Manufacturing method of self-adhesive elastic bandage and self-adhesive elastic bandage

An elastic bandage and the technology of the manufacturing method, which are applied in the medical field, can solve the problems of poor elasticity and self-adhesiveness of non-woven fabrics, high cost of materials, equipment and processes, and complicated process, so as to achieve soft texture, simplify the process and equipment structure , good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

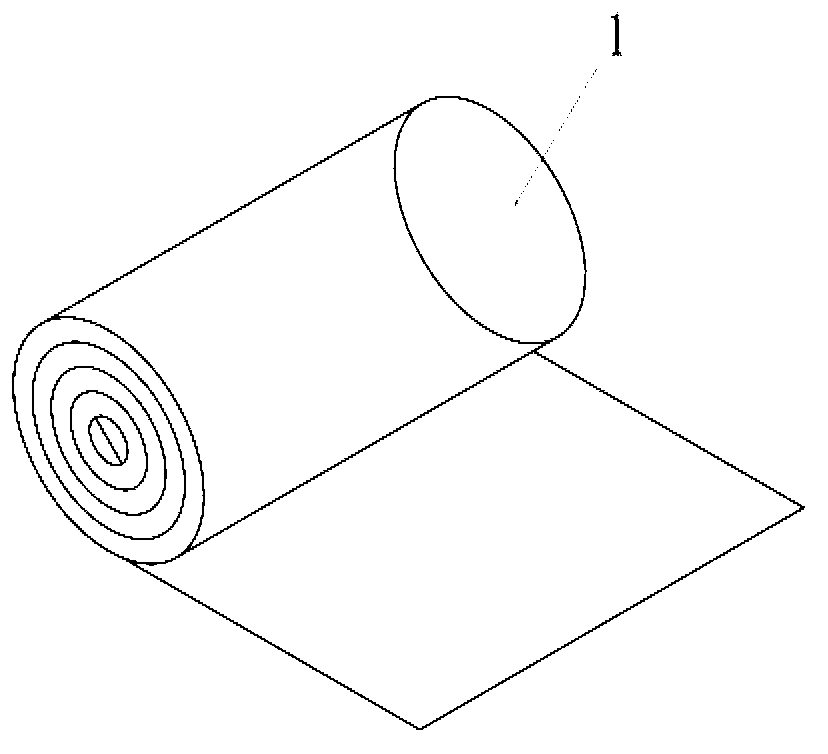

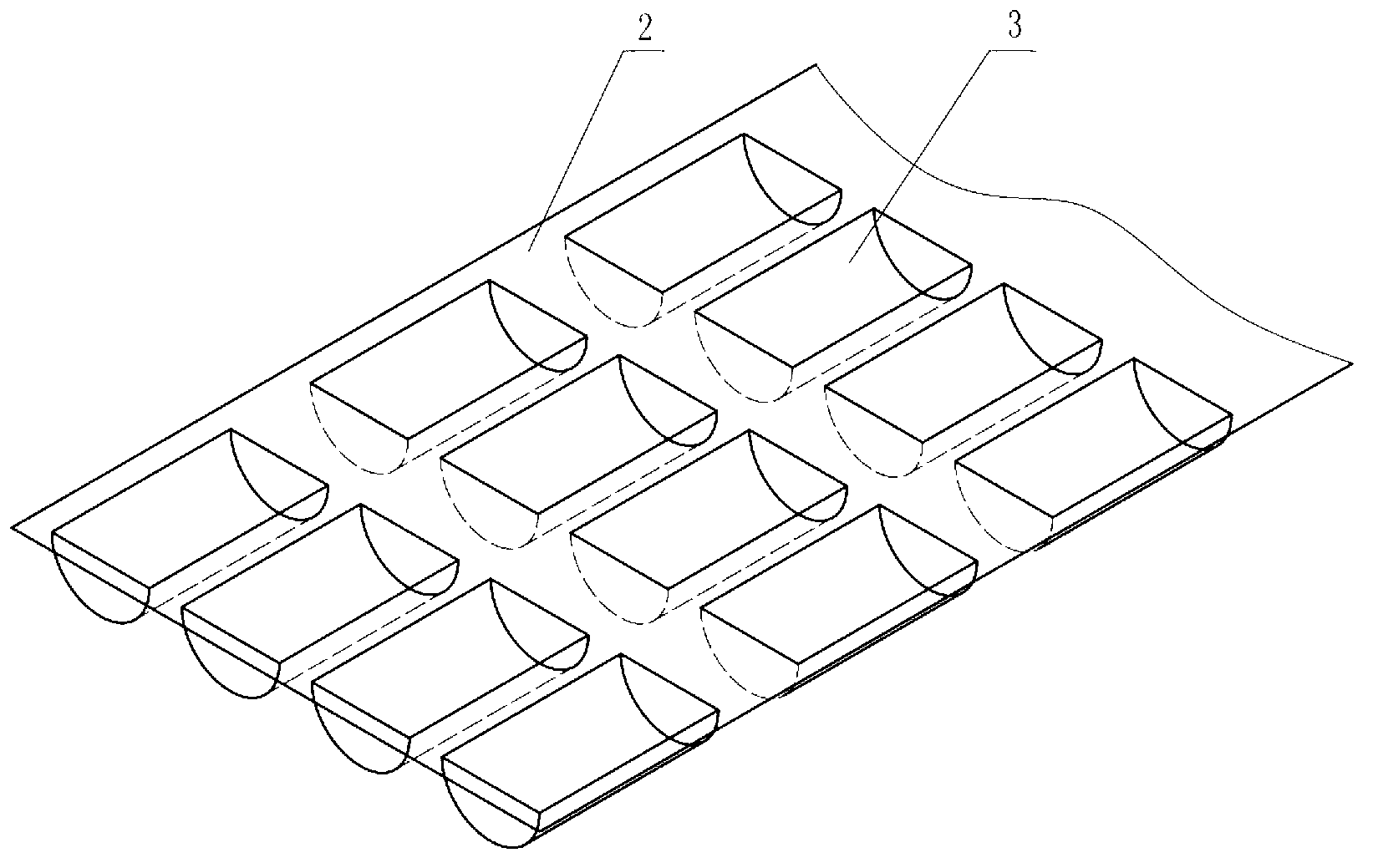

[0027] In the embodiment of the present application, the method for manufacturing a self-adhesive elastic bandage is to directly obtain a self-adhesive and elastic bandage after the sizing-treated non-woven fabric substrate is subjected to shrinkage treatment.

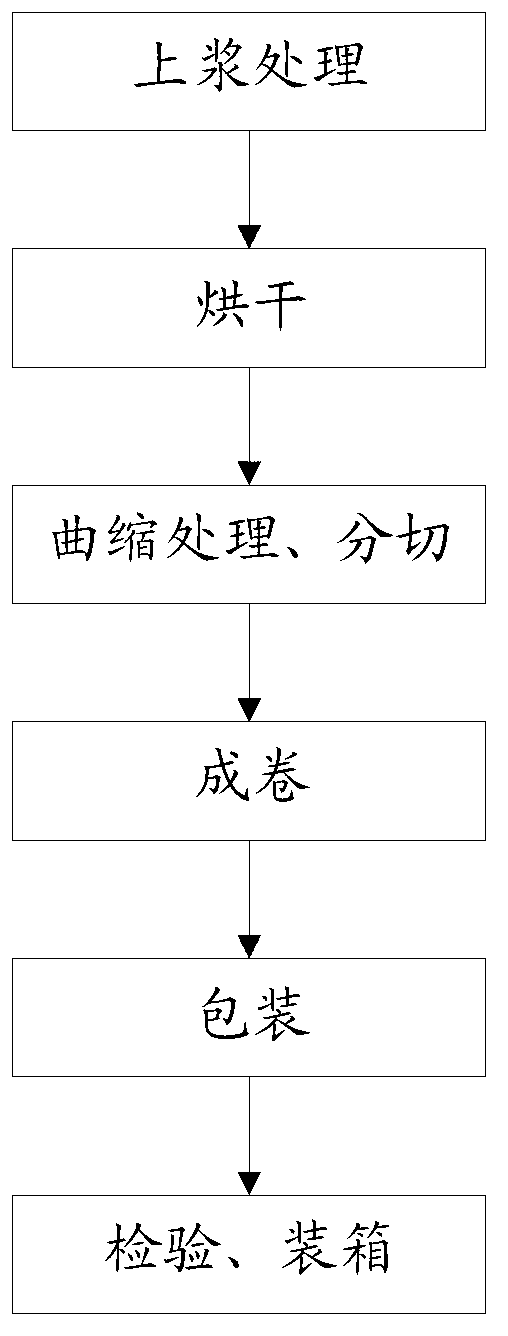

[0028] Such as figure 1 Shown, the manufacture method of the self-adhesive elastic bandage of the present embodiment, comprises the following steps:

[0029] Step 1: a sizing step, performing sizing treatment on the non-woven fabric base material, the sizing treatment slurry includes an adhesive, a penetrating agent and a solvent, and the solvent can be water.

[0030] In this step, the non-woven fabric substrate is usually hydroentangled, for example, it can be a non-woven fabric substrate used in the prior art to manufacture self-adhesive elastic bandages, including vis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com