Anticorrosive pressure sensitive adhesive tape and preparation method thereof

A technology of pressure-sensitive tape and pressure-sensitive adhesive, which is applied in pipeline anti-corrosion/rust protection, adhesives, damage protection, etc. It can solve the problems of poor self-adhesiveness, low bonding strength, poor sealing and durability of pressure-sensitive tape , to achieve the effect of good self-adhesiveness, good flexibility at low temperature and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A pressure-sensitive adhesive tape for anti-corrosion, which is composed of a backing material and a pressure-sensitive adhesive material distributed on the polyethylene backing material. The backing material is a polyethylene backing material; the pressure-sensitive adhesive material is mainly made of butyl 25 parts of rubber, 20 parts of terpene resin, 5 parts of polyisobutylene with a weight average molecular weight of 800-1100, 10 parts of naphthenic oil, 20 parts of talc, 20 parts of mica powder and 0.5 parts of antioxidant 1010, by weight Count.

[0033] The preparation method of the pressure-sensitive adhesive tape for anticorrosion of the present invention is:

[0034] First add the butyl rubber to the kneader, and then add the terpene resin, polyisobutylene with a weight average molecular weight of 800 to 1100, naphthenic oil, talc, mica powder and antioxidant 1010 to the kneader , Kneading at a temperature of 135~150℃ for 40~60min to prepare pressure sensitive adh...

Embodiment 2~6

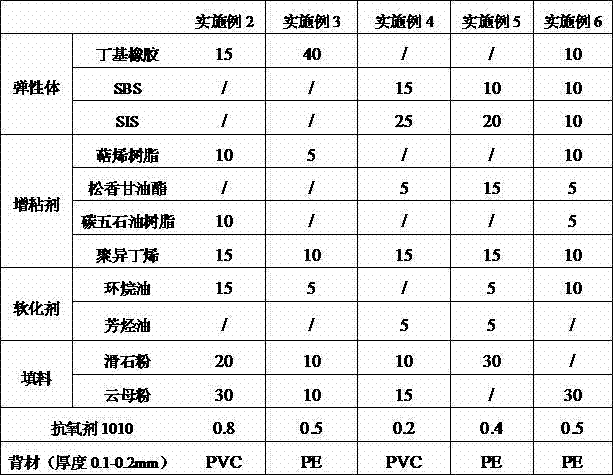

[0037] A pressure-sensitive adhesive tape for compression corrosion, wherein the raw material components and contents of the pressure-sensitive adhesive material are shown in Table 1, and the kneading temperature and kneading time of the pressure-sensitive adhesive material are shown in Table 2, and the specific preparation method is the same as in Example 1.

[0038] Table 1: The components and dosage tables in Examples 2 to 6 Unit: kg

[0039]

[0040] Table 2 Kneading temperature and kneading time of the pressure-sensitive adhesive materials in Examples 2-6

[0041] Example23456 Kneading temperature (℃)135140145150160 Kneading time (minutes)3050556070

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com