Making method of non-inflammable self-adhesion insulation tape

An insulating tape and a technology of a manufacturing method, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of agglomeration or uneven dispersion, loose insulation layer wrapping, local concentration of pigments, etc., and achieve superior comprehensive performance , Good insulation performance, good self-adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

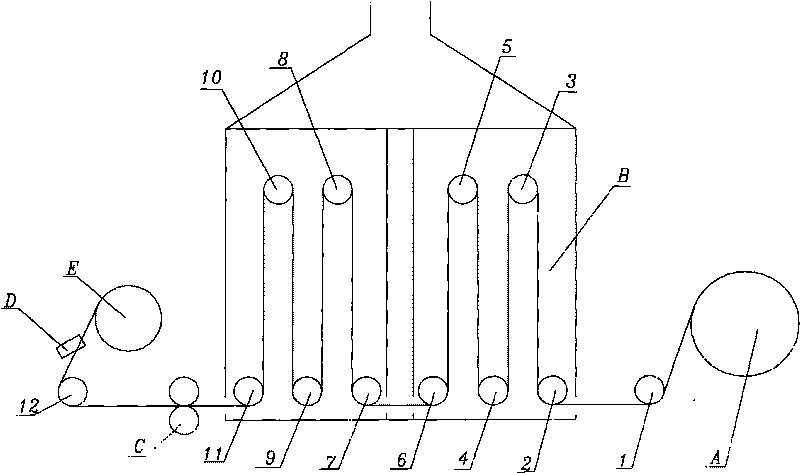

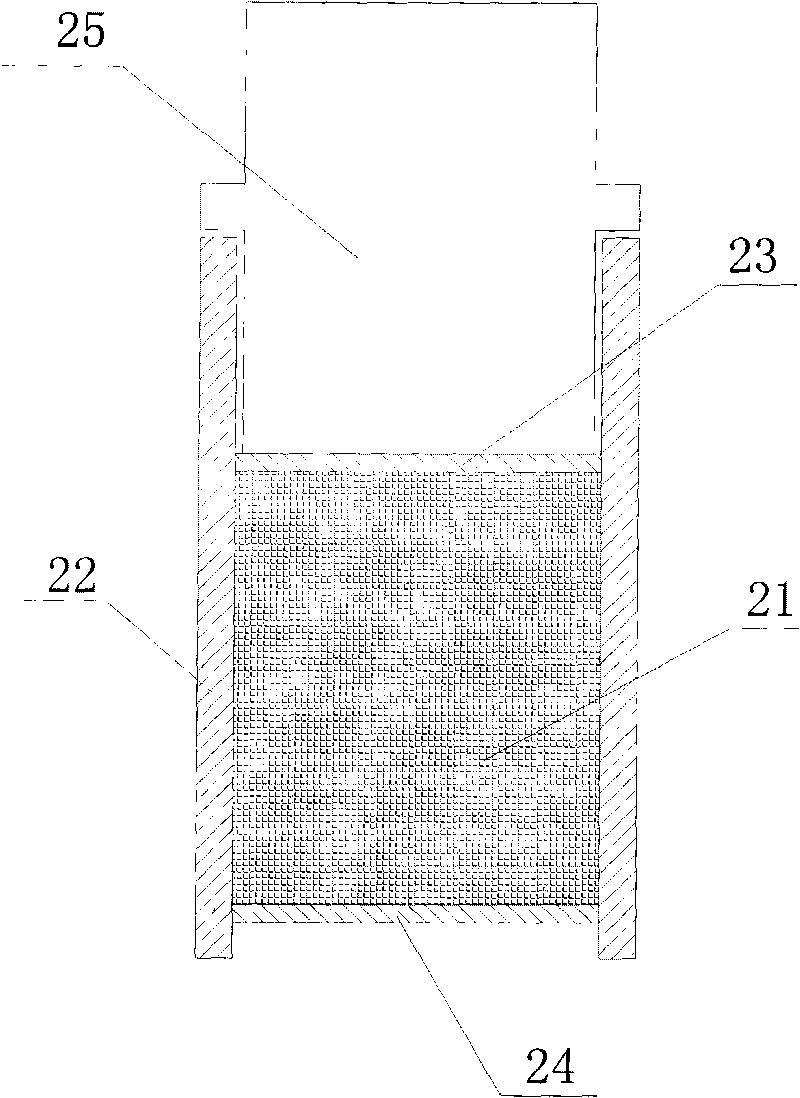

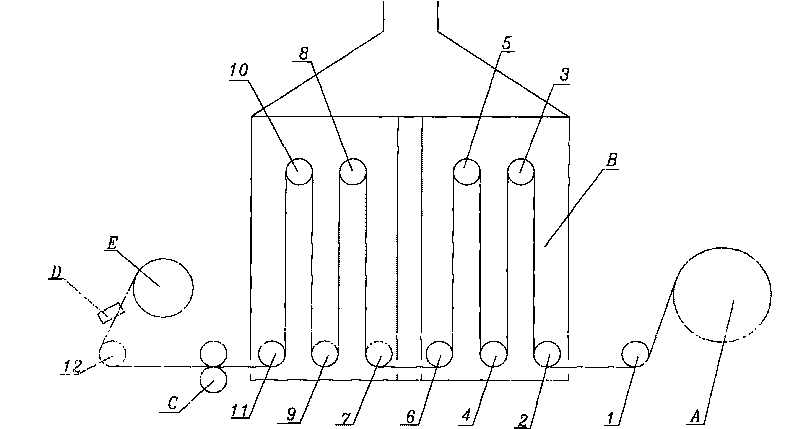

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] 1. Production of colored polytetrafluoroethylene dispersion resin

[0022] Add 100-140 parts by weight of polytetrafluoroethylene dispersion, 140-180 parts by weight of distilled water, 20-35 parts by weight of high boiling point solvent and 8-14 parts by weight of pigment into the mixer and stir, then add 70 parts by weight of water 90 parts by weight and 50 to 80 parts by weight of acetone in a mixed solvent for coagulation; through coagulation, the primary particles of 0.1 to 0.2 microns are agglomerated into secondary particles of 450 microns, and finally the condensate is filtered and Dry at a temperature of 90-130°C to obtain a colored polytetrafluoroethylene dispersion resin. The color of the resin prepared by this method is uniformly dispersed, with excellent electrical properties, and its viscosity is not higher than that of o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com