Electromagnetic shielding composite material with multilayer gradient isolation network and preparation method thereof

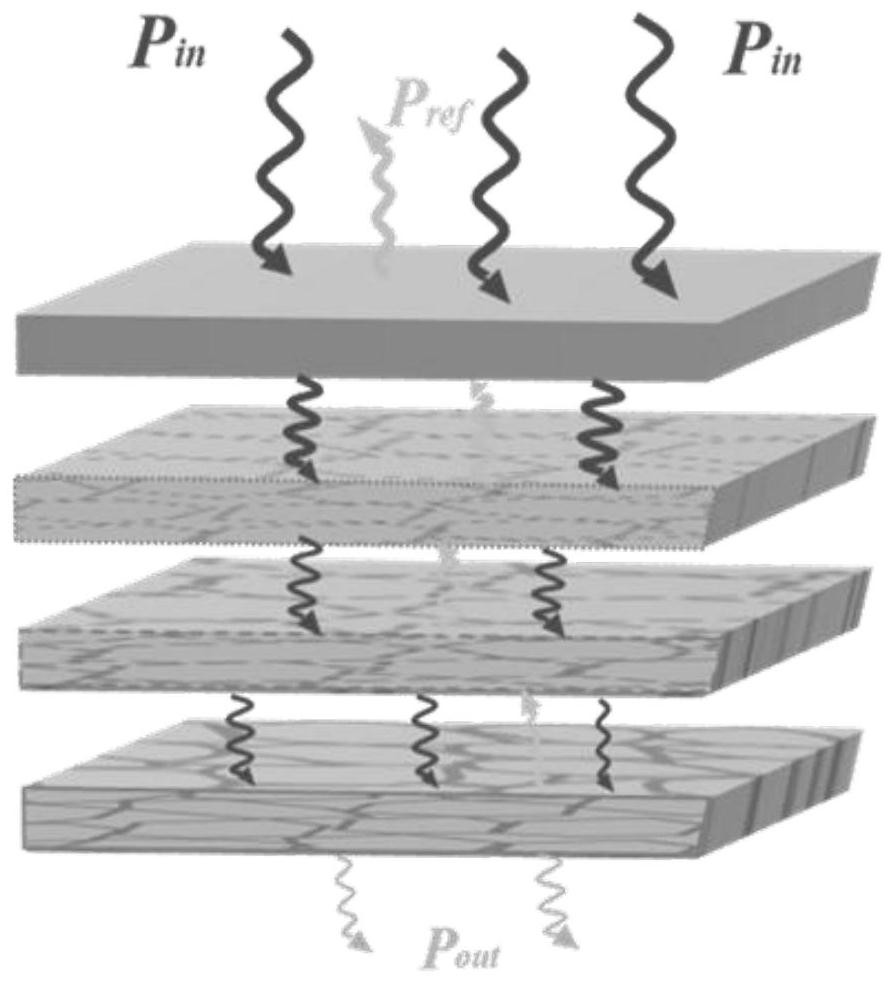

A technology of electromagnetic shielding and composite materials, applied in the fields of magnetic field/electric field shielding, chemical instruments and methods, electrical components, etc., to achieve the effect of convenient operation, reducing reflection loss and increasing absorption loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

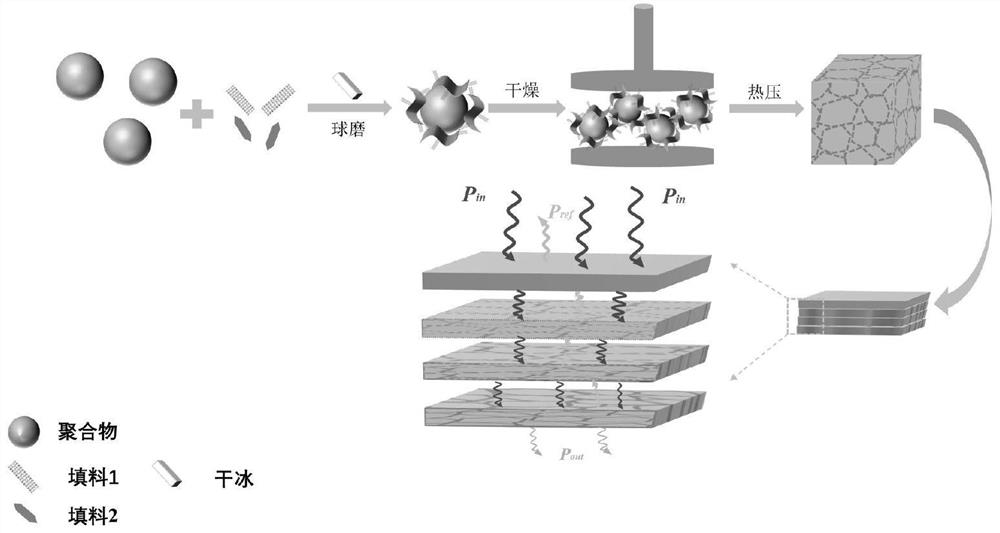

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: A preparation method of an electromagnetic shielding composite material with a multilayer gradient isolation network, comprising the following steps:

[0035] S1. Selection of raw materials: polyvinylidene fluoride (PVDF, Solvay 6010, the United States), the melt index is 8g / 10min (190°C, 2.16Kg), and the density is 1.75g / cm 3 , melting point 165°C; graphite (Qingdao Xingyuan Graphite Co., Ltd.), density 2.21g / cm 3 ; Dry ice (Chengdu Kelong Chemical Co., Ltd.).

[0036] The polyvinylidene fluoride and graphite were placed in a vacuum oven, and dried in vacuum at a temperature of 60° C. for 12 hours.

[0037] S2. Add the pure polyvinylidene fluoride treated in step S1 into a stainless steel vacuum ball mill tank, and perform ball milling with a planetary ball mill at a milling speed of 500 rpm and a milling time of 36 hours to obtain a ball milling product 1 .

[0038] S3. Add polyvinylidene fluoride, graphite and dry ice treated in step S1 to a planetary...

Embodiment 2

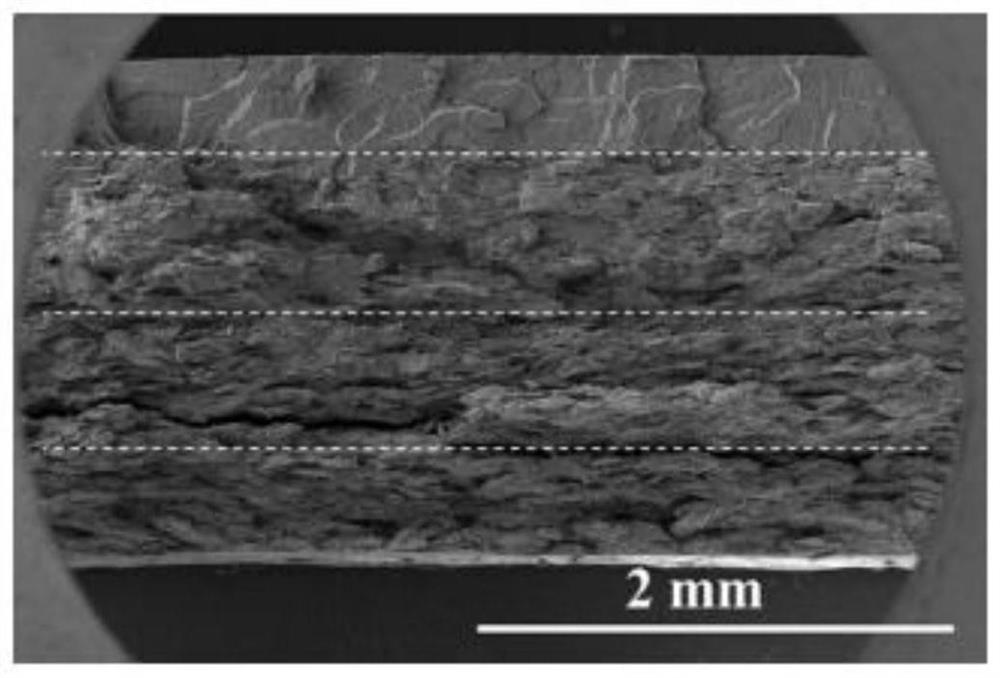

[0041] Embodiment 2: A kind of preparation method of electromagnetic shielding composite material with multi-layer gradient isolation network, such as figure 1shown, including the following steps:

[0042] S1. Selection of raw materials: polyvinylidene fluoride (PVDF, Solvay 6010, the United States), the melt index is 8g / 10min (190°C, 2.16Kg), and the density is 1.75g / cm 3 , melting point 165° C.; carbon nanotubes (NC7000, Belgium, average diameter 9.5 nm); dry ice (Chengdu Kelong Chemical Co., Ltd.).

[0043] The polyvinylidene fluoride and carbon nanotubes were placed in a vacuum oven, and dried in vacuum at a temperature of 60° C. for 12 hours.

[0044] S2. Add the pure polyvinylidene fluoride treated in step S1 into a stainless steel vacuum ball mill tank, and perform ball milling with a planetary ball mill at a milling speed of 500 rpm and a milling time of 36 hours to obtain a ball milling product 1.

[0045] S3. Add the polyvinylidene fluoride, carbon nanotubes and dr...

Embodiment 3

[0048] Embodiment 3: A preparation method of an electromagnetic shielding composite material with a multilayer gradient isolation network, comprising the following steps:

[0049] S1. Selection of raw materials: polystyrene (Chimei, Taiwan), melting index 8g / 10min (190°C, 2.16Kg), density 1.15g / cm 3 , melting point 173°C; graphite oxide (Qingdao Xingyuan Graphite Co., Ltd.), density 2.21g / cm 3 ; Dry ice (Chengdu Kelong Chemical Co., Ltd.).

[0050] The polystyrene and graphite oxide were placed in a vacuum oven, and dried in vacuum at a temperature of 60° C. for 12 hours.

[0051] S2. Add the pure polystyrene treated in step S1 into a stainless steel vacuum ball mill tank, and perform ball milling with a planetary ball mill at a milling speed of 500 rpm and a milling time of 36 hours to obtain a ball milling product 1.

[0052] S3, adding polystyrene, graphite oxide and dry ice treated in step S1 to a planetary ball mill for ball milling, the ratio of graphite oxide mass to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com