Hydrogel flexible strain sensor and preparation method thereof

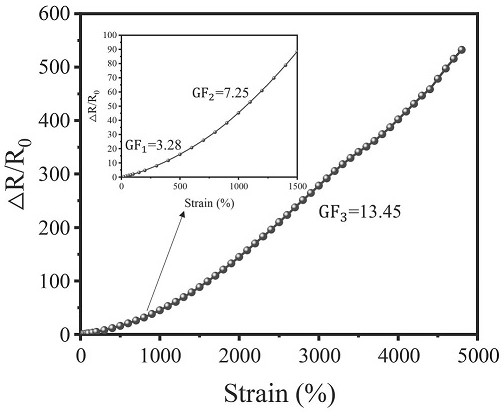

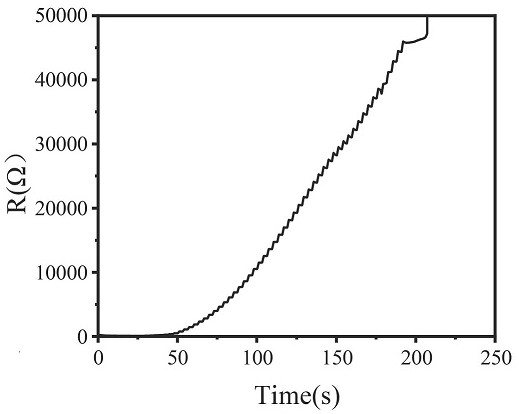

A strain sensor, hydrogel flexible technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, etc., can solve the problems of low sensitivity, low elongation rate of hydrogel flexible sensor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

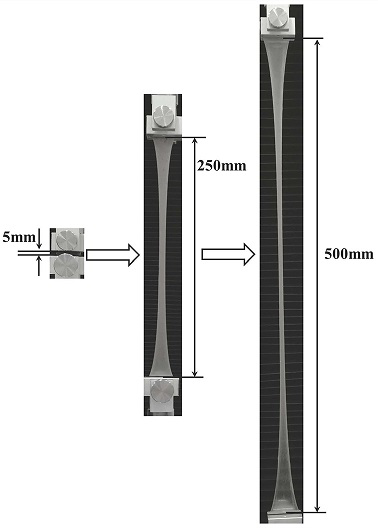

[0038] A method for preparing a hydrogel flexible strain sensor, comprising the steps of:

[0039] Fabrication of hydrogel flexible strain sensors:

[0040] A. Synthesis of polydopamine:

[0041] Dissolve 0.5 g of dopamine hydrochloride in 10 ml of deionized water and stir with a glass rod until completely dissolved. Then, mix 40ml of ethanol and 1ml of ammonia solution (25-28%) with 90ml of deionized water, stir magnetically at room temperature for 30 minutes, and slowly inject into the above solution, the color of the mixed solution turns light brown and gradually turns dark brown, The reaction continued for 24 hours to obtain a polydopamine solution. It is also possible to accelerate the polymerization of dopamine by stirring vigorously under the heating condition of 60°C and high-speed stirring condition of 300r / min for 0.5h;

[0042] B. Preparation of Graphene Oxide Dispersion

[0043] Monolayer graphene oxide powder was prepared by the Hummers method. After the prepar...

Embodiment 2

[0053] A. Synthesis of polydopamine:

[0054] Dissolve 0.5 g of dopamine hydrochloride in 10 ml of deionized water and stir with a glass rod until completely dissolved. Then, mix 40ml of ethanol and 1ml of ammonia solution (25-28%) with 90ml of deionized water, stir magnetically at room temperature for 30 minutes, and slowly inject into the above solution, the color of the mixed solution turns light brown and gradually turns dark brown, The reaction continued for 24 hours to obtain a polydopamine solution. It is also possible to accelerate the polymerization of dopamine by stirring vigorously under the heating condition of 60°C and high-speed stirring condition of 300r / min for 0.5h;

[0055] B. Preparation of Graphene Oxide Dispersion

[0056] Monolayer graphene oxide powder was prepared by the Hummers method. After the preparation is completed, weigh 20 mg of graphene oxide powder, disperse it in 10 ml of deionized water, and carry out ultrasonic dispersion. The ultrasonic...

Embodiment 3

[0065] A. Synthesis of polydopamine:

[0066] Dissolve 0.5 g of dopamine hydrochloride in 10 ml of deionized water and stir with a glass rod until completely dissolved. Then, mix 40ml of ethanol and 1ml of ammonia solution (25-28%) with 90ml of deionized water, stir magnetically at room temperature for 30 minutes, and slowly inject into the above solution, the color of the mixed solution turns light brown and gradually turns dark brown, The reaction continued for 24 hours to obtain a polydopamine solution. It is also possible to accelerate the polymerization of dopamine by stirring vigorously under the heating condition of 60°C and high-speed stirring condition of 300r / min for 0.5h;

[0067] B. Preparation of Graphene Oxide Dispersion

[0068] Monolayer graphene oxide powder was prepared by the Hummers method. After the preparation is completed, weigh 20 mg of graphene oxide powder, disperse it in 10 ml of deionized water, and carry out ultrasonic dispersion. The ultrasonic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com