Non-slip floor

A floor and raised rib technology, applied in the field of flooring, can solve problems such as poor anti-slip performance of the floor and unusable floors, and achieve the effects of low VOC, excellent fit and improved anti-slip performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

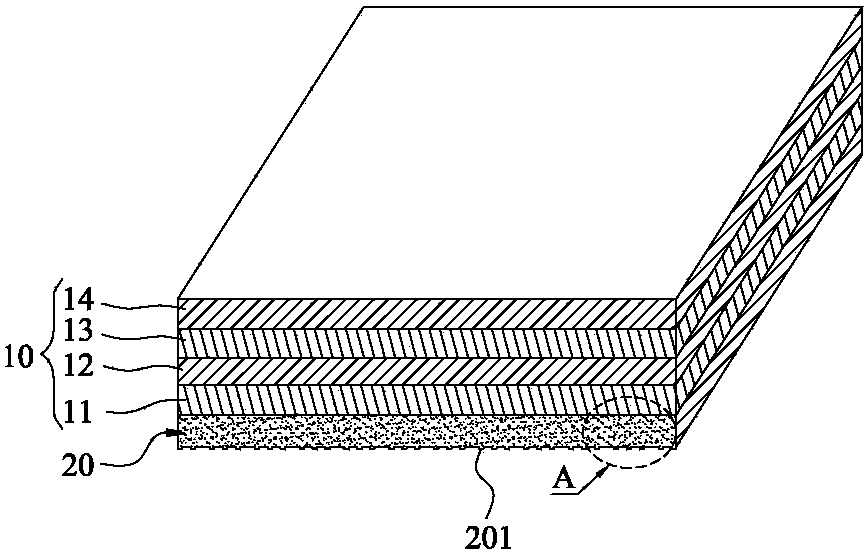

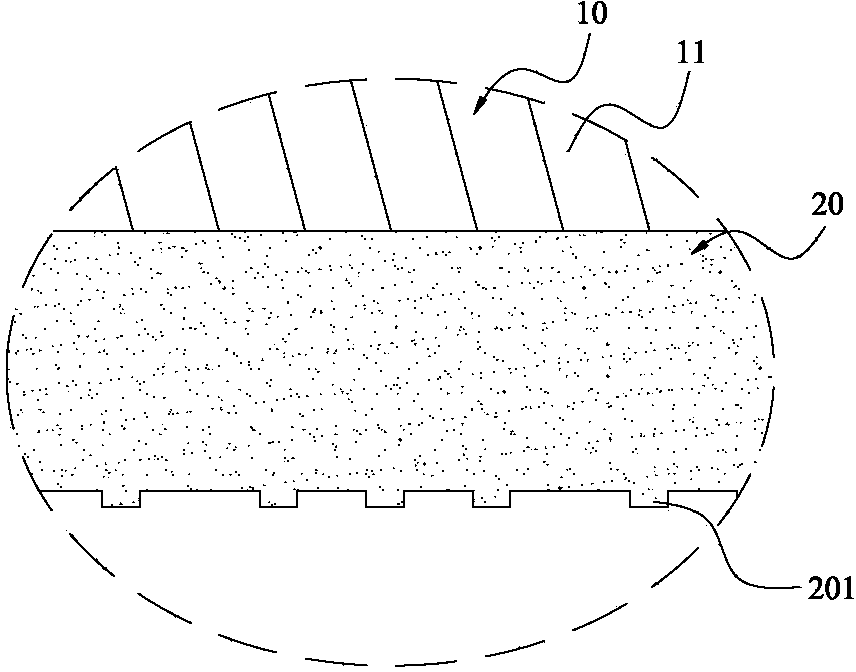

[0026] Please refer to Figure 1 to Figure 3 As shown, it shows the specific structure of the preferred embodiment of the present invention, including the main body 10 .

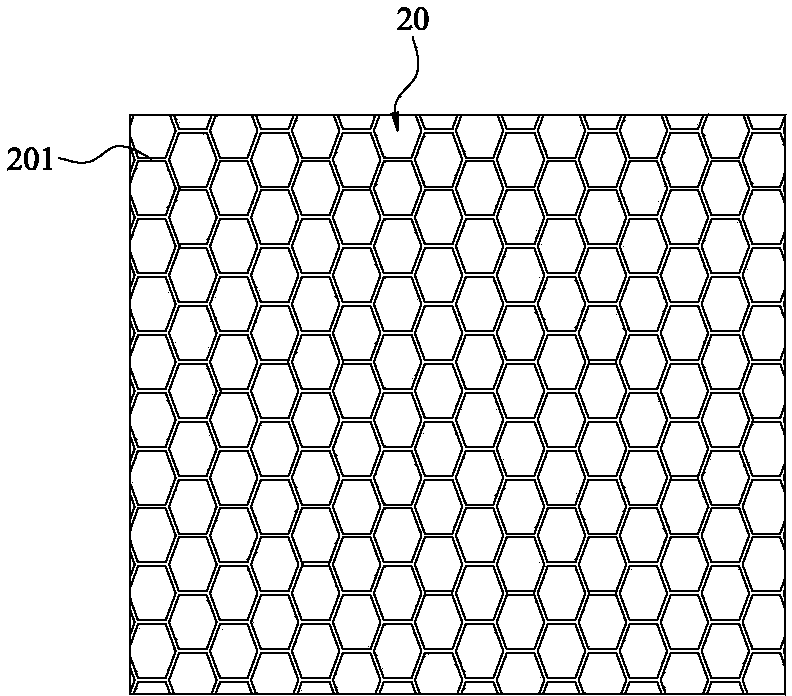

[0027] The bottom surface of the main body 10 is laminated with an adhesive layer 20, and the bottom surface of the adhesive layer 20 in contact with the ground is protruded with a plurality of convex ribs 201, and the plurality of convex ribs 201 form a plurality of closed cavity suction cups. The adhesive layer is made of pressure-sensitive heat-sensitive adhesive; and, the material formula of the adhesive layer 20 is: by weight, it includes: 35%-55% of tackifying resin, 10%-20% of softener, and 2% of antioxidant ~5%, butyl rubber 10%~20%, naphthenic oil 5%~10%, the sum of the total amount of the above substances is 100%. In this embodiment, the tackifying resin includes a main resin (SBS) and a polyester resin, the main resin accounts for 25% to 40% of the total amount of the aforementioned substances, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com