Quantum cascade laser regular polygonal microcavity laser and manufacturing method thereof

A quantum cascade and regular polygon technology, applied in the direction of lasers, phonon exciters, laser components, etc., can solve the problems of inconvenient process, difficult to peel off, large process limitations, etc., to achieve convenient manufacturing process, improve quality factor, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

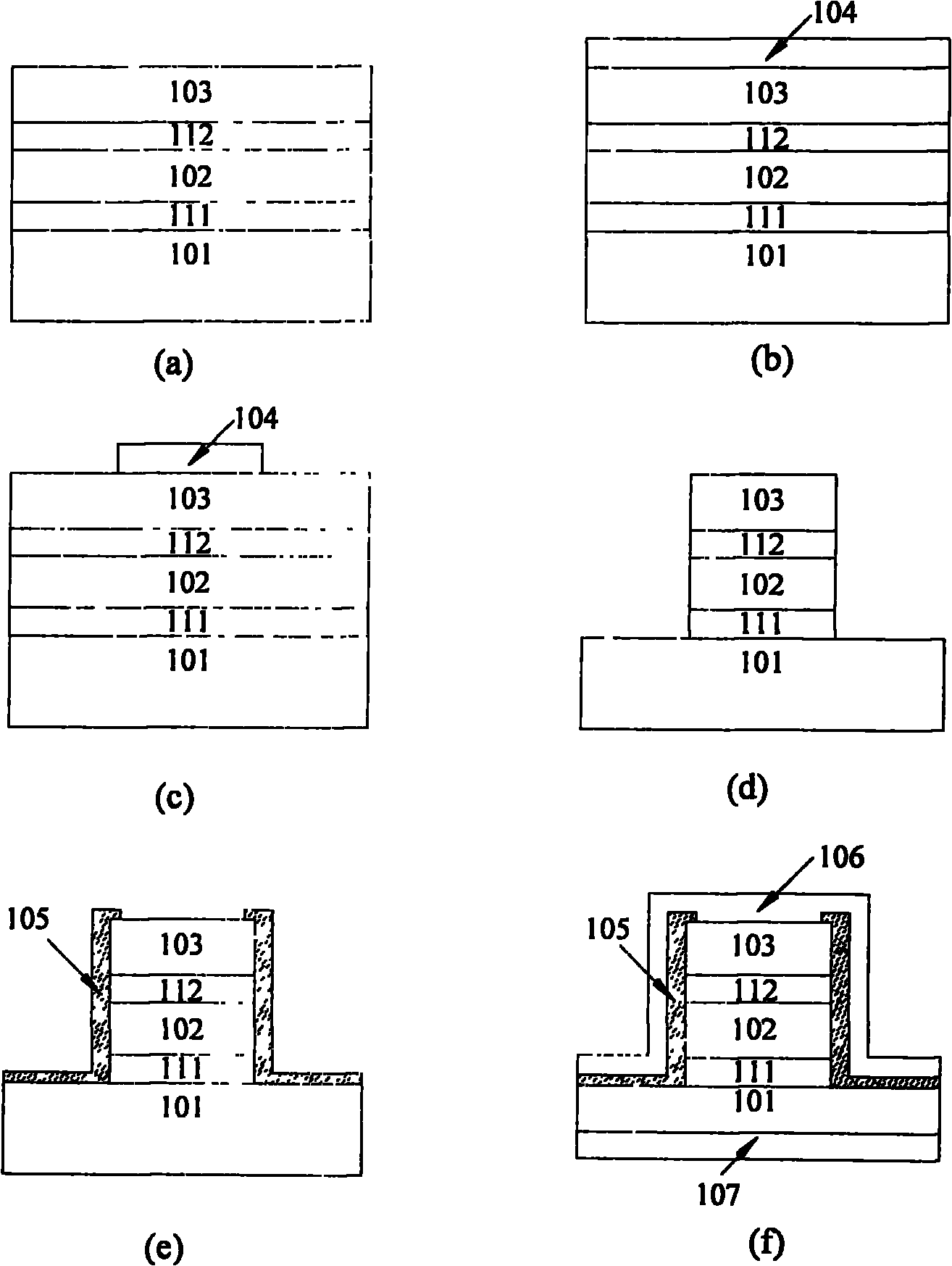

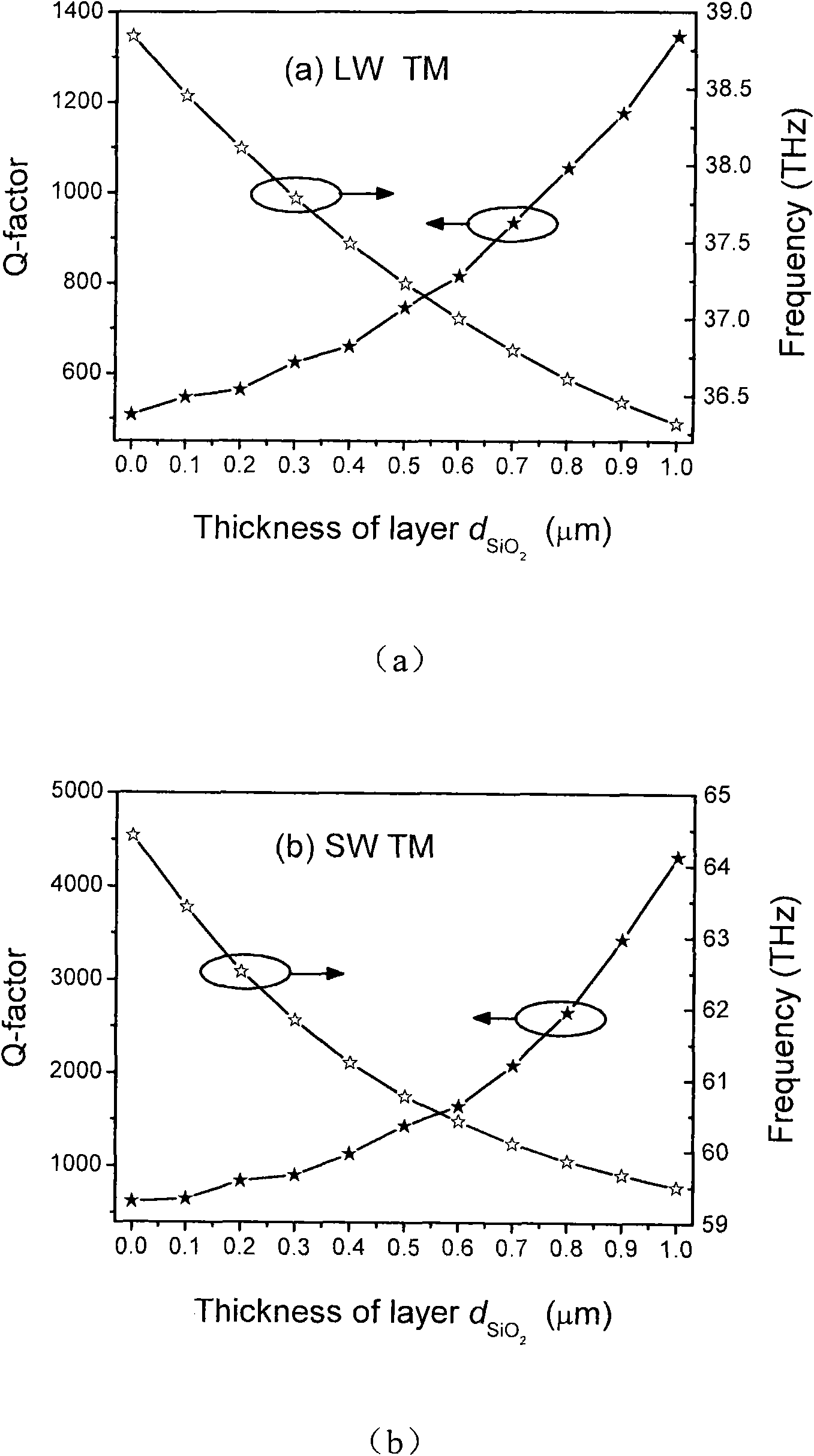

[0054] Taking the quantum cascade square microcavity laser in the mid-to-far infrared band as an example, the present invention will be described in conjunction with the accompanying drawings.

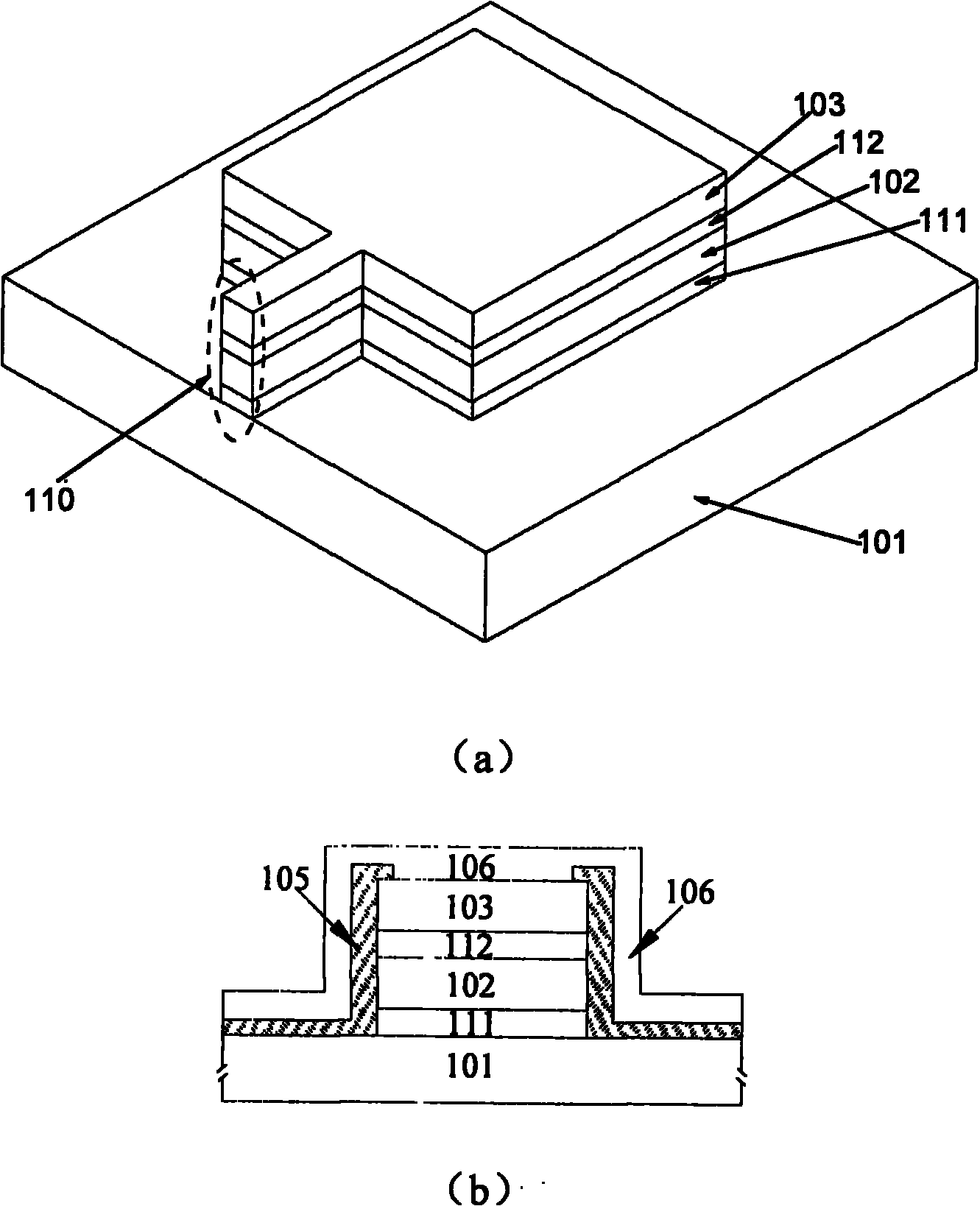

[0055] figure 1 It is a schematic diagram of the structure of a quantum cascade square microcavity laser. The quantum cascade epitaxial wafer includes a substrate 101 , a lower confinement layer 111 , an active region / implantation region 102 , an upper confinement layer 112 , and an upper cladding layer (including an ohmic contact layer) 103 . The sidewall of the square microcavity wraps the insulating layer 105 and the front electrode layer 106; a waveguide 110 perpendicular to the boundary is drawn from the midpoint of the boun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com