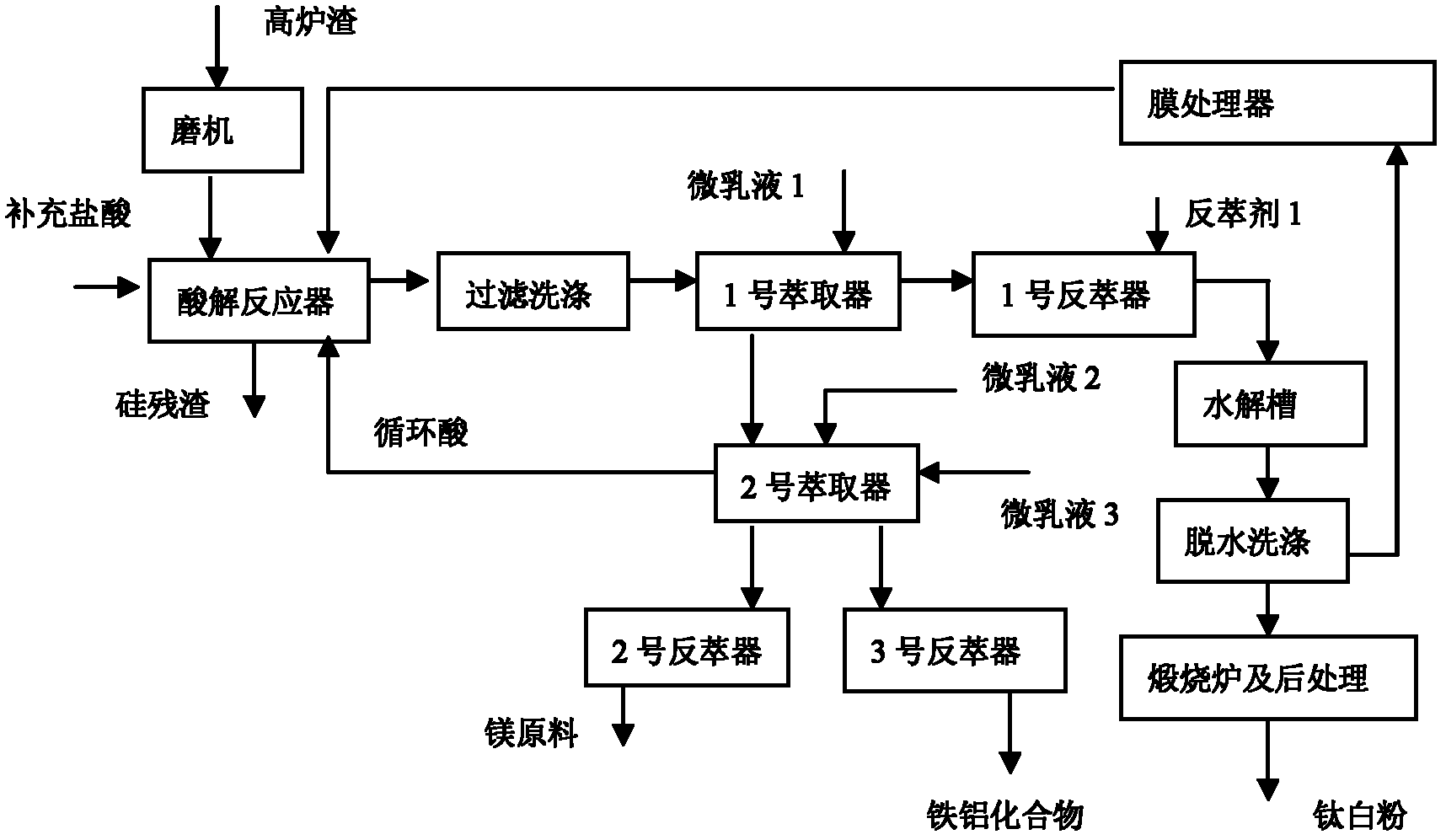

[0034] The process of this embodiment is attached figure 1 Shown, is the use of titanium-rich blast furnace slag to produce rutile titanium dioxide and other resources in the recovery of raw materials.

[0035] (1) TiO 2 100 parts by mass of blast furnace slag with a mass content of 25% (generally 20-42%), ground and sieved to 200 mesh, added to the hydrolysis reactor for acid hydrolysis, and the mass concentration of hydrochloric acid in the acid hydrolysis process is controlled to be about 20% (generally controlled in the range of 15-34%), the amount of hydrochloric acid is added according to the liquid-solid mass ratio of 4:1 (the liquid-solid ratio is generally controlled in the range of 4-8:1), and the temperature is about 85°C (generally controlled in 80-105 ℃ range), the time is about 120min. The acid hydrolyzed slurry is filtered and washed, and the obtained acid hydrolyzed clear liquid enters the next process, and the obtained silicon residue can be used as a high-s...

Embodiment 2

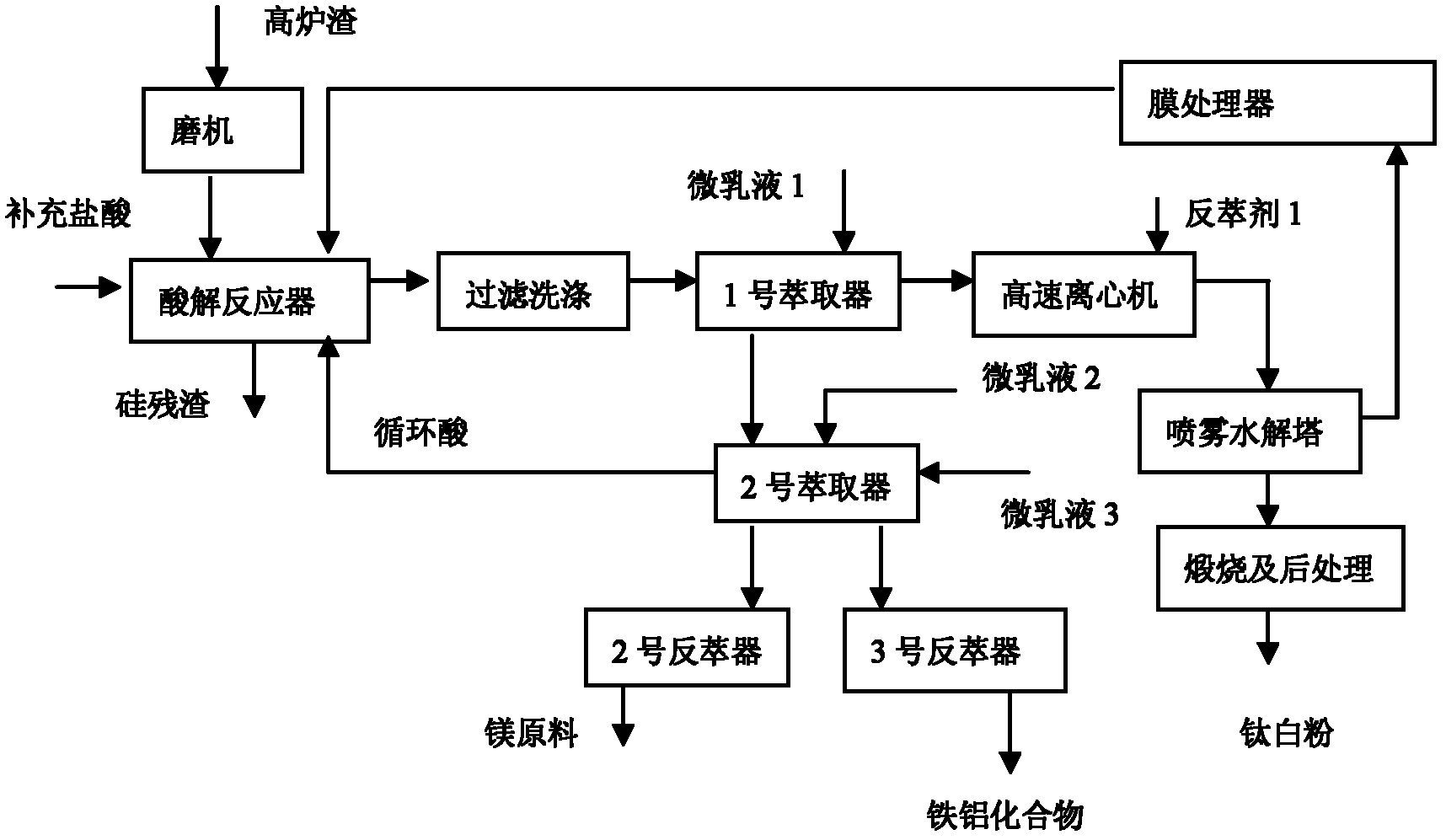

[0048] The process of this embodiment is attached figure 2 Shown, is the use of titanium-rich blast furnace slag to produce nano-scale or sub-nano-scale rutile titanium dioxide and other resources in the recovery of raw materials.

[0049] In the flow process of this embodiment, except that the treatment process of the organic extract discharged from the No. 1 extractor is different from the flow process in Example 1, the flow process of other parts is the same as the flow process in Example 1. In this example, the organic microemulsion added to the No. 1 extractor needs to be swollen with water and a small amount of lye before it is added to the No. 1 extractor, so that it forms an inner phase coated with an alkaline liquid. The temperature of the organic extract discharged from the No. 1 extractor is raised to 70-80°C to disintegrate the inner phase of the microemulsion to a certain extent, and then it is sent to a high-speed centrifuge to hydrolyze the microbubbles. The h...

Embodiment 3

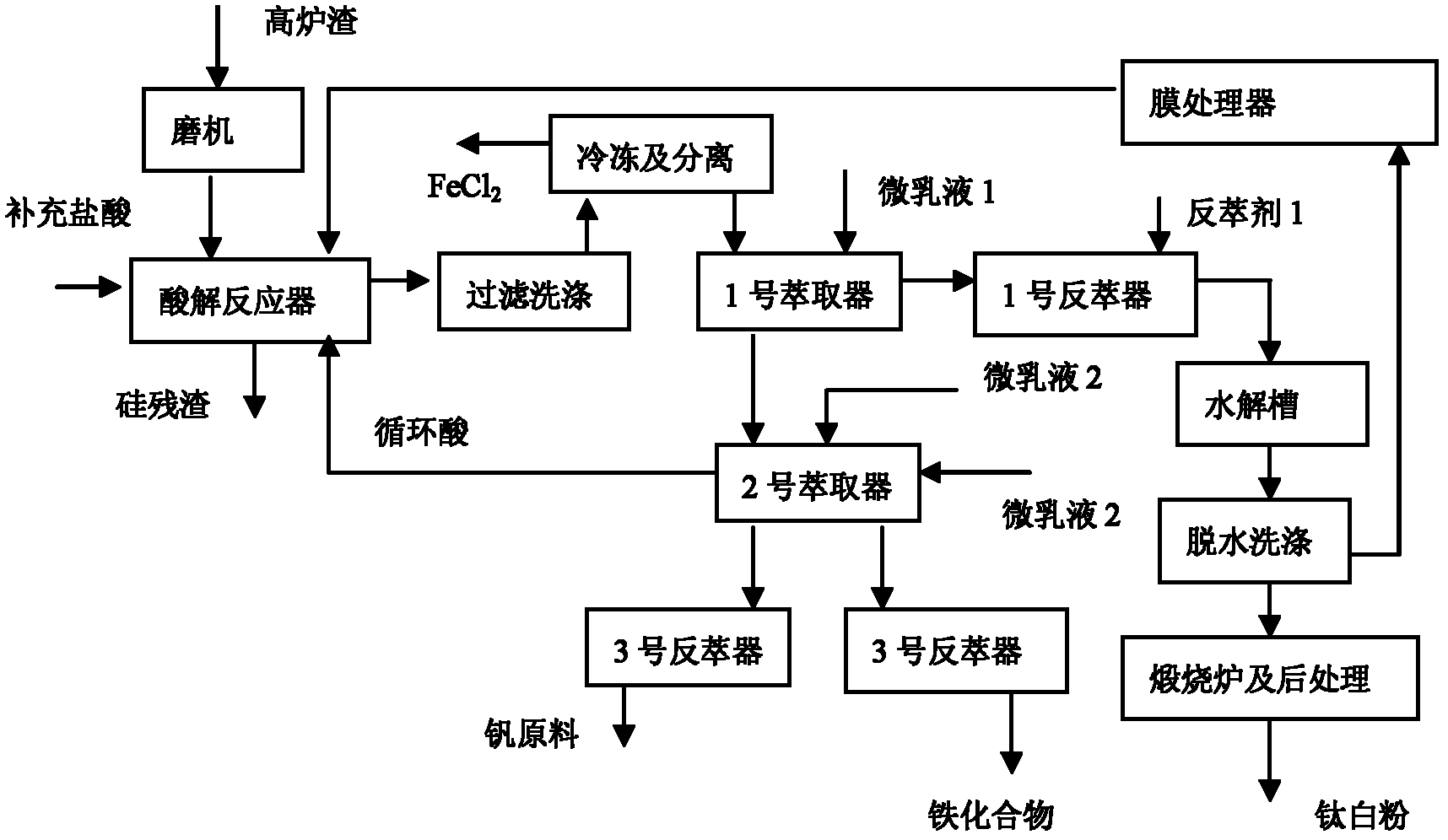

[0055] The process of this embodiment is attached image 3 As shown, it is to use refractory vanadium-titanium magnetite or titanium concentrate to directly produce rutile titanium dioxide and recover other resources in raw materials.

[0056] The flow process of this embodiment is different from the process flow of Example 1. One is that the acidolysis slurry discharged from the acidolysis reactor is filtered and washed to obtain the acidolysis clear liquid. (generally controlled at -10-5°C) crystallization reaction for about 120 minutes (generally controlled in the range of 60-180 minutes), so that the ferric chloride and ferric chloride contained in it are crystallized and separated by a centrifuge to obtain ferric chloride And the preliminary purified acid hydrolysis clear liquid, in which ferric chloride can be decomposed by spraying to obtain high-grade ferric oxide, that is, iron concentrate; to obtain iron red, it is only necessary to separate and purify the liquid bef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com